Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Amul PDF

Caricato da

utkarsh1308960 valutazioniIl 0% ha trovato utile questo documento (0 voti)

71 visualizzazioni5 pagineTitolo originale

Amul.pdf

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

71 visualizzazioni5 pagineAmul PDF

Caricato da

utkarsh130896Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 5

AMUL

AMUL is a Cooperative Dairy Industry, founded in 1946 by Dr. Verghese

Kurien, initially based in the Anand district of Gujrat.

AMUL, derived from the Sanskrit word Amoolya means priceless.

AMUL stands for Anand Milk Products Union Limited.

The Kaira District Co-operative Milk Producers Union Limited,

popularly known as Amul Dairy is a US $1billion turnover institution.

[Revenue : INR 67.11 billion (2008-2009).]

AMUL is the worlds biggest vegetarian cheese brand and the largest

pouched milk brand.

AMUL is currently the largest food brand in India.

AMUL is responsible for spurring the White Revolution in India.

AMUL : INTERNAL STRUCTURE

It is a institution built up with a network of over 10,000 Village

Cooperative Societies and 5,00,000 plus members.

Managed by an apex cooperative organization, Gujarat Co-

operative Milk Marketing Federation Ltd. (GCMMF), which is

today jointly owned by around 3.18 million milk producers in

Gujarat, India. (2011-12 records).

Employees : Marketing : 735 , Milk Producers: 3.81 million.

AMUL: GCMMFs Supply Chain

A short and lucid Description of AMULs Supply Chain

1. PROCUREMENT from SUPPLIERS :

On an average, around thousand farmers sell milk at their local

cooperative milk collection center (i.e. to GCMMF).

The milk is weighed and the fat content of the milk is measured by

an electronic fat testing machine.

This milk is then promptly transported to district facilities for

further dispatch to consumers/ processing units.

2. COLD STORAGE TRANSPORTATION :

Chilled milk is transported in trucks to be processed/delivered.

Delivery to local chillers is achieved by insulated rail tankers and

chilled trucks.

Refrigerators and freezers with retailers and departmental stores

are usually used to retain freshness.

Various LEGS in CHILLED Transportation

I. First leg

Manufacturing units to company depots using 9 and 18

MT trucks.

Frozen food : below 18 C

Dairy wet : 0-4 C

II. Second leg

Depots to WDs.

Transport through insulated 3 and 5 MT TATA 407s.

III. Third leg

WDs to retailers.

Transport through rickshaws according to the beat plan.

3. DISTRIBUTION :

GCMMF coordinates the regular supply of milk and dairy products.

The processed milk and dairy products are procured from district

dairy unions and distributed through third party distributors.

To ensure quality and timely deliveries, GCMMF and the district unions have

several mechanisms in place, including Friday Quality Checkups.

GCMMF An Overview (2011-12)

FEW NOTEWORTHY POINTS

Extensive IT INFRASTRUCTURE of AMUL Ltd.

Automatic Milk Collection System Units (AMCUS) System after

implementation under GCMMF IT Initiatives, has lead to reduced

humar error and time wastage.

Amul is one of the first FMCG (Fast Moving Consumer Goods) firms

in India which employs internet technologies.

Implementation of GIS (Geographical Information System) at both

ends of supply chain, i.e. Milk Collection as well as the Marketing

Process, for business planning and optimization of collection

processes.

Utilization of Data Analysis software (DAS) for milk production

estimation and increasing productivity has proved beneficial.

EVOLUTION OF IT

The milk collection center at village cooperative societies, were first

automated.

Data analysis software utilization for milk production estimation and

increasing productivity.

VATS network between all the level of distribution network and GCMMF.

Benefits of IT

Processing of 10 Million payments daily, amounting to transactions

worth USD 3.78 million in cash.

Improved delivery mechanisms and transparency of business operations.

Due to this process, AMUL is able to collect six million litres of milk per

day.

Huge reduction in processing time for effecting payments to the farmers

from a week to couple of minute.

---- THE END ----

Potrebbero piacerti anche

- Noida Holiday Calender 2019Documento1 paginaNoida Holiday Calender 2019utkarsh130896Nessuna valutazione finora

- BannerDocumento1 paginaBannerutkarsh130896Nessuna valutazione finora

- Admission - Batch 2020-2022Documento1 paginaAdmission - Batch 2020-2022utkarsh130896Nessuna valutazione finora

- List of Candidates Shortlisted For IIM Rohtak PGP Admission PDFDocumento464 pagineList of Candidates Shortlisted For IIM Rohtak PGP Admission PDFutkarsh130896Nessuna valutazione finora

- CMAT 2019 Question Paper PDF Download With SolutionsDocumento63 pagineCMAT 2019 Question Paper PDF Download With Solutionsutkarsh130896Nessuna valutazione finora

- SP GuidelinesDocumento21 pagineSP Guidelinesutkarsh130896Nessuna valutazione finora

- Detection of Fake Images Using Metadata Analysis and Error Level AnalysisDocumento28 pagineDetection of Fake Images Using Metadata Analysis and Error Level Analysisutkarsh130896Nessuna valutazione finora

- Social Welfare and Constitutional Responsibilities of Government - An Analysis of The Current Scenario - Vivekananda International FoundationDocumento5 pagineSocial Welfare and Constitutional Responsibilities of Government - An Analysis of The Current Scenario - Vivekananda International Foundationutkarsh130896Nessuna valutazione finora

- Hartz EllDocumento28 pagineHartz Ellutkarsh130896Nessuna valutazione finora

- Signal Handling in Linux: Tushar B. KuteDocumento27 pagineSignal Handling in Linux: Tushar B. Kuteutkarsh130896Nessuna valutazione finora

- Evolution of PRIs in APDocumento77 pagineEvolution of PRIs in APutkarsh130896Nessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Director Commissioner Food (Govt. Pradesh) : AndhraDocumento1 paginaDirector Commissioner Food (Govt. Pradesh) : AndhraJpNessuna valutazione finora

- Introduction in Etiquettes and Customs of Mexican Business CultureDocumento45 pagineIntroduction in Etiquettes and Customs of Mexican Business CultureAkshay ChaudhryNessuna valutazione finora

- h1 2021 Mill ListDocumento18 pagineh1 2021 Mill ListenquirysakuragawaNessuna valutazione finora

- 486 - Assignment 2 - Marketing Plan With The 7Ps-AZ - Highland CoffeeDocumento61 pagine486 - Assignment 2 - Marketing Plan With The 7Ps-AZ - Highland CoffeeNguyen Minh Khang (FGW DN)100% (1)

- ONE BANK Written Test For Recruitment of SpecialDocumento7 pagineONE BANK Written Test For Recruitment of SpecialMubassher Ahmed Shoaib100% (1)

- Carrot Industry ProfileDocumento30 pagineCarrot Industry Profilejunar200257% (7)

- Class A Group C Taj Mahal Palace Hotel PDFDocumento38 pagineClass A Group C Taj Mahal Palace Hotel PDFPriya KumariNessuna valutazione finora

- Barn DetailsDocumento9 pagineBarn DetailszulukachNessuna valutazione finora

- Case Study Analysis On Cargill India PVTDocumento11 pagineCase Study Analysis On Cargill India PVTPallav Bansal100% (2)

- EdsDocumento19 pagineEdsfasahmadNessuna valutazione finora

- ZeptoDocumento31 pagineZeptoSAJAL SRIVASTAVANessuna valutazione finora

- Business ROI Plan - Romeo Lane - NepalDocumento6 pagineBusiness ROI Plan - Romeo Lane - NepalGood HueNessuna valutazione finora

- Social Responsibility, Business Strategy and Development: The Case of Grameen-Danone Foods LimitedDocumento16 pagineSocial Responsibility, Business Strategy and Development: The Case of Grameen-Danone Foods LimitedstefanNessuna valutazione finora

- Functional Properties of Food RevisionDocumento6 pagineFunctional Properties of Food Revisionapi-323952126Nessuna valutazione finora

- Assignment 02Documento8 pagineAssignment 02Zandile NgcoboNessuna valutazione finora

- Buxton Real Ale Trail Web VersionDocumento2 pagineBuxton Real Ale Trail Web VersionIan McNair100% (1)

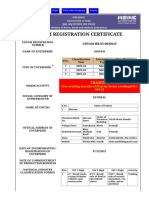

- Print - Udyam Registration CertificateDocumento2 paginePrint - Udyam Registration CertificateshivamNessuna valutazione finora

- Lesson 3Documento21 pagineLesson 3salai08128491Nessuna valutazione finora

- Food Defense Guidelines-20100827Documento49 pagineFood Defense Guidelines-20100827pamela sicp100% (8)

- Ioan Constant in CVDocumento2 pagineIoan Constant in CVJitariu Ioan CatalinNessuna valutazione finora

- Colgate-Palmolive CompanyDocumento7 pagineColgate-Palmolive CompanyDanielle Clarice ReyesNessuna valutazione finora

- (Salad WorldsDocumento32 pagine(Salad WorldsHong Hanh PhanNessuna valutazione finora

- FSSC Version 6 Requirements (Foodkida)Documento6 pagineFSSC Version 6 Requirements (Foodkida)jacky786Nessuna valutazione finora

- Haleeb MilkDocumento18 pagineHaleeb MilkREhan RIazNessuna valutazione finora

- FNB Training Service UpsellingDocumento38 pagineFNB Training Service Upsellingmackyamores100% (2)

- Scedhule Service: OO OO OO Ooph O PH OO O PH OO OO OO OO OO OO OPH S O OO O O O OO PH O O O O ODocumento5 pagineScedhule Service: OO OO OO Ooph O PH OO O PH OO OO OO OO OO OO OPH S O OO O O O OO PH O O O O Odwi endah palupiNessuna valutazione finora

- Uas Bib Kelompok 1Documento15 pagineUas Bib Kelompok 1salsabil yoritefania asyadillaNessuna valutazione finora

- Mini Assessment Block 3 - Answers - Year 2 MoneyDocumento2 pagineMini Assessment Block 3 - Answers - Year 2 MoneyPaulette CaruanaNessuna valutazione finora

- Factors Influencing Purchase Intention For Organic ProductsDocumento10 pagineFactors Influencing Purchase Intention For Organic ProductsInternational Journal of Business Marketing and Management100% (2)

- Musse Choco ZUMBO - OdtDocumento4 pagineMusse Choco ZUMBO - OdtRodrigoOliveira2607Nessuna valutazione finora