Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

8 Polymer

Caricato da

Hasan WaqarTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

8 Polymer

Caricato da

Hasan WaqarCopyright:

Formati disponibili

POLYMER BASICS

What is a Polymer?

The word Polymer comes from the Greek poly meaning many, and meros, parts or

units. A polymer is a group of many units. You combine many monomers (one unit) to

create a polymer.

Polymer is often used as a synonym for plastic, but many biological and inorganic

molecules are also polymeric. All plastics are polymers, but not all polymers are plastics.

Plastic actually refers to the way a material melts and flows.

Commercial polymers are formed through chemical reactions in large vessels under

heat and pressure. Other ingredients are added to control how the polymer is formed

and to produce the proper molecular length and desired properties. This chemical process

is called polymerization.

A homopolymer results from polymerizing only one kind of monomer. A copolymer

results from using different monomers. Homopolymers have the same repeating unit

while copolymers (which can be random, block or graft) can very have different numbers

of repeating units. A terpolymer results from using three different monomers.

Polymerisation

X

MONOMER POLYMER X Times

X Y

CO-MONOMER COPOLYMER X+Y Times

Arla Plast AB, Box 33, Vstanavgen, SE-590 30 Borensberg, Sweden

Tel +46 (0)141 20 38 00 | Fax +46 (0)141 414 30 | info@arlaplast.se | www.arlaplast.com

POLYMER BASICS

Materials for thermoforming

Definition

Thermoplastic materials can be repeatedly softened by elevated heating

and hardened by cooling. They are either linear polymers or slightly branched.

They consist of long molecules and each may have side chains or molecular groups

not attached (not cross-linked). There are now newly developed thermoplastics that

process as usual, but, at the end of the process are cross-linked with special techniques

(e.g., nucleating agent, hot mold above forming temperature, etc.) Materials can

also be across- linked by radiation. This cross-linking turns them into either an undeveloped

or full thermoset and can greatly improve the physicals properties of the part.

Thermoplastics make up approximately 88-90% of all plastics processed today.

Any thermoplastic resin that can be extruded can be thermoformed. However, those

with low hot strenght at forming temperature may be very difficult to form. Sheet and

film is produced by extrusion, co extrusion, continuos casting, extrusion casting,

calendring, compression molded, autoclave and press laminating, etc.

Classification of polymers

Polymers

Thermoplastics Elastomers Thermosets

Crystalline

Amorphous

Arla Plast AB, Box 33, Vstanavgen, SE-590 30 Borensberg, Sweden

Tel +46 (0)141 20 38 00 | Fax +46 (0)141 414 30 | info@arlaplast.se | www.arlaplast.com

POLYMER BASICS

Basics

Elastomers are plastic material which can be expanded considerably by little force

and which will return quickly to their original shape without force. There will be no

plastic flow if temperature is increased as occurs with thermoplastics.

Thermosettings plastics are hard, solid and remain in this state up to the decomposition

temperature.

Thermoplastics soften with increasing temperature after the softening point has

been exceeded and harden again when cooled down. This procedure, which can be

repeated as often as requested, is used for thermoforming of semi-finished products.

Representative skeletal structure of polymers

Themoplastics Thermosets and rubbers

Linear Branched Network

The structure of thermoplastics

Thermoplastics are plastic materials which consist of linear or branched macromolecules

(filamentary molecule). With random convolution of the filamentary molecules

one talks about amorpous thermoplastics. If atomic groups of several linear

molecule chains are arranged, they create a crystal lattice. So-called crystallites are

formed and these integrate randomly into the amorphous substance.

Arla Plast AB, Box 33, Vstanavgen, SE-590 30 Borensberg, Sweden

Tel +46 (0)141 20 38 00 | Fax +46 (0)141 414 30 | info@arlaplast.se | www.arlaplast.com

POLYMER BASICS

Types of thermoplastics

There are two phases of Thermoplastics-amorphous and crystalline.

Amorphous phase- Devoid of crystallinity; no definite order. Amorphous materials

have a randomly ordered molecular structure. Its behavior is very similar to a very

viscous, inelastic liquid. Upon heating, an amorphous sheet gradually softens and

eventually acquires the characteristics of a liquid, but without a definite point of transition

from solid to liquid state. These resins usally require less energy to bring them

to forming temperature and to cool they do not reach a totally "non-flowing" solid

state. They do, therefore, have a tendancy toward "creep" or "movement" with age

when a load is applied. Such plastics as the following are amorphous: ABS, HIPS,

PVC, PMMA and PC are typical examples.

Structure of thermoplastics

Amorf Crystalline

Crystalline Phase - A very good orderly group of molecules.

Crystalline thermoplastics molecules have natural tendancy to line up in rigid, precise,

highly-ordered structures but a part of the material will always be amorphous

(e.g., polypropylene normally is about 65% crystalline and 35% amorphous). When

a crystalline sheet is heated it remains stiff until it reaches the transformation temperature.

For amorphous polymers this transformation temperature corresponds to

Tg, but for crystalline polymers this temperature is slightly below the melt temperature.

This temperature is the minimum forming temperature and in case of HDPE it

is 105degC. The ideal forming temperature is higher, but unfortunately, just some

degrees below the melt temperature. This is why sheets from crystalline polymers

are formed cold, which can result in internal stresses in the formed detail which in

turn can lead to warpage. less impact strength, etc.

This is why these materials are very difficult to thermoform.

HDPE and PP (natural or filled) are the most usual types of crystalline sheet material.

Arla Plast AB, Box 33, Vstanavgen, SE-590 30 Borensberg, Sweden

Tel +46 (0)141 20 38 00 | Fax +46 (0)141 414 30 | info@arlaplast.se | www.arlaplast.com

POLYMER BASICS

Definitions

Organic Substance Substance containing carbon

Polymer Poly=many Mer=part. Chemical, often organic,

substance built up by chain shaped molecules.

Polymeric Material Material containing polymer as a main substance.

Often containing different kinds of additives.

Ex. Plastics, Rubber, Glue, Paint

Plastics Material Polymeric materials which turns stiff after forming

in a soft plastic state.

Plastic = Polymer+Additives

Thermoplastic Material Plastic Materials which can be melted and

reshaped time after time

Thermosetting Plastic Plastic Material which can not be reshaped.

The material is decomposed during heating.

Elastic Material Polymeric material that after fabrication in the

plastic state turns soft with large elastic flexibility.

Arla Plast AB, Box 33, Vstanavgen, SE-590 30 Borensberg, Sweden

Tel +46 (0)141 20 38 00 | Fax +46 (0)141 414 30 | info@arlaplast.se | www.arlaplast.com

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

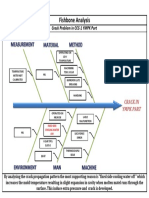

- Fishbone Analysis: Crack Problem in CCC-1 YMPK PartDocumento1 paginaFishbone Analysis: Crack Problem in CCC-1 YMPK PartHasan WaqarNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Suzuki Cultus NewDocumento9 pagineSuzuki Cultus NewNaeem AsadNessuna valutazione finora

- Die Casting Furnace LossesDocumento27 pagineDie Casting Furnace LossesHasan WaqarNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Kelloggs 12 FullDocumento4 pagineKelloggs 12 Fullapi-3705095100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- YWCHSB Sample Form Workplace Risk Assessment YWCHSB LIB0266 v1Documento3 pagineYWCHSB Sample Form Workplace Risk Assessment YWCHSB LIB0266 v1Hasan WaqarNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- RA Leader: Approved by Reference NumberDocumento2 pagineRA Leader: Approved by Reference NumberHasan WaqarNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- 51 107 1 PB PDFDocumento10 pagine51 107 1 PB PDFHasan WaqarNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- CH 2 Solver Reddy Mi KksDocumento1 paginaCH 2 Solver Reddy Mi KksHasan WaqarNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- VSM Final Real 2Documento16 pagineVSM Final Real 2Hasan WaqarNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- PolymersDocumento31 paginePolymersShivangani RawatNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Composite Materials - Final - Exam - M2R - ENSPD - May 2022Documento2 pagineComposite Materials - Final - Exam - M2R - ENSPD - May 2022Landry LemsNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Thermoplastic, Thermosetting, Thermoplastic Elastomer and Rubber Materials Classification and SpecificationDocumento36 pagineThermoplastic, Thermosetting, Thermoplastic Elastomer and Rubber Materials Classification and SpecificationIsrael FidelesNessuna valutazione finora

- Polyols and Powder Coating ResinsDocumento51 paginePolyols and Powder Coating Resinskang8886021100% (1)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Colloidal Emulsions in Inks and AdhesivesDocumento4 pagineColloidal Emulsions in Inks and AdhesivesAnujNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- 2 Puc Neet Ploymers Q.PDocumento3 pagine2 Puc Neet Ploymers Q.PGowri ShankarNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Leepol™ - HighlightsDocumento1 paginaLeepol™ - HighlightsMohit GautamiNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Polyester Polyol From Recycled PETDocumento3 paginePolyester Polyol From Recycled PETA MahmoodNessuna valutazione finora

- CHEM-E2100 Polymer Synthesis Exercise 2: Chain Polymerization I: Radical PolymerizationDocumento2 pagineCHEM-E2100 Polymer Synthesis Exercise 2: Chain Polymerization I: Radical Polymerization王怀成Nessuna valutazione finora

- N7-Natural Fibre Bio Composites Incorporating Poly Lactic AcidDocumento20 pagineN7-Natural Fibre Bio Composites Incorporating Poly Lactic Acidphan thị thúy 2k2Nessuna valutazione finora

- Dichtomatik: Matik Dichtomatik Dichtomatik Dic Htomatik Dichtom Atik DichtomatikDocumento29 pagineDichtomatik: Matik Dichtomatik Dichtomatik Dic Htomatik Dichtom Atik Dichtomatikpavel10082020Nessuna valutazione finora

- Elvax 250Documento3 pagineElvax 250Mohammed RazaNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Bioplastic Foam Net MadeDocumento12 pagineBioplastic Foam Net MadeYumi Jackylyn CrimonaNessuna valutazione finora

- Zimmer Polymer Technologies 210x270 WebDocumento11 pagineZimmer Polymer Technologies 210x270 WebatifaliwajidNessuna valutazione finora

- Vinnapas SpekDocumento5 pagineVinnapas SpekThomas GunawanNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Requirement: Unsaturated Monomer: Addition PolymerizationDocumento24 pagineRequirement: Unsaturated Monomer: Addition PolymerizationLester John VeraNessuna valutazione finora

- Addition Polymers (4.8.1)Documento4 pagineAddition Polymers (4.8.1)KeerthikaNessuna valutazione finora

- Product: High Density Polyethylene (HDPE) Grade: Film Trade Name: HD-7000FDocumento2 pagineProduct: High Density Polyethylene (HDPE) Grade: Film Trade Name: HD-7000F李万福Nessuna valutazione finora

- Plastic Materials 1Documento12 paginePlastic Materials 1Anbu M S TNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Polymer AM Landscape V6Documento1 paginaPolymer AM Landscape V6liang.2407.87Nessuna valutazione finora

- ElastomerDocumento3 pagineElastomersiswoutNessuna valutazione finora

- KCC Brochure Silicone PersonalCare 2017Documento16 pagineKCC Brochure Silicone PersonalCare 2017khoachiNessuna valutazione finora

- AxDocumento11 pagineAxAMB SpainNessuna valutazione finora

- End GR Analysis PEGDocumento4 pagineEnd GR Analysis PEGShreya PramanikNessuna valutazione finora

- Fluorocarbon Polymers For Sealing: How To Choose?Documento2 pagineFluorocarbon Polymers For Sealing: How To Choose?Luis ReyesNessuna valutazione finora

- Polyvinyl Alcohol ("PVA") Resin Global Business StrategyDocumento7 paginePolyvinyl Alcohol ("PVA") Resin Global Business StrategyZhong LiNessuna valutazione finora

- Functional Silicone Reactivity Guide: VinylDocumento44 pagineFunctional Silicone Reactivity Guide: VinylPranshu JainNessuna valutazione finora

- Dse 3Documento4 pagineDse 3Neha NegiNessuna valutazione finora

- Advances in Superporous Hydrogels: Hossein Omidian, Jose G. Rocca, Kinam ParkDocumento10 pagineAdvances in Superporous Hydrogels: Hossein Omidian, Jose G. Rocca, Kinam ParkYernagula Kalyan KumarNessuna valutazione finora

- Polymer StructureDocumento34 paginePolymer StructureQaz ZaqNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)