Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

GSL Actuator Sizing Calculation PDF

Caricato da

Anonymous yQ7SQrDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

GSL Actuator Sizing Calculation PDF

Caricato da

Anonymous yQ7SQrCopyright:

Formati disponibili

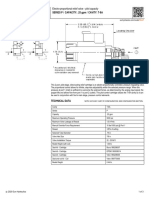

Actuator sizing calculation for Gate & Globe Valves

Information required Examples

1 Bore diameter at seat (use actual diameter if known) 12 inch 3 inch 3 inch

2 Differential pressure, using 30psi minimum, and line psi if higher 200 psi 2250 psi 2250 psi

3 Type of valve and service Wedge gate, oil Globe, steam Globe, steam

4 Stem diameter and lead of screw thread 1 x 1/3 1 x 1 x

(pitch x number of starts) rising stem rising rotating rising stem

5 Travel time/speed in inches per minute (if critical) About 1 minute

Method Having obtained the above information proceed as follows

A Obtain bore area (full bore assumed) (1) 113 sq in 7.06 sq in 7.06 sq in

B Differential psi 200 psi 2250 psi 2250 psi

C Obtain valve factor Table 1 0.35 1.15 1.15

D Multiply A x B x C to obtain seating thrust 7950 lbf 18200 lbf 18200 lbf

For rising stem valves: Yes No Yes

E Add packing friction thrust = 2000 x stem diameter (2) 3500 lbf ---- 3000 lbf

For gate valves: Yes No No

F Add piston effect = 0.785 x diam. of stem^2 x diff. Pressure (For 481 lbf ---- ----

globe valves, the stem area is included with the disc area, so piston

effect can be ignored)

G D+ E+F gives total thrust 11931 lbf 18200 lbf 21200 lbf

H Obtain Stem Factor K Table 2 0.014 0.012 0.012

J G x H gives torque 167 lbf-ft 218 lbf-ft 254 lbf-ft

For rotating stem valves: No Yes No

K Add gland friction torque = (1000 x stem diameter^2) 12 (2) ---- 188 lbf-ft ----

L J+K gives total thrust (rotating stem) 406 lbf-ft

M Actuator RPM = Speed in inches per min Lead of stem 12 1/3

= 36 RPM

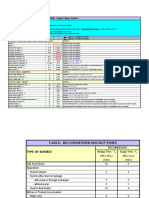

Table 1 Valve Factors (3) Notes

(1) API-600 and API-603 Gate Valves must have full ports according to Annex

Gases/

Gases/ A form ASME B16.34. Valves conforming to API-602 have reduced ports

Liquids Liquids Steam indicated in this standard. Other valves may differ according to

Steam manufacturing standard or published CV factor. Consult plant for an

Valve type Below Above above or

below specific valve port diameter.

750F 750F close

1000F (2) Factors based on Flexible Graphite Packing. For PTFE Packing, the results

1000F can be divided by 2.

Parallel slide and (3) Valve factors are based on metallic seats, when valve is new. If you

foresee seats oxidation or aging during the service, multiply this factors by

Flexible or double 0.28 0.3 0.35 0.45 1.25 to 1.5 depending the severity of seats oxidation or aging. Stroking the

disc valve frequently, maintain the seats cleaner and the thrust and torque lower.

Solid wedge gate 0.35 0.4 0.45 0.5 (4) For inside screw threads multiply factors by 1.5 for exposed sluice gates

(penstocks) multiply factors by 1.25 and insure that thrust estimate is a

Globe above 2 1.15 1.15 1.15 1.15 minimum of three times the weight of the gate. This factors assume a

Globe below 2 1.5 1.5 1.5 1.5 proper lubrication on stem threads, if a poor maintenance is predicted

multiply this factors by 1.15 to 1.3. Depending on the specified speed, the

stems can have single, double or triple start. Consult plant for actual stem

diameter, pitch and lead.

Table 2 Stem Factors (4)

Factor is lbf-ft per lbf of thrust, for ACME thread, using a coefficient of friction equal to 0.14

Lead Stem Dia In

Ins 3/4 1 1 1 1 2 2 2 2 3 3 3 3 4 4 4 4 5 5 5 6 6

1/8 .006 .007

1/5 .007 .008 .010 .011

1/4 .007 .009 .010 .012 .013 .015 .016 .018 .019 .021 .022

2/7 .008 .009 .011 .012 .014 .015 .017 .018 .020 .021 .023

1/3 .008 .010 .011 .013 .014 .016 .017 .019 .020 .022 .023

2/5 .009 .010 .012 .013 .015 .016 .018 .019 .021 .022 .024 .025 .027 .028 .030 .031 .033 .034 .036 .037 .040

1/2 .012 .013 .014 .016 .017 .019 .020 .022 .023 .025 .026 .028 .029 .031 .032 .034 .035 .037 .038 .041

2/3 .016 .019 .020 .022 .023 .025 .026 .028 .030 .031 .032 .034 .035 .037 .038 .040 .041 .044 .047

1 .020 .023 .024 .026 .027 .029 .030 .032 .032 .035 .036 .038 .039 .041 .042 .044 .045 .048 .051

1 1/2 .040 .042 .043 .045 .046 .048 .049 .051 .052 .055 .058

2 .048 .050 .051 .053 .054 .056 .057 .059 .062 .065

GSL Actuator sizing calculation of Gate & Globe Valves JB

Potrebbero piacerti anche

- Design. Ref - Decuments: API 650, 11TH - ED M09Documento31 pagineDesign. Ref - Decuments: API 650, 11TH - ED M09hgagNessuna valutazione finora

- Handbook of Heating, Ventilating and Air ConditioningDa EverandHandbook of Heating, Ventilating and Air ConditioningValutazione: 4 su 5 stelle4/5 (6)

- BOP Drawing Template BaseDocumento38 pagineBOP Drawing Template BaseSamir MuzaffarovNessuna valutazione finora

- Eaton Series 70122 70422Documento28 pagineEaton Series 70122 70422Aijaz Akbar100% (1)

- Rectangular Tank Design ROARKS FORMULADocumento40 pagineRectangular Tank Design ROARKS FORMULANavasOT100% (2)

- UG-37 F FactorDocumento7 pagineUG-37 F FactorjamesNessuna valutazione finora

- UG-37 F FactorDocumento7 pagineUG-37 F FactorjamesNessuna valutazione finora

- Zexel VRZ Pump PDFDocumento12 pagineZexel VRZ Pump PDFalvarikokexNessuna valutazione finora

- Pressure ControlsDocumento56 paginePressure Controlsapi-3854910100% (1)

- Gothic ArchitectureDocumento6 pagineGothic ArchitectureleeNessuna valutazione finora

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- Loads On FlangesDocumento16 pagineLoads On Flangesccoollest100% (3)

- Zick AnalysisDocumento12 pagineZick AnalysisrksahayNessuna valutazione finora

- Zick AnalysisDocumento12 pagineZick AnalysisrksahayNessuna valutazione finora

- Centrifugal PumpDocumento2 pagineCentrifugal Pumpsong LiNessuna valutazione finora

- Smath StudioDocumento47 pagineSmath StudiokeikunbrNessuna valutazione finora

- Smath StudioDocumento47 pagineSmath StudiokeikunbrNessuna valutazione finora

- Variable Parallel Pumps DPVP: Short DescriptionDocumento4 pagineVariable Parallel Pumps DPVP: Short DescriptionЕкатерина КалашниковаNessuna valutazione finora

- Israeli Standard SI 413Documento30 pagineIsraeli Standard SI 413rrrrmmmm1100% (1)

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Documento4 pagineS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Юрий ТрофимовNessuna valutazione finora

- R9350 EN New PDFDocumento123 pagineR9350 EN New PDFSubairi bain100% (1)

- Gap & Prosper WorkshopDocumento60 pagineGap & Prosper WorkshopWael FaragNessuna valutazione finora

- Lift Calculation DemoDocumento4 pagineLift Calculation Demoa_toups0% (1)

- Tables - TechnicalProperties - EN 10088 PDFDocumento24 pagineTables - TechnicalProperties - EN 10088 PDFeugenio.gutenbertNessuna valutazione finora

- EMCO Floating Suctions enDocumento2 pagineEMCO Floating Suctions enAnonymous yQ7SQrNessuna valutazione finora

- Valve Sizing Calculation - Docx INEGAS 3Documento2 pagineValve Sizing Calculation - Docx INEGAS 3jhon.rojas.ery1489Nessuna valutazione finora

- Centrifuge ComparisonDocumento6 pagineCentrifuge ComparisonRicardo VillarNessuna valutazione finora

- Op Uc 101Documento1 paginaOp Uc 101Fabian SNessuna valutazione finora

- Mechanical Specifications For Fiberbond ProductDocumento8 pagineMechanical Specifications For Fiberbond ProducthasnizaNessuna valutazione finora

- PRDC Sun ValveDocumento3 paginePRDC Sun ValvekhairulanuarjunNessuna valutazione finora

- Fiche Split Mural InverterDocumento2 pagineFiche Split Mural InverterOULDITTOU MohamedNessuna valutazione finora

- DataSheet L3HC 140-225 AHOKVO-GDocumento1 paginaDataSheet L3HC 140-225 AHOKVO-GJAC 91Nessuna valutazione finora

- 9161Documento5 pagine9161BaytolgaNessuna valutazione finora

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Documento5 pagineS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaNessuna valutazione finora

- VT IPV 21 BDI 90116 enDocumento20 pagineVT IPV 21 BDI 90116 enEraldo MendesNessuna valutazione finora

- Pressure Reducing - Relieving Valve PRFBDocumento3 paginePressure Reducing - Relieving Valve PRFBkocho79Nessuna valutazione finora

- Ipvp 6-80 101 Voith PumpDocumento24 pagineIpvp 6-80 101 Voith Pumppapinaidu2Nessuna valutazione finora

- 4802 10 02 JZ70 Spec (UK) PDFDocumento8 pagine4802 10 02 JZ70 Spec (UK) PDFaiulica20Nessuna valutazione finora

- RBAP Full en Us Letter PDFDocumento3 pagineRBAP Full en Us Letter PDFfrancis_15inNessuna valutazione finora

- Vertical Two-Phase Separator Design: Liquid / Vapor ServiceDocumento11 pagineVertical Two-Phase Separator Design: Liquid / Vapor ServiceDhanny MiharjaNessuna valutazione finora

- Ytg PDFDocumento2 pagineYtg PDFHarshitShuklaNessuna valutazione finora

- PSI HD Technical Standard 56300004x - 8.1L Turbo Engine Ratings and Specifications Rev CDocumento3 paginePSI HD Technical Standard 56300004x - 8.1L Turbo Engine Ratings and Specifications Rev CfreyespadaaNessuna valutazione finora

- Hoerbiger Recip Compressor Training PDFDocumento18 pagineHoerbiger Recip Compressor Training PDFnajamsyed6754Nessuna valutazione finora

- Serie D31 - Cetop 5Documento35 pagineSerie D31 - Cetop 5Hugo MenendezNessuna valutazione finora

- 1-AM012-C - World CupDocumento35 pagine1-AM012-C - World CupHeather MurphyNessuna valutazione finora

- Data Sheet: 25 Frame Plunger PumpsDocumento4 pagineData Sheet: 25 Frame Plunger PumpsGioNessuna valutazione finora

- IPC Medium-Pressure Internal Gear Pumps: Technical Data SheetDocumento20 pagineIPC Medium-Pressure Internal Gear Pumps: Technical Data SheetNutrición SaludableNessuna valutazione finora

- 95AF Technical SpecificationsDocumento12 pagine95AF Technical SpecificationsIan OsorioNessuna valutazione finora

- Steam Sizing Chart-Technical Information PDFDocumento2 pagineSteam Sizing Chart-Technical Information PDFgustavoNessuna valutazione finora

- 104700-9191 Hyundai̇ Kia 2500Documento5 pagine104700-9191 Hyundai̇ Kia 2500BaytolgaNessuna valutazione finora

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocumento2 pagineModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNessuna valutazione finora

- RXQ 32Documento1 paginaRXQ 32Surya LiemNessuna valutazione finora

- Compresor Reciprocante W Info AdicionalDocumento67 pagineCompresor Reciprocante W Info Adicionaljcastell100Nessuna valutazione finora

- DRBCLBN Full Es Us A4Documento2 pagineDRBCLBN Full Es Us A4Erasmo LimaNessuna valutazione finora

- Solved Example With ExerciseDocumento10 pagineSolved Example With Exercisesarmistha patnaiKNessuna valutazione finora

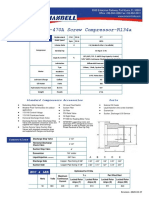

- Hanbell Spec Sheet RC2-470ADocumento1 paginaHanbell Spec Sheet RC2-470ATran Van TienNessuna valutazione finora

- 15W40 Alt 2Documento9 pagine15W40 Alt 2ruben estebanNessuna valutazione finora

- Hanbell Spec Sheet RC2-230B PDFDocumento1 paginaHanbell Spec Sheet RC2-230B PDFDaniel Naoe FestinNessuna valutazione finora

- Hanbell Spec Sheet RC2-200BDocumento1 paginaHanbell Spec Sheet RC2-200BMuhammadAsim100% (1)

- (TDB) ERV For Europe (Nasa, 50Hz - 60Hz) - Ver.1.4Documento17 pagine(TDB) ERV For Europe (Nasa, 50Hz - 60Hz) - Ver.1.4carlo jose cortez montanoNessuna valutazione finora

- Performance Information: Series PVP 23/33 Technical InformationDocumento10 paginePerformance Information: Series PVP 23/33 Technical InformationhaggNessuna valutazione finora

- Crest Boiler Product Summary: (FB) 750,000 - 2,000,000 BTU/HRDocumento1 paginaCrest Boiler Product Summary: (FB) 750,000 - 2,000,000 BTU/HRAnonymous 7xHNgoKE6eNessuna valutazione finora

- RXQ 6Documento1 paginaRXQ 6selauNessuna valutazione finora

- Appendix A - Factory Specifications PDFDocumento40 pagineAppendix A - Factory Specifications PDFRobert RooseNessuna valutazione finora

- RPEI Full en Metric LetterDocumento4 pagineRPEI Full en Metric LetteressamNessuna valutazione finora

- 4-3/4" LBTB: - Mud Lubricated Bearing PackDocumento3 pagine4-3/4" LBTB: - Mud Lubricated Bearing PackGina Vanessa Quintero CruzNessuna valutazione finora

- T4900 T41200Documento2 pagineT4900 T41200Grover CondoriNessuna valutazione finora

- Cryogenic Upper Stage PropulsionDocumento25 pagineCryogenic Upper Stage Propulsionrobson_hahnNessuna valutazione finora

- Valvula DireccionalDocumento2 pagineValvula Direccionalleo hernandezNessuna valutazione finora

- Model 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocumento2 pagineModel 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveErasmo LimaNessuna valutazione finora

- Acid MaterialsDocumento6 pagineAcid MaterialsrivrsideNessuna valutazione finora

- Ice Handbook For EngineersDocumento31 pagineIce Handbook For EngineersruayoNessuna valutazione finora

- ProgrammingWithSMathStudio2012 PDFDocumento30 pagineProgrammingWithSMathStudio2012 PDFMarioNessuna valutazione finora

- User-Defined Functions in Smath StudioDocumento21 pagineUser-Defined Functions in Smath StudiobricemikNessuna valutazione finora

- SMathStudio.0 85.IOFiles - Article.engDocumento8 pagineSMathStudio.0 85.IOFiles - Article.eng_mikkaNessuna valutazione finora

- Am2 To Sii 413Documento18 pagineAm2 To Sii 413amit sharmaNessuna valutazione finora

- SMathStudio.0 85.NumericFunctions - Article.Eng PDFDocumento8 pagineSMathStudio.0 85.NumericFunctions - Article.Eng PDFpiramidonNessuna valutazione finora

- MSDS Eng FoamglasDocumento4 pagineMSDS Eng FoamglasAnonymous yQ7SQrNessuna valutazione finora

- Foamglas Data Sheet EngDocumento2 pagineFoamglas Data Sheet EngAnonymous yQ7SQrNessuna valutazione finora

- Brochure Foamglas EngDocumento36 pagineBrochure Foamglas EngAnonymous yQ7SQrNessuna valutazione finora

- DBYBHY2007 English Chapters1,2Documento28 pagineDBYBHY2007 English Chapters1,2Ergin ÇelikNessuna valutazione finora

- Fluoraz - FEPM797 - TypicalPropsDocumento3 pagineFluoraz - FEPM797 - TypicalPropsAnonymous yQ7SQrNessuna valutazione finora

- Tecnicas para Cartas de Amor U OdioDocumento4 pagineTecnicas para Cartas de Amor U OdioChristian Gabriel Stampacchio100% (16)

- Corrosion Comparision Between SS Steel in H2SO4Documento20 pagineCorrosion Comparision Between SS Steel in H2SO4Anonymous yQ7SQrNessuna valutazione finora

- Caged, With Inner Ring, No End Washers, Sealed, Yoke-Type (Na22 Series)Documento1 paginaCaged, With Inner Ring, No End Washers, Sealed, Yoke-Type (Na22 Series)Anonymous yQ7SQrNessuna valutazione finora

- Tecnicas para Cartas de Amor U OdioDocumento4 pagineTecnicas para Cartas de Amor U OdioChristian Gabriel Stampacchio100% (16)

- Flange DesignDocumento10 pagineFlange DesignAnonymous yQ7SQrNessuna valutazione finora

- Comparison of Recent Us Seismic CodesDocumento8 pagineComparison of Recent Us Seismic CodesAnonymous yQ7SQrNessuna valutazione finora

- Corrosion Comparision Between SS Steel in H2SO4Documento20 pagineCorrosion Comparision Between SS Steel in H2SO4Anonymous yQ7SQrNessuna valutazione finora

- Pell (2017) - Trends in Real-Time Traffic SimulationDocumento8 paginePell (2017) - Trends in Real-Time Traffic SimulationJorge OchoaNessuna valutazione finora

- Reservoir Bag Physics J PhilipDocumento44 pagineReservoir Bag Physics J PhilipJashim JumliNessuna valutazione finora

- Session 1: Strategic Marketing - Introduction & ScopeDocumento38 pagineSession 1: Strategic Marketing - Introduction & ScopeImrul Hasan ChowdhuryNessuna valutazione finora

- Chapter 12Documento15 pagineChapter 12kk5522Nessuna valutazione finora

- Chapter 5 - Amino acids and Proteins: Trần Thị Minh ĐứcDocumento59 pagineChapter 5 - Amino acids and Proteins: Trần Thị Minh ĐứcNguyễn SunNessuna valutazione finora

- Florida Gov. Ron DeSantis Provides Update As Hurricane Ian Prompts EvDocumento1 paginaFlorida Gov. Ron DeSantis Provides Update As Hurricane Ian Prompts Evedwinbramosmac.comNessuna valutazione finora

- Ccu 3900alDocumento3 pagineCcu 3900alTourchianNessuna valutazione finora

- Lab Report 2Documento5 pagineLab Report 2Md jubayer SiddiqueNessuna valutazione finora

- Sample Valuation ReportDocumento15 pagineSample Valuation Reportayush singlaNessuna valutazione finora

- Huawei - ESM48100 - User ManualDocumento44 pagineHuawei - ESM48100 - User ManualNguyen Minh ThanhNessuna valutazione finora

- Tso C197Documento6 pagineTso C197rdpereirNessuna valutazione finora

- Forex 1 PDFDocumento3 pagineForex 1 PDFChandreshNessuna valutazione finora

- El TontoDocumento92 pagineEl TontoRobertNessuna valutazione finora

- Resolution: Owner/Operator, DocketedDocumento4 pagineResolution: Owner/Operator, DocketedDonna Grace Guyo100% (1)

- IBS and SIBO Differential Diagnosis, SiebeckerDocumento1 paginaIBS and SIBO Differential Diagnosis, SiebeckerKrishna DasNessuna valutazione finora

- A Quantitative Method For Evaluation of CAT Tools Based On User Preferences. Anna ZaretskayaDocumento5 pagineA Quantitative Method For Evaluation of CAT Tools Based On User Preferences. Anna ZaretskayaplanetalinguaNessuna valutazione finora

- 762id - Development of Cluster-7 Marginal Field Paper To PetrotechDocumento2 pagine762id - Development of Cluster-7 Marginal Field Paper To PetrotechSATRIONessuna valutazione finora

- CCTV Guidelines - Commission Letter Dated 27.08.2022Documento2 pagineCCTV Guidelines - Commission Letter Dated 27.08.2022Sumeet TripathiNessuna valutazione finora

- Straw Bale ConstructionDocumento37 pagineStraw Bale ConstructionelissiumNessuna valutazione finora

- Chanakya: For The Indian Television Series Based On His Life, SeeDocumento11 pagineChanakya: For The Indian Television Series Based On His Life, SeeTrinadh CrazyguyNessuna valutazione finora

- Alem Ketema Proposal NewDocumento25 pagineAlem Ketema Proposal NewLeulNessuna valutazione finora

- Cs205-E S3dec18 KtuwebDocumento2 pagineCs205-E S3dec18 KtuwebVighnesh MuralyNessuna valutazione finora

- Intergard 475HS - Part B - EVA046 - GBR - ENG PDFDocumento10 pagineIntergard 475HS - Part B - EVA046 - GBR - ENG PDFMohamed NouzerNessuna valutazione finora

- Cutler Hammer Dry Type TransformerDocumento220 pagineCutler Hammer Dry Type TransformernprajanNessuna valutazione finora

- Sinamics g120 BrochureDocumento16 pagineSinamics g120 BrochuremihacraciunNessuna valutazione finora

- Ezpdf Reader 1 9 8 1Documento1 paginaEzpdf Reader 1 9 8 1AnthonyNessuna valutazione finora

- Sungbo's Eredo, Southern Nigeria: Nyame Akuma NoDocumento7 pagineSungbo's Eredo, Southern Nigeria: Nyame Akuma NosalatudeNessuna valutazione finora

- ERP22006Documento1 paginaERP22006Ady Surya LesmanaNessuna valutazione finora

- A Vision System For Surface Roughness Characterization Using The Gray Level Co-Occurrence MatrixDocumento12 pagineA Vision System For Surface Roughness Characterization Using The Gray Level Co-Occurrence MatrixPraveen KumarNessuna valutazione finora