Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

E 50B 4KG1 - Fire PDF

Caricato da

Patricia J ÁngelesTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

E 50B 4KG1 - Fire PDF

Caricato da

Patricia J ÁngelesCopyright:

Formati disponibili

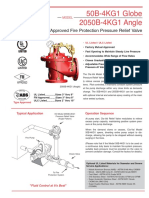

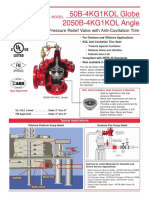

MODEL

50B-4KG1 Globe

2050B-4KG1 Angle

Listed/Approved Fire Protection Pressure Relief Valve

U.L. Listed / U.L.C. Listed

Factory Mutual Approved

Fast Opening to Maintain Steady Line Pressure

LAB

LLED B

Y

Accommodates Wide Range of Flow Rates

Closes Gradually for Surge-Free Operation

ULC

U N D E R W RIT

CANADA

Adjustable Pressure Settings, Not Affected by

OF

R

E

S E

LAB RI

O R AT O

Pressure At Valve Discharge

The Cla-Val Model 50B-4KG1 Globe / 2050B-4KG1 Angle

Pressure Relief Valve is designed specifically to automati-

cally relieve excess pressure in fire protection pumping sys-

tems. Pilot controlled, it maintains constant system pres-

2050B-4KG1 (Angle)

sure at the pump discharge within very close limits as

DESIGN

demands change. The 50B-4KG1 and 2050B-4KG1 can be

U.L. Listed...............Sizes 3" thru 8" supplied with optional internal and external epoxy coating of

ASSE

SSED

F.M. Approved.........Sizes 3" thru 8" the main valve wetted surfaces.

U.L.C. Listed............Sizes 2 thru 10

Type Approved

Typical Application KOModel 2050B-4KG1 Operation Sequence

Pressure Relief Valve

(Angle Pattern) At pump start, Cla-Val Relief Valve modulates to relieve

excess pump capacity, maintaining positive system pres-

sure at the pump discharge.

When fire demand slows or ceases, Cla-Val Model

50B-4KG1 opens, diverting entire pump output to dis-

charge, allowing fire pump to be stopped without causing

Fire Pump surging in the lines.

(Please note that if the Model 50B-4KG1 is to be used on

a continuous duty basis to maintain fire-system pressure,

suitable back pressure must be provided on the valve to

prevent cavitation damage. Consult the factory for details.)

Check Valve

Optional UL Listed Materials for Seawater and Severe

Service Applications:

Nickel Aluminum Bronze (NAB) - ASTM B148 Alloy C95800

To Fire Monel - QQ-N-288 Comp B - ASTM A494 Grade M30H

Protection System Cast Steel - ASTM A216 Grade WCB

316 Stainless Steel - ASTM A743 Grades CF3M and CFM8

Super Austenitic Stainless Steel - ASTM A351 Grade

CK3MCuN (SMO 254)

Super Duplex Stainless Steel - ASTMA890 Grade 5A

"Fluid Control at It's Best" (CE3MN)

Specifications Dimensions

B

Sizes Globe: 2" - 10 flanged = U.L., F.M. and

Angle: 2" - 10" flanged ULC sizes

End Details 150 and 300 ANSI B16.42

Pressure Ratings Class 150 - 250 psi Max. G

= ULC sizes only

Class 300 - 400 psi Max

Water, to 180F Max.

Model 50B-4KG1 Globe Model 2050B-4KG1 Angle

Standard Materials Main Valve Body & Cover

A H E

Ductile Iron ASTM A536 Grade 65-45-12

Standard Main Valve Trim:

Bronze Seat, Teflon Coated

Stainless Steel Stem, Dura-Kleen Stem

C

Standard Pilot Control System: C

Cast Bronze with

Stainless Steel trim

Available in the following relief

pressure ranges: D F

Adjustment Range 20-200 psi (150 Class)

100-300 psi (300 Class) We recommend providing adequate space around valve for maintenance work.

Protective epoxy resin coating

of wetted surfaces of main Valve Size (inches) 2 2-1/2 3 4 6 8 10

Optional valve cast iron components Threaded Ends 9.38 11.00 12.50 --- --- --- ---

(UL listed HNFX EX2855) A 150 Flanged 9.38 11.00 12.00 15.00 20.00 25.38 29.75

300 Flanged 10.00 11.62 13.25 15.62 21.00 26.38 31.12

300 X 150 12.88 15.31 20.56 25.88 30.44

Purchase Specifications B 3.31 4.00 4.56 5.75 7.88 10.00 11.81

The Fire Pump Pressure Relief Valve shall modulate to relieve excess C 12.00 12.25 12.50 13.00 14.31 16.31 18.00

pressure in a fire protection system. It shall maintain constant pressure D 1.50 1.69 2.66 3.19 4.31 5.31 9.25

in the system regardless of demand changes. It shall be pilot controlled Threaded Ends 4.75 5.50 6.25 --- --- --- ---

and back pressure shall not affect its set point. It shall be actuated by

E 150 Flanged 4.75 5.50 6.00 7.50 10.00 12.75 14.88

line pressure through a pilot control system and open fast in order to

300 Flanged 5.00 5.88 6.38 7.88 10.50 13.25 15.56

maintain steady system pressure as system demand decreases. It shall

close gradually to control surges and shall re-seat drip-tight within 5% of Threaded Ends 3.25 4.00 4.50 --- --- --- ---

its pressure setting. The main valve shall be of the hydraulically-operat- F 150 Flanged 3.25 4.00 4.00 5.00 6.00 8.00 8.62

ed, pilot-controlled, diaphragm-type, globe or angle valve. It shall have 300 Flanged 3.50 4.31 4.38 5.31 6.50 8.50 9.31

a single, removable, teflon-coated seat, a grooved stem guided at both G&H 6.00 6.69 7.75 7.88 8.50 9.75 13.25

ends, and a resilient disc with a rectangular cross section, being con-

tained on 3 1/2 sides. No external packing glands shall be permitted and Valve Size (mm) 50 65 80 100 150 200 250

the diaphragm shall not be used as a seating surface. The pilot control Threaded Ends 238 279 318 --- --- --- ---

shall be a direct-acting, adjustable, spring-loaded, diaphragm-type valve

A 150 Flanged 234 279 305 381 508 645 756

designed for modulating service to permit flow when controlling pressure

300 Flanged 254 295 337 397 533 670 790

exceeds spring setting. This valve shall be UL Listed and Factory Mutual

approved. It shall be the Model 50B-4KG1 (globe) or Model 2050B- 300 X 150 --- --- 327 389 522 657 773

4KG1 (angle) Pressure Relief Valve as manufactured by Cla-Val Newport B 84 102 116 146 200 254 300

Beach, California. C 305 311 1318 330 363 414 457

*Special Note: D 38 43 65 81 109 135 235

The Model 50B-4KG1 Pressure Relief Valve is available with 300# ANSI Threaded Ends 121 140 159 --- --- --- ---

inlet flange and 150# ANSI outlet flange. This valve is used on higher

E 150 Flanged 121 140 152 191 254 324 378

pressure systems where 300# flange connections are required, and

300 Flanged 127 149 162 200 267 337 395

allows for adapting of a discharge cone (generally supplied with 150#

flange) to accommodate "atmospheric break" at relief valve discharge. Threaded Ends 83 102 114 --- --- --- ---

This relief valve, with 300# / 150# flanges is available on special order, F 150 Flanged 83 102 102 127 152 203 219

and is UNDERWRITERS LABORATORIES LISTED AND FACTORY 300 Flanged 89 109 111 135 165 216 236

MUTUAL APPROVED. G&H 152 170 197 200 216 248 337

Specifications: Seawater Service Option Valve Capacity

Sizes Globe: 2" - 8" flanged

Angle: 2" - 8" flanged Valve Sizes in Inches: 2" 2 1/2" 3" 4" 6" 8" 10"

Consult factory for flange ratings. NFPA 20 Maximum

See page 1 for seawater service materials options. Recommended GPM 208 300 500 1000 2500 5000 11000

CLA-VAL Represented By:

1701 Placentia Avenue Costa Mesa CA 92627 Phone: 949-722-4800

Fax: 949-548-5441 Web Site: cla-val.com E-mail: claval@cla-val.com

CLA-VAL CANADA CLA-VAL EUROPE CLA-VAL UK

4687 Christie Drive Chemin des Msanges 1 Dainton House, Goods Station Road

Beamsville, Ontario CH-1032 Romanel/ GB - Tunbridge Wells

Canada L0R 1B4 Lausanne, Switzerland Kent TN1 2 DH England

Phone: 905-563-4963 Phone: 41-21-643-15-55 Phone: 44-1892-514-400

Fax: 905-563-4040 Fax: 41-21-643-15-50 Fax: 44-1892-543-423

E-Mail: sales@cla-val.ca E-Mail: cla-val@cla-val.ch E-Mail: info@cla-val.co.uk

Copyright CLA-VAL 2015 Printed in USA Specifications subject to change without notice.

E-50B-4KG1/2050B-4KGL1 (R-04/2015)

Potrebbero piacerti anche

- DelugeDocumento12 pagineDelugeHaitham MohammadNessuna valutazione finora

- Additive Manufacturing Stainless Steel Alloy (UNS S31603) With Powder Bed FusionDocumento9 pagineAdditive Manufacturing Stainless Steel Alloy (UNS S31603) With Powder Bed FusionwerrteNessuna valutazione finora

- Mass Iron and Steel IndustryDocumento19 pagineMass Iron and Steel Industrynabaz muhamadNessuna valutazione finora

- MCQ in General Engineering and Applied Sciences by ExcelDocumento347 pagineMCQ in General Engineering and Applied Sciences by Excelreggieguapo100% (1)

- Cal Val Refile ValveDocumento1 paginaCal Val Refile Valvesourav samadderNessuna valutazione finora

- Claval Pressure Relief Valve (UL&FM)Documento2 pagineClaval Pressure Relief Valve (UL&FM)engineering projectNessuna valutazione finora

- 50B-4KG1 Globe 2050B-4KG1 Angle: Listed/Approved Fire Protection Pressure Relief ValveDocumento2 pagine50B-4KG1 Globe 2050B-4KG1 Angle: Listed/Approved Fire Protection Pressure Relief ValveNazrul IslamNessuna valutazione finora

- Attachments DrawingsDocumento8 pagineAttachments DrawingsMOHNISHKUMARJHANessuna valutazione finora

- 50B-4KG1 Globe 2050B-4KG1 Angle: Fire Protection Pressure Relief ValveDocumento2 pagine50B-4KG1 Globe 2050B-4KG1 Angle: Fire Protection Pressure Relief ValveAlbeiro LeivaNessuna valutazione finora

- 50B-4KG1 Globe 2050B-4KG1 Angle: Fire Protection Pressure Relief ValveDocumento2 pagine50B-4KG1 Globe 2050B-4KG1 Angle: Fire Protection Pressure Relief ValveArdhana ArdhanaNessuna valutazione finora

- Gco Ecp FRB Ppu Doc PRV BrochureDocumento2 pagineGco Ecp FRB Ppu Doc PRV BrochureRafael AguilarNessuna valutazione finora

- Cla-Val: Fire Protection Pressure Relief ValveDocumento2 pagineCla-Val: Fire Protection Pressure Relief ValveShoaib AhmedNessuna valutazione finora

- PRV e 50b 4kg1kolDocumento2 paginePRV e 50b 4kg1kolmoh. rusli bahtiarNessuna valutazione finora

- Claval PRV (UL)Documento2 pagineClaval PRV (UL)engineering projectNessuna valutazione finora

- Claval Pressure Reducing ValveDocumento2 pagineClaval Pressure Reducing ValverachitNessuna valutazione finora

- wp-contentuploads202302B-FP Commercial Services Brochure PDFDocumento8 paginewp-contentuploads202302B-FP Commercial Services Brochure PDFAhmad AbdalhayNessuna valutazione finora

- E69001 PRV ClavalDocumento4 pagineE69001 PRV ClavalPlanner CyberNessuna valutazione finora

- Main Relief ValveDocumento2 pagineMain Relief ValveJesseNessuna valutazione finora

- Pressure Relief Valve/ Pump Casing Relief Valve: ModelDocumento2 paginePressure Relief Valve/ Pump Casing Relief Valve: ModelJosé ArgüelloNessuna valutazione finora

- 90 01KO Data Sheet USDocumento4 pagine90 01KO Data Sheet USAngga ArdanaNessuna valutazione finora

- E55L60.pdf Relief ValveDocumento2 pagineE55L60.pdf Relief ValveYasser ShehataNessuna valutazione finora

- Pressure Relief Valve/ Pump Casing Relief Valve: ModelDocumento2 paginePressure Relief Valve/ Pump Casing Relief Valve: ModelEng Salah RamadanNessuna valutazione finora

- 08 Parts in Body Valves-Counter Balance Valves Ir2Documento82 pagine08 Parts in Body Valves-Counter Balance Valves Ir2Guillermo Jara MatosNessuna valutazione finora

- FT - E55l60 - v. AlivioDocumento2 pagineFT - E55l60 - v. AlivioLuiggy Garcia SuarezNessuna valutazione finora

- CLA-VAL Reguladora de Presion 90-01 BlueDocumento4 pagineCLA-VAL Reguladora de Presion 90-01 BlueSergio HoyosNessuna valutazione finora

- Válvula Reductora de Presión PDFDocumento4 pagineVálvula Reductora de Presión PDFPaola LopezNessuna valutazione finora

- E4036Documento2 pagineE4036Pablo Cardenas SandovalNessuna valutazione finora

- Pressure Reducing Valve CatalogueDocumento4 paginePressure Reducing Valve CatalogueSteveNessuna valutazione finora

- Pressure Reducing Valve: ModelDocumento4 paginePressure Reducing Valve: ModelTiam Yee YongNessuna valutazione finora

- Model RV-1 Pressure Relief Valve 2 To 8 Inch (DN50 To DN200), 250 Psi (17,2 Bar) Pilot-Operated, Globe and Angle Body Styles General DescriptionDocumento8 pagineModel RV-1 Pressure Relief Valve 2 To 8 Inch (DN50 To DN200), 250 Psi (17,2 Bar) Pilot-Operated, Globe and Angle Body Styles General DescriptionmarioNessuna valutazione finora

- Differential Pressure Valve E-250-01Documento3 pagineDifferential Pressure Valve E-250-01Navin RamnauthNessuna valutazione finora

- Valvula de Aire E-90-21 - FireDocumento2 pagineValvula de Aire E-90-21 - FirePaola LopezNessuna valutazione finora

- Valvula de Alivio 55LDocumento2 pagineValvula de Alivio 55LRobinzonJVilcchezzNessuna valutazione finora

- CounterbalanceGuide R2Documento2 pagineCounterbalanceGuide R2Samuel Lopez BenitesNessuna valutazione finora

- Kuriauto C505ECO Brochure-EnDocumento2 pagineKuriauto C505ECO Brochure-EnIman Faisal0% (1)

- GSD Valvula Reductora de Presion Psi - ClavalDocumento2 pagineGSD Valvula Reductora de Presion Psi - ClavalGonzalo DominguezNessuna valutazione finora

- 7.5. Cla-Val E-650-01Documento4 pagine7.5. Cla-Val E-650-01sigithvacNessuna valutazione finora

- Preset Valve Ocv Model Sheet 115 - 25 Aviation 2020Documento2 paginePreset Valve Ocv Model Sheet 115 - 25 Aviation 2020varadarajck893Nessuna valutazione finora

- Válvula Control de Bomba - CLAVALDocumento4 pagineVálvula Control de Bomba - CLAVALJose CabanaNessuna valutazione finora

- Butterfly Valves (BFV) : ApplicationDocumento120 pagineButterfly Valves (BFV) : ApplicationMuhammad azeemNessuna valutazione finora

- Expansion Devices: TXV in ControlDocumento2 pagineExpansion Devices: TXV in ControlRajat JunejaNessuna valutazione finora

- Pressure Reducing Valve: ModelDocumento4 paginePressure Reducing Valve: ModeltorqueuNessuna valutazione finora

- Pressure Reducing Valve: ModelDocumento4 paginePressure Reducing Valve: Modelguangyu LuNessuna valutazione finora

- E 90 21 - FireDocumento2 pagineE 90 21 - FireJun AntonioNessuna valutazione finora

- Seawater Service Pressure Relief Valve: ModelDocumento2 pagineSeawater Service Pressure Relief Valve: ModelHemant RasamNessuna valutazione finora

- Model Sheet 115 - 25 Terminal 9 - 20Documento2 pagineModel Sheet 115 - 25 Terminal 9 - 20Gusukuma JGNessuna valutazione finora

- Pressure Relief Valve/ Pump Casing Relief Valve: ModelDocumento2 paginePressure Relief Valve/ Pump Casing Relief Valve: ModelYeraldin SalinasNessuna valutazione finora

- Al-425 Catalogo CompletoDocumento2 pagineAl-425 Catalogo CompletoJosé Sánchez ChávezNessuna valutazione finora

- Annular Frac System 1595037957 PDFDocumento1 paginaAnnular Frac System 1595037957 PDFjhon sarmientoNessuna valutazione finora

- Alarm Check Valve UL-FMDocumento3 pagineAlarm Check Valve UL-FMLIJINNessuna valutazione finora

- SS Series (Wiring System: Central Terminal Box) Wet Type Solenoid ValveDocumento12 pagineSS Series (Wiring System: Central Terminal Box) Wet Type Solenoid ValveMarcelo Partes de OliveiraNessuna valutazione finora

- RV12-26 Relief, Pilot-Operated Spool: Pressure ControlsDocumento2 pagineRV12-26 Relief, Pilot-Operated Spool: Pressure Controlsjuanchis650Nessuna valutazione finora

- PS10-40 Sequence, Normally Closed - . .: Pressure ControlsDocumento2 paginePS10-40 Sequence, Normally Closed - . .: Pressure ControlsandresNessuna valutazione finora

- Ficha Tecnica Control de Nivel McDonnell & Miller 150SDocumento1 paginaFicha Tecnica Control de Nivel McDonnell & Miller 150Sccastillo.vaporaustralNessuna valutazione finora

- 95S, 125S & 165SDocumento4 pagine95S, 125S & 165Sabet_4Nessuna valutazione finora

- Model Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADocumento2 pagineModel Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AErasmo LimaNessuna valutazione finora

- Inbal DG04C Deluge Valve Electric Actuation PDFDocumento4 pagineInbal DG04C Deluge Valve Electric Actuation PDFjakkol11Nessuna valutazione finora

- Relief Valve 5k 6-015-1Documento2 pagineRelief Valve 5k 6-015-1francis_15inNessuna valutazione finora

- VPL Valve OverviewDocumento12 pagineVPL Valve OverviewKhaled RashedNessuna valutazione finora

- Ss 03010Documento4 pagineSs 03010Necati Yunus OrbayNessuna valutazione finora

- BE1 - 50-51B-244 RetrofitDocumento8 pagineBE1 - 50-51B-244 RetrofitMina HannaNessuna valutazione finora

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- SSW-05 - Manual Do UsuárioDocumento98 pagineSSW-05 - Manual Do Usuárioaleeecarvalho3795Nessuna valutazione finora

- Lutz Drum PumpsDocumento2 pagineLutz Drum PumpsPatricia J ÁngelesNessuna valutazione finora

- FLOWSERVE LNN Training CustomerDocumento44 pagineFLOWSERVE LNN Training CustomerPatricia J Ángeles100% (1)

- Flowserve LNNDocumento8 pagineFlowserve LNNPatricia J ÁngelesNessuna valutazione finora

- Lutz Diferentes Tipos Motores PDFDocumento1 paginaLutz Diferentes Tipos Motores PDFPatricia J ÁngelesNessuna valutazione finora

- Drum and Container Pumps PDFDocumento23 pagineDrum and Container Pumps PDFPatricia J ÁngelesNessuna valutazione finora

- Pss 10 5.1 e PDFDocumento2 paginePss 10 5.1 e PDFPatricia J ÁngelesNessuna valutazione finora

- AOD Motors LutzDocumento1 paginaAOD Motors LutzPatricia J ÁngelesNessuna valutazione finora

- Clyde Union Uniglide Brochure 0Documento2 pagineClyde Union Uniglide Brochure 0Patricia J ÁngelesNessuna valutazione finora

- Curva Bomba KUNZ NTDocumento1 paginaCurva Bomba KUNZ NTPatricia J ÁngelesNessuna valutazione finora

- Rexnord Elastomer CouplingDocumento20 pagineRexnord Elastomer Couplingidontlikeebooks100% (1)

- DEAN RA Bulletin8 24 10 PDFDocumento6 pagineDEAN RA Bulletin8 24 10 PDFPatricia J ÁngelesNessuna valutazione finora

- Catalogo Fire 2009 PDFDocumento7 pagineCatalogo Fire 2009 PDFPatricia J ÁngelesNessuna valutazione finora

- Duoglide Brochure - 0 PDFDocumento2 pagineDuoglide Brochure - 0 PDFPatricia J ÁngelesNessuna valutazione finora

- Curva Bomba KUNZ NTDocumento1 paginaCurva Bomba KUNZ NTPatricia J ÁngelesNessuna valutazione finora

- Hydraulic InstituteDocumento4 pagineHydraulic InstitutePatricia J ÁngelesNessuna valutazione finora

- 0 PDFDocumento170 pagine0 PDFPatricia J ÁngelesNessuna valutazione finora

- Schmitt 175 PumpDocumento1 paginaSchmitt 175 PumpPatricia J ÁngelesNessuna valutazione finora

- Ebara 3DDocumento53 pagineEbara 3DPatricia J ÁngelesNessuna valutazione finora

- Curva Bomba KUNZ NTDocumento1 paginaCurva Bomba KUNZ NTPatricia J ÁngelesNessuna valutazione finora

- Curva Bomba KUNZ NTDocumento1 paginaCurva Bomba KUNZ NTPatricia J ÁngelesNessuna valutazione finora

- Curva Bomba KUNZ NTDocumento1 paginaCurva Bomba KUNZ NTPatricia J ÁngelesNessuna valutazione finora

- Manual Bomba Layne Bowler PDFDocumento21 pagineManual Bomba Layne Bowler PDFPatricia J ÁngelesNessuna valutazione finora

- Urea Ammon Nitrate Solution 32-0-0Documento2 pagineUrea Ammon Nitrate Solution 32-0-0Patricia J ÁngelesNessuna valutazione finora

- Curva Bomba KUNZ NTDocumento1 paginaCurva Bomba KUNZ NTPatricia J ÁngelesNessuna valutazione finora

- Vinaza ViscosidadDocumento8 pagineVinaza ViscosidadPatricia J ÁngelesNessuna valutazione finora

- Reliable Pressure Boosting.: Self-Priming Side Channel Pump SFHDocumento3 pagineReliable Pressure Boosting.: Self-Priming Side Channel Pump SFHPatricia J ÁngelesNessuna valutazione finora

- BornemannDocumento1 paginaBornemannPatricia J ÁngelesNessuna valutazione finora

- Dresser Rand MD001 Steam Mech Drive and TG SetDocumento1 paginaDresser Rand MD001 Steam Mech Drive and TG SetPatricia J ÁngelesNessuna valutazione finora

- Speed Deck 508: Metal Roof & Wall Cladding SystemDocumento6 pagineSpeed Deck 508: Metal Roof & Wall Cladding SystemMuraleedharanNessuna valutazione finora

- Copper Loops For 222 and 440MHzDocumento5 pagineCopper Loops For 222 and 440MHzBenjamin Dover100% (1)

- A Model To Predict The Performance of Roadheaders Based On The Rock Mass Brittleness IndexDocumento10 pagineA Model To Predict The Performance of Roadheaders Based On The Rock Mass Brittleness IndexmzulfikarmuslimNessuna valutazione finora

- P&O Lecture 3Documento30 pagineP&O Lecture 3FarhaanKhanHaleemNessuna valutazione finora

- Design and Efficiency of Heat Exchanger in Chlorination UnitDocumento77 pagineDesign and Efficiency of Heat Exchanger in Chlorination Unitrakesh suriyaNessuna valutazione finora

- The Australian Welding Guide 2012Documento220 pagineThe Australian Welding Guide 2012notsofar100% (2)

- Attachment 1Documento468 pagineAttachment 1Ali JarkhiNessuna valutazione finora

- Exhibitor List - IfEX 2017 & Cast India 2017Documento1 paginaExhibitor List - IfEX 2017 & Cast India 2017sentamil vigneshwaranNessuna valutazione finora

- Temperature & Density For CastingsDocumento46 pagineTemperature & Density For CastingsRobinson GnanaduraiNessuna valutazione finora

- 3 - Redox and Electrolysis (Pp2)Documento36 pagine3 - Redox and Electrolysis (Pp2)api-3700944100% (1)

- Rusting of Iron-1 PDFDocumento10 pagineRusting of Iron-1 PDFDeepanshu ThakurNessuna valutazione finora

- Advance Surface TreatmentDocumento48 pagineAdvance Surface TreatmentdelramdaniawatiNessuna valutazione finora

- 1991 - Hinchliffe - Refactory Linings For BoilersDocumento3 pagine1991 - Hinchliffe - Refactory Linings For BoilersChris BothaNessuna valutazione finora

- Chemistry Reviewer 1Documento13 pagineChemistry Reviewer 1John Van Dave TaturoNessuna valutazione finora

- Nickel and Other Super Alloys: TSUF 06 Materiales AeronauticosDocumento28 pagineNickel and Other Super Alloys: TSUF 06 Materiales AeronauticosFam HandmNessuna valutazione finora

- 4U Electrochem PracDocumento7 pagine4U Electrochem PracRomar Angelo AvilaNessuna valutazione finora

- Stress-Based Uniaxial Fatigue Analysis Using Methods Described in FKM-GuidelineDocumento40 pagineStress-Based Uniaxial Fatigue Analysis Using Methods Described in FKM-GuidelineclevercogNessuna valutazione finora

- Non-Ferrous MetalsDocumento26 pagineNon-Ferrous MetalsNicole May Dela CruzNessuna valutazione finora

- Foundry Process:: Casting TermsDocumento23 pagineFoundry Process:: Casting TermskalaivananmekNessuna valutazione finora

- Evaporator ScaleDocumento3 pagineEvaporator ScaleRoddy UlieNessuna valutazione finora

- Systematic Analysis of Simple Salt-7Documento7 pagineSystematic Analysis of Simple Salt-7Bala Murugan.VNessuna valutazione finora

- Submission Form IntertekDocumento26 pagineSubmission Form Intertekkillaruna04Nessuna valutazione finora

- Definitions and MCQs of Ninth Class Chemistry (Acids, Bases and Salts)Documento8 pagineDefinitions and MCQs of Ninth Class Chemistry (Acids, Bases and Salts)Sajid AliNessuna valutazione finora

- C2 Representing Reactions HigherDocumento11 pagineC2 Representing Reactions HigherdownendscienceNessuna valutazione finora

- Chapther Ii Literature Review: II.1 Basic Theory II.1.1 Deffinition of PotentiometryDocumento12 pagineChapther Ii Literature Review: II.1 Basic Theory II.1.1 Deffinition of PotentiometryVerychafinishNessuna valutazione finora

- Aalco Metals LTD Stainless Steel 155 PH 310Documento3 pagineAalco Metals LTD Stainless Steel 155 PH 310Ria MustikaNessuna valutazione finora

- Grade 10 Chemistry Week 3 Lesson 2Documento2 pagineGrade 10 Chemistry Week 3 Lesson 2Nikoli MajorNessuna valutazione finora