Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Industrial Machinery and Installations Automatism Rules For The Creation of The Electrical Files

Caricato da

Guidson Oliveira SantosTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Industrial Machinery and Installations Automatism Rules For The Creation of The Electrical Files

Caricato da

Guidson Oliveira SantosCopyright:

Formati disponibili

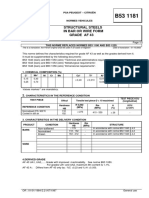

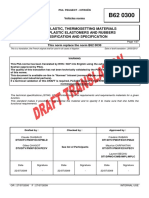

PSA PEUGEOT - CITRON

E03.03.250.G

Equipment Goods Standards

ICS: 01.080.40, 01.110, 25.040.01, 29.020, 35.240.10

INDUSTRIAL MACHINERY AND INSTALLATIONS

AUTOMATISM

RULES FOR THE CREATION OF THE ELECTRICAL FILES

Page 1/37

No use restriction

This is a translation, the French original shall be used in all cases of litigation Date of translation: 30/07/2007

This standard REPLACES PARTIALLY:

- the E03.65.572.G standard

- the GE03-026N, GE03-008G , GE03-050G guides

FOREWORD

This document lists the rules to observe at the time of the realization of the electrical files in order to:

standardize the electrical circuits and wirings of the equipments,

decrease if possible the costs, still observing the rules into force, and in particular the norm CEI 60204-1

A glossary of the terms used in this norm is provided in the norm E03.65.015.G

This document does not resume the rules of the decrees and norms, therefore the initial statutory control visit must

be achieved on the basis of the regulatory texts into force.

The blue texts in Italic constitute information intended to come with the rules.

1. The black texts preceded by a number constitute the rules. Each of these must be applied and self-controlled by

the integrator supplier.

A training support is associated to this document.

2. The control of the good application of this document is to be achieved using the control support of the guide

GE03-006G part 2: checking of the electrical file.

3. The supports of the expected by PSA (CD, hard copy) electrical file are defined in specifications.

Drafted by Checked by Approved by

Grard GREMAUD See list of participants Frderic TOURNUT

DTI/DITV/ISP/IMAI/AUT/ATA/VSA DTI/DITV/ISP/IMAI/AUT/ATA/MAU

Date Signature Date Signature Date Signature

23/03/2007 23/03/2007

OR: 01/06/2001 A: 23/03/2007 Network of competence : 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 2/37

RECORDS

Index Date Nature of modifications

OR 01/06/2001 Creation of the norme

A 23/03/2007 Complete rewriting of the document.

PARTICIPANTS

The following persons took part in the drafting and/or checking of this norme:

DTI/DITV/ISP/IMAI/AUT/BOME Damien CHATELAIN, Christian GISSINGER

DTI/DITV/ISP/IMAI/AUT/EMFE Robert BARZASI

DTI/DITV/ISP/IMAI/AUT/FERV Lionel PINEAU

DTI/DITV/ISP/IMAI/AUT/MONV Patrick Henri BELLARDANT

DTI/DITV/ISP/IMAI/AUT/PEMO Marc STEULLET, Laurent LABEUCHE

DTI/DITV/RHN/NCF Sylvain BIGOT

CONTENTS

FOREWORD 1

1. OBJECT AND FIELD OF APPLICATION 4

2. REFERENCE DOCUMENTS 4

2.1. NORMES 4

2.1.1. PSA NORMS 4

2.1.2. External NORMs 4

2.2. REGULATIONS 4

2.3. OTHER DOCUMENTS 4

2.4. EXPRESSION ON THE DOCUMENTS 4

3. TERMINOLOGY AND DEFINITION 4

3.1. DEFINITIONS 4

3.2. LOGOS 4

4. INTRODUCTION 6

5. COMPOSITION OF AN ELECTRICAL FILE 6

5.1. THE DOCUMENTS OF A FILE 6

5.2. FORMAT OF A BUNDLE 6

5.2.1. Definitions 6

5.3. IDENTIFICATION 7

5.4. THE FUNCTIONAL ELECTRICAL DRAWING 7

5.4.1. Content 7

5.4.2. Composition 8

5.4.3. Organization 8

5.5. THE TOPOLOGY OF THE AUTOMATISM NETWORKS 8

5.6. THE EQUIPMENT FILE 9

5.6.1. Content 9

6. PSA PEUGEOT CITRON WORK ENVIRONMENT - COMPOSING 10

7. PSA PEUGEOT CITRON WORK ENVIRONMENT - MANAGEMENT 10

8. DATA CAPTURE RULES OF THE PRINCIPLE ELECTRICAL DRAWING 10

8.1. LAYOUT 10

8.2. CONNECTIONS 10

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 3/37

8.2.1. Identification of the control equipotentials 10

8.2.2. Identification of the power equipotentialS 10

8.2.3. Identification of the equipotentials connected to the input/output cards 11

8.3. IDENTIFICATION OF THE ELECTRICAL COMPONENTS 12

8.4. CROSS REFERENCES 12

8.5. LOCALISATIONS 12

8.6. TERMINALS 13

8.7. EXCHANGES WITH THE OTHER EQUIPMENTS 13

9. RULES FOR THE DESIGN OF A ELECTRICAL DRAWING 13

9.1. ELECTRICAL POWER SUPPLY 13

9.1.1. Generalities 13

9.1.2. alternate current (A.C.) power supplies 14

9.1.3. compensation of the cosine 14

9.1.4. Power supply sectioning Device 15

9.2. PROTECTION AGAINST THE ELECTRICAL SHOCKS: PROTECTION AGAINST THE INDIRECT

CONTACTS 15

9.3. PROTECTION OF THE EQUIPMENT 15

9.3.1. Protection against the over-currents 15

9.3.2. calibration and Adjustment of the protectiON devices against the over-currents 16

9.4. CONTROL AND POWER CIRCUITS OF THE MOTORS 19

9.4.1. The coordination of the motors startup. 19

9.4.2. Triggering Classes of the thermal relays 19

9.4.3. The motor startup solutions valid at PSA Peugeot Citron 19

9.4.4. Thermal protection by PTC PROBE 20

9.4.5. Engine starts on local network 20

9.4.6. The power supply of the brakes 20

9.4.7. The total cut-off panel 21

9.4.8. The control by variator 22

9.4.9. The electrical and software management 23

9.4.10. The detection of the position 23

9.5. ELECTROMAGNETIC COMPATIBILITY (EMC) 23

9.6. AMBIENT TEMPERATURE OF THE AIR 23

9.7. EQUIPOTENTIAL LINKS 24

9.8. CIRCUITS AND CONTROL FUNCTIONS 24

9.8.1. Cutting of the control circuits 24

9.8.2. power supply of the control circuit 25

9.8.3. Voltages of the control circuit 25

9.8.4. Protection of the control circuits 26

9.9. INTERFACE BETWEEN THE OPERATOR AND CONTROL DEVICES MOUNTED ON THE MACHINE 26

9.9.1. electromechanical control devices 26

9.9.2. Indicator lamps and luminous pushbuttons 26

9.9.3. Color of the control devices 26

9.10. ELECTRONIC EQUIPMENT 27

9.11. REPRESENTATION OF THE LOCAL NETWORKS 27

9.11.1. LEVEL 1: synoptic 29

9.11.2. LEVEL 2: workstation 29

9.11.3. LEVEL 3: Module - card 35

9.12. REPRESENTATION OF THE INTER-PLCS NETWORKS 35

9.12.1. Identification of the elements connected on the network 35

9.12.2. Identification of the cables 35

9.13. ACCESSORIES AND LIGHTING 35

9.13.1. Accessories 35

9.13.2. lighting of the machine premises and of the equipment 36

10. SUPPLYING OF THE DOCUMENTS 37

10.1. PAPER BUNDLE 37

10.2. DATA FORMATS 37

10.3. ELECTRICAL DRAWINGS WITHOUT DIGITAL SOURCE 37

11. SUB-CONTRACTING OF THE UPDATING 37

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 4/37

1.OBJECT AND FIELD OF APPLICATION

The present document treats the electrical file: general electrical drawing, networks topology equipment file. It has

for object:

explaining the choice of the PSA Peugeot Citron Group concerning the electrical file,

defining the composition of the documents to achieve, the data capture rules, and the design rules.

2.REFERENCE DOCUMENTS

2.1.NORMES

2.1.1.PSA NORMS

E00.10.180.G Title blocks for Equipment Goods plans - Definition and presentation.

E03.15.605.G General electrical installations - Industrial machines and installations - Standard of electrical

and electronic materials

E03.65.015.G Industrial machines and installations Automatism Transverse technical rules

E03.65.036.G Industrial machines and installations Automatism Rules for the design and the

achievement of software.

E03.18.051.G Industrial machines and installations Automatism Electrical and software implementation

of the safety functions.

GE03-021G Technical guide - PSA library of the symbols and components for electrical drawings of

automatisms created in C.A.D.

GE03-006G Acceptance guide of electrical equipments of the facilities of the machines and industrial

installations.

2.1.2.EXTERNAL NORMS

CEI 60204-1 Safety of the machines - Electrical equipment of the machines - Part 1: General rules

2.2.REGULATIONS

Irrelevant

2.3.OTHER DOCUMENTS

Irrelevant

2.4.EXPRESSION ON THE DOCUMENTS

Irrelevant

3.TERMINOLOGY AND DEFINITION

A dictionary (glossary) of the principal terms and their used within Direction Technique et Industrielle [Technical

and Industrial Division], in the domain of the automatisms, is provided in norm E03.65.015.G

3.1.DEFINITIONS

Irrelevant

3.2.LOGOS

Irrelevant

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 5/37

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 6/37

4.INTRODUCTION

The PSA Peugeot Citron Group has selected one CAD software for the execution of the automatism electrical

drawings of its facilities and production machines in digital format.

This choice must bring to the PSA Peugeot Citron Group and to its suppliers, important quality and

productiveness gains at the time of the implementation, the acceptance and the maintaining of the digital

documents. Now, only the general electrical drawing is exacted under the CAD format, but that does not forbid the

suppliers using the software in his totality, in order to benefit of the entire power of the system.

Though the first function of the general electrical drawing is the implementation of the installation, its presentation

must be oriented towards exploitation (see contents of the general electrical drawing).

The correct utilization of the diagrammatic tool implies a good application of the rules contained in this document

and the knowledge of the software and of the PSA Peugeot Citron work environment.

4. At the time of the installation of the diagrammatic tool, apply the rules of guide GE03-021G.

5.COMPOSITION OF AN ELECTRICAL FILE

5.1.THE DOCUMENTS OF A FILE

5. Each installation comes with of an electrical file composed of three distinct documents bearing different

numbers:

the principle electrical drawing: is necessary for the implementation and for the repairing. It is exploited and

updated during the life of the installation. It is achieved and updated in digital format and used as paper

bundle,

The topology of the networks (inter-PLCs networks and field buses) is necessary for the implementation

and the repairing. It is exploited and updated during the life of the installation. It is achieved and updated in

digital format and used as paper print,

the equipment file is necessary for the implementation. It is required at the end of studies for validation, but

it is not recovered at the end. It can be achieved in digital format or on reproducible paper.

6. If the equipment file is judged useful during the life of certain installations, it is required in the deals

specifications.

5.2.FORMAT OF A BUNDLE

7. The formats of the bundles are in conformity with the PSA Peugeot Citron norm E00.10.180.G.

For all the following headings, it is important to refer to the PSA Peugeot technical guide GE03-021G.

5.2.1.DEFINITIONS

By format, one understands the dimensions and the presentation of the frames used for the flyleaf, the folio (A4

format, base used by the system).

8. The folios are subdivided them-selves in two types:

electrical drawing folio, initialized with a grid of 5 x 5 mm (imperative),

equipment folio, initialized with a grid of 1 x 1 mm (that allows the execution of the drawing with

dimensions).

The source of the grids must always be the same.

9. The folios are divided in 40 vertical columns, spaced at 10 mm and materialized by marks (01 to 39 for the odd-

numbered columns, and a line for the even columns).

This column system serves for the placing of the symbols in order to permit a cross reference between the

elements.

The flyleaf, the summary and folios assembly constitute the bundle.

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 7/37

A bundle without flyleaf doesnt have a legal existence

5.3.IDENTIFICATION

The rules below are general for the contents; their way of application depends of the functionalities of the software.

Each bundle must be clearly identified:

10. The flyleaf includes:

a title, to be defined with the Automatism pilot, for its structure and its contents,

the logo of the initiator,

a number to be requested from the initiator (DPTA Automatism pilot, maintenance service),

11. The folios include:

the same number as the one of the flyleaf,

the same logo of the initiator.

12. In the framework of the archiving of digital information, the name of the computer file must be identical to the

number of the paper bundle.

13. Different bundles must never bear the same number.

14. When several machines are identical, they can be object, after agreement of the deal driver of a unique

electrical file.

15. If an evolution occurs on one of these machines, a specific electrical file must be created for this one.

16. If standard numbered documents (example: wiring head have been transmitted to serve as work basis, the

identification numbers appearing on these mustnt ever be reused on the applications.

17. All the other fields of the flyleaf must be communicated:

original: creation date and name of the executant,

modifications: the successive indexes, the content and the date

the indication "Replaces plan" must be used at the time of the reconstruction of an installation

the indication "Plan(s) to consult",

Some supplementary texts can be added in the upper left-end part, if these fields are insufficient.

18. The titles of the folios must be informed and made clear, see organization paragraph.

5.4. THE FUNCTIONAL ELECTRICAL DRAWING

5.4.1.CONTENT

The schematic electrical drawing is the graphical representation of the different electrical components and their

interconnections.

19. All the components of the installation must be:

represented by the symbols of the libraries

Marked: see chapter identification of the components

Communicated (Calibers, size, color, detailed connectors, physical characteristics, )

localized

If a symbol does not exist, request its creation from AUT/ATA or use the "standing text" library; representing the

totality of the wiring elements is not obligatory, such as terminals or jack boxes in order not to overload the

electrical drawing.

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 8/37

5.4.2.COMPOSITION

20. a flyleaf and a summary,

21. the functional breakdown table (1),

22. the planting of the sensors and actuators (1),

23. the simplified view of the machine or installation (1),

(1)

These three documents must be copied since the detailed functional analysis.

24. the power supplies folios,

25. the power distribution folios,

26. the relays folios,

27. the configuration of the PLCs (Rack or module),

28. the configuration of the modular equipments (Variators, offset inputs / outputs, )

29. the folios of the PLCs inputs/outputs with their sensors or actuators,

30. the signaling folios,

31. the exchanges with the other equipments

32. the arranging of the cards in a rack, the configuration straps of the cards, the design of specific strands, the

adjustment instructions, the necessary connection details

33. the design of the wear parts and mobile cords (for the control installations during the manufacture progress and

those with intensive usage),

34. the list of the names of the represented components with cross references, folio/column, localization

35. the grid of the identifications of the used wires,

36. the documentation (detail of the connector broaching, connection or functioning description of complex

equipments).

5.4.3.ORGANIZATION

37. The electrical drawing must be organized in chapters, according to the functional breakdown, up to "entity"

breakdown level

38. The chapters are Classified in the order of the production flow,

39. Each chapter begins with an inset:

It includes a title indicating the element of the functional breakdown

It describes the contents of the inset: list of the functional breakdown elements composing it,

40. Each chapter is organized in the order described in the composition paragraph.

41. The title of each folio is compound of two parts:

The first part identifies the PLC and the inset,

The second part describes the contents of the folio.

5.5.THE TOPOLOGY OF THE AUTOMATISM NETWORKS

The area or workshop plan, created with the mechanical CAD system validated at PSA, must be updated and

completed by the integrator according to the achieved works.

42. This document must be enriched with a supplementary layer on which one can find the position of the stations

and the pathway of the connection cables between these last.

43. This planting can be made in relation to the machine, in relation to the part, in relation to the shop,

44. Some different color pellets symbolize the workstations.

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 9/37

The "light-blue" squares correspond to the IP20 inputs/outputs into the cabinet and network accessories

(switches, repeaters).

The "red" rounds correspond to the IP65/67 inputs/outputs installed on the facilities.

The "yellow" triangles correspond to the intelligent slaves of the master workstation, MMI, robot, soldering

sequence, screwing, lecture/writing eyelet

45. Each pellet carries the name of the workstation

The creation rules of the names of the workstations are defined norm E03.65.015.G.

46. This document must be created for the local networks and for the inter-PLCs networks.

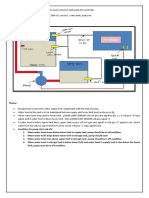

Example for a local network

FR EN

Rseau FIPIO (bus de terrain) FIPIO network (fieldbus)

Module IP20 sur FIPIO IP20 module on FIPIO

Priphrique intelligent sur FIPIO (XBT, ROBOT, REP Intelligent peripheral on FIPIO (XBT, ROBOT, REP

Module IP65 sur FIPIO IP65 module on FIPIO

5.6.THE EQUIPMENT FILE

5.6.1.CONTENT

47. Generally for the installation:

the wiring synoptic, describing the links between the divers cabinets,

the cables specification,

48. For each cabinet:

the planting of the equipments in the cabinets,

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 10/37

the terminal blocks,

6.PSA PEUGEOT CITRON WORK ENVIRONMENT - COMPOSING

49. Apply the rules of the guide GE03-021G.

7.PSA PEUGEOT CITRON WORK ENVIRONMENT - MANAGEMENT

In order to assure within the PSA Peugeot Citron Group, the compatibility, the coherence and the homogeneity of

the documents, the work environment management at PSA Peugeot Citron is centralized by the

DMOV/IMT/rgles de construction AUT/ATA service which assumes the responsibility. Refer to the GE03 021G

guide.

8.DATA CAPTURE RULES OF THE PRINCIPLE ELECTRICAL DRAWING

The data capture of the principle electrical drawing is achieved using the functionalities of the CAD software.

8.1.LAYOUT

50. When creating the folio, observe the concordance between the folio number / system page number.

Consequently, the folios bis, Aare prohibited.

51. Do not create empty folios.

52. Fill sufficiently the folios keeping a clear presentation of the electrical drawing.

53. Change the folio between two elements of the functional breakdown.

For example: inputs of entity 1 in folios 10, 11, 12; inputs of entity 2 starting from folio 13.

54. Observe the horizontal partition of the folios, for the placing of the symbols, alignment on the marks, (odd -

numbered number and lines at a pitch of 10 mm).

55. Observe the 5 mm grid (if necessary 2.5 mm) for the placing of symbols in vertical direction.

56. Never represent several times the same element in the electrical drawing (electrical drawing and design mode).

57. Do not represent a common polarity only if it is used in the folio.

58. The readability must be perfect, do not overburden the folios. Avoid the superposition of the texts amongst them

or with graphics.

8.2.CONNECTIONS

59. Any potential distribution must be represented since the source as polarity.

60. Each equipotential connection must possess a unique mark in the electrical drawing.

8.2.1.IDENTIFICATION OF THE CONTROL EQUIPOTENTIALS

61. The general principle of the identification of the equipotentials is the numbering from 1 to n, without linking the

identification with that of the folio (independent identification).

8.2.2.IDENTIFICATION OF THE POWER EQUIPOTENTIALS

62. The general identification principle of the power equipotentials is L < serial number from 1 to >< order of the

phases >.

63. The serial number of a system of equipotentials with several phases is given from left to right, and from down

upwards in order to observe the marks engraved on the equipments.

Example

1st identification N L1 L2 L3

2nd identification N1 L11 L12 L13

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 11/37

8.2.3.IDENTIFICATION OF THE EQUIPOTENTIALS CONNECTED TO THE INPUT/OUTPUT

CARDS

64. Any connection, leaving from a component and arriving on an PLC input or output, must recall in its mark the

address of the input or of the output.

65. If several marks are necessary (following derogation, several components are connected on the same entry),

they are indexed with a suffix from A to Z.

Example: Input E0.1 arriving equipotential E01

Preceding equipotential E01A

KA1

E01A

KA2

E01

E0.1

66. If the electrical drawing contains several PLCs, use a prefix from 1 to n to differentiate the equipotentials of the

inputs/outputs.

67. The preceding rule concerning the suffixes applies also to this case.

Example: Input E0.1 PLC 1 arriving equipotential 1E01

Preceding equipotential 1E01A

Input E0.1 PLC 2 arriving equipotential 2E01

Preceding equipotential 2E01A

8.2.3.1.Identification of the equipotentials connected to the input/output cards of Schneider PLCs

68. The lead wires connected to the rack entries are marked Ixyyzzz: x is the rack number; yy is the card number;

zzz is the number of the channel.

69. The lead wires connected to the rack outputs are marked Qxyyzzz: x is the rack number; yy is the card number;

zzz is the number of the channel.

70. The lead wires connected to the momentum offset inputs on field bus are marked IQGxxxyzz: ; xxx is the

workstation number; y is the module number; zz is the number of the channel.

71. The lead wires connected to the momentum offset outputs on field bus are marked QGxxxyzz: ; xxx is the

workstation number; y is the module number; zz is the number of the channel.

72. The lead wires connected to Advantys STB offset inputs on field bus are marked IGxxxyyz: ; xxx is the

workstation number; yy is the module number; z is the number of channel.

73. The lead wires connected to Advantys STB offset outputs on field bus are marked QGxxxyyz: ; xxx is the

workstation number; yy is the module number; z is the number of channel.

8.2.3.2.Identification of the equipotentials connected to the of input/output cards of the SIEMENS PLCs

74. The lead wires connected to the inputs are marked Exxxy: xxx is the number of the input byte between 0 and n;

y it is the number of the channel in the byte between 0 and 7

75. The lead wires connected to the output are marked Axxxy: xxx is the number of the output byte between 0 and

n; y is the number of the channel in the byte between 0 and 7

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 12/37

8.2.3.3.Identification of the equipotentials connected o the of input/output cards of the ROCKWELL PLCs

8.2.3.4.Identification of the equipotentials connected to the input/output cards of the GE-FANUC digital

controls.

76. The lead wires connected to the I/O card inputs are marked Ixxxx: xxxx is the number of the input between 0

and n

77. The lead wires connected to the I/O card outputs are marked Qxxxx: xxxx is the number of the output between

0 and n

78. The lead wires connected to the PROFIBUS inputs/ outputs are marked MExxxx: xxxx is the number of the

channel between 0 and n

8.2.3.5.Identification of the equipotentials connected to the input/output cards of the NUM digital controls.

79. The lead wires connected to the inputs are marked Ixyzv: x is the rack number, y is the number of the input

card, z is the number of byte; v is the number of the channel in the input byte.

80. The lead wires connected to the outputs are marked Qxyzv: x is the rack number, y is the number of the input

card, z is the byte number; v is the number of the channel in the output byte.

8.2.3.6.Identification of the equipotentials connected to the input/output cards of the Siemens numeric

controls.

81. For the lead wires connected to classical inputs/outputs, see the preceding chapter "SIEMENS PLCs"

82. The lead wires connected to safety inputs are marked SIxAy: x is the emplacement of the card; y is the number

of the input.

83. The lead wires connected to safety outputs are marked SIxAy: x is the emplacement of the card; y is the

number of the input.

8.2.3.7.Identification of the equipotentials connected to the input/output cards of the ABB and FANUC

Robots

84. The lead wires connected to the inputs are marked DIxxx: xxx is the number of the defined input channel in the

configuration of the robot.

85. The lead wires connected to the outputs are marked DOxxx: xxx is the number of the channel defined in the

configuration of the robot.

8.3.IDENTIFICATION OF THE ELECTRICAL COMPONENTS

86. The mnemonics used to identify the electrical components must be in conformity with the norm E03.65.015.G:

transverse technical reference.

87. The annotations associated to these mnemonics must be the most precise possible.

They must signal the logical state of the component

Example: closed gate input. The input is state one when the door is shut

When that is not possible (component functioning in negative logic) they begin by 0 =

Example: 0 = front over-travel position. The input is in zero state when the mobile is in over-travel position.

8.4.CROSS REFERENCES

88. They must be achieved by the functionalities of the CAD software.

8.5.LOCALISATIONS

89. All the components of an installation must be localized by the functionalities of the CAD software (Folio,

highlighting ).

90. In the document must not subsist any un-listed localizations

91. In a localization foreign to the electrical drawing, the symbol must be entered and linked with the terminals of

the localization in free design.

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 13/37

8.6.TERMINALS

92. All the terminals are represented by an independent symbol, and are part of a terminal block that must be

identified.

8.7.EXCHANGES WITH THE OTHER EQUIPMENTS

93. All the cabled exchanges with the other equipments must be represented in the electrical drawing.

94. The folio(s) representing these exchanges are placed in the corresponding inset at the functional breakdown

element concerned by the exchange.

95. Each terminal block and/or connector must be represented.

96. Each cable must be represented.

97. The supplying of the common points, of the terminals and of the potentials must be represented

98. A timing chart must describe the operation of the exchange.

9.RULES FOR THE DESIGN OF A ELECTRICAL DRAWING

9.1.ELECTRICAL POWER SUPPLY

9.1.1.GENERALITIES

Recall on the TN grounding electrical drawings.

In the PSA Peugeot Citron Group factories two grounding schematics exist: TN and IT. There are three

distributions in the TN grounding electrical drawings: TN, TNS, and TNC.

It is the TN schematic that is the most used in our buildings.

The grounding schematic can be different in of the old buildings or some sectors.

Reconstitution of the neutral: Transformation of a TN-C distribution into TN-S

TN-C Regime When a TN-C type network is available, it is possible by

TN-S regime

3 Phases + PEN respecting the conditions below and schematized

Main sectioning

section 10 mm Cu and protection opposite, to reconstitute locally the neuter lead wire in

section 16 mm Alu device

order to benefit of the advantages of a TN S

Black

L3 L13 distribution (suppression of transformers).

Black

L2 L12

Black

L1 L11

V/J N Blue

PEN PE Blue

N1

Main PE bar

V/J

PE

Cabinet

99.The reconstitution of the Neutral is forbidden when the section of the power supply lead wires is smaller than 10

mm Copper or 16 mm Aluminum.

100. When the TN distribution-C has been transformed in TN-S, redoing down-stream of the TN-C is forbidden.

101. To know the installed power supply characteristics, refer to the deals specification.

102. The neutral regime must be indicated in the principle electrical drawing.

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 14/37

9.1.2.ALTERNATE CURRENT (A.C.) POWER SUPPLIES

Several electrical power supply networks are available in our buildings:

- LIGHTING network marked "LU", (No development in the document).

- DRIVING POWER network marked "FM"

- WELDING POWER network marked "FS". (No development in the document).

- BACKUP network: this network assures the continuity of the supplying with energy. The need for backup

network is to be studied case by case (no development in the document).

See arguments in appendix 1.

- ASSISTED network: this network allows the control of the duration of the lack of energy supplying.

It permits, under certain conditions, resuming totally or partially the supplying with energy of the

equipment whose lack of operation due to the breakdown of the NORMAL DRIVING POWER network can

incite dangers or deteriorations of the production tool. There is a switching on an ASSISTANCE DRIVING

POWER (ex.: maintenance oven, stirring tank...).

- SAFETY network (for the security of the personnel, beacons no development in the document).

Driving power network

This paragraph treats the facilities connected on the DRIVING POWER network.

103. In the recent buildings the nominal voltage is 3 X 400 V + PE, the tolerances are 360 < Un < 424 V.

104. There are several types of power supplies:

3 x 400 V + N + PE,

3 x 400 V + PE,

230 V Phase + N + PE for the small single phase equipments.

105. In the factories where the grounding schematic is TN-C and in case of need of 230 V single-phase supply, the

neutral has to be reconstituted inside the cabinet if this solution is more economic (according to the rules

described in Reconstitution of the neutral).

106. The distributed nominal voltages, the grounding schematic and the value of short circuit current of the

presumed connection point are specified in the specifications.

9.1.3.COMPENSATION OF THE COSINE

107. In low voltage, the compensation is achieved with fix capacitors intended for the individual compensation

(production of the reactive energy on the same site where it is consumed).

108. Their installation is direct, assisting the terminals of a receiver. They are used:

at the terminals of inductive type receivers (motors and transformers), absorbing active power of 60 kW,

on a bar rack where many small loads can be found, of a total actual power 60 KW, for which the

individual compensation would be too costly.

9.1.3.1.Calculation of the compensation

109. The corrected cosine must be to the minimum of 0.93

9.1.3.2.Dimensioning of the condensers in presence of harmonics

The facilities requiring power electronics (variable speed motors, static rectifiers, etc.), the ballasts of fluorescent

tubes, are responsible for the flow of harmonics on the network.

The condensers are extremely sensitive to these harmonics because their impedance decreases proportionally

with the rank of the present harmonics. If the proper frequency of the condenser-network assembly - is close to a

harmonic rank, resonance will occur amplifying the corresponding harmonic. The resulting current will provoke the

heating then the strain of the condenser.

9.1.3.3.Choice of the protection devices, control and of the connecting cables

The admissible variations of the value of the fundamental voltage and the component harmonics can drive to an

amplification of the current by 30 %. In addition, the variations due to the tolerances on the condensers (EN 60831-

1 norm) can drive to an amplification of the current by 15 %.

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 15/37

110. The accumulated effect of the two phenomenon lead to an appropriate dimensioning of the components for:

(1.3 x In) x (1.15 x In) that is 1.5 In

9.1.3.4.Selection of the equipment destined to the compensation

111. The equipments must be part of the PSA Peugeot standard Citron of the equipments E03.15.605.G.

112. The condensers batteries are connected at the bar rack level of the electrical cabinet of the equipment to

compensate, through the intermediary of a circuit breaker and a connection trough correctly dimensioned

cables.

113. They are put automatically under voltage at the time of the installation of the equipment by facilities of their

control contactor.

9.1.4.POWER SUPPLY SECTIONING DEVICE

9.1.4.1.Type

114. The cut and separation device must be a disconnecting switch breaker (with or without fuses), with lateral

exterior command, lockable in opened position by three padlocks.

115. The utilization of devices with frontal command is forbidden.

116. The use of a device with lateral right exterior command is preferred.

117. The number of poles is determined according to the type of network. The neuter lead wire, if it exists is

interrupted but not protected.

9.1.4.2.Excluded Circuits

118. The following circuits, if they exist, must not be cut by the sectioning device of the power supply.

the All or Nothing control information exchanges.

the lighting circuits of the cupboards,

the power outlets reserved for the maintenance.

9.2.PROTECTION AGAINST THE ELECTRICAL SHOCKS: PROTECTION AGAINST THE

INDIRECT CONTACTS

It is protection by auto power off in case of failure of the isolation which is retained for our facilities. Actually:

119. The connection of the grounds of the devices to the protection circuit (PE) is obligatory, except for the devices

of class II.

9.3.PROTECTION OF THE EQUIPMENT

9.3.1.PROTECTION AGAINST THE OVER-CURRENTS

120. The interrupting capacity of the protection device against the over-currents must be greater than the current of

the most powerful motor with blocked rotor, added to the nominal current of the other motors.

121. The value of the short circuit current at the branch box of the distribution sheath is specified in the

specifications. In the absence of precision, the presumed value is 30 kA, it must be confirmed by PSA for the

design.

122. The general protection the equipment socket is offset in the branch box implanted on the distribution sheath of

the Driving Power network if the following conditions are reunited:

the fuses are easily accessible for exchange (without utilization of ladder or skiff),

the supply concerns only one equipment.

123. If the general protection is offset in the branch box:

at the equipment socket a simple breaker is enough.

The protection fuses placed in the branch box of the distribution sheath are of gG type. They assure the

protection of the power supply line against short-circuits and the protection of the equipment against the

over-currents.

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 16/37

124. If the general protection is inside the equipment one must:

use at the equipment socket a breaker provided with fuses correctly calibrated.

assure the total selectivity between the upstream and downstream protection. The (upstream) network

short-circuit safety being generally achieved by of the fuses of aM type, the use of gG type fuses is

recommended at the equipment socket (downstream protection).

Principle electrical drawing of an offset safety and an integrated safety

Branch box Branch box

easily accessible difficultly accessible

Precast pathway

DRIVING POWER

Short-circuit protection

of the la power supply

Short-circuit and line of the equipment.

overload protection of aM type fuses

the la power supply line

of the equipment. Assure the total

Gg (1) type fuses selectivity of the

protections

Equipment

Breaker with gG (1)

Breaker without fuse type fuse

Protection assured by the Overload protection

network box of the equipment

(1) The gG fuses are calibrated in function of the power absorbed by the equipment.

9.3.2.CALIBRATION AND ADJUSTMENT OF THE PROTECTION DEVICES AGAINST THE

OVER-CURRENTS

125. Total selectivity between the upstream and downstream protection has to be applied.

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 17/37

9.3.2.1.Selectivity between fuses

126. The total selectivity between fuses is ensured by the choice in the tables A and B according to CEI 60269-1

and CEI 60269-2-1.

Table A Table B

Upstream Downstream Fuse Upstream Downstream Fuse

Fuse Fuse

gG gG aM aM gG aM

caliber (A) caliber (A)

2 2 1 1

4 1 1 4 4 2

6 2 2 6 6 2

8 2 2 8 8 4

10 4 2 10 10 6

12 4 2 12 12 6

16 6 4 16 16 10

20 10 6 20 20 12

25 16 8 25 25 12

32 20 10 32 32 20

40 25 12 40 32 25

50 32 16 50 40 25

63 40 20 63 50 40

80 50 25 80 63 50

100 63 32 100 80 63

125 80 40 125 100 80

160 100 63 160 125 100

200 125 80 200 160 125

250 160 125 250 160 160

315 200 125 315 200 200

400 250 160 400 250 250

500 315 200 500 315 315

630 400 250 630 400 400

800 500 315 800 500 500

1000 630 400 1000 500 630

1250 800 500 1250 630 800

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 18/37

9.3.2.2.Caliber of the fuses retained by PSA according to their size

The strong point of the fuse is its high cut-off power 80 kA by construction of fuses of sizes 10 x 38 to Size 4 and

at low cost.

This table summarizes the calibers of the existing fuses for a given size. The sectioning device must be well

adapted to the needs of the application. For that, refer to the manufacturers data.

127. One must choose among the non cross-hatched and not grayed calibers of the following table:

Caliber and size of gG 500V fuses Caliber and size of aM 500V fuses

10x38 14x51 22x58 T0 T1 T2 T3 T4 10x38 14x51 22x58 T0 T1 T2 T3 T4

1 1 1 1

2 2 2 2 2

4 4 4 4 4 4

6 6 6 6 6 6

8 8 8 8 8 8

10 10 10 10 10 10

12 12 12 12 12 12

16 16 16 16 16 16 16 16

20 20 20 20 20 20 20 20

25 25 25 25 25 25 25 25

32 32 32 32 32 32 32

40 40 40 40 40 40

50 50 50 50 50 50

63 63 63 63 63 63

80 80 80 80 80 80

100 100 100 100 100 100 100 100

125 125 125 125 125 125 125 125

160 160 160 160 160 160

200 200 200 200 200 200

250 250 250 250

315 315 315 315 315 315 315 315

400 400 400 400 400 400

500 500 500 500 500 500

Legend 630 630 630 630

not to be used ; too bulky and expensive 800 800

compared with the caliber

1000 1000

400 V fuses, forbidden at PSA 1250 1250

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 19/37

9.3.2.3.Selectivity between the other protection facilities

There is no table resulting from the norms such as for the fuses.

The circuit breaker manufacturers give in their technical documentation selectivity some circuit breaker tables of

the same brand.

In order to determine and verify the selectivity between the upstream and downstream protection of the following

associations cases:

- upstream circuit breaker of a different brand than the downstream circuit breaker,

- upstream fuse and down-stream circuit breaker,

- upstream circuit breaker and fusible down-stream.

128. One must refer to the characteristics of the downstream protection on the triggering electrical drawing of the

upstream protection and assure a good selectivity: the triggering curve of the downstream protection must be

placed inside the upstream curve, without ever cutting it. Refer to the manufacturers documentations.

Examples of selectivity between upstream fusible and downstream circuit breaker:

fusion time fusion time

fuse Circuit breaker

cartridge

fusible

Circuit

breaker

failure current failure current

There is no selectivity between The selectivity is assured until the

the circuit breaker and the fuse. current value called selectivity

threshold (point B)

On a same abacus, the operation

areas must not be cut.

9.4.CONTROL AND POWER CIRCUITS OF THE MOTORS

9.4.1.THE COORDINATION OF THE MOTORS STARTUP.

129. PSA Peugeot Citron requests the application of a type 2 coordination according to norm CEI 60947-461 for

the startup of the motors. Namely after a short-circuit:

the isolation is preserved;

no maladjustment is admitted for the equipments;

the risk of soldering of the poles of the contactor is admitted if those are easily separable without

appreciable deformation.

130. Before release to service a quick inspection is sufficient, no equipment replacement must be necessary.

9.4.2.TRIGGERING CLASSES OF THE THERMAL RELAYS

131. The thermal relays installed at PSA Peugeot Citron must be of triggering class 10 or 20 according to norm

CEI 60 947-4-1.

9.4.3.THE MOTOR STARTUP SOLUTIONS VALID AT PSA PEUGEOT CITRON

132. The starting by triangle star coupling is prohibited; only the motors whose plugging voltage is 230/400VAC

are retained within the electrical equipments standard E03.15.605.G.

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 20/37

133. The maximum motor power limit for a direct starting (according to the load and structure of the network) is

defined in the specification of the deal.

Example: maximum limit = 37 KW. All the motors with powers 37 KW can be started directly.

134. If the direct starting is not possible, the electronic starters specified in the standard of the electrical equipments

E03.15.605.G must be used.

135. The motors with Dahlander coupling are prohibited at PSA. The function must be achieved by a 1 speed motor

associated to a variator.

136. For all the motor powers up to 32 KW and feeble cadences it is possible to use an integrated product " motor

starter.

137. For motor powers higher than 45 KW it is possible to use 3 products for the startup of the motors: breaker with

fuses + contactor + thermal relay.

138. For the entire power range of the motors it is possible to use 2 products for the startup of the motors: circuit

breaker + contactor.

139. The equipments must be selected to permit a mechanical and electrical minimal useful life of 6 years at

nominal conditions of utilization defined in the specifications (rhythm, opening time, environment)

Do not forget and use advisedly:

- the prefabricated bar racks with 25A or 50 A branch plates for direct motors starting or "2 products"

reverser

- the bar racks systems with centre to centre distance of 60 mm, 630 or 800 A according to the

constructor, with derivation plates until 630 A

- the startup of the communicating motors in IP 20

- the startup of the communicating motors in IP 65

9.4.4.THERMAL PROTECTION BY PTC PROBE

140. The thermal protection of the coils by 3 Positive Temperature Coefficient probes is obligatory for the three

phase asynchronous motors as soon as they are equipped with probes.

141. A study is to achieve for the motors supplied by speed variators. (Case of feeble rotation speed without forced

ventilation, )

142. When the Positive Temperature Coefficient probe is installed, its action is treated according to the application:

immediate halt in the case of the control of a continuous process motor (pump, fan, ),

deferred stop in the case of the control of a cycled process motor (ferry, elevator section

9.4.5.ENGINE STARTS ON LOCAL NETWORK

143. Only the solutions of the constructors of the PLCs are authorized.

144. Control by AS-i: The utilization of the AS-i bus is not authorized

9.4.6.THE POWER SUPPLY OF THE BRAKES

9.4.6.1.Direct supplying by the motor

This electrical drawing is applicable to the startup of the 1 speed 1 or 2 running directions motors.

The brake is engaged by the motor contactor. The supplying with alternate voltage is taken from the motors

terminals. For a quicker dropping of the break, it is possible to cut the direct current circuit of the brake.

145. In this case, the rectified circuit must be cut in the same time as the alternate current circuit (DC 13 use

category) by two serial contacts of the same rank (either based on relay, either an additional bloc) in order to

increase the electrical endurance.

146. This electrical drawing is authorized only if the electrical useful life of the auxiliary contacts is at least equal to

the one of the power poles, according to the category of use and the power of the break.

Example:

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 21/37

Quick braking

option

KM KM

KM

YB

9.4.6.2.Separated power supply without supplementary equipment

This solution is applicable to the motors with 2 speeds, 2 running directions

147. The brake is supplied by a separate cable, plugged downstream the running direction contactors.

148. The installation conditions are the same as for the direct supply.

149. The brake cable must be protected; therefore according to the power of the motor, an individual protection of

the brake cable can be necessary.

9.4.6.3.Separated power supply with supplementary equipment

When the electrical drawing above is not applicable, or for particular operations (example: maintaining of the brake

when the engine is stopped) it is necessary to achieve a separate supplying of the brake.

150. The alternative supply circuit of the brake must be equipped with a circuit breaker, whose opening cuts the

control of the motor.

151. The sectioning of the motors power circuit sections also the brake circuit.

Example:

KM KA

KA

KA

YB

9.4.7.THE TOTAL CUT-OFF PANEL

The purpose is forbidding the starting of the motor: Lock in an absolute manner the starting up of a motor in order

to allow the intervention of the maintenance personnel on the mover or on what it drags. The retained solution is

the locking of the power.

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 22/37

In order to be certain that the right motor was locked:

152. A total cut-off panel must be installed:

When it is necessary to perform a selective cutting of a motor in order to achieve certain maintenance

operations.

Every time when one does not see the control cabinet since the motor and there is a risk of locking a

cupboard, other than the one that contains the control circuit of the considered motor

example: fan for the fumes exhaust, conveyer carpet,...)

153. In the case of great powers, the installation of such panels close to the motor has to be avoided.

9.4.7.1.Constitution

154. The total cut-off panel must be IP 65. It includes:

155. A breaker with the following features:

exterior lockable command by three padlocks,

visible or fully visible cutting (CEI 60947-3),

in the case of a breaker with fuses, fusible elements replaced by neutral tubes.

If the motor is equipped with a break with separate power supply the alternative power supply circuit must

also be sectioned.

the auxiliary contact must IMPERATIVELY cut in CABLED and PROGRAMMED logic the control circuit of

the motor.

156. The connecting terminals to the necessary protection circuit.

157. The 0-1 label specifying the open (0) or closed (1) position of the breaker.

158. The mounting of control bodies (pushbuttons, switches) on the door of the panel is authorized.

9.4.7.2.Installation

159. These panels are to be installed with the assistance of the safety agent of the sector and of the maintenance

personnel.

160. They must be marked with a label bearing the same mark as on the motor.

161. This label is secured with rivets on the lid of the panel.

9.4.8.THE CONTROL BY VARIATOR

162. The protection and sectioning device must be inserted upstream of the variator.

163. The power contactor, if necessary, must be inserted downstream the variator, except contrary rule of the

constructor.

164. The control of the brake must be driven by the variator.

165. The all or nothing inputs /outputs of the variators must be electrically compatible with inputs /outputs the control

systems that they are connected to.

166. At the time of the triggering of a safety (by the personnel or mechanically) a category 1 stopping must be

achieved according to norm EN 60204-1: uphold of the power to achieve the braking by the variator, then

temporized cut-off of the brake and of the power contactor.

167. At the time of the triggering of a second level safety (for example over travel after slowing down) a category 0

stopping has to be carried out according to norm EN 60204-1: cut-off of the power and of the break power

supply.

168. The size of the variator must be selected according to the duty ratio of the motor (curve of the consumed

current (thermocouple) in the time) for the most penalizing cycle. It must be validated by the supplier of the

variator.

169. For the vertical movements, a failure or an overloading of the variator must trigger the stopping of the motor

(blocking of the variator, cutting of the breaks power supply).

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 23/37

170. The utilization with constant couple up to 87 Hz with a motor plugged in "Triangle" is prohibited:

Indeed, the dimensioning of the motor and of the variator is foreseen for a "Star" coupling of the motor; in this case,

the couple decreases for an operation beyond 50 Hz.

9.4.9.THE ELECTRICAL AND SOFTWARE MANAGEMENT

9.4.9.1.Power circuits

171. In the control cabinet, the cutting of all the power circuits of the engine and of the brake must be possible from

a single sectioning device (case of the motors with 2 speeds and/or 2 running directions)

172. The total cutting panel must achieve the cutting of all the power circuits of the motor and of the brake

173. The reverser contactors must be equipped with devices of mechanical bolting

9.4.9.2.Control circuits

The following processing must be achieved in hard-wired logic

174. The opening of the sectioning device provokes the cutting of the control of the contactors of the motor and of

the brake.

175. The opening of the total cutting panel provokes the cutting of the control of the motors contactors and of the

brake.

176. The triggering of the protection device(s) triggers the cutting of the control of the contactors of the motor and of

the brake.

177. The power circuit breaker of the brake triggers the cutting of the control of the contactors of the motor.

178. The electrical bolting of the reverser contactors control must be cabled.

The processing in programmable logic

179. The states of all the control and power devices of the motor and of the brake must be cabled on the PLCs

inputs (only one information by input) to allow the programmable processing.

9.4.10.THE DETECTION OF THE POSITION

180. Up to 3 positions, the position detection of an electrical axis is achieved by all or nothing sensors (mechanical,

inductive).

181. Beyond that the axis has to be driven by a position measurement, achieved by an absolute encoder.

182. The position measurement of by incremental encoder is prohibited.

9.5.ELECTROMAGNETIC COMPATIBILITY (EMC)

183. All the inductive loads of actuators (relays, contactors, electrovalve controls) must be equipped with anti-

interference devices.

9.6.AMBIENT TEMPERATURE OF THE AIR

The obligation of equipping an electrical cabinet with a cooling component depends:

- on the dissipated heat release rate,

- on the ambient temperature of the shop in summer period.

- on the maximum temperature tolerated by the components inside the cupboard.

- on the protection degree of the cabinet to observe.

184. A loss calculation is therefore to be done systematically. It allows asses the necessity of installing of a cooling

device.

185. The value of the ambient temperature retained for a shop is 40C; if of there are more restricting conditions,

these are specified in the specification of the deal.

186. By default the maximum temperature inside the cabinet is of 45 except if some components require more

restricting conditions (refer to the constructors documentations).

187. The study must be achieved at the time of the design of the facilities. The principle schematic will be then

completed with the installed devices.

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 24/37

188. The choice of a cooling component is possible after having performed a balance of the heat release rates of

the electrical equipment (transformers, power supply, auxiliary relays, contactors, programmable PLCs,

variators...).

189. The elements with high dissipation (braking resistances...) must be placed in a dedicated cabinet, and outside

the conditioned cabinet.

The separation of the electrical cabinet in distinct enclosures allows limiting the power of the cooling device:

- part 1: Control electronics (PLC, digital control, computer)

- part 2: Power electronics (variators, power supplies..),

- part 3: Electro-mechanic components (transformers, contactors, auxiliary relays)

190. According to the heat balance, the parts 1 and 2 can be in a common enclosure, the part 3 must be in a distinct

enclosure.

191. The cooling component must be selected from the standard of the PSA confirmed equipments E03.15.605.G

and to observe the following characteristics:

The regulation is of thermostatic type or with electronic regulator.

The service and alarm contacts must be available and managed by the automatism:

no current carrying device

live device without failure nor alarm

live device with failure or alarm

9.7.EQUIPOTENTIAL LINKS

192. The achieving of functional equipotential links is compulsory (according to EN 60204-1), in order to:

protect the personnel against the risks of untimely startup in case of isolation fault,

protect the equipment against the electromagnetic perturbations.

193. To that so, the negative polarity of the supply of the control circuits must be connected to the PE circuit.

194. The utilization of a local earth terminal is prohibited.

195. If, for some technological reasons, some equipment does not support this plugging, the installation of insulation

supervision is compulsorily.

24 Vdc 230/ 115

Power supply 400 Vac

9.8.CIRCUITS AND CONTROL FUNCTIONS

9.8.1.CUTTING OF THE CONTROL CIRCUITS

196. The control circuits must be cut out under short-circuits, for each function and each cabinet (cabinet or panel).

197. The functions are:

The relays,

The programmable PLC inputs, numeric control, industrial computers

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 25/37

The outputs of the PLC, numeric control, industrial computers not cut by the security devices

The outputs of the PLC, numeric control, industrial computers cut by the security devices, with stopping of

category 0 (according to EN 60 204-1)

The PLCs outputs, numeric control, industrial computers cut by the security devices, with stopping of

category 1 (according to EN 60 204-1)

198. If the functions must be cut for electrical reasons, the cutting must be done according to the functional

breakdown

Example: 1 relay circuit islet 1 and 1 relay circuit islet 2.

199. The modules and input /output racks, when they require a 24Vdc power supply, are connected to the input

circuit of the PLC.

200. The impervious offset input/output modules can be grouped, a group being considered as a cabinet. A group

must correspond to an element of the functional breakdown.

201. The particular equipments requiring a 24Vdc power supply (bar code reader, programmable label reading

plot) are connected to the inputs circuit

Example:

24Vdc

Power supply

Main cupboard relays

Main cupboard automaton inputs

Uncut outputs of the main cupboard

Cut outputs of category 0 of the main cupboard

Relays of offset cupboard 1

Offset cupboard 1 automaton inputs

Not cut outputs of offset cupboard 1

Cut outputs of category from the offset cupboard

Automaton inputs panel 2

Cut automaton outputs panel 2

9.8.2.POWER SUPPLY OF THE CONTROL CIRCUIT

202. A permanent power balance of all the circuits has to be performed, in order to determine the power of the

supply, or of the control transformer.

203. When the control circuits are supplied with 24 Vdc, use in priority a single power supply.

9.8.3.VOLTAGES OF THE CONTROL CIRCUIT

204. Except in the case of supplying of standard subsets (generally with 230 Vac, 50 Hz), the voltages of the control

circuits are:

direct current relay circuit: 24 Vdc,

alternate current relay circuit: 115 Vac, 50 Hz, to use solely for the hardwired logic control circuits of the

high power pre-actuators,

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 26/37

PLCs input circuits, numeric controls, industrial computers: 24 VDC,

output circuits of the PLCs , numeric controls, industrial computers: 24 VDC

205. The 24 VDC power supplies must be adjusted to not deliver more than 26 VDC on load. The lead wires and

cables must be dimensioned so that the voltage at the receptors terminals is compatible with the tolerances

defined by the constructors.

206. The safety against the single-phase operation (loss of a phase) is to include in the protection device into the

primary three-phase power supply circuit, when this functionality is not included in the three-phase power

supply. (installation of a control relay of the three-phase network)

9.8.4.PROTECTION OF THE CONTROL CIRCUITS

207. Each circuit defined in paragraph "cutting of the control circuits" is protected individually:

by preference a protection electronic module for 24 VDC control circuit with auxiliary contact,

or a C curve magneto-thermal circuit breaker with auxiliary contact.

The protection by fusible or by magnetic circuit breaker is forbidden,

208. The polarity connected to the protection circuit must be sectioned but not protected.

209. The auxiliary contact of each protection body must be connected to an PLC input and monitored by the

program.

210. For the input and output circuits, sectional terminals have to added on the positive and negative polarities, for

each input / output card (for the impervious modules: for each group defined to the cutting paragraph of the

control circuits) or by group of channels in order to allow the repairs at the time of searching for isolation

failures.

211. The protection of the circuits must be selective with the protections integrated in the input/output cards in rack

or decentralized

9.9.INTERFACE BETWEEN THE OPERATOR AND CONTROL DEVICES MOUNTED ON

THE MACHINE

9.9.1.ELECTROMECHANICAL CONTROL DEVICES

212. The minimal commutation ability of the control elements with electromagnetic contact, when they are

connected to PLC inputs, must be compatible with the 24 Vdc input characteristics.

9.9.2.INDICATOR LAMPS AND LUMINOUS PUSHBUTTONS

213. Use signaling lights with LEDs

214. They can be driven directly by a static output of 100 mA of the programmable industrial PLC or of the numeric

control.

215. It is necessary foresee a lamp test device for any desk having more than 10 indicator lamps.

216. A failure of the signaling device must not generate abnormalities in the operation of the equipment.

9.9.3.COLOR OF THE CONTROL DEVICES

Color Pushbutton luminous pushbutton Indicator lamp

Green -manual request of work -Movement in work position

movement

- Authorization

Red -Emergency shutdown -Emergency shutdown

-Fault

Yellow -Fault acknowledgement -Manual movement rest request -Movement in rest position

or

-Movement recall -Movement recall

orange

-Local stop, specific equipment

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 27/37

stop, not to be mistaken as

emergency shutdown

Blue -Lamps test -Manual mode, maintenance

mode

-Work memories erasure

-Work memory status

Black All the other functions

White Same function as the black Associated to a black button:

button.

- blinking = pushing authorized

State of the indicator: or pushing taken into account

- blinking = pushing authorized

or pushing taken into account - solid = request achieved

- solid = request achieved

Grayed cell = color not used

9.10.ELECTRONIC EQUIPMENT

217. The input cards of type 2 or type 3 have to be used according to the norm CEI 61131-2 for the connection of

the inductive sensors on 2 unbiased wires.

218. All the informations of the inputs or outputs of the same element of the functional breakdown have to be

regrouped consecutively.

219. a 15 % of each of the following capacities must remain available:

the in rack or offset inputs outputs,

the dimensioning of the fieldbuses (length, number of slaves...)

220. Even if the reserve is not installed, the equipment and the installation are ready to accommodate them.

For example, a free position a rack for the inputs/ outputs, possibility of passing to higher size memory cartridge

221. It is forbidden to put serial or parallel information on the same input. This allows achieving a precise diagnosis

of the deficient element.

222. The output power of the PLC or of the numerical control has to be adjusted to the power of the actuator, this

particularly under a control voltage of 24 Vdc.

223. The compatibility of a static output with the input on which it is connected has to be assured.

224. The static output interfaces are preferred. In any case, the interface must be selected to permit a useful life of 6

years in nominal use conditions.

225. Only the bodies achieving a hardwired logic processing, defined to the paragraph "electrical and software

management" can be inserted between an output and the controlled actuator.

226. Particularly, the control of a movement mustnt be cut by the position sensor: conceive the detection in order to

be compatible with the API processing time. See norm E03.65.036.G.

227. No device must be inserted between the minus polarity of an actuator coil and the common minus of the circuit.

228. For the installation of the parts of the control system relative to safety, refer to norm E03.18.051.G

9.11.REPRESENTATION OF THE LOCAL NETWORKS

229. The electrical drawing is conceived that all the identification modifications can be done automatically based on

the CAD tool.

230. The electrical drawing allows the identification of each component, its software addresses, its geographic

position and the length of each bundle of the different networks.

231. The design of the local network must hold account of the functional breakdown of the installation:

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 28/37

The classification of the addresses of the positions is done by the functional breakdown element, in the

order of the flow,

The distribution of the inputs/ outputs on the modules regroups on a same module the informations of a

same element of the breakdown

The outputs are regrouped on the modules according to the safety groups that they belong,

The reserves in input/output channels are foreseen by element of the functional breakdown.

232. The electrical drawing, conceived before the achieving of the installation, must compulsorily be resumed and

updated

after execution in order to identify well each element composing the local network.

233. On the electrical drawing, three levels of representation of the networks must be represented.

A first level with a synoptic resuming the bus and the workstations in the real installation order without

forgetting the repeaters, the branch panel and other line termination.

On this synoptic each cable will bear its serial number and its length, each workstation will bear its nature,

its name, its addresses, its geographic localization in the installation in conformity with the network

topology document of the local network

With this level one must have all the elements in order to be capable disclosing a breakdown or replacing a

cable between two workstations.

A second level with the connection of each workstation.

On this level shall be represented, the connection of the bus bundles on the specific terminals, the position

of the addressing switches and/or of end of line.

With the elements of this level one will be able to connect a workstation on the bus and perform its material

configuration.

A third and last level where one will find the detail of each workstation.

This level is no other than the conventional principle electrical drawing with the representation of the

sensors, pre-actuators and actuators, connections, pilot-wires, common wires and safety wires.

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 29/37

9.11.1.LEVEL 1: SYNOPTIC

234. The local network is represented as synoptic and it must include:

each terminal connecting point of the network:

master workstation (CPU, coupler, gateway, ),

IP65 slave workstations,

panels containing IP20 slaves workstations,

repeater panels,

accessories: bypasses, bus terminators

intelligent on-line equipment (robot, gluing bay, programmable tag readers),

identifier of each cable.

length of each bundle.

9.11.1.1.Identification of the cables

235. Each cable has a mark of maximum 8 characters, defined as follows:

W + serial number. The serial number evolves since the moment where there is a complete separation of

the cable.

name of the network: DP for profibus-DP; FP for FIP ; DN for device-net ; ET pour Ethernet, MP for MPI.

number of the network

number of the network branch

Example: W123DP12

9.11.1.2.Length of the cables

236. The length of each cable of the network must be indicated on the synoptic.

237. In the case of link between 2 panels by over mold cable and partition crossing it the length of the over mold

cable + the length of the 2 cables of the partition crossing which is indicated.

9.11.1.3.Example

See figure 1

9.11.2.LEVEL 2: WORKSTATION

238. Each position of the local network is detailed on a configuration folio in the same way as the PLC is detailed on

a configuration folio.

239. On this folio the following must appear:

The name of the workstation, in conformity with the synoptic,

The extension modules if they exist,

The power supply cables,

The network cables. In the case of link between panels trough partition crossing, the cable of the partition

crossing bears the same identification as the over mold cable connected to it.

The position of the different configuration switches.

Example of PLC configuration folio: see figure 2

Example of Workstation configuration folio: see figure 3

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 30/37

Figure 1

Name of Address of

Switches the the type of Localisation of Identification Length of the

position workstation workstation workstation the workstation of the cable cable

Figure 2

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 31/37

Figure 3

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 32/37

Text in figure 3

FR EN

Telemecanique TSI PSY 8500I Telemecanique TSI PSY 8500I

ALARME ALARM

Emplacement Position

Carte Card

Rfrence croise Cross reference

Codage Encoding

Rack extensible Extensible rack

8 emplacements 8 positions

TELEMECANIQUE TSX RKY 8FX TELEMECANIQUE TSX RKY 8FX

Arrive Arrival

Dpart Starting point

Processeur Processor

TELEMECANIQUE TSX 453 M TELEMECANIQUE TSX 453 M

RESEAU NETWORK.

CARTE 64 ENTREES TOR 64 DIGITAL INPUTS CARD

TELEMECANIQUE TSX DEY 64D2K TELEMECANIQUE TSX DEY 64D2K

PREPARATION RENFORT PIED AVANT DROIT FRONT RIGHT FOOT REINFORCEMENT PREPARATION

Batim Building

Pilier Pillar

Niveau Level

Coupleur coupler

RESEAU FIPWAY FIPWAY NETWORK

Botier de drivation rseau Network breakout box

Rouge Red

Vert Green

Terminaison Termination

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 33/37

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 34/37

Text in figure 4

FR EN

ATTENTION: RACCORDER Vout COUPLEUR ATTENTION: CONNECT VOUT OF THE

Uc EMBASE LINKAGE TO BASE UC

TELEMATIQUE APP-1B4 TELEMATIQUE APP-1B4

Tension Voltage

TECO POWER embase . TECO POWER BASE .

Vert Green

Bleu Blue

Coupleur coupler

Codage adresse Address encoding

Rseau Network

Bloc liaison dpart moteur Engine startup linkage bloc

Bloc liaison dpart moteur Engine startup linkage bloc

Cble de liaison Connection cable

OR: 01/06/2001 A: 23/03/2007 Network of competence: 04A INTERNAL USE

PSA PEUGEOT - CITRON

RULES FOR THE REALIZATION OF THE ELECTRICAL FILES E03.03.250.G 35/37

9.11.3.LEVEL 3: MODULE - CARD

240. The representation of the input/output card on the local network is the same as that of the card in rack.

9.12.REPRESENTATION OF THE INTER-PLCS NETWORKS

241. The inter PLCs network is an application using a higher and different level than the local network.

242. The electrical drawing of this network is specific because it links several applications. It constitutes a full

electrical drawing.

243. The 2 levels (general view and workstation view) must be represented.

244. All the elements constituting the network must be represented.

245. All the configurations (switch, shunt, plug ) must be represented.

9.12.1.IDENTIFICATION OF THE ELEMENTS CONNECTED ON THE NETWORK

246. Each element is clearly identified by:

The installation on which it exists and the corresponding electrical drawing number (maximum 10

characters, cross reference).

The localization of the PLC on which the network is connected (to be determined according to the deals:

building, pillar, level, machine, workstation...)

The name of the PLC, maximum 8 characters (to specify according to the deals)

The rules of the PLC,

The rules of the coupler and its version number.

The address of the coupler on the network.

9.12.2.IDENTIFICATION OF THE CABLES

247. Between each connected element on the network is drawn the cable, which is identified as follows:

For the cable:

Name of the network, type of cable

For each bundle:

Name of the bundle.

Length of the bundle.

For each connection:

The type of connection and its reference. To the jack boxes and accessories, use the equipment

proposed by the manufacturer.

9.13.ACCESSORIES AND LIGHTING

9.13.1.ACCESSORIES

9.13.1.1."Maintenance" power outlet

Before installing a "Maintenance" power outlet, verify that the power outlets of the building cannot assure this

function.

These power outlets are intended for the supplying of the repairing assistance equipment (oscilloscope, soldering

iron...).