Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Compressed Gas and Cryogenic Hose Literature

Caricato da

US Hose CorporationCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Compressed Gas and Cryogenic Hose Literature

Caricato da

US Hose CorporationCopyright:

Formati disponibili

Compressed Gas & Cryogenic Hose

The US Hose Corp Advantage

US Hose Corp delivers problem-solving products to the Compressed Gas Industry worldwide as part of the

United Flexible group of companies with manufacturing and distribution facilities worldwide. The United Flexible

group specializes in providing high performance flexible engineered solutions for the transfer of gas and liquids

in critical demanding conditions. US Hose Corp is a fully integrated manufacturer in cooperation with our United

Flexible partner Habia Teknofluor (http://www.habiateknofluor.se/). We combine the latest production

technologies for metal cryogenic hose and state-of-the art Fluoropolymer hose/assembly manufacturing.

A complete selection of Fluoropolymer and metal cryogenic hose products are designed specifically for gas fill

plants, air separation and bulk trailer transportation. The “Guard Check™” cylinder filling assembly has been

widely used for more than a decade in the compressed gas industry. “Guard Check” is now augmented with

the introduction of the new “Armor Check™” assembly which takes operational safety to another level for

cylinder filling operations.

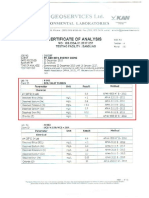

Safety and Quality are the core disciplines in all manufacturing facilities. Our oxygen hoses are cleaned per the

CGA cleaning guideline, G-4.1. Ultra modern cleaning technology assures that potentially ozone depleting solvents

are avoided. All of our Fluoropolymer pigtails are subject to testing and rigorous inspection prior to shipment.

Our quick response time is unparalled in the industry. Expedite service is available for emergency orders so you

are assured you will get what you need fast and on-time. The combination of quality factory built hose

assemblies, problem-solving engineering and a knowledgeable customer service group make US Hose Corp the

ideal choice the next time you need to purchase hoses.

Standard Cylinder Filling Hose

Size Max WP Hose Type Fitting Alloy

Standard Pigtail for Oxygen, Argon, Nitrogen, ¼” 3000 PSI Single Braid PTFE Lined Hose Brass & Stainless Steel

Acetylene & Other Gases ¼” 4200 PSI Double Braid PFA Lined Hose Brass & Stainless Steel

Standard Pigtail Low Effusion Fluoropolymer ¼” 3000 PSI Single Braid Tefzel™ Lined Hose Brass & Stainless Steel

Tube for Hydrogen & Helium

Extra High Pressure Hose for High Pressure Gas ¼” 6000 PSI Multi-Layer Braid PTFE Lined Hose Stainless Steel

Zero Effusion for Hydrogen and Helium ¼” 3600 PSI Type 316 SS Lined Metal Hose Stainless Steel

Extra Pressure Tube Trailer Hose for ¼” 3600-6,500 PSI Type 316 SS Lined Metal Hose Stainless Steel

High Pressure Helium

US Hose Corp. 800/473-0474 815/886-1140 Fax: 815/886-4550

815 Forestwood Drive, Romeoville, IL 60446

www.ushosecorp.com Email: customersupport@ushose.net

Armor-Check™ Cylinder Filling Hose

Size Max WP Hose Type Fitting Alloy

Armor-Check™ 3000 & Armor-Check™ 3600 for ¼” 3000 PSI Single Braid PTFE Lined Hose Brass & Stainless Steel

Oxygen, Argon, Nitrogen, Acetylene & Other Gases ¼” 4200 PSI Double Braid PFA Lined Hose Brass & Stainless Steel

Armor-Check™ LP Low Permeation Fluoropolymer

Tube for Hydrogen & Helium ¼” 3000 PSI Single Braid Tefzel™ Lined Hose Brass & Stainless Steel

Armor-Check™ EPT for High Pressure Gas ¼” 6000 PSI Multi-Layer Braid PTFE Lined Hose Stainless Steel

Armor-Check™ ZE Corrugated Metal Hose for

Hydrogen and Helium ¼” 3600 PSI Type 316 SS Lined Metal Hose Stainless Steel

Armor-Check™ EPM Tube Trailer Hose for

High Pressure Helium ¼” 3600-6,500 PSI Type 316 SS Lined Metal Hose Stainless Steel

Guard-Check™ Cylinder Filling Hose

• Designed to control hose associated with

over-pressurization or falling cylinder

• High tensile stainless spiral guard is

permanently locked to the end fitting

• Improves kink and crush resistance versus

standard un-guarded pigtails

Size Max WP Hose Type Fitting Alloy

Guard-Check™ 3000 & Guard-Check™ 3600 for ¼” 3000 PSI Single Braid PTFE Lined Hose Brass & Stainless Steel

Oxygen, Argon, Nitrogen, Acetylene & Other Gases ¼” 4200 PSI Double Braid PFA Lined Hose Brass & Stainless Steel

Guard-Check™ LP Low Permeation Fluoropolymer

Tube for Hydrogen & Helium ¼” 3000 PSI Single Braid Tefzel™ Lined Hose Brass & Stainless Steel

Guard-Check™ EHP Extra High Pressure Hose for ¼” 6000 PSI Multi-Layer Braid PTFE Lined Hose Stainless Steel

High Pressure Gas

Quality Standard for Cylinder Fill Hose

• Meets CGA E9 Specifications

• Each hose tested to 150% of the Maximum Working Pressure

• In-house oxygen cleaning without using ozone depleting solvents

US Hose Corp. 800/473-0474 815/886-1140 Fax: 815/886-4550

815 Forestwood Drive, Romeoville, IL 60446

www.ushosecorp.com Email: customersupport@ushose.net

Cryogenic Cylinder Fill Hose

Features include:

• High cycle life and flexibility ensure

ease of installation and use.

• CGA or NPT flare fittings available.

• Optional full armor guard is available

for applications involving rugged han-

dling environments.

• Ideal for hospital and fill plant applica-

tions due to high aesthetic appeal.

Max. Hose Static

End Fitting Options Size Working Pressure Bend Radius

3/8" 1450 PSI 1.5"

1/2" 1075 PSI 1.7"

90° Elbow

(with 45°

3/4" 950 PSI 2.7"

CGA 45° Flare Male NPT Flare) 1" 725 PSI 3.5"

Liquid Croyogenic Transfer Hose

Corrugated metal hose assemblies are value

engineered for the best combination of opera-

tor handling ease and dependable daily per-

formance. Liquid transfer hose asse

• All metal construction.

• Full armor available on request.

• Stainless steel armor cuff for operator

safety.

• Less force and weight to flex for better

handling.

• Close pitch construction to reduce

turbulence.

Max. Hose Static

Size Working Pressure Bend Radius

1" 900 PSI 3.34"

1-1/2" 435 PSI 5.11"

Optional Features for Bulk Delivery Hose:

2" 425 PSI 6.29"

• Nylon Cover

2-1/2" 377 PSI 7.90"

• Full Armor Guard

3" 250 PSI 7.00"

• CGA Fittings

4" 210 PSI 9.00"

US Hose Corp. 800/473-0474 815/886-1140 Fax: 815/886-4550

815 Forestwood Drive, Romeoville, IL 60446

www.ushosecorp.com Email: customersupport@ushose.net

Potrebbero piacerti anche

- MK0002 Heat Exchanger Product Line Guide ENG Low ResDocumento8 pagineMK0002 Heat Exchanger Product Line Guide ENG Low ResKzsr FrostNessuna valutazione finora

- Catalogo FlowtekDocumento8 pagineCatalogo FlowtekGuillermo de la Fuente SantiagoNessuna valutazione finora

- Triple Tap Line Stop Fitting 2 2014 PDFDocumento4 pagineTriple Tap Line Stop Fitting 2 2014 PDFcartarNessuna valutazione finora

- Best Swivel Joints CatalogDocumento8 pagineBest Swivel Joints CatalogWalter PierNessuna valutazione finora

- Dezurik Valve Selection PDFDocumento28 pagineDezurik Valve Selection PDFnoklit15100% (1)

- FlowTek - Ball Valve Selection Guide PDFDocumento8 pagineFlowTek - Ball Valve Selection Guide PDFrodriguez.gaytanNessuna valutazione finora

- Valve Selection GuideDocumento20 pagineValve Selection GuideGagandeep SinghNessuna valutazione finora

- HY10 1630US 5 2012-Bladder AccumulatorsDocumento14 pagineHY10 1630US 5 2012-Bladder AccumulatorsAlejandro GilNessuna valutazione finora

- Aragon U M P S: Pa SeriesDocumento2 pagineAragon U M P S: Pa SeriesIon Riswan SinagaNessuna valutazione finora

- 4660 Food PDFDocumento12 pagine4660 Food PDFhansegvNessuna valutazione finora

- APV Plug Valve CatalogueDocumento40 pagineAPV Plug Valve CatalogueVeerapandianNessuna valutazione finora

- Enerpac HoseDocumento2 pagineEnerpac HoseArindam Misra100% (1)

- CVH Series PDFDocumento9 pagineCVH Series PDFhendrabudimanNessuna valutazione finora

- Rotary Control Valve: K-MaxDocumento12 pagineRotary Control Valve: K-MaxBrLuxy1952Nessuna valutazione finora

- Rotary Control Valve: K-MaxDocumento12 pagineRotary Control Valve: K-MaxBrLuxy1952Nessuna valutazione finora

- Ke Masterhose: Metallic and Rubber Flexible HosesDocumento40 pagineKe Masterhose: Metallic and Rubber Flexible HosesfcspekNessuna valutazione finora

- HosesDocumento13 pagineHosessreelu100% (1)

- Check Valves ParkerDocumento2 pagineCheck Valves ParkerArikNessuna valutazione finora

- 052 Steel 2013 For WebDocumento16 pagine052 Steel 2013 For WebJuan GonzalesNessuna valutazione finora

- Industrial Fiberglass Specialties, Inc.: Series 11500 Contact Molded FRP Composite Pipe, Duct and FittingsDocumento4 pagineIndustrial Fiberglass Specialties, Inc.: Series 11500 Contact Molded FRP Composite Pipe, Duct and FittingskamnooNessuna valutazione finora

- TBMA Rotary Valve-High DutyDocumento4 pagineTBMA Rotary Valve-High DutyYing Kei ChanNessuna valutazione finora

- DeepFlex BrochureDocumento4 pagineDeepFlex Brochureribeiro30Nessuna valutazione finora

- Spring Loaded Conservation VentDocumento5 pagineSpring Loaded Conservation VentMustafa PardawalaNessuna valutazione finora

- Aurora Regenerative Turbine 150 Series BrochureDocumento8 pagineAurora Regenerative Turbine 150 Series Brochurethehammer2Nessuna valutazione finora

- Galvanized Carbon Steel Hose Reels w/Manual RewindDocumento1 paginaGalvanized Carbon Steel Hose Reels w/Manual RewindebsboliviaNessuna valutazione finora

- 02 Hose Reel PDFDocumento1 pagina02 Hose Reel PDFRangga AsengNessuna valutazione finora

- High Pressure Pigtail Guide Picks Best Hose TypeDocumento4 pagineHigh Pressure Pigtail Guide Picks Best Hose TypeDedi KartiwaNessuna valutazione finora

- ProductCatalog Cyrus Shank PSVDocumento95 pagineProductCatalog Cyrus Shank PSVmramos4191Nessuna valutazione finora

- Synclok Ball ValveDocumento3 pagineSynclok Ball ValveNilesh MistryNessuna valutazione finora

- Pressure Surges AnDocumento4 paginePressure Surges AnAnonymous NR3qZ30Nessuna valutazione finora

- HX HN Compressors Brochure 2015 0318 LRDocumento20 pagineHX HN Compressors Brochure 2015 0318 LRAlbert Paco GoytiaNessuna valutazione finora

- API 608 Ball ValvesDocumento4 pagineAPI 608 Ball ValvesRizki AgustiarNessuna valutazione finora

- CPT Us BrochureDocumento4 pagineCPT Us BrochureSIMON S. FLORES G.Nessuna valutazione finora

- CC Marine 2013-14 Catalogue - PumpsDocumento94 pagineCC Marine 2013-14 Catalogue - PumpsGregGGHNessuna valutazione finora

- FMC - Knife Edge Gate ValveDocumento5 pagineFMC - Knife Edge Gate ValvesheshidharrajubNessuna valutazione finora

- Apollo Safety Valves Serie 19Documento5 pagineApollo Safety Valves Serie 19Daniel SanNessuna valutazione finora

- DeZURIK VPB VPort Ball 031317Documento19 pagineDeZURIK VPB VPort Ball 031317Joel VeraNessuna valutazione finora

- Coiled Tubing StringDocumento10 pagineCoiled Tubing StringVirnando NainggolanNessuna valutazione finora

- Inbound1489398261588462301 PDFDocumento16 pagineInbound1489398261588462301 PDFAbdellaoui nadaNessuna valutazione finora

- KN Ife Ga Te & Bu Tte Rfly Va Lve S E: Valves & EquipmentDocumento14 pagineKN Ife Ga Te & Bu Tte Rfly Va Lve S E: Valves & EquipmentravishankarNessuna valutazione finora

- BakerSPD Choke Tech Handbook 5-9-06 PDFDocumento14 pagineBakerSPD Choke Tech Handbook 5-9-06 PDFCassielAlexzylalas LiambaNessuna valutazione finora

- DVMX. Between-Bearings, Multistage, Axially Split Pump. API-610,10th Edition ISO M A R E L L IDocumento6 pagineDVMX. Between-Bearings, Multistage, Axially Split Pump. API-610,10th Edition ISO M A R E L L Imiguel hernandezNessuna valutazione finora

- Restek Gas SamplingDocumento4 pagineRestek Gas SamplingtomysetiyadiNessuna valutazione finora

- Rock Plast Pipe BrochureDocumento28 pagineRock Plast Pipe BrochureHusna Mega JayaNessuna valutazione finora

- SPD - PTFE Hose Assemblies (OTS)Documento1 paginaSPD - PTFE Hose Assemblies (OTS)Dağhan ArpacıNessuna valutazione finora

- SellosDocumento8 pagineSellosAlvaro RamirezNessuna valutazione finora

- Control Valves Two PortDocumento16 pagineControl Valves Two Portwendelreis19746883100% (1)

- Vertical Turbine Fire PumpsDocumento4 pagineVertical Turbine Fire PumpsAlex Armendariz100% (1)

- Petropipe Brochure (English)Documento16 paginePetropipe Brochure (English)Nuaym KhalidNessuna valutazione finora

- Parker Push Fitting CatalogueDocumento12 pagineParker Push Fitting CatalogueAndrew McLeodNessuna valutazione finora

- TRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFDocumento8 pagineTRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFjdietz4Nessuna valutazione finora

- Pressure Vessel: Closure High Temperature / High Pressure Style ComparisonDocumento4 paginePressure Vessel: Closure High Temperature / High Pressure Style ComparisonCesar BerruecoNessuna valutazione finora

- Cartdrige Filter Pentair Industrial Brochure Rev D JE15Documento8 pagineCartdrige Filter Pentair Industrial Brochure Rev D JE15dilkisunoNessuna valutazione finora

- Kunkle OverviewDocumento8 pagineKunkle Overviewsamix999Nessuna valutazione finora

- MK0024 Test and Iso Prod Line Guide - ENGDocumento8 pagineMK0024 Test and Iso Prod Line Guide - ENGSagar SamantNessuna valutazione finora

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- Pocket Guide to Flanges, Fittings, and Piping DataDa EverandPocket Guide to Flanges, Fittings, and Piping DataValutazione: 3.5 su 5 stelle3.5/5 (22)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Da EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Valutazione: 5 su 5 stelle5/5 (2)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerDa EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerValutazione: 5 su 5 stelle5/5 (1)

- Foam Pig TDW PDFDocumento2 pagineFoam Pig TDW PDFeka resmanaNessuna valutazione finora

- AutoPIPE V8i Standard Vs Advanced Vs NuclearDocumento3 pagineAutoPIPE V8i Standard Vs Advanced Vs NuclearZoranNessuna valutazione finora

- Vertical Drum Separator Calculation SheetDocumento2 pagineVertical Drum Separator Calculation Sheeteka resmana100% (2)

- Metal Loss & Geometry InspectionsDocumento43 pagineMetal Loss & Geometry Inspectionseka resmanaNessuna valutazione finora

- Honeywell Notifier 2017Documento56 pagineHoneywell Notifier 2017eka resmanaNessuna valutazione finora

- Steam CompositionDocumento2 pagineSteam Compositioneka resmanaNessuna valutazione finora

- API 650 Tank Design CalculationDocumento8 pagineAPI 650 Tank Design Calculationmail_younes659283% (29)

- Calculating Centrifugal Chiller Condenser LoadsDocumento49 pagineCalculating Centrifugal Chiller Condenser Loadseka resmana100% (1)

- NPSH calculations for suction systemsDocumento9 pagineNPSH calculations for suction systemsrajkamal_eNessuna valutazione finora

- 02 - Heat ExchangersDocumento88 pagine02 - Heat ExchangersDana GuerreroNessuna valutazione finora

- PN13 ConstructabilityDocumento7 paginePN13 ConstructabilityTeniozo_MesdwardNessuna valutazione finora

- INCO TermsDocumento1 paginaINCO TermscypraegeanNessuna valutazione finora

- Allowable Pipe WeightDocumento8 pagineAllowable Pipe Weighteka resmanaNessuna valutazione finora

- PIPEMILL - Piping Engineering, Design and Analysis: Pipe Wall Thickness Calculation To Asme B31.3 (2012) para 304.1.2Documento1 paginaPIPEMILL - Piping Engineering, Design and Analysis: Pipe Wall Thickness Calculation To Asme B31.3 (2012) para 304.1.2eka resmanaNessuna valutazione finora

- 02 - Heat ExchangersDocumento88 pagine02 - Heat ExchangersDana GuerreroNessuna valutazione finora

- Pipe Flow Friction Factor CalculationsDocumento11 paginePipe Flow Friction Factor CalculationsVictor ValenciaNessuna valutazione finora

- AutoPIPE Training WorkbookDocumento189 pagineAutoPIPE Training Workbookeka resmanaNessuna valutazione finora

- AG 606 - 1997 Prep Safety & Operating Plan Gas Networks PDFDocumento20 pagineAG 606 - 1997 Prep Safety & Operating Plan Gas Networks PDFeka resmanaNessuna valutazione finora

- OE Spec MTU16V2000DS1100 3B 50Hz 1 15Documento7 pagineOE Spec MTU16V2000DS1100 3B 50Hz 1 15eka resmanaNessuna valutazione finora

- Design Practice - Piping Supports Design PDFDocumento36 pagineDesign Practice - Piping Supports Design PDFeka resmanaNessuna valutazione finora

- PSF Project Execution Plan for Physical Sciences FacilityDocumento54 paginePSF Project Execution Plan for Physical Sciences FacilityihllhmNessuna valutazione finora

- 220cmr112 General O&M LNG Plan FacilitiesDocumento12 pagine220cmr112 General O&M LNG Plan Facilitieseka resmanaNessuna valutazione finora

- Pigging System for Dense Slurry PipelineDocumento4 paginePigging System for Dense Slurry Pipelineeka resmanaNessuna valutazione finora

- WRI Manual of Standard Practice 109497Documento38 pagineWRI Manual of Standard Practice 109497Maximiliano Rivas AlferoNessuna valutazione finora

- Paper09 Zamriahmad Petronas PmuDocumento28 paginePaper09 Zamriahmad Petronas PmugengiskahnNessuna valutazione finora

- Pipe Reducer StandardDocumento3 paginePipe Reducer StandardSyifa Alfi HabibiNessuna valutazione finora

- LNG Design StandardDocumento41 pagineLNG Design Standardamirlng100% (1)

- Engineering Design Calculation - Dennis Kirk Single Stage Centrifugal Pump Calculation (Clean Water Use) System CurveDocumento1 paginaEngineering Design Calculation - Dennis Kirk Single Stage Centrifugal Pump Calculation (Clean Water Use) System Curvebuntimehta007Nessuna valutazione finora

- View TendDocumento8 pagineView Tendeka resmanaNessuna valutazione finora

- Astm A473-99Documento5 pagineAstm A473-99NadhiraNessuna valutazione finora

- Centrifugal CatalogDocumento5 pagineCentrifugal CatalogJOAN SEBASTIAN LUNA MARTINEZNessuna valutazione finora

- DIN EN 10088-3: Stainless SteelsDocumento55 pagineDIN EN 10088-3: Stainless SteelsClaudio Rodrigues100% (1)

- Steel Group 4Documento32 pagineSteel Group 4Habiba AhmedNessuna valutazione finora

- 440C DS CarpenterDocumento5 pagine440C DS CarpenterdaymonNessuna valutazione finora

- En 14509 (Hőszigetelő Szendvicspanelek)Documento148 pagineEn 14509 (Hőszigetelő Szendvicspanelek)UroboroszNessuna valutazione finora

- Bombas Centífugas KSBDocumento12 pagineBombas Centífugas KSBkarmencitaconk4035Nessuna valutazione finora

- X1 Classic Brass and Alum.Documento10 pagineX1 Classic Brass and Alum.Scott HoldmanNessuna valutazione finora

- Fontaine Aquanox 2016Documento6 pagineFontaine Aquanox 2016MarceloNessuna valutazione finora

- Conval Clampseal CatalogDocumento40 pagineConval Clampseal CatalogGohilakrishnan Thiagarajan0% (1)

- EPRI Galvanic CorrosionDocumento138 pagineEPRI Galvanic CorrosionJaime AndrewsNessuna valutazione finora

- Amp16304p036 PDFDocumento3 pagineAmp16304p036 PDFMarius Alin LupașcuNessuna valutazione finora

- A479A479M-15 Standard Specification For Stainless Steel Bars and Shapes For Use in Boilers and Other Pressure VesselsDocumento8 pagineA479A479M-15 Standard Specification For Stainless Steel Bars and Shapes For Use in Boilers and Other Pressure Vesselstjt4779Nessuna valutazione finora

- Watlow Agency Heaters CertificationsDocumento6 pagineWatlow Agency Heaters CertificationsEliasNessuna valutazione finora

- HDS Benefits From Plate Heat ExchangersDocumento6 pagineHDS Benefits From Plate Heat Exchangerssaleh4060Nessuna valutazione finora

- As 4312-2008 Atmospheric Corrosivity Zones in AustraliaDocumento7 pagineAs 4312-2008 Atmospheric Corrosivity Zones in AustraliaSAI Global - APACNessuna valutazione finora

- Passivating Pickling enDocumento16 paginePassivating Pickling enWirote ArcheepkosolNessuna valutazione finora

- Martensitic Transformation in AISI 440C Stainless SteelDocumento5 pagineMartensitic Transformation in AISI 440C Stainless SteelSergio Fernando Resendiz PerezNessuna valutazione finora

- A262-14 Standard Practices For Detecting Susceptibility To Intergranular Attack in Austenitic Stainless SteelsDocumento20 pagineA262-14 Standard Practices For Detecting Susceptibility To Intergranular Attack in Austenitic Stainless Steelstjt4779Nessuna valutazione finora

- Metal: Ferrous and Mild SteelDocumento74 pagineMetal: Ferrous and Mild SteelRoshan MauryaNessuna valutazione finora

- Orbital Welding in Compliance With The New ASME Bioprocessing Equipment (BPE) 1997 Standard - Arc Machines, IncDocumento9 pagineOrbital Welding in Compliance With The New ASME Bioprocessing Equipment (BPE) 1997 Standard - Arc Machines, IncHoque AnamulNessuna valutazione finora

- Duplex Stainless Steel 2205 PDFDocumento1 paginaDuplex Stainless Steel 2205 PDFSalmanNessuna valutazione finora

- Section 21 - Liquid Turbine MeterDocumento9 pagineSection 21 - Liquid Turbine MeterhammamiNessuna valutazione finora

- ASTM A 368 - 95a R00 - QTM2OADocumento3 pagineASTM A 368 - 95a R00 - QTM2OAEjat ISNessuna valutazione finora

- Keeping Your Food Processing Plant Sanitary and SafeDocumento34 pagineKeeping Your Food Processing Plant Sanitary and SafeThẩm NguyễnNessuna valutazione finora

- Saep 1025Documento50 pagineSaep 1025Aneesh JosephNessuna valutazione finora

- Rockwool 159Documento37 pagineRockwool 159ashish2783Nessuna valutazione finora

- Sec611 - Steel ReinforcementDocumento7 pagineSec611 - Steel ReinforcementAmr Adel HameedNessuna valutazione finora

- Pipe rack design overview and guidelinesDocumento8 paginePipe rack design overview and guidelinessinisacarNessuna valutazione finora

- YMC PIEZOTRONICS INC. Catalog 2022Documento43 pagineYMC PIEZOTRONICS INC. Catalog 2022rafiqul RamNessuna valutazione finora