Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Viking Solid Cone Spray Nozzle

Caricato da

balaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Viking Solid Cone Spray Nozzle

Caricato da

balaCopyright:

Formati disponibili

Page 1 of 13

SOLID CONE

TECHNICAL DATA

SPRAY NOZZLES

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

1. DESCRIPTION

Viking Model A-2, A-2X, B-2, C-2, and D-2 Solid Cone Spray Nozzles are non-auto-

matic pattern, open, directional discharge spray nozzles. The spray nozzle units feature

two-piece construction consisting of a cast bronze body and threaded insert. The insert

determines the included angle of discharge and the body construction provides a uniform

distribution throughout the discharge pattern. When spraying, the nozzle discharge forms

a solid, cone-shaped spray pattern meeting the requirements for medium- and high-veloc-

ity water spray systems.

Optional dust plugs are available to prevent foreign material from entering the open end of

the spray nozzle. They are designed to blow off when the system piping is pressurized.

2. LISTINGS AND APPROVALS

cULus Listed: Category VGYZ

FM Approved: Water-Spray Systems

NYC Approved: Calendar Number 219-76-SA, Bulletin No. 16, Vol. LXI

NOTE: International approval certificates are available upon request.

The nozzles are approved for use in medium- and high-velocity water spray

systems. Refer to the Approval Charts on pages 4-5 and Design Criteria on Solid Cone Spray Nozzles

page 6 for cULus and FM approval requirements that must be followed.

3. TECHNICAL DATA

Specifications:

Available since 1971.

The water inlet is at a 90 angle to the nozzle outlet. The smallest nozzle passage is 1/4 (6 mm) for Part Nos. 05133AAJ through

05134AJN; 11/32 (9 mm) for Part Nos. 05135AAJ through 05135AJN; 3/8 (10 mm) for Part Nos. 19505J through 19505JN; and

7/16 (11 mm) for Part Nos. 19506AJ through 19506JN.

All bodies are permanently marked with the model number.

All inserts are permanently marked with the angle of discharge and model.

Inserts are available in spray angles of 30, 60, 90, 120, and 140

Refer to pages 7-13 for spray nozzle water distribution patterns.

Thread size: 1/2 (15 mm) NPT male thread is standard

Nominal K-Factors: Refer to the Approval Charts

Dust Plugs (Optional):

Red Polyethylene Cap: 1 (25 mm) deep

Rated for a continuous temperature of 220 F (104 C).

Spray Nozzle Material Standards:

Body Casting: Brass UNS-C84400

Insert: Brass UNS-C36000

Ordering Information: (Also refer to the current Viking price list.)

Order Model A-2, A-2X, B-2, C-2, and D-2 Solid Cone Spray Nozzles by selecting Spray Nozzle Dust Plug

the appropriate part number from the Approval Charts.

Available Finishes: Brass or Electroless Nickel. Refer to the Approval Charts

For example, Spray Nozzle Model A-2 (VK740) with a 1.2 K-Factor, a 30

spray angle, and a Brass finish = Part No. 05133AAJ Viking Technical Data may be found on

Dust Plugs (Optional): Dust plugs are used to prevent the depositing of The Viking Corporations Web site at

foreign materials in the waterway, which could interfere with the discharge http://www.vikinggroupinc.com.

of the spray nozzles. The plugs are designed to blow off when the system The Web site may include a more recent

piping is pressurized. edition of this Technical Data Page.

Part Number 02409A for use with Spray Nozzle Part Nos. 05133AAJ

through 05135AJN.

Part Number 02410A for use with Spray Nozzle Part Nos. 19505AJ through 19506JN.

Form No. F_030789 Rev 14.1 (Added C&D nozzles, UL only)

Page 2 of 13

SOLID CONE

TECHNICAL DATA

SPRAY NOZZLES

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

4. INSTALLATION

WARNING: Viking Model A-2, A-2X, B-2, C-2, and D-2 Solid Cone Spray Nozzles are manufactured and tested to meet the rigid

requirements of the approving agency. The nozzles are designed to be installed in accordance with recognized installation stand-

ards. Deviation from the standards or any alteration to the nozzle after it leaves the factory including, but not limited to: painting,

plating, coating, or modification, may render the unit inoperative and will automatically nullify the approval and any guarantee made

by The Viking Corporation.

The Approval Charts on pages 4-5 show listings and approvals of Model A-2, A-2X, B-2, C-2, and D-2 Spray Nozzles for use on

water spray systems. The charts show listings and approvals available at the time of printing. Other approvals are in process. Check

with the manufacturer for any additional approvals.

A. Spray nozzles are to be installed in accordance with the latest edition of Viking technical data, the latest published

standards of NFPA, FM Global, LPCB, APSAD, VdS or other similar organizations, and also with the provisions of gov-

ernmental codes, ordinances, and standards whenever applicable. The use of Model A-2, A-2X, B-2, C-2, and D-2 Spray

Nozzles may be limited due to occupancy and hazard. Refer to the Authority Having Jurisdiction prior to installation.

B. Spray nozzles are installed on fixed fire protection systems, such as deluge systems, where total flooding is required.

C. Handle Spray Nozzles with care. They must be stored in a cool, dry place in their original shipping container. Never install a

spray nozzle that has been dropped or damaged.

D. Corrosion-resistant spray nozzles must be installed when subject to corrosive atmospheres. When installing corrosion resistant

nozzles, take care not to damage the corrosion resistant coating.

E. Spray nozzles must be installed after the piping is in place to prevent mechanical damage.

F. Before installing, be sure to have the appropriate model, with the correct K-Factor and spray angle. Spray nozzle bodies are

permanently marked with the model number. All inserts are permanently marked with the angle of discharge and model.

1. Apply a small amount of pipe-joint compound or tape to the external threads of the spray nozzle only, taking care not to allow

a build-up of compound inside the inlet.

2. Install the nozzle on the fixed piping using a standard crescent wrench. Take care not to over-tighten or damage the spray

nozzle.

G. Spray nozzles must be protected from mechanical damage. Where open spray nozzles are used, care must be taken to prevent

foreign materials from entering the orifice. Foreign materials may accumulate and restrict or plug the waterway and may prevent

proper operation of the spray nozzle.

H. Install dust plugs (if used): After installing the spray nozzle unit, press the dust cover over the end of the nozzle insert.

5. OPERATION

Model A-2, A-2X, B-2, C-2, and D-2 Solid Cone Spray Nozzles are designed to apply cooling water to exposed vertical, horizontal,

curved, and irregular shaped surfaces to allow cooling of objects externally when exposed to an adjacent fire. Cooling is done to

prevent objects from absorbing heat that could cause structural damage and possible spread of fire to the protected object. In some

applications, Model A-2, A-2X, B-2, C-2, and D-2 Spray Nozzles may be applied to control or extinguish fire of the protected area

(depending on water design application density).

6. INSPECTIONS, TESTS AND MAINTENANCE

NOTICE: The owner is responsible for maintaining the fire protection system and devices in proper operating condition. For minimum

maintenance and inspection requirements, refer to the NFPA standard (e.g., NFPA 25) that describes care and maintenance of sprin-

kler systems. In addition, the Authority Having Jurisdiction may have additional maintenance, testing, and inspection requirements

that must be followed.

A. Spray nozzles must be inspected on a regular basis for corrosion, mechanical damage, obstructions, paint, etc. Where open

spray nozzles are installed, verify that foreign materials (such as dust, dirt, etc.) do not restrict or plug the waterspray. The fre-

quency of inspections may vary due to corrosive atmospheres, water supplies, and activity around the device. It is also recom-

mended that outdoor installations of Solid Cone Spray Nozzles with dust plugs be periodically inspected, during freezing weather

conditions, for the presence of ice buildup from trapped condensate which could effect the proper release of the plugs.

B. Spray nozzles that have been painted or mechanically damaged must be replaced immediately. Nozzles showing signs of corrosion

shall be tested and/or replaced immediately as required. When replacing spray nozzles, use only new spray nozzles.

1. Using a standard crescent wrench, remove the old spray nozzle and install the new unit. Care must be taken to ensure that

the replacement spray nozzle is the proper model with the correct K-Factor. Spray nozzle bodies are permanently marked

with the model number. All inserts are permanently marked with the angle of discharge and model.

C. The spray nozzle discharge pattern is critical for proper fire protection. Therefore, nothing should be hung from, attached to, or oth-

erwise obstruct the discharge pattern. All obstructions must be immediately removed or, if necessary, additional nozzles installed.

Form No. F_030789 Rev 14.1

Page 3 of 13

SOLID CONE

TECHNICAL DATA

SPRAY NOZZLES

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

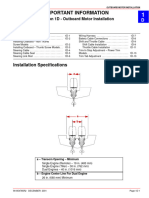

TABLE 1: SPRAY NOZZLE DIMENSIONS

SIN A B C D E F G H

1-7/8 7/8 1/2 1-5/8 13/16 5/16 1-17/64 1-11/16

VK740-VK764

(48 mm) (22 mm) (13 mm) (41 mm) (21 mm) (8 mm) (32 mm) (43 mm)

2-1/16 1 5/8 2-3/16 1 3/8 1-17/32 2

VK770-VK784

(52 mm) (25 mm) (16 mm) (56 mm) (25 mm) (10 mm) (39 mm) (51 mm)

Figure 1: Spray Nozzle Dimensions

Form No. F_030789 Rev 14.1

Page 4 of 13

SOLID CONE

TECHNICAL DATA

SPRAY NOZZLES

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

Approval Chart 1

Model A-2, A-2X, B-2, C-2, and D-2 Spray Nozzles - Brass Finish

Listings and Approvals3 Listings and Approvals3

Nominal Nominal

Part (Refer also to Design Criteria Part (Refer also to Design Criteria

SIN K-Factor Angle SIN K-Factor Angle

Number1 on page 6.) Number1 on page 6.)

U.S. metric2 cULus4 NYC5 FM LPCB VdS U.S. metric2 cULus4 NYC5 FM LPCB VdS

Model A-2 Brass Finish

05133AAJ VK740 1.2 17.3 30 Yes Yes Yes 6

Yes -- 05133AAM VK743 1.4 20.2 120 Yes Yes Yes6 Yes --

05133AAK VK741 1.2 17.3 60 Yes Yes Yes6 Yes -- 15581AM VK743 1.5 21.5 120 Yes Yes Yes6 Yes Yes

05133AAL VK742 1.2 17.3 90 Yes Yes Yes6 Yes -- 05133AAN VK744 1.4 20.2 140 Yes Yes Yes6 Yes --

15581AL VK742 1.2 17.5 90 Yes Yes Yes6 Yes Yes -- -- -- -- -- -- -- -- -- --

Model A-2X Brass Finish

05134AAJ VK750 2.0 28.8 30 Yes Yes Yes6 -- -- 05134AAM VK753 2.2 31.7 120 Yes Yes Yes6 -- --

05134AAK VK751 2.0 28.8 60 Yes Yes Yes6 -- -- 05134AAN VK754 2.2 31.7 140 Yes Yes Yes6 -- --

05134AAL VK752 2.0 28.8 90 Yes Yes Yes 6

-- -- -- -- -- -- -- -- -- -- -- --

Model B-2 Brass Finish

05135AAJ VK760 2.8 40.4 30 Yes Yes Yes Yes --

05135AAM VK763 3.3 47.6 120 Yes Yes Yes Yes --

05135AAK VK761 2.8 40.4 60 Yes Yes Yes Yes -- 05135AAN VK764 3.3 47.6 140 Yes Yes Yes Yes --

05135AAL VK762 2.8 40.4 90 Yes Yes Yes Yes -- -- -- -- -- -- -- -- -- --

Model C-2 Brass Finish

19505AJ VK770 3.3 49.0 30 Yes -- -- -- -- 19505AM VK773 3.7 56.2 120 Yes -- -- -- --

19505AK VK771 3.3 49.0 60 Yes -- -- -- -- 19505AN VK774 3.7 56.2 140 Yes -- -- -- --

19505AL VK772 3.8 54.8 90 Yes -- -- -- -- -- -- -- -- -- -- -- -- -- --

Model D-2 Brass Finish

19506AJ VK780 4.3 67.8 30 Yes -- -- -- -- 19506AM VK783 4.9 75.0 120 Yes -- -- -- --

19506AK VK781 4.8 67.8 60 Yes -- -- -- -- 19506AN VK784 4.9 75.0 140 Yes -- -- -- --

19506AL VK782 5.0 72.1 90 Yes -- -- -- -- -- -- -- -- -- -- -- -- -- --

Footnotes

1

Spray nozzle bodies are permanently marked with the model number. All inserts are permanently marked with the angle of discharge and model.

2

Metric K-Factor shown is when pressure is measured in Bar. When pressure is measured in kPa, divide the metric K-Factor shown by 10.0.

3

This table shows the listings and approvals available at the time of printing. Check with the manufacturer for any additional approvals.

4

Listed by Underwriters Laboratories Inc. for use in the U.S. and Canada.

5

Approved by the NYC Board of Standards and Appeals, MEA No. 219-76-SA, Bulletin No. 16, Vol. LXI.

6

Orifice diameter is less than 3/8 (9.4mm) for Model A-2 Nozzles with K-Factors of 1.2 and 1.4 and Model A-2X Nozzles with K-Factors of 2.0 and 2.2.

A pipeline strainer with a 1/8 (3.2mm) or less perforation is required for FM Approval.

Form No. F_030789 Rev 14.1

Page 5 of 13

SOLID CONE

TECHNICAL DATA

SPRAY NOZZLES

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

Approval Chart 2

Model A-2, A-2X, B-2, C-2, and D-2 Spray Nozzles - Electroless Nickel Finish

Listings and Approvals3 Listings and Approvals3

Nominal Nominal

Part (Refer also to Design Part (Refer also to Design

SIN K-Factor Angle SIN K-Factor Angle

Number1 Criteria on page 6.) Number1 Criteria on page 6.)

U.S. metric2 cULus4 NYC5 FM LPCB U.S. metric2 cULus4 NYC5 FM LPCB

Model A-2 Electroless Nickel Finish

05133AJJ VK740 1.2 17.3 30 Yes Yes Yes6 Yes 05133AJM VK743 1.4 20.2 120 Yes Yes Yes6 Yes

05133AJK VK741 1.2 17.3 60 Yes Yes Yes6 Yes 05133AJN VK744 1.4 20.2 140 Yes Yes Yes6 Yes

05133AJL VK742 1.2 17.3 90 Yes Yes Yes 6

Yes -- -- -- -- -- -- -- -- --

Model A-2X Electroless Nickel Finish

05134AJJ VK750 2.0 28.8 30 Yes Yes Yes6 Yes 05134AJM VK753 2.2 31.7 120 Yes Yes Yes6 Yes

05134AJK VK751 2.0 28.8 60 Yes Yes Yes 6

Yes 05134AJN VK754 2.2 31.7 140 Yes Yes Yes 6

Yes

05134AJL VK752 2.0 28.8 90 Yes Yes Yes6 Yes -- -- -- -- -- -- -- -- --

Model B-2 Electroless Nickel Finish

05135AJJ VK760 2.8 40.4 30 Yes Yes Yes Yes 05135AJM VK763 3.3 47.6 120 Yes Yes Yes Yes

05135AJK VK761 2.8 40.4 60 Yes Yes Yes Yes 05135AJN VK764 3.3 47.6 140 Yes Yes Yes Yes

05135AJL VK762 2.8 40.4 90 Yes Yes Yes Yes -- -- -- -- -- -- -- -- --

Model C-2 Electroless Nickel Finish

19505JJ VK770 3.3 49.0 30 Yes -- -- -- 19505JM VK773 3.7 56.2 120 Yes -- -- --

19505JK VK771 3.3 49.0 60 Yes -- -- -- 19505JN VK774 3.7 56.2 140 Yes -- -- --

19505JL VK772 3.8 54.8 90 Yes -- -- -- -- -- -- -- -- -- -- -- --

Model D-2 Electroless Nickel Finish

19506JJ VK780 4.3 67.8 30 Yes -- -- -- 19506JM VK783 4.9 75.0 120 Yes -- -- --

19506JK VK781 4.8 67.8 60 Yes -- -- -- 19506JN VK784 4.9 75.0 140 Yes -- -- --

19506JL VK782 5.0 72.1 90 Yes -- -- -- -- -- -- -- -- -- -- -- --

Footnotes

1

Spray nozzle bodies are permanently marked with the model number. All inserts are permanently marked with the angle of discharge and model.

2

Metric K-Factor shown is when pressure is measured in Bar. When pressure is measured in kPa, divide the metric K-Factor shown by 10.0.

3

This table shows the listings and approvals available at the time of printing. Check with the manufacturer for any additional approvals.

4

Listed by Underwriters Laboratories Inc. for use in the U.S. and Canada.

5

Approved by the NYC Board of Standards and Appeals, MEA No. 219-76-SA, Bulletin No. 16, Vol. LXI.

6

Orifice diameter is less than 3/8 (9.4mm) for Model A-2 Nozzles with K-Factors of 1.2 and 1.4 and Model A-2X Nozzles with K-Factors of 2.0 and 2.2. A pipeline

strainer with a 1/8 (3.2mm) or less perforation is required for FM Approval.

Form No. F_030789 Rev 14.1

Page 6 of 13

SOLID CONE

TECHNICAL DATA

SPRAY NOZZLES

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

DESIGN CRITERIA

(Also refer to the Approval Charts on pages 4-5.)

cULus Listing Requirements:

Refer to the installation standards, such as NFPA 15, for minimum water supply requirements, nozzle pressure, and installation guidelines.

FM Approval Requirements:

For installation in accordance with the latest applicable FM Loss Prevention Data Sheets and Technical Advisory Bulletins. FM Global Loss Prevention

Data Sheets and Technical Advisory Bulletins contain guidelines relating to, but not limited to: minimum water supply requirements, hydraulic design,

ceiling slope and obstructions, minimum and maximum allowable spacing, and distance below the ceiling.

Pipeline Strainers Orifice diameter is less than 3/8 (9.4mm) for Model A-2 Nozzles with K-Factors of 1.2 and 1.4 and Model A-2X Nozzles with K-Factors

of 2.0 and 2.2. A pipeline strainer with a 1/8 (3.2mm) or less perforation is required for FM Approval.

NOTE: The FM installation guidelines may differ from cULus and/or NFPA criteria.

IMPORTANT: Always refer to Bulletin Form No. F_091699 - Care and Handling of Sprinklers. Viking spray nozzles

are to be installed in accordance with the latest edition of Viking technical data, the appropriate standards of

NFPA, FM Global, LPCB, APSAD, VdS or other similar organizations, and also with the provisions of governmen-

tal codes, ordinances, and standards, whenever applicable.

D. Fire protection systems that have been subjected to a fire must be returned to service as soon as possible. The entire system

must be inspected for damage and repaired or replaced as necessary. Spray nozzles that have been exposed to corrosive

products of combustion or high ambient temperatures, should be replaced. Refer to the Authority Having Jurisdiction for minimum

replacement requirements.

7. AVAILABILITY

The Viking Model A-2, A-2X, B-2, C-2, and D-2 Solid Cone Spray Nozzles are available through a network of domestic and inter-

national distributors. See The Viking Corporation web site for the closest distributor or contact The Viking Corporation.

8. GUARANTEE

For details of warranty, refer to Vikings current list price schedule or contact Viking directly.

Form No. F_030789 Rev 14.1

Page 7 of 13

SOLID CONE SPRAY

TECHNICAL DATA NOZZLES - WATER

DISTRIBUTION PATTERNS

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

Spray Nozzle Model: Spray Nozzle Model:

A2X (VK750-VK754) A2X (VK750-VK754)

Spray Nozzle Base P/Ns: Spray Nozzle Base P/Ns:

05134AA & 05134AJ* 05134AA & 05134AJ*

Angle: 30 Angle: 60

Thread Size: 1/2 NPT Thread Size: 1/2 NPT

K-Factor: 2.0 U.S. (28.8 K-Factor: 2.0 U.S. (28.8

metric) metric)

Top View-Horizontal Spray Top View-Horizontal Spray

Side View Spray Up Side View Spray Up

Side View-Horizontal Spray Side View-Horizontal Spray

Spray Nozzle Model: Spray Nozzle Model:

A2X (VK750-VK754) A2X (VK750-VK754)

Spray Nozzle Base P/Ns: Spray Nozzle Base P/Ns:

05134AA & 05134AJ* 05134AA & 05134AJ*

Angle: 90 Angle: 120

Thread Size: 1/2 NPT Thread Size: 1/2 NPT

K-Factor: 2.0 U.S. (28.8 K-Factor: 2.2 U.S. (31.7

metric) metric)

Top View-Horizontal Spray Top View-Horizontal Spray

Side View Spray Up Side View Spray Up

FormSide

No.View-Horizontal

F_030789 Rev 14.1

Spray Side View-Horizontal Spray

Scale: Each square equals one square foot. Spray Nozzle Identification Numbers provided in accordance with the 1999 edition of NFPA 13, Section 3-2.2.

* Base part numbers shown. For complete part number, refer to Vikings current price list.

Page 8 of 13

SOLID CONE SPRAY

TECHNICAL DATA NOZZLES - WATER

DISTRIBUTION PATTERNS

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

Spray Nozzle Model: Spray Nozzle Model:

A2X (VK750-VK754) A2 (VK740-VK744)

Spray Nozzle Base P/Ns: Spray Nozzle Base P/Ns:

05134AA & 05134AJ* 05133AA & 05133AJ*

Angle: 140 Angle: 30

Thread Size: 1/2 NPT Thread Size: 1/2 NPT

K-Factor: 2.2 U.S. (31.7 K-Factor: 1.2 U.S. (17.3

metric) metric)

Top View-Horizontal Spray Top View-Horizontal Spray

Side View Spray Up Side View Spray Up

Side View-Horizontal Spray Side View-Horizontal Spray

Spray Nozzle Model: Spray Nozzle Model:

A2 (VK740-VK744) A2 (VK740-VK744)

Spray Nozzle Base P/Ns: Spray Nozzle Base P/Ns:

05133AA & 05133AJ* 05133AA & 05133AJ*

Angle: 60 Angle: 90

Thread Size: 1/2 NPT Thread Size: 1/2 NPT

K-Factor: 1.2 U.S. (17.3 K-Factor: 1.2 U.S. (17.3

metric) metric)

Top View-Horizontal Spray Top View-Horizontal Spray

Side View Spray Up Side View Spray Up

FormSide

No.View-Horizontal

F_030789 Rev 14.1

Spray Side View-Horizontal Spray

Scale: Each square equals one square foot. Spray Nozzle Identification Numbers provided in accordance with the 1999 edition of NFPA 13, Section 3-2.2.

* Base part numbers shown. For complete part number, refer to Vikings current price list.

Page 9 of 13

SOLID CONE SPRAY

TECHNICAL DATA NOZZLES - WATER

DISTRIBUTION PATTERNS

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

Spray Nozzle Model: Spray Nozzle Model:

A2 (VK740-VK744) A2 (VK740-VK744)

Spray Nozzle Base P/Ns: Spray Nozzle Base P/Ns:

05133AA & 05133AJ* 05133AA & 05133AJ*

Angle: 120 Angle: 140

Thread Size: 1/2 NPT Thread Size: 1/2 NPT

K-Factor: 1.4 U.S. (20.2 K-Factor: 1.4 U.S. (20.2

metric) metric)

Top View-Horizontal Spray Top View-Horizontal Spray

Side View Spray Up Side View Spray Up

Side View-Horizontal Spray Side View-Horizontal Spray

Spray Nozzle Model: Spray Nozzle Model:

B2 (VK760-VK764) B2 (VK760-VK764)

Spray Nozzle Base P/Ns: Spray Nozzle Base P/Ns:

05135AA & 05135AJ* 05135AA & 05135AJ*

Angle: 30 Angle: 60

Thread Size: 1/2 NPT Thread Size: 1/2 NPT

K-Factor: 2.8 U.S. (40.4 K-Factor: 2.8 U.S. (40.4

metric) metric)

Top View-Horizontal Spray Top View-Horizontal Spray

Side View Spray Up Side View Spray Up

FormSide

No.View-Horizontal

F_030789 Rev 14.1

Spray Side View-Horizontal Spray

Scale: Each square equals one square foot. Spray Nozzle Identification Numbers provided in accordance with the 1999 edition of NFPA 13, Section 3-2.2.

* Base part numbers shown. For complete part number, refer to Vikings current price list.

Page 10 of 13

SOLID CONE SPRAY

TECHNICAL DATA NOZZLES - WATER

DISTRIBUTION PATTERNS

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

Spray Nozzle Model: Spray Nozzle Model:

B2 (VK760-VK764) B2 (VK760-VK764)

Spray Nozzle Base P/Ns: Spray Nozzle Base P/Ns:

05135AA & 05135AJ* 05135AA & 05135AJ*

Angle: 90 Angle: 120

Thread Size: 1/2 NPT Thread Size: 1/2 NPT

K-Factor: 2.8 U.S. (40.4 K-Factor: 3.3 U.S. (47.6

metric) metric)

Top View-Horizontal Spray Top View-Horizontal Spray

Side View Spray Up Side View Spray Up

Side View-Horizontal Spray Side View-Horizontal Spray

Spray Nozzle Model: Spray Nozzle Model:

B2 (VK760-VK764) C2 (VK770-VK774)

Spray Nozzle Base P/Ns: Spray Nozzle Base P/Ns:

05135AA & 05135AJ* 19505A & 19505J*

Angle: 140 Angle: 30

Thread Size: 1/2 NPT Thread Size: 1/2 NPT

K-Factor: 3.3 U.S. (47.6 K-Factor: 3.3 U.S. (49.0

metric) metric)

Top View-Horizontal Spray Top View-Horizontal Spray

Side View Spray Up Side View Spray Up

FormSide

No.View-Horizontal

F_030789 Rev 14.1 Side View-Horizontal Spray

Spray

Scale: Each square equals one square foot. Spray Nozzle Identification Numbers provided in accordance with the 1999 edition of NFPA 13, Section 3-2.2.

* Base part numbers shown. For complete part number, refer to Vikings current price list.

Page 11 of 13

SOLID CONE SPRAY

TECHNICAL DATA NOZZLES - WATER

DISTRIBUTION PATTERNS

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

Spray Nozzle Model: Spray Nozzle Model:

C2 (VK770-VK774) C2 (VK770-VK774)

Spray Nozzle Base P/Ns: Spray Nozzle Base P/Ns:

19505A & 19505J* 19505A & 19505J*

Angle: 60 Angle: 90

Thread Size: 1/2 NPT Thread Size: 1/2 NPT

K-Factor: 3.3 U.S. (49.0 K-Factor: 3.8 U.S. (54.8

metric) metric)

Top View-Horizontal Spray Top View-Horizontal Spray

Side View Spray Up Side View Spray Up

Side View-Horizontal Spray Side View-Horizontal Spray

Spray Nozzle Model: Spray Nozzle Model:

C2 (VK770-VK774) C2 (VK770-VK774)

Spray Nozzle Base P/Ns: Spray Nozzle Base P/Ns:

19505A & 19505J* 19505A & 19505J*

Angle: 120 Angle: 140

Thread Size: 1/2 NPT Thread Size: 1/2 NPT

K-Factor: 3.7 U.S. (56.2 K-Factor: 3.7 U.S. (56.2

metric) metric)

Top View-Horizontal Spray Top View-Horizontal Spray

Side View Spray Up Side View Spray Up

Form No.View-Horizontal

Side F_030789 Rev 14.1

Spray Side View-Horizontal Spray

Scale: Each square equals one square foot. Spray Nozzle Identification Numbers provided in accordance with the 1999 edition of NFPA 13, Section 3-2.2.

* Base part numbers shown. For complete part number, refer to Vikings current price list.

Page 12 of 13

SOLID CONE SPRAY

TECHNICAL DATA NOZZLES - WATER

DISTRIBUTION PATTERNS

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

Spray Nozzle Model: Spray Nozzle Model:

D2 (VK780-VK784) D2 (VK780-VK784)

Spray Nozzle Base P/Ns: Spray Nozzle Base P/Ns:

19506A & 19506J* 19506A & 19506J*

Angle: 30 Angle: 60

Thread Size: 1/2 NPT Thread Size: 1/2 NPT

K-Factor: 4.3 U.S. (67.8 K-Factor: 4.3 U.S. (67.8

metric) metric)

Top View-Horizontal Spray Top View-Horizontal Spray

Side View Spray Up Side View-Horizontal Spray Side View Spray Up

Side View-Horizontal Spray

Spray Nozzle Model: Spray Nozzle Model:

D2 (VK780-VK784) D2 (VK780-VK784)

Spray Nozzle Base P/Ns: Spray Nozzle Base P/Ns:

19506A & 19506J* 19506A & 19506J*

Angle: 90 Angle: 120

Thread Size: 1/2 NPT Thread Size: 1/2 NPT

K-Factor: 5.0 U.S. (72.1 K-Factor: 4.9 U.S. (75.0

metric) metric)

Top View-Horizontal Spray Top View-Horizontal Spray

Side View Spray Up Side View Spray Up

FormSide

No.View-Horizontal

F_030789 Rev 14.1

Spray Side View-Horizontal Spray

Scale: Each square equals one square foot. Spray Nozzle Identification Numbers provided in accordance with the 1999 edition of NFPA 13, Section 3-2.2.

* Base part numbers shown. For complete part number, refer to Vikings current price list.

Page 13 of 13

SOLID CONE SPRAY

TECHNICAL DATA NOZZLES - WATER

DISTRIBUTION PATTERNS

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

Spray Nozzle Model:

D2 (VK780-VK784)

Spray Nozzle Base P/Ns:

19506A & 19506J*

Angle: 140

Thread Size: 1/2 NPT

K-Factor: 4.9 U.S. (75.0

metric)

Top View-Horizontal Spray

Side View Spray Up

Side View-Horizontal Spray

Form No. F_030789 Rev 14.1

Scale: Each square equals one square foot. Spray Nozzle Identification Numbers provided in accordance with the 1999 edition of NFPA 13, Section 3-2.2.

* Base part numbers shown. For complete part number, refer to Vikings current price list.

Potrebbero piacerti anche

- ANEXO B ToberaDocumento13 pagineANEXO B Toberaernesto garciaNessuna valutazione finora

- Viking Solid Cone NozzleDocumento13 pagineViking Solid Cone NozzleFurkan KadıNessuna valutazione finora

- Viking NozzlezDocumento10 pagineViking NozzlezamardonesNessuna valutazione finora

- Manual Boquillas VikingDocumento15 pagineManual Boquillas VikingCarlos Arturo Porras AbaunzaNessuna valutazione finora

- Model E Spray Nozzles VikingDocumento10 pagineModel E Spray Nozzles VikingDeniNessuna valutazione finora

- Catalogo - Rociador Nozzle - ContraincendioDocumento10 pagineCatalogo - Rociador Nozzle - ContraincendiopedroNessuna valutazione finora

- Sprinkler 3Documento4 pagineSprinkler 3magalyguinez1Nessuna valutazione finora

- Viking - C-1 Window SprinklersDocumento6 pagineViking - C-1 Window SprinklersVictor Poh Yong BoonNessuna valutazione finora

- Technical Data: 1. DescriptionDocumento6 pagineTechnical Data: 1. DescriptiongiowokNessuna valutazione finora

- Viking Sprinkler Shield & GuardDocumento4 pagineViking Sprinkler Shield & Guardshankar_04Nessuna valutazione finora

- Technical Data: 1. DescriptionDocumento3 pagineTechnical Data: 1. Descriptiontranhuy3110Nessuna valutazione finora

- SPK 503 VikingDocumento6 pagineSPK 503 VikingClaytonNessuna valutazione finora

- Technical Data: Pressure Operated Relief Valve (Porv) Models D-3 & D-4Documento2 pagineTechnical Data: Pressure Operated Relief Valve (Porv) Models D-3 & D-4peerlessNessuna valutazione finora

- Technical Data: 1. DescriptionDocumento7 pagineTechnical Data: 1. DescriptionpippoNessuna valutazione finora

- Technical Data: 1. DescriptionDocumento9 pagineTechnical Data: 1. DescriptionGabo Barrios LedesmaNessuna valutazione finora

- 0Documento6 pagine0Mihai STANNessuna valutazione finora

- Viking ESFR-14Documento16 pagineViking ESFR-14Md. Mominul IslamNessuna valutazione finora

- Viking K25 ESFRDocumento16 pagineViking K25 ESFRnsantos102415Nessuna valutazione finora

- Viking VK 503Documento6 pagineViking VK 503ozkan28adanaNessuna valutazione finora

- Technical Data: 1. DescriptionDocumento7 pagineTechnical Data: 1. DescriptionashishtanjeaaNessuna valutazione finora

- Technical Data: 1. DescriptionDocumento4 pagineTechnical Data: 1. DescriptionAnthonyNessuna valutazione finora

- Technical Data: Specific Application Esfr Pendent Sprinkler VK514 (K28.0)Documento6 pagineTechnical Data: Specific Application Esfr Pendent Sprinkler VK514 (K28.0)pippoNessuna valutazione finora

- Technical Data: 1. DescriptionDocumento5 pagineTechnical Data: 1. DescriptionChitradeep FalguniyaNessuna valutazione finora

- SBC (Safety Break-Away Couplings) v140630Documento16 pagineSBC (Safety Break-Away Couplings) v140630Robert Villavicencio0% (1)

- Viking Esfr Upright SprinklersDocumento5 pagineViking Esfr Upright SprinklersAhamed KyanaNessuna valutazione finora

- Tyco Water SprayDocumento6 pagineTyco Water SprayFadlul Akbar HerfiantoNessuna valutazione finora

- Technical Data: 1. DescriptionDocumento6 pagineTechnical Data: 1. DescriptionDanie CastilloNessuna valutazione finora

- VK514 (k28)Documento6 pagineVK514 (k28)carlos yepezNessuna valutazione finora

- Unit Injector - Install: Disassembly and AssemblyDocumento13 pagineUnit Injector - Install: Disassembly and AssemblyAnung Nugroho100% (1)

- Type D3 MV Sprayer 1Documento4 pagineType D3 MV Sprayer 1lavascudoNessuna valutazione finora

- Viega Profipress ManualDocumento16 pagineViega Profipress Manualhasmit1Nessuna valutazione finora

- Series TY-B, 5.6 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard Coverage General DescriptionDocumento4 pagineSeries TY-B, 5.6 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard Coverage General DescriptionMohd FitriNessuna valutazione finora

- TC FLS Sihi ZTND enDocumento19 pagineTC FLS Sihi ZTND enFosseni DialloNessuna valutazione finora

- Technical Data: 1. DescriptionDocumento6 pagineTechnical Data: 1. DescriptionCarlosNessuna valutazione finora

- Water Motor Alarm F2Documento4 pagineWater Motor Alarm F2Pepes HiuuNessuna valutazione finora

- VK960Documento19 pagineVK960AngeloNessuna valutazione finora

- Technical Data: 1. DescriptionDocumento9 pagineTechnical Data: 1. DescriptionRamesh arumugamNessuna valutazione finora

- Side Wall SprinklersDocumento6 pagineSide Wall SprinklersRamesh arumugamNessuna valutazione finora

- 042519-Window SprinklersDocumento10 pagine042519-Window SprinklersVINOD PAULNessuna valutazione finora

- Tyco Nozzle D-3Documento6 pagineTyco Nozzle D-3Rowsedk MoleroNessuna valutazione finora

- 051393Documento6 pagine051393KaushikNessuna valutazione finora

- Important Information: Section 1D - Outboard Motor InstallationDocumento13 pagineImportant Information: Section 1D - Outboard Motor InstallationDr. Centelha Mecânica NaúticaNessuna valutazione finora

- Rociador Seco VK188Documento6 pagineRociador Seco VK188José Alberto RodríguezNessuna valutazione finora

- SC Fepa Sa Bârlad: Installation, Operation&Maintenance Ball Valve Type RSD-BBDocumento15 pagineSC Fepa Sa Bârlad: Installation, Operation&Maintenance Ball Valve Type RSD-BBtoader56Nessuna valutazione finora

- Technical Data: 1. DescriptionDocumento6 pagineTechnical Data: 1. DescriptionTevfik KurtulusNessuna valutazione finora

- Model S0430-AS: Wall Mounted Eyewash, All Stainless SteelDocumento2 pagineModel S0430-AS: Wall Mounted Eyewash, All Stainless Steelfranki hari mNessuna valutazione finora

- Type D3 Protectospray Directional Spray Nozzles, Open, Medium Velocity General DescriptionDocumento6 pagineType D3 Protectospray Directional Spray Nozzles, Open, Medium Velocity General DescriptionsamNessuna valutazione finora

- ESCOUTCHEONSDocumento8 pagineESCOUTCHEONSAlexis PradoNessuna valutazione finora

- Spray Nozzle-VIKING PDFDocumento6 pagineSpray Nozzle-VIKING PDFbecpavanNessuna valutazione finora

- Technical Data: 1. DescriptionDocumento2 pagineTechnical Data: 1. DescriptionlucasNessuna valutazione finora

- Rotalock™: Quick Opening ClosureDocumento2 pagineRotalock™: Quick Opening Closureagung wijayaNessuna valutazione finora

- Medium Velocity Water Spray Nozzle: HD Fire Protect Pvt. Ltd. Technical DataDocumento8 pagineMedium Velocity Water Spray Nozzle: HD Fire Protect Pvt. Ltd. Technical DataDileesh DineshanNessuna valutazione finora

- HD 108 MV-A AS NozzleDocumento8 pagineHD 108 MV-A AS NozzleVINOD PAULNessuna valutazione finora

- VK469 K11.2 Concealed PendentDocumento5 pagineVK469 K11.2 Concealed PendentPhung BaoNessuna valutazione finora

- Hydrostop AWDocumento2 pagineHydrostop AWosama mohNessuna valutazione finora

- 05 Tyco TJRDocumento6 pagine05 Tyco TJRsamNessuna valutazione finora

- WHCP - Long Term Storage InstructionsDocumento5 pagineWHCP - Long Term Storage InstructionsYasin ElaswadNessuna valutazione finora

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- Fluidic Components and Equipment 1968–9: Pergamon Electronics Data SeriesDa EverandFluidic Components and Equipment 1968–9: Pergamon Electronics Data SeriesNessuna valutazione finora

- eArt-Calculating Overpressure From BLEVE ExplosionsDocumento6 pagineeArt-Calculating Overpressure From BLEVE ExplosionsJurizal Julian LuthanNessuna valutazione finora

- Fta Oil+gasdistilcolumn PDFDocumento7 pagineFta Oil+gasdistilcolumn PDFPrasanna GNessuna valutazione finora

- Kelompok 10 - Metode Optimasi Senyawa PenuntunDocumento36 pagineKelompok 10 - Metode Optimasi Senyawa Penuntunapr_aprililianti100% (1)

- 11-Fraunhofer DiffractionDocumento30 pagine11-Fraunhofer DiffractionFAGUN BaskeyNessuna valutazione finora

- Refrigerator Test R1Documento9 pagineRefrigerator Test R1GHyukendo Shaddiq AkhbarNessuna valutazione finora

- Chemguard c333 Ar-Afff 3% MsdsDocumento7 pagineChemguard c333 Ar-Afff 3% MsdsrendydunNessuna valutazione finora

- Ball Valve SeatDocumento2 pagineBall Valve Seatmrkadu_61Nessuna valutazione finora

- Experiment 2 - Study of Packed Column DistillationDocumento7 pagineExperiment 2 - Study of Packed Column DistillationAdawiyah Az-zahra100% (1)

- Processes 02 00265 v2 PDFDocumento28 pagineProcesses 02 00265 v2 PDFGu VhvNessuna valutazione finora

- 10 - Chapter 2 PDFDocumento72 pagine10 - Chapter 2 PDFAwais SargodianNessuna valutazione finora

- Astm C 171-07Documento2 pagineAstm C 171-07jun floresNessuna valutazione finora

- TankJet 65 Tank Cleaning CatalogDocumento2 pagineTankJet 65 Tank Cleaning Catalogvalerian1988Nessuna valutazione finora

- Molten Salt Storage Systems For Solar Thermal Prower PlantsDocumento8 pagineMolten Salt Storage Systems For Solar Thermal Prower PlantsSaul RamNessuna valutazione finora

- Tpl-Kipl Jvkarnalstp-20cdd003 Design Docoments Part 1 Client 28-11-18Documento1.057 pagineTpl-Kipl Jvkarnalstp-20cdd003 Design Docoments Part 1 Client 28-11-18navneet3bawa100% (1)

- Ur m60Documento3 pagineUr m60Goran JurisicNessuna valutazione finora

- Biology Unit PlanDocumento10 pagineBiology Unit Planapi-246097943Nessuna valutazione finora

- NSTSE Class 7 SolutionDocumento5 pagineNSTSE Class 7 SolutionMota ChashmaNessuna valutazione finora

- Safety Data Sheet Belzona® 1111 (Super Metal) Solidifier: According To Regulation (EU) No 453/2010Documento10 pagineSafety Data Sheet Belzona® 1111 (Super Metal) Solidifier: According To Regulation (EU) No 453/2010Andreas EkaNessuna valutazione finora

- AIATS Schedule (2011, 2012)Documento7 pagineAIATS Schedule (2011, 2012)goelbharatNessuna valutazione finora

- Voe Main2Documento4 pagineVoe Main2prevrtljivacNessuna valutazione finora

- Simulation Report TemplateDocumento11 pagineSimulation Report TemplateFahmi FahreziNessuna valutazione finora

- Practice Exam 2.4Documento6 paginePractice Exam 2.4jamalNessuna valutazione finora

- Melamine ProductionDocumento49 pagineMelamine ProductionImtiaz HussainNessuna valutazione finora

- Technical Discussion - Cutless BearingsDocumento7 pagineTechnical Discussion - Cutless BearingsSoodyod Yodyod0% (1)

- Computer Methods and Experimental Measurements For Surface Effects and Contact MechanicsDocumento353 pagineComputer Methods and Experimental Measurements For Surface Effects and Contact MechanicsRuben CallisayaNessuna valutazione finora

- Assignment For Iupac Nomenclature: CH - CH-CH - CHDocumento5 pagineAssignment For Iupac Nomenclature: CH - CH-CH - CHapi-233404189Nessuna valutazione finora

- Autolab Brochure 2013 en LRDocumento40 pagineAutolab Brochure 2013 en LRdanidondoniNessuna valutazione finora

- Calcium and Magnesium Determinations by EDTA Titrations1 (Soil Science Society of America Journal, Vol. 25, Issue 1) (1961)Documento3 pagineCalcium and Magnesium Determinations by EDTA Titrations1 (Soil Science Society of America Journal, Vol. 25, Issue 1) (1961)Heba TahaNessuna valutazione finora

- Synthesis and CharacterizationDocumento162 pagineSynthesis and CharacterizationVioleta MarcuNessuna valutazione finora

- Spectrophotometric Determination of Nitrite and Nitrate Using Phosphomolybdenum Blue ComplexDocumento8 pagineSpectrophotometric Determination of Nitrite and Nitrate Using Phosphomolybdenum Blue ComplexkhekhyNessuna valutazione finora