Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

53a5a95ead2747cb5d447875bbb343af

Caricato da

Adi PrasetyoCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

53a5a95ead2747cb5d447875bbb343af

Caricato da

Adi PrasetyoCopyright:

Formati disponibili

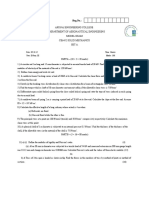

ACI STRUCTURAL JOURNAL TECHNICAL PAPER

Title no. 107-S59

Shear Behavior of Steel Fiber-Reinforced Concrete Beams

without Stirrup Reinforcement

by Hai H. Dinh, Gustavo J. Parra-Montesinos, and James K. Wight

Results from a comprehensive investigation aimed at studying the volume fractions Vf greater than or equal to 0.75%. Most of

behavior of steel fiber-reinforced concrete (SFRC) beams in shear, the available data, however, corresponded to beams with

as well as the possibility of using steel fibers as minimum shear overall depths smaller than 405 mm (16 in.). These data were

reinforcement, are presented. A total of 28 simply supported beams used as the basis for a new provision in the 2008 ACI

with a shear span-to-effective depth ratio of approximately 3.5

Building Code (ACI Committee 318 2008), which allows the

were subjected to a monotonically increased, concentrated load.

The target concrete compressive strength for all of the beams use of deformed steel fibers in volume fractions greater than

was 41 MPa (6000 psi). The studied parameters included beam or equal to 0.75% as minimum shear reinforcement in

depth (455 or 685 mm [18 or 27 in.]), fiber length (30 or 60 mm [1.2 normal-strength concrete beams subjected to factored shear

or 2.4 in.]), fiber aspect ratio (55 or 80), fiber strength (1100 or stresses between (1/12)fc and (1/6)fc MPa ( 1fc and

2300 MPa [160 or 330 ksi]), and fiber volume fraction (between 2fc psi) and with an overall depth not exceeding 610 mm

0.75 and 1.5%). In total, three types of steel fibers were considered, (24 in.). Besides the minimum fiber volume fraction of

all with hooks at their ends. The behavior of beams failing in 0.75%, the ACI Code prescribes a flexural performance

shear prior to or after flexural yielding was also investigated by varying criteria for the acceptance of steel fiber-reinforced concrete

the longitudinal reinforcement ratio (1.6, 2.0, and 2.7%). (SFRC) as a replacement for minimum shear reinforcement,

Test results showed that the use of hooked steel fibers in a based on ASTM C1609 (2005) four-point bending tests.

volume fraction greater than or equal to 0.75% led to multiple

The research presented herein was aimed at experimentally

diagonal cracking and a substantial increase in shear strength

compared to reinforced concrete (RC) beams without stirrup investigating the behavior of relatively large SFRC beams in

reinforcement. All SFRC beams sustained a peak shear stress of shear, which is not well known due to the limited availability

at least 0.33 fc MPa (4.0 fc psi). The results also indicated of test data. In particular, this research focused on the study

that the hooked steel fibers evaluated in this investigation can of: 1) the behavior and shear strength of SFRC beams with

safely be used as minimum shear reinforcement in RC beams various depths and reinforcement ratios; 2) the effect of fiber

constructed with normal-strength concrete and within the range volume fraction, aspect ratio, and strength on the shear

of member depths considered. behavior of SFRC beams; and 3) the possibility of using steel

fibers as minimum shear reinforcement in RC beams.

Keywords: ductility; fiber-reinforced concrete; hooked steel fibers; shear

strength; stirrups. RESEARCH SIGNIFICANCE

Results from a large experimental program aimed at

INTRODUCTION evaluating the shear behavior of SFRC beams are presented.

The use of discontinuous, randomly oriented fibers has Data presented herein are considered unique in the sense that

long been recognized to provide post-cracking tensile they provide information on the effect of parameters such as

resistance to concrete. Thus, their use as shear reinforcement fiber geometry, strength and volume fraction, and longitudinal

in reinforced concrete (RC) beams has been the focus of reinforcement ratio on the shear behavior of relatively large

several investigations in the past four decades (an extensive SFRC beams.

list of references was reported by Parra-Montesinos [2006]).

Fiber reinforcement enhances shear resistance by transferring EXPERIMENTAL PROGRAM

tensile stresses across diagonal cracks and reducing diagonal A total of 28 beams were tested under a monotonically

crack spacing and width, which increases aggregate interlock. increased concentrated load to investigate the shear behavior

The reduction in crack spacing due to the presence of fibers of SFRC beams. The experimental program consisted of two

indicates that the use of fiber reinforcement could potentially lead series of beams: Series B18, with an overall beam depth of

to a reduction or even an elimination of the shear size effect in 455 mm (18 in.), and Series B27, with a beam depth of

beams without stirrup reinforcement, whose shear strength is 685 mm (27 in.). There were eight pairs of beams for Series B18

known to decrease as the overall beam depth increases (Wight and four pairs plus four single beams for Series B27. Beams

and MacGregor 2008). The effectiveness of fiber reinforcement from each pair were nominally identical to reduce the

to increase shear resistance, however, is dependent on uncertainty of the shear data. Table 1 lists the properties of

several factors, including fiber properties (that is, material the test beams. For Series B18, a pair of beams with neither

properties, aspect ratio, and shape), fiber content, and bond

stress versus slip response of fibers.

A survey of published experimental data conducted by ACI Structural Journal, V. 107, No. 5, September-October 2010.

MS No. S-2009-277.R1 received December 16, 2009, and reviewed under Institute

Parra-Montesinos (2006) revealed that an average shear publication policies. Copyright 2010, American Concrete Institute. All rights reserved,

stress of 0.3fc MPa (3.6fc psi) represented a lower bound including the making of copies unless permission is obtained from the copyright proprietors.

Pertinent discussion including authors closure, if any, will be published in the July-

for the shear strength of beams with deformed steel fibers in August 2011 ACI Structural Journal if the discussion is received by March 1, 2011.

ACI Structural Journal/September-October 2010 597

Potrebbero piacerti anche

- Regression analysis of stock market dataDocumento9 pagineRegression analysis of stock market dataAdi PrasetyoNessuna valutazione finora

- CV Chalioris (ENG)Documento6 pagineCV Chalioris (ENG)Adi PrasetyoNessuna valutazione finora

- Zonasi Tingkat Kerentanan (Vulnerability) Banjir Daerah Kota SurakartaDocumento17 pagineZonasi Tingkat Kerentanan (Vulnerability) Banjir Daerah Kota SurakartaAdi PrasetyoNessuna valutazione finora

- Corrosing Control Measures For Sewerage Concrete Sstructure PDFDocumento5 pagineCorrosing Control Measures For Sewerage Concrete Sstructure PDFAdi PrasetyoNessuna valutazione finora

- Characteristics of Bamboo Leaf Ash Blended Cement Paste and MortarDocumento7 pagineCharacteristics of Bamboo Leaf Ash Blended Cement Paste and MortarAdi PrasetyoNessuna valutazione finora

- Civil Eng-MRSA PDFDocumento19 pagineCivil Eng-MRSA PDFAdi PrasetyoNessuna valutazione finora

- Cement & Concrete Composites - Reduced Shear Reinforcement in Fiber Reinforced Concrete BeamsDocumento9 pagineCement & Concrete Composites - Reduced Shear Reinforcement in Fiber Reinforced Concrete BeamsAdi PrasetyoNessuna valutazione finora

- Corrosing Control Measures For Sewerage Concrete Sstructure PDFDocumento5 pagineCorrosing Control Measures For Sewerage Concrete Sstructure PDFAdi PrasetyoNessuna valutazione finora

- Zonasi Tingkat Kerentanan (Vulnerability) Banjir Daerah Kota SurakartaDocumento17 pagineZonasi Tingkat Kerentanan (Vulnerability) Banjir Daerah Kota SurakartaAdi PrasetyoNessuna valutazione finora

- Experimental and Numerical Investigation of Stress Condition in Unstable SoilDocumento11 pagineExperimental and Numerical Investigation of Stress Condition in Unstable SoilAdi PrasetyoNessuna valutazione finora

- Experiment and Numeric Analysis of Brick Masonry Wall With Bracing Under Cyclic LoadingDocumento9 pagineExperiment and Numeric Analysis of Brick Masonry Wall With Bracing Under Cyclic LoadingAdi PrasetyoNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Pressure Pressure - Manometry Manometry: Man Tech 4Tf3 Man Tech 4Tf3Documento22 paginePressure Pressure - Manometry Manometry: Man Tech 4Tf3 Man Tech 4Tf3aushad3mNessuna valutazione finora

- Replica Metallography and Penetrant TestingDocumento14 pagineReplica Metallography and Penetrant TestingBala Singam100% (1)

- Australian Orthodontic WiresDocumento5 pagineAustralian Orthodontic WiresMadan Chinta100% (1)

- Metallurgical Failure AnalysisDocumento4 pagineMetallurgical Failure AnalysisgirishnitwNessuna valutazione finora

- Mechanical and Microstructure Properties of 304 Stainless Steel Friction Welded JointDocumento10 pagineMechanical and Microstructure Properties of 304 Stainless Steel Friction Welded JointSUBHASHIS SAHOONessuna valutazione finora

- A Review of Zinc-Oxide As Nano Materials and DevicesDocumento5 pagineA Review of Zinc-Oxide As Nano Materials and DevicesidescitationNessuna valutazione finora

- Thermodynamics Problem SetDocumento15 pagineThermodynamics Problem SetafiqzeroNessuna valutazione finora

- Material Testing Lab ManualDocumento65 pagineMaterial Testing Lab ManualchetanNessuna valutazione finora

- Montazni Prednapregnuti Nosaci PDFDocumento5 pagineMontazni Prednapregnuti Nosaci PDFBruce HollandNessuna valutazione finora

- Design of Steel Beam SectionDocumento30 pagineDesign of Steel Beam SectionjeyavaniNessuna valutazione finora

- CSWIP QuizDocumento12 pagineCSWIP Quizmushruff100% (1)

- Effect of Depth On Shear Capacity of Transfer Beam in High Rise BuildingDocumento46 pagineEffect of Depth On Shear Capacity of Transfer Beam in High Rise BuildingSheffy Abraham100% (1)

- Boundary Layer FlowsDocumento28 pagineBoundary Layer FlowsAmy RamirezNessuna valutazione finora

- Steel Column Buckling Axial and Transverse LoadingDocumento31 pagineSteel Column Buckling Axial and Transverse LoadingTor GrimlundNessuna valutazione finora

- Polipropileno Hostacom Xm2 v05Documento2 paginePolipropileno Hostacom Xm2 v05LucasNessuna valutazione finora

- High Throughput Production of Nanoscale Liposomes Using Extreme Aspect Ratio Hydrodynamic Flow FocusingDocumento3 pagineHigh Throughput Production of Nanoscale Liposomes Using Extreme Aspect Ratio Hydrodynamic Flow Focusingmrh2767Nessuna valutazione finora

- Nanoelectronics: ECT292 Category L T P CreditDocumento7 pagineNanoelectronics: ECT292 Category L T P CreditanoopegNessuna valutazione finora

- MCQS .... CSWIP Questions and AnswersDocumento67 pagineMCQS .... CSWIP Questions and AnswersAli Kashif100% (1)

- Differential Movement of Masonry WorksDocumento4 pagineDifferential Movement of Masonry WorksSudan ShresthaNessuna valutazione finora

- Design Prestressed Force SLSDocumento28 pagineDesign Prestressed Force SLSAlif Akhmizan100% (1)

- Steel Cal CulDocumento1 paginaSteel Cal CulheinsteinzNessuna valutazione finora

- Theories of Adhesion: Mechanical TheoryDocumento5 pagineTheories of Adhesion: Mechanical TheoryRehan KMNessuna valutazione finora

- 1 CE132P - Introduction To Indeterminate StructuresDocumento7 pagine1 CE132P - Introduction To Indeterminate StructuresEliminated Pro100% (2)

- Astm D7405Documento4 pagineAstm D7405jegancivil100% (3)

- Acta MaterialiaDocumento14 pagineActa MaterialiaSapandeepNessuna valutazione finora

- SM Model Exam QuestionDocumento5 pagineSM Model Exam QuestionAravind PhoenixNessuna valutazione finora

- Mechanical Specifications For Fiberbond ProductDocumento8 pagineMechanical Specifications For Fiberbond ProducthasnizaNessuna valutazione finora

- B 91 - 12Documento5 pagineB 91 - 12phaindikaNessuna valutazione finora

- Compression test neoprene rubber padsDocumento22 pagineCompression test neoprene rubber padsNikil PujariNessuna valutazione finora

- Superalloys For Industry Applications PDFDocumento120 pagineSuperalloys For Industry Applications PDFSgk Manikandan100% (1)