Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Technical Delivery Condition (TDC) : Exhibit 3 - 2 Rev. 0 Dtd. 12.12.2014

Caricato da

shazanDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Technical Delivery Condition (TDC) : Exhibit 3 - 2 Rev. 0 Dtd. 12.12.2014

Caricato da

shazanCopyright:

Formati disponibili

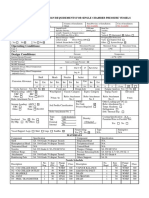

TECHNICAL DELIVERY CONDITION (TDC)

1) Code / Standard &

ASME Section II Part A Edition 2013

Addenda Year of Edition TDC

2) Quantity & Dimension As per Purchase order for :

3) Name of product Carbon Steel Plates

Plates shall be Fine Grain, Fully Killed & Normalised -

4) Condition

Condition

SA 516 Gr. 60

5) Specification Designation

[NACE as per Clause 14 (d) below]

6) Impact test Requirement As per clause 13 (c) below

7) Limits of refining element

Not Applicable

other than aluminium

8) Paint Marking Not Applicable

9) Marking Requirement As per section 13 of SA 20

10) General Requirement As per Specification of SA 20

11) Certification As per section 19 of SA 20

As per SA 20 & Plates having positive tolerances in

12) Tolerance

thickness.

Carbon Steel Plates (NACE)

13) Supplementary Requirement

a) S19. Restricted Chemical Requirement &S20. Maximum Carbon Equivalent for

Weldability of SA-20

Chemical analysis shall be applicable as per SA 516.

As per NACE SP0472, when carbon content exceeds 0.18 wt. % then Carbon

equivalent shall be lower than 0.43%.

Ceq = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15

Maximum Vanadium content of 0.02 wt. %

Maximum Niobium content of 0.02 wt. %

Exhibit 3 2 Rev. 0 Dtd. 12.12.2014 Page 1 of 3

TECHNICAL DELIVERY CONDITION (TDC)

Maximum V plus Nb content of 0.03 wt. %

b) S8: Ultrasonic Examination in accordance with specification SA 435 of SA 516

Plates having thickness greater than or equal to20 mm shall be examined

ultrasonically as per specification SA 435 with S1 scanning.

c) S5. Charpy V-Notch Impact testing

Plates shall be impact tested at minus 46 degree centigrade with minimum

average energy value for three specimens shall be 18 Joules and for single

minimum value shall be 14 Joules.

14) Additional Requirement

a) When plates thickness exceeds 50 mm, specimens for mechanical testing shall be taken

at half the thickness (1/2 T).

b) Metal stamping shall be done with low-stress stamp. Markings shall be protected from

erosion, wear, or other events that may render them unreadable.

c) Hardness of plates shall not exceed 180 BHN.

d) Material shall be NACE MR0103 & NACE SP0472 Compliant. Hardness testing method

shall be as specified in NACE MR0103.

e) Deleted.

f) Simulated Heat Treatment Cycle-2 for J-152061

MINIMUM PWHT CYCLE MAXIMUM PWHT CYCLE

Holding Holding

635C ( 5 C) 635C ( 5 C)

Temperature Temperature

Holding Time Min. 160 minutes Holding Time Min. 480 minutes

56C per hour above 56C per hour above

Heating Rate Heating Rate

300C 300C

56C per hour upto 56C per hour upto

Cooling Rate Cooling Rate

300C 300C

I) Mechanical Properties for Dished End Plates (107 mm Thk) -152061

i. As received condition: As per material specification

1. Plates shall be impact tested at minus 46 degree centigrade with

minimum average energy value for three specimens shall be 18 Joules

and for single minimum value shall be 14 Joules.

2. Tensile, Through Thickness Test with minimum Reduction in area shall be

35%, Elongation and yield test shall be carried out at room temperature.

ii. After Normalizing and Minimum PWHT Cycle

Exhibit 3 2 Rev. 0 Dtd. 12.12.2014 Page 2 of 3

TECHNICAL DELIVERY CONDITION (TDC)

1. Plates shall be impact tested at minus 46 degree centigrade with

minimum average energy value for three specimens shall be 18 Joules

and for single minimum value shall be 14 Joules.

2. Tensile, Through Thickness Test with minimum Reduction in area shall be

35%, Elongation and yield test shall be carried out at room temperature.

3. Hardness Test 180 BHN max.

iii. After Normalizing and Maximum PWHT Cycle

1. Plates shall be impact tested at minus 46 degree centigrade with

minimum average energy value for three specimens shall be 18 Joules

and for single minimum value shall be 14 Joules.

2. Tensile, Through Thickness Test with minimum Reduction in area shall be

35%, Elongation and yield test shall be carried out at room temperature.

iv. Normalizing temperature and soaking time shall be as specified by the Mill.

1. Temperature: 910 10 C

2. Holding Time: 130 min x 1Cycle

3. Heating Rate: 150 170 C/Hr.

4. Cooling in Still air.

g) Carbon steel plates shall not contain intentional addition of elements such as lead,

selenium or sulphur to improve machinability.

h) The plates shall be free from injurious defects and shall have workmanlike finish.

Reconditioning/repair of plates by welding shall not be permitted. Surface conditions

shall meet requirements of EN 10163 Class A Subclass 3.

i) Plates shall be certified in accordance with EN 10204:2004 & by B.V or LR at mills

option comply with type 3.2.

__________________ _____________________

Prepared By Reviewed & Approved By

Design Engineer Head Design & Engineering

Head QA/QC Head QA/QC

Quality Control Engineer

Exhibit 3 2 Rev. 0 Dtd. 12.12.2014 Page 3 of 3

Potrebbero piacerti anche

- TDC Tech Spec For PlateDocumento3 pagineTDC Tech Spec For PlateBantoo RajamandiNessuna valutazione finora

- TDC For Plates - SA 516 65Documento3 pagineTDC For Plates - SA 516 65Renny DevassyNessuna valutazione finora

- Rapid p0030 CPP U0030 Qac Mom 0024 Quality MeetingDocumento13 pagineRapid p0030 CPP U0030 Qac Mom 0024 Quality MeetingAtuk Safiz100% (1)

- Ut PQRDocumento10 pagineUt PQRArvind Sahani100% (1)

- Anilkumar Gopinathan Nair: Phone: +91-6380325363Documento2 pagineAnilkumar Gopinathan Nair: Phone: +91-6380325363Anilkumar GNessuna valutazione finora

- Nig VT Spec QB S2 - Level IiDocumento12 pagineNig VT Spec QB S2 - Level Iikingston100% (1)

- ST 37Documento7 pagineST 37rendra.farisrNessuna valutazione finora

- HMC Spec 001 - Welding and Fabrication of Structural SteelDocumento29 pagineHMC Spec 001 - Welding and Fabrication of Structural SteelJohnnyNessuna valutazione finora

- Painting Report - C1742 & 43 PDFDocumento1 paginaPainting Report - C1742 & 43 PDFRyan Flores100% (1)

- PQR Editable SampleDocumento2 paginePQR Editable SampleKoya ThangalNessuna valutazione finora

- RNS - NDT - MT - 001 Rev.0Documento10 pagineRNS - NDT - MT - 001 Rev.0Goutam Kumar DebNessuna valutazione finora

- CF8M VS CF8 Stainless Steel Casting - JC CastingDocumento7 pagineCF8M VS CF8 Stainless Steel Casting - JC CastingSHivaprasad APITNessuna valutazione finora

- Sample Forms WPS PQRDocumento22 pagineSample Forms WPS PQRGMNessuna valutazione finora

- Welding Procedure Specification (WPS) : in The Outer TubeDocumento1 paginaWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaNessuna valutazione finora

- CV Painting InsulationDocumento3 pagineCV Painting Insulationhamza brahmiNessuna valutazione finora

- VT QB S4 Pro Wiyh KeyDocumento12 pagineVT QB S4 Pro Wiyh KeykingstonNessuna valutazione finora

- Hardness Pro Form1Documento2 pagineHardness Pro Form1gst ajah100% (1)

- STD-InSP-0007 (Fitting Inspection Report)Documento3 pagineSTD-InSP-0007 (Fitting Inspection Report)airbroomNessuna valutazione finora

- OCS Prel WPS 007Documento2 pagineOCS Prel WPS 007vinothNessuna valutazione finora

- STD-InSP-0006 (Flange Inspection Procedure)Documento3 pagineSTD-InSP-0006 (Flange Inspection Procedure)airbroom100% (1)

- Pull Off Test Report RefinaryDocumento3 paginePull Off Test Report RefinaryZaid Raslan AyoubNessuna valutazione finora

- QW-403.2 InterpretationDocumento1 paginaQW-403.2 Interpretationlaz_kNessuna valutazione finora

- T.C.L. Co. - Test & Control LaboratoriesDocumento2 pagineT.C.L. Co. - Test & Control LaboratoriesA. ΒρατσισταNessuna valutazione finora

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDocumento9 pagine2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanNessuna valutazione finora

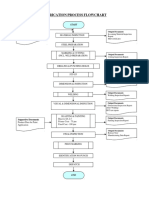

- Process Flow Chart - SeeDocumento2 pagineProcess Flow Chart - Seesukanth tejaswiNessuna valutazione finora

- Vinoth Kumar P CV QC Qa WiwDocumento13 pagineVinoth Kumar P CV QC Qa Wiwvignesh0tNessuna valutazione finora

- Std-Insp-0002 (Incoming Material Inspection Procedure)Documento3 pagineStd-Insp-0002 (Incoming Material Inspection Procedure)airbroomNessuna valutazione finora

- Purchase Spec. For Tubes (Sa789 S31803)Documento6 paginePurchase Spec. For Tubes (Sa789 S31803)Daison PaulNessuna valutazione finora

- Ancillary Specification (Generic) : Subject: Full Length Drift/End Drift Inspection ProcedureDocumento4 pagineAncillary Specification (Generic) : Subject: Full Length Drift/End Drift Inspection ProcedureDefi Jodi PermanaNessuna valutazione finora

- PMI TestingDocumento3 paginePMI TestinghungNessuna valutazione finora

- Pressure Test Sample Form R2Documento1 paginaPressure Test Sample Form R2Ruel fernandezNessuna valutazione finora

- Quality Assurance PlanDocumento3 pagineQuality Assurance PlanDeepak HoleNessuna valutazione finora

- TDC 004 CS Fittings r0Documento1 paginaTDC 004 CS Fittings r0samkarthik47Nessuna valutazione finora

- Srihari Katari 11 Jan 2022Documento50 pagineSrihari Katari 11 Jan 2022Abhishek DevarajNessuna valutazione finora

- NDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023Documento16 pagineNDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023SANJEEV YADAVNessuna valutazione finora

- SAIC-W-2078 Review PWHT Proc For TankDocumento5 pagineSAIC-W-2078 Review PWHT Proc For Tankkarioke mohaNessuna valutazione finora

- Fcaw 16 THKDocumento5 pagineFcaw 16 THKAnonymous Ij6VfaNessuna valutazione finora

- SSIS Visual Examination Report FormatDocumento1 paginaSSIS Visual Examination Report FormatSalman KhanNessuna valutazione finora

- Hemps 11.100 A1Documento33 pagineHemps 11.100 A1हेमंत कुमार मीणाNessuna valutazione finora

- Flange 10 & 12 InchDocumento2 pagineFlange 10 & 12 InchreniNessuna valutazione finora

- QAP For FlangesDocumento2 pagineQAP For FlangesGOPINATH KRISHNAN NAIRNessuna valutazione finora

- Tungstenelectrodesize and Type' 2,4 MM As Per Sfa 5.12 Ewth - 2Documento23 pagineTungstenelectrodesize and Type' 2,4 MM As Per Sfa 5.12 Ewth - 2Abdelkader AbdelkaderNessuna valutazione finora

- Test Certification PDFDocumento1 paginaTest Certification PDFDany ChlNessuna valutazione finora

- SAW Presentation - SSDocumento62 pagineSAW Presentation - SSRishabh KumarNessuna valutazione finora

- Material Test Certificate: For: Priminox OverseasDocumento2 pagineMaterial Test Certificate: For: Priminox OverseasDSAFNessuna valutazione finora

- Eng052 20erw 000 Qa WQS 0004 000 - 01Documento7 pagineEng052 20erw 000 Qa WQS 0004 000 - 01Mohammed ShehinNessuna valutazione finora

- Carbon Steel Forgings, Class 2: Corporate Purchase Specification AA 193 31 Rev. No. 11 Preface SheetDocumento7 pagineCarbon Steel Forgings, Class 2: Corporate Purchase Specification AA 193 31 Rev. No. 11 Preface Sheetraghav248Nessuna valutazione finora

- Magnetic Particle Testing ReporDocumento2 pagineMagnetic Particle Testing ReporGabriela MotaNessuna valutazione finora

- I-963 Welder Certificate Smaw-Gtaw-1Documento1 paginaI-963 Welder Certificate Smaw-Gtaw-1nivedithdigitals onlineservices100% (1)

- Ultrasonic Test Report: Testing TechniqueDocumento2 pagineUltrasonic Test Report: Testing TechniqueMd RizwanNessuna valutazione finora

- Gate & Globe PDFDocumento0 pagineGate & Globe PDFZoebairNessuna valutazione finora

- STD-InSP-0005 (Plate Inspection Procedure)Documento3 pagineSTD-InSP-0005 (Plate Inspection Procedure)airbroomNessuna valutazione finora

- Welding Procedure Welding Procedure Specification SpecificationDocumento2 pagineWelding Procedure Welding Procedure Specification SpecificationHamid MansouriNessuna valutazione finora

- P 11 CNDT JP41 Ut-Aws D1.1 Rev 07Documento22 pagineP 11 CNDT JP41 Ut-Aws D1.1 Rev 07Vimal MenonNessuna valutazione finora

- Quality Procedure Procedure For Weld RepairDocumento1 paginaQuality Procedure Procedure For Weld Repairbalakumar rajaramNessuna valutazione finora

- WPS-PQR ListDocumento1 paginaWPS-PQR ListSandra SandersNessuna valutazione finora

- b2020-Tdc-Fas-004 Fasteners r3Documento2 pagineb2020-Tdc-Fas-004 Fasteners r3Ramalingam PrabhakaranNessuna valutazione finora

- 4130wog0913 - Rev14Documento3 pagine4130wog0913 - Rev14Quality controller100% (1)

- ASTM A182 Grade F51 Requirement As Per API 6A-60KDocumento8 pagineASTM A182 Grade F51 Requirement As Per API 6A-60KPalkesh TrivediNessuna valutazione finora

- API 510 CB Mockup 3 R0 26112010Documento18 pagineAPI 510 CB Mockup 3 R0 26112010essnelsonNessuna valutazione finora

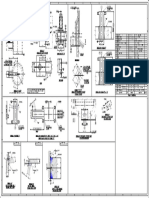

- Checking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumberDocumento1 paginaChecking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumbershazanNessuna valutazione finora

- Clearance CalculationDocumento12 pagineClearance CalculationshazanNessuna valutazione finora

- Weld CalculationsDocumento12 pagineWeld Calculationshakr5100% (1)

- Flange Details & DrawingsDocumento338 pagineFlange Details & DrawingsshazanNessuna valutazione finora

- Bolt Torque Calculations 1 PDFDocumento1 paginaBolt Torque Calculations 1 PDFshazanNessuna valutazione finora

- Bolt Torque Calculations 1 PDFDocumento1 paginaBolt Torque Calculations 1 PDFshazanNessuna valutazione finora

- Bolt Torque Calculations 1 PDFDocumento1 paginaBolt Torque Calculations 1 PDFshazanNessuna valutazione finora

- Training Course ASMEDocumento2 pagineTraining Course ASMEshazan100% (1)

- Seismic Calculation IS 1893 - RSMDocumento3 pagineSeismic Calculation IS 1893 - RSMshazanNessuna valutazione finora

- U Stamp - KK Form - SampleDocumento5 pagineU Stamp - KK Form - SampleshazanNessuna valutazione finora

- Tailing Lug - 173004-05Documento1 paginaTailing Lug - 173004-05shazan100% (1)

- Welding EngineeringDocumento1 paginaWelding EngineeringshazanNessuna valutazione finora

- Welding GuidelineDocumento1 paginaWelding GuidelineshazanNessuna valutazione finora

- IBR Design Calculations - FinalDocumento6 pagineIBR Design Calculations - Finalshazan100% (1)

- Drawing Pressure VesselDocumento1 paginaDrawing Pressure VesselshazanNessuna valutazione finora

- Tailing Lug - 173004-05Documento1 paginaTailing Lug - 173004-05shazan100% (1)

- Bolt Torque CalculationDocumento3 pagineBolt Torque Calculationshazan100% (1)

- Saddle Stresses On Shell During Transportation: Equipment NoDocumento5 pagineSaddle Stresses On Shell During Transportation: Equipment NoshazanNessuna valutazione finora

- Design Planning ScheduleDocumento2 pagineDesign Planning ScheduleshazanNessuna valutazione finora

- NEOM-NEN-TGD-304 - 01.00 - Wind Design Requirements For Building StructuresDocumento11 pagineNEOM-NEN-TGD-304 - 01.00 - Wind Design Requirements For Building Structuresmahmudulalam konokNessuna valutazione finora

- PR 1 Series Pressure Regulator Repair Kits 23297bDocumento2 paginePR 1 Series Pressure Regulator Repair Kits 23297bJames JansonNessuna valutazione finora

- Slope Deflection Assignment - 2023Documento2 pagineSlope Deflection Assignment - 2023Andrew ChikuselaNessuna valutazione finora

- Load Transfer Characteristics of Dowel Bar System in Jointed Concrete PavementDocumento9 pagineLoad Transfer Characteristics of Dowel Bar System in Jointed Concrete PavementAbhishek SinghNessuna valutazione finora

- Certificado Brida 3Documento1 paginaCertificado Brida 3juan aguilarNessuna valutazione finora

- HUKM Maintenance and Operation CostDocumento5 pagineHUKM Maintenance and Operation CostmohdkamalhaziqNessuna valutazione finora

- SBS Waterproofing ITP & ChecklistDocumento27 pagineSBS Waterproofing ITP & Checklistlike saddamNessuna valutazione finora

- A Civil Engg. Final Year Training Report On Residential Building Construction.Documento71 pagineA Civil Engg. Final Year Training Report On Residential Building Construction.Monu Khand84% (261)

- Design of Self Supported Steel ChimneyDocumento27 pagineDesign of Self Supported Steel ChimneyAlok JhaNessuna valutazione finora

- Pressure Vessel Inspection Record: in Accordance With API 510, 10th EditionDocumento2 paginePressure Vessel Inspection Record: in Accordance With API 510, 10th Editionbgonzalez1981Nessuna valutazione finora

- Fencing PermitDocumento2 pagineFencing PermitjordanarkiNessuna valutazione finora

- Lire FVGJXDocumento2 pagineLire FVGJXThiruThirunavukkarasuNessuna valutazione finora

- Case Study - Successful Application of NEC in Government (DSD) Projects - DEBVDocumento76 pagineCase Study - Successful Application of NEC in Government (DSD) Projects - DEBVOlay KwongNessuna valutazione finora

- Structural Notes PDFDocumento40 pagineStructural Notes PDFEnrico luis EscobarNessuna valutazione finora

- BFS SG Product ProfileDocumento9 pagineBFS SG Product ProfileRaja S ManiNessuna valutazione finora

- Noise Prediction ModelDocumento12 pagineNoise Prediction ModelNivedita JhaNessuna valutazione finora

- Bending Stress CalculationsDocumento4 pagineBending Stress Calculationsschaali100% (5)

- Steel Construction - 2012 - Espion - The Vierendeel Bridges Over The Albert Canal Belgium Their Significance in TheDocumento6 pagineSteel Construction - 2012 - Espion - The Vierendeel Bridges Over The Albert Canal Belgium Their Significance in TheJoao SilvaNessuna valutazione finora

- L RFD Bridge Design ManualDocumento969 pagineL RFD Bridge Design ManualNguyễn Văn CôngNessuna valutazione finora

- Extensible RMU - GIS BushingDocumento1 paginaExtensible RMU - GIS BushingvikrantNessuna valutazione finora

- Cat Excavadeiras PesoDocumento16 pagineCat Excavadeiras PesoBruno BaroniNessuna valutazione finora

- Beam ColumnDocumento15 pagineBeam Columntatakere100% (3)

- 250HP 2T - 2004Documento0 pagine250HP 2T - 2004Ray Cepeda MenaNessuna valutazione finora

- LG Mini Split ManualDocumento38 pagineLG Mini Split ManualMark ChaplinNessuna valutazione finora

- DO 005 s2017Documento195 pagineDO 005 s2017Tina Rosales0% (1)

- Atlas 65 RozdzielaczDocumento23 pagineAtlas 65 RozdzielaczPawel TomwidlakNessuna valutazione finora

- 10-Planning and Design of Wind FarmDocumento42 pagine10-Planning and Design of Wind FarmSein Win TunNessuna valutazione finora

- Apartment Hunting ChecklistDocumento1 paginaApartment Hunting ChecklistTime Warner Cable NewsNessuna valutazione finora

- Daftar Kosakata Things in The BathroomDocumento4 pagineDaftar Kosakata Things in The Bathroomfransiska ikaNessuna valutazione finora

- Bridge Inventory Guidelines JICA SrilankaDocumento54 pagineBridge Inventory Guidelines JICA SrilankaAdamNessuna valutazione finora