Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Blind Calculation - Roark

Caricato da

rustamriyadiDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Blind Calculation - Roark

Caricato da

rustamriyadiCopyright:

Formati disponibili

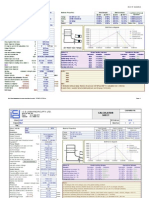

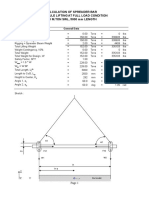

PT PROFAB INDONESIA Page 3

PLATE THICKNESS CHECK

For Pipe Dia 711 x 6mm Thk

Based on Roark's & Young Formula of Stress and Strain

Design Pressure P 1.10 MPa

Design Temperature T 21.00 C

Test Pressure TP 1.65 Mpa = 16.5 Bar

Pipe Diameter OD 711.00 mm

Pipe Thickness ts 6.00 mm

Pipe Inside Diameter d 699.00 mm

Pipe radius a 349.50 mm

Blind Diameter Bd 731.00 mm

Blind section angle for calculation 90.00 deg

Material of blind SS316 or equivalent

Material Yield strength Sy 290.00

Allowable Stress of blind = 0.67 * Sy Sab 115.00 N/mm2

Blind thickness choosen t 33.00 mm

Blind Adequacy per Roark & Young Plate Thickness

Total Load for one sector q = TP = 1.65 N/mm2

Modulus of Elastisity E = 193053.00 N/mm2

poisson's ratio used = 0.30

Maximum stress in the plate, 1

(Ref. Formulas for stress and strain by Roark & Young )

Table 24, Case No. 28

max = qa2

t2

As, = 90.00 deg

= 0.293

Hence max = 54.19 N/mm2

Result max < Sab SAFE

Maximum deflection of the plate,

(Ref. Formulas for stress and strain by Roark & Young )

Table 24, Case No. 28

Ymax = (*q*a^4)/E*t^3

As, = 90.00 deg

= 0.0144

Hence Ymax (uncorroded) = 0.0510995 mm

Result Ymax < t/2 SAFE

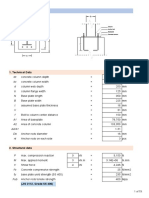

PT PROFAB INDONESIA Page 4

JN1154 Blind Flange Welding Check - 4" & Below

For Nitrogen Condition

Design Pressure P 0.10 MPa

Design Temperature T 21.00 C

Test Pressure TP 0.10 MPa

Pipe Diameter OD 114.00 mm

Pipe Thickness ts 6.00 mm

Pipe Inside Diameter d 102.00 mm

Pipe radius a 51.00 mm

Tension force due to internal pressure at blind flange : Pt 817.13 N 183.698 lbf

Fillet weld length around on Pipe & blind, Lf = *OD = 358 mm = 14.10 in

Groove weld length around on Pipe & blind, Lg = *OD = 358 mm = 14.10 in

Fillet weld leg dimension, wf = 2 mm = 0.08 in

Groove weld depth dimension, wg = 0 mm = 0.00 in

Welding area of fillet weld, Af = wf * Lf = 716 mm2

Welding area of groove weld, Ag = wg * Lg = 0 mm2

Allowable weld stress, Sw = 66.19 MPa = 9600 psi

Load on weld per linear length of weld:

Tension stress of weld, St = Pt / (Af + Ag) = 1.14 MPa = 165 psi

Weld Status St < Sa PASS

PT PROFAB INDONESIA Page 3

JN1154 PLATE THICKNESS CHECK - 4" OVER

For NITROGEN PURGING

Based on Roark's & Young Formula of Stress and Strain

Design Pressure P 0.10 MPa

Design Temperature T 21.00 C

Test Pressure TP 0.10 MPa

Pipe Diameter OD 457.20 mm

Pipe Thickness ts 11.07 mm

Pipe Inside Diameter d 435.06 mm

Pipe radius a 217.53 mm

Blind Diameter Bd 465.06 mm

Blind section angle for calculation 90.00 deg

Material of blind SS304 or equivalent

Material Yield strength Sy 215.00

Allowable Stress of blind = 0.67 * Sy Sab 144.05 N/mm2

Blind thickness choosen t 4.00 mm

Blind Adequacy per Roark & Young Plate Thickness

Total Load for one sector q = TP = 0.10 N/mm2

Modulus of Elastisity E = 193053.00 N/mm2

poisson's ratio used = 0.30

Maximum stress in the plate, 1

(Ref. Formulas for stress and strain by Roark & Young )

Table 24, Case No. 28

max = qa2

t2

As, = 90.00 deg

= 0.293

Hence max = 86.59 N/mm2

Result max < Sab SAFE

Maximum deflection of the plate,

(Ref. Formulas for stress and strain by Roark & Young )

Table 24, Case No. 28

Ymax = (*q*a^4)/E*t^3

As, = 90.00 deg

= 0.0144

Hence Ymax (uncorroded) = 0.2609652 mm

Result Ymax < t/2 SAFE

PT PROFAB INDONESIA Page 4

JN1154 Blind Flange Welding Check - 4" Over

For Nitrogen Condition

Design Pressure P 0.10 MPa

Design Temperature T 21.00 C

Test Pressure TP 0.10 MPa

Pipe Diameter OD 457.20 mm

Pipe Thickness ts 11.07 mm

Pipe Inside Diameter d 435.06 mm

Pipe radius a 217.53 mm

Tension force due to internal pressure at blind flange : Pt 14865.80 N 3341.96 lbf

Fillet weld length around on Pipe & blind, Lf = *OD = 1436 mm = 56.55 in

Groove weld length around on Pipe & blind, Lg = *OD = 1436 mm = 56.55 in

Fillet weld leg dimension, wf = 4 mm = 0.16 in

Groove weld depth dimension, wg = 0 mm = 0.00 in

Welding area of fillet weld, Af = wf * Lf = 5745 mm2

Welding area of groove weld, Ag = wg * Lg = 0 mm2

Allowable weld stress, Sw = 66.19 MPa = 9600 psi

Load on weld per linear length of weld:

Tension stress of weld, St = Pt / (Af + Ag) = 2.59 MPa = 375 psi

Weld Status St < Sa PASS

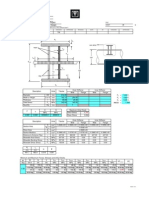

JN919 Blind Flange Thickness Calculation

For Hydrotest Condition

Based on Roark's & Young Formula of Stress and Strain

Design Pressure P 13.00 MPa

Design Temperature T 80.00 C

Test Pressure TP 19.50 MPa

Pipe Diameter OD 914.00 mm

Pipe Thickness ts 44.45 mm

Pipe Inside Diameter d 825.10 mm

Pipe inside radius r 412.55 mm

Blind Diameter Bd 825.10 mm

Material of blind SA-516 Gr.70

Material Yield strength Sy 240.00 MPa

Allowable Stress of blind = 0.67 * Sy Sab 160.80 MPa (For safety factor)

Blind thickness choosen t 75.00 mm

Blind Adequacy per Roark & Young Plate Thickness

Total Load for one sector q = TP = 19.50 N/mm2

Modulus of Elastisity E = 200000.00 N/mm2

poisson's ratio used = 0.30

Rectangular plate dimension a= 300.00 mm

b= 300.00 mm

Maximum stress in the plate,

(Ref. Formulas for stress and strain by Roark & Young, 7th Edition )

Table 11.4, Case No. 1a

max = qb2

t2

As, a/b = 1.00

= 0.287

Hence max = 89.67 N/mm2

Result max < Sab SAFE

Maximum deflection of the plate,

(Ref. Formulas for stress and strain by Roark & Young, 7th Edition )

Table 11.4, Case No. 1a

Ymax = (*q*b^4)/E*t^3

As, a/b = 1.00

= 0.0444

Hence Ymax (uncorroded) = 0.0831168 mm

Result Ymax < t/2 SAFE

JN919 Stiffener of Blind Flange

For Hydrotest Condition

1. Vertical stiffener Calculation

Stiffener to be used :

Stiffener size 25mm THK x 100 width

Stiffener thick, ta = 25.0 mm 1.0 in

Elastic modulus, E = 200000 MPa

Minimum yield strength, Sy = 275.0 MPa 39885.4 psi

Allowable stress, Sa = 0.67*Sy = 184.25 MPa 26723.2 psi

Allow. moment of inertia for horizontal stiffener (I a) = 208.333 cm4 5.01 in4

Allow. section modulus of vertical stiffener (Za) = 41.67 cm3 2.5 in3

Distance between vertical stiffener, L = 300 mm 11.8 in

Height of vertical stiffener, H = 300 mm 11.8 in

Load per unit length w = TP x d = 16089 N/mm

Required section modulus of vertical stiffener

Z = 0.0642*0.036*w*L*H2 = 18.16 cm3 1.11 in3

Sa

Check Stiffener Z < Za = PASS

Required moment of inertia

Imin = 0.7*w*L4 = 9.50 cm4 0.23 in4

192*E*ta

Check Stiffener Imin < Ia = PASS

2. Horizontal stiffener Calculation

Stiffener to be used :

Stiffener size 25mm THK x 100 width

Stiffener thick, ta = 25.0 mm 1.0 in

Elastic modulus, E = 200000 MPa

Minimum yield strength, Sy = 275.0 MPa 39885.4 psi

Allowable stress, Sa = 0.67*Sy = 184.25 MPa 26723.2 psi

Allow. moment of inertia for horizontal stiffener (I a) = 208.333 cm4 5.01 in4

41.67 cm

3

Allow. section modulus of vertical stiffener (Za) = 2.5 in3

Distance between horizontal stiffener, L = 300 mm 11.8 in

Length of horizontal stiffener, H = 300 mm 11.8 in

Load per unit length w = TP x d = 16089 N/mm

Required section modulus of horizontal stiffener

Z = 0.0642*0.036*w*H*L2 = 18.16 cm3 1.11 in3

Sa

Check Stiffener Z < Za = PASS

Required moment of inertia

Imin = 0.7*w*H4 = 9.50 cm4 0.23 in4

192*E*ta

Check Stiffener Imin < Ia = PASS

Potrebbero piacerti anche

- Davit CalcDocumento4 pagineDavit CalcrustamriyadiNessuna valutazione finora

- ASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelDocumento16 pagineASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelPanya Purahong100% (1)

- Design of Flat Head For HydrotestDocumento12 pagineDesign of Flat Head For HydrotestSAGARNessuna valutazione finora

- Lift Lug SpreadsheetDocumento2 pagineLift Lug Spreadsheetpgarrett775814233100% (1)

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Pad Foundation With Two Columns ExampleDocumento10 paginePad Foundation With Two Columns ExampleakankwasaNessuna valutazione finora

- Raft+foundationDocumento8 pagineRaft+foundationRavi Kumar100% (3)

- Design of Circular Flat Endplate With Stiffeners - Boiler and Pressure Vessel Engineering - Eng-TipsDocumento2 pagineDesign of Circular Flat Endplate With Stiffeners - Boiler and Pressure Vessel Engineering - Eng-Tipsisrar khanNessuna valutazione finora

- Lifting Lug CalculationDocumento4 pagineLifting Lug CalculationLokesh PatelNessuna valutazione finora

- Saddle Road Transportation Analysis 1Documento2 pagineSaddle Road Transportation Analysis 1vpjagannaathNessuna valutazione finora

- Trunnion Calc r6Documento4 pagineTrunnion Calc r6Chirag Shah50% (2)

- Lifting Lug Calculation RefDocumento2 pagineLifting Lug Calculation Refmarc_albertoNessuna valutazione finora

- Trunnion CalculationDocumento8 pagineTrunnion CalculationPrashant ChauhanNessuna valutazione finora

- FlangeCalc AS1210 v1.5Documento28 pagineFlangeCalc AS1210 v1.5Ben100% (1)

- Weldstrength Calc ProgDocumento10 pagineWeldstrength Calc ProgSajal KulshresthaNessuna valutazione finora

- Thickness CalcuationDocumento6 pagineThickness CalcuationRanjan KumarNessuna valutazione finora

- DEST Pipeline Calculation Rev.1 (By Hasan Asif)Documento11 pagineDEST Pipeline Calculation Rev.1 (By Hasan Asif)Saqib LaeeqNessuna valutazione finora

- Bentley Limcon v3.63Documento4 pagineBentley Limcon v3.63rustamriyadiNessuna valutazione finora

- Flat Head Calculation (Based On Ug 34)Documento2 pagineFlat Head Calculation (Based On Ug 34)rustamriyadiNessuna valutazione finora

- Lifting Lug STD Design 5tDocumento3 pagineLifting Lug STD Design 5trustamriyadi50% (2)

- 0132497468-Ch13 ISMDocumento48 pagine0132497468-Ch13 ISMJeison Rincón Garzón100% (2)

- Advanced Earthquake Resistant Design TechniquesDocumento5 pagineAdvanced Earthquake Resistant Design TechniquesGnanam1Nessuna valutazione finora

- Square Blind Flange With Stiffener ULDocumento5 pagineSquare Blind Flange With Stiffener ULjoeriji100% (1)

- Clamped Cover Plate DesignDocumento7 pagineClamped Cover Plate DesignChiedu OkonduNessuna valutazione finora

- Flat Plate - Roark & YoungDocumento15 pagineFlat Plate - Roark & YoungPrasad Pingle0% (1)

- LIFTING LUG Weld Check KGDocumento4 pagineLIFTING LUG Weld Check KGjoerijiNessuna valutazione finora

- Design of Flanges - Loose Hub Type 2010Documento58 pagineDesign of Flanges - Loose Hub Type 2010bakellyNessuna valutazione finora

- Lifting Lug SampleDocumento1 paginaLifting Lug Sampleabdul marpaung0% (1)

- Blind Flange DesignDocumento1 paginaBlind Flange DesignSachin5586Nessuna valutazione finora

- Bolted Flange Thickness CalculationDocumento6 pagineBolted Flange Thickness Calculationshazan0% (1)

- Structural TrunnionDocumento4 pagineStructural TrunnionecsalomNessuna valutazione finora

- RoarkTable17 (Ring)Documento5 pagineRoarkTable17 (Ring)tekstep7Nessuna valutazione finora

- BuoyancyDocumento1 paginaBuoyancyLcm TnlNessuna valutazione finora

- Saddle CalcDocumento26 pagineSaddle CalcVamsi S100% (2)

- Tailing LugDocumento12 pagineTailing LuguvarajmecheriNessuna valutazione finora

- Design of Saddle Supported VesselsDocumento10 pagineDesign of Saddle Supported Vesselsvikas100% (1)

- Calculation of Trunnions Rev3Documento3 pagineCalculation of Trunnions Rev3Bilel MahjoubNessuna valutazione finora

- Tailing Lug - 173004-05Documento1 paginaTailing Lug - 173004-05shazan100% (1)

- Pipe Is Under Clamping ForceDocumento7 paginePipe Is Under Clamping Forcejosediaz141Nessuna valutazione finora

- Cover Plate CalculationDocumento1 paginaCover Plate CalculationSachin5586Nessuna valutazione finora

- Flange DesignDocumento6 pagineFlange DesignDinesh VaghelaNessuna valutazione finora

- Wind Calculation SheetDocumento32 pagineWind Calculation SheetaauppalNessuna valutazione finora

- Calculation Lifting LugDocumento4 pagineCalculation Lifting Lugelang purbayaNessuna valutazione finora

- New - Reinforcement of NozzleDocumento24 pagineNew - Reinforcement of NozzleVaniya GoelNessuna valutazione finora

- Base Ring Fillet Size CalculationDocumento4 pagineBase Ring Fillet Size Calculationmiteshpatel191Nessuna valutazione finora

- BlindDocumento3 pagineBlindSajal KulshresthaNessuna valutazione finora

- Saddle Reaction Summary - For Empty CaseDocumento12 pagineSaddle Reaction Summary - For Empty CasesridharNessuna valutazione finora

- Annexure - Bolt Torque CalculationDocumento4 pagineAnnexure - Bolt Torque CalculationDarshan PanchalNessuna valutazione finora

- Standard Pad Eye 10T SWL-modifDocumento8 pagineStandard Pad Eye 10T SWL-modifrustamriyadiNessuna valutazione finora

- Lifting Lug DesignDocumento27 pagineLifting Lug Designmramico100% (1)

- Lifting Lug CalculationsDocumento1 paginaLifting Lug CalculationsshazanNessuna valutazione finora

- 302 - Nozzle Design Tool Ver E4.01Documento2 pagine302 - Nozzle Design Tool Ver E4.01Honey TiwariNessuna valutazione finora

- Skirt Support TrialDocumento11 pagineSkirt Support TrialAbhishek Nag50% (2)

- Padeye .5MT CHKDocumento12 paginePadeye .5MT CHKDhanraj VasanthNessuna valutazione finora

- Lifting Lug Calculation For Small Horizontal VesselDocumento2 pagineLifting Lug Calculation For Small Horizontal Vesselmiteshpatel191100% (2)

- Saddle SupportDocumento12 pagineSaddle SupportrustamriyadiNessuna valutazione finora

- Design of Flanges - Welded-On Integral Type 2010Documento59 pagineDesign of Flanges - Welded-On Integral Type 2010bakellyNessuna valutazione finora

- Saddle v1-5: Fixed Saddle Sliding SaddleDocumento9 pagineSaddle v1-5: Fixed Saddle Sliding Saddleduf fuNessuna valutazione finora

- Blind Flange CalculationDocumento12 pagineBlind Flange CalculationrajarajanNessuna valutazione finora

- YoussefDocumento1 paginaYoussefhhgjdfNessuna valutazione finora

- HDD Installation CalculationsDocumento4 pagineHDD Installation Calculationslive4sankar100% (1)

- Baseplate-Kolom wf250Documento79 pagineBaseplate-Kolom wf250Gary JonathanNessuna valutazione finora

- Flat End With A Full-Face Gasket For A Pair of OpeningsDocumento3 pagineFlat End With A Full-Face Gasket For A Pair of OpeningsEng-CalculationsNessuna valutazione finora

- Ibr Stand PipeDocumento11 pagineIbr Stand PipeP s JagatheesanNessuna valutazione finora

- Rectangular Tank Satu LagiDocumento1 paginaRectangular Tank Satu LagiSteve MoonNessuna valutazione finora

- Manual Roark FormulaDocumento5 pagineManual Roark FormulaPeja JusohNessuna valutazione finora

- Larsen & Toubro Limited: 1. Sectional PropertiesDocumento8 pagineLarsen & Toubro Limited: 1. Sectional Propertiesprajjwal patidarNessuna valutazione finora

- Line Pipe THK CalculationDocumento2 pagineLine Pipe THK CalculationRanjan KumarNessuna valutazione finora

- HDD Installation CalculationsDocumento4 pagineHDD Installation CalculationsN FantinNessuna valutazione finora

- Hook Pallet Capacity CalculationDocumento2 pagineHook Pallet Capacity CalculationrustamriyadiNessuna valutazione finora

- Calculation of Lifting (Horizontal Position) Piperack Module 14A 24tons Total WeightDocumento14 pagineCalculation of Lifting (Horizontal Position) Piperack Module 14A 24tons Total WeightrustamriyadiNessuna valutazione finora

- Rectangular Tank Calc - STDDocumento24 pagineRectangular Tank Calc - STDrustamriyadiNessuna valutazione finora

- Lifting Calculation Pipe-Pipe Jn680 Turret Access Structure, Bluewater 110 Ton WeightDocumento10 pagineLifting Calculation Pipe-Pipe Jn680 Turret Access Structure, Bluewater 110 Ton WeightrustamriyadiNessuna valutazione finora

- SPMT BrochureDocumento15 pagineSPMT BrochureAnonymous qT66pyKNessuna valutazione finora

- Shape 2000Documento217 pagineShape 2000rustamriyadiNessuna valutazione finora

- Tutorial Manual Safi PDFDocumento53 pagineTutorial Manual Safi PDFrustamriyadiNessuna valutazione finora

- Spreader 150T - PL100 A36Documento8 pagineSpreader 150T - PL100 A36rustamriyadiNessuna valutazione finora

- Beam DesignDocumento6 pagineBeam DesignrustamriyadiNessuna valutazione finora

- Mech-Intro 13.0 WS07.1 SStherm PDFDocumento14 pagineMech-Intro 13.0 WS07.1 SStherm PDFrustamriyadiNessuna valutazione finora

- Mech-HT 13.0 L05 SteadyStateDocumento9 pagineMech-HT 13.0 L05 SteadyStaterustamriyadiNessuna valutazione finora

- Spreader 150T - PL100 A36Documento8 pagineSpreader 150T - PL100 A36rustamriyadiNessuna valutazione finora

- AnsysDocumento26 pagineAnsysrustamriyadiNessuna valutazione finora

- Weld KcalculationDocumento1 paginaWeld KcalculationrustamriyadiNessuna valutazione finora

- Lifting Lug CalculationDocumento2 pagineLifting Lug Calculationrustamriyadi100% (2)

- Spreader 150T - PL100 A36Documento8 pagineSpreader 150T - PL100 A36rustamriyadiNessuna valutazione finora

- Gusset Plate Stability Using Variable Stress TrajectoriesDocumento6 pagineGusset Plate Stability Using Variable Stress TrajectoriestmaNessuna valutazione finora

- Iqbal Et Al. - 2016 - An Investigation of The Constitutive Behavior of Armox 500T Steel and Armor Piercing Incendiary Projectile MaterialDocumento19 pagineIqbal Et Al. - 2016 - An Investigation of The Constitutive Behavior of Armox 500T Steel and Armor Piercing Incendiary Projectile MaterialvenkatesanjsNessuna valutazione finora

- Handbook For Marine Geotechnical Engineering Version 2Documento256 pagineHandbook For Marine Geotechnical Engineering Version 2José Ignacio RamírezNessuna valutazione finora

- 5.1 Seismic Waves TheoryDocumento50 pagine5.1 Seismic Waves TheoryAFRIADMA AULIA PERDANANessuna valutazione finora

- Effect of Shear Box Size On Shear Strength of SoilDocumento20 pagineEffect of Shear Box Size On Shear Strength of Soillokesh loharNessuna valutazione finora

- TIMBERDocumento4 pagineTIMBERjella21875% (4)

- Block Shear Failure in Steel Members - A Review of Design Practice PDFDocumento11 pagineBlock Shear Failure in Steel Members - A Review of Design Practice PDFJohn PaulsyNessuna valutazione finora

- Finite Element Analysis of Reinforced Concrete CorbelsDocumento5 pagineFinite Element Analysis of Reinforced Concrete CorbelsreenaNessuna valutazione finora

- Bearing Capacity - 2Documento36 pagineBearing Capacity - 2EICQ/00154/2020 SAMUEL MWANGI RUKWARONessuna valutazione finora

- 2D Numerical Analysis of Hydraulic Fracturing in Heterogeneous Geo-Materials - 2009 - c49 PDFDocumento11 pagine2D Numerical Analysis of Hydraulic Fracturing in Heterogeneous Geo-Materials - 2009 - c49 PDFMoataz Hesham SolimanNessuna valutazione finora

- Problems (Axial-Force 2)Documento8 pagineProblems (Axial-Force 2)Haftom Gebreegziabiher100% (1)

- Three Major Design PhilosophiesDocumento4 pagineThree Major Design PhilosophiesFatima Ahmed100% (1)

- Auckland Uni International Formblock TestDocumento30 pagineAuckland Uni International Formblock TestNoe LandaverdeNessuna valutazione finora

- Chap 6 Graphical Method UpdatedDocumento11 pagineChap 6 Graphical Method UpdatedAhmad IkhwanNessuna valutazione finora

- Ipc2022-87090 Modification of Existing Pipeline Corrosion Assessment Methods ForDocumento9 pagineIpc2022-87090 Modification of Existing Pipeline Corrosion Assessment Methods ForOswaldo MontenegroNessuna valutazione finora

- Final Exam OutlineDocumento2 pagineFinal Exam OutlineBilal BatroukhNessuna valutazione finora

- CIVL311 CIVL911 2019 Sample Examination 2Documento3 pagineCIVL311 CIVL911 2019 Sample Examination 2Mah KanxuNessuna valutazione finora

- Structure II: Course Code: ARCH 209Documento29 pagineStructure II: Course Code: ARCH 209layaljamal2Nessuna valutazione finora

- 1 s2.0 S0142112316303723 MainDocumento12 pagine1 s2.0 S0142112316303723 MainClaudio JuniorNessuna valutazione finora

- 321 Chapter 5 Splice DesignDocumento91 pagine321 Chapter 5 Splice DesignHemant Ramesh NarkarNessuna valutazione finora

- ការសិក្សាគណនាមុខកាត់បេតុងពង្រឹងដោយដែក Reinforced concrete khmerDocumento725 pagineការសិក្សាគណនាមុខកាត់បេតុងពង្រឹងដោយដែក Reinforced concrete khmerBunlyNessuna valutazione finora

- Final PresentationDocumento24 pagineFinal PresentationJoy DumlaoNessuna valutazione finora

- Manutapen Baru BH. 02 Dan BHDocumento11 pagineManutapen Baru BH. 02 Dan BHRektorUnitelNessuna valutazione finora

- Diagrid Mono Column Structures With Different Geometry in Plan A ReviewDocumento6 pagineDiagrid Mono Column Structures With Different Geometry in Plan A ReviewIJRASETPublicationsNessuna valutazione finora

- Comparison Between Pushover Analysis Techniques and Validation of The Simplified Modal Pushover AnalysisDocumento12 pagineComparison Between Pushover Analysis Techniques and Validation of The Simplified Modal Pushover AnalysisMahmut KarataşNessuna valutazione finora

- D 3737 - 03 RDM3MZCDocumento28 pagineD 3737 - 03 RDM3MZCIsrael Orta SánchezNessuna valutazione finora