Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Maintenance Planning: Brian Parsons of Foresight Solutions Says To Have A First Rate Planning System Makes All The

Caricato da

Anonymous OuY6oAMggxTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Maintenance Planning: Brian Parsons of Foresight Solutions Says To Have A First Rate Planning System Makes All The

Caricato da

Anonymous OuY6oAMggxCopyright:

Formati disponibili

MAINTENANCE

Maintenance planning

Brian Parsons of Foresight Solutions says to have a first rate planning system makes all the

difference in the world

H

e who every morning plans the to implement any new standards or programs

transaction of the day and follows out that come down the line and must be

that plan, carries a thread that will responsible for implementing improvements or

guide him through the maze of the most busy special projects. Of course at sometime they

life. But where no plans are laid, where the need to plan the work that is required to not

disposal of time is surrendered merely to only keep the place running but also moving

chance of incidence, chaos will soon reign: forward.

Victor Hugo (1802 1885). Many who work in Lets go back to our 85% compliance to

mine maintenance will probably tell you that plan and 35% breakdown scenario to see

chaos not only reigns but has moved in and what is going on, assuming that such a result

set up shop. This is not because no planning is even possible. Managers for the most part

goes into mine maintenance; in fact many like to look at and make decisions based on

mining operations have entire departments numbers and as the planners have little or no

dedicated to maintenance planning. The control, to say nothing of the required support,

problem in many instances is that the effort to make their plans work, they devise ways to

that goes into creating those plans is not make the compliance to plan number appear

matched by the support required to make high. Why? because that is the standard

them effective. Take for example a hypothetical that management has decreed as the

Monday morning when all the parts, people measurement for the effectiveness of the

and resources are ready to service a slurry maintenance program. There is nothing to

pump which was planned at least a week ago. suggest anyone is being deliberately deceitful,

Just when the crew are about to lock out the it is just due to such a lack of control and

system someone informs them that support that to be held accountable for the

Operations has decided that they need that Photo courtesy of www.ormarc.com.au level of compliance to plan under such

pump and Maintenance cannot have it for circumstances is much more than the stress

service. It is about this time the maintenance level is worth. As many mines continuously

planner gets the call about the change in just a bit odd, in fact it just cant be or at least discover; such a scenario often leads to the

plan. As this is not an uncommon occurrence. that is what you would think until you delve mine coming dangerously close to being

The planner looks at what is on the backlog into what is really happing at this planning unviable.

list and then tries to put together some type of department. What you will discover is a system Is there a way to get away from such a

plan to try and salvage the rest of the day, if that has most of the tools, personnel and path? Fortunately there is and the wheel need

not the rest of the week. Meanwhile later that wherewithall to do the job the way it should not be reinvented to get it done.

same week the pump fails late at night and be done the way it must be done if it is to The first step is to put in place the required

has to remain out of service until those same be the major contributing factor in an support system that will make the planning

people, parts and resources can be operations viability. department a truly functioning entity. Such

reassembled in the same way they were on The difficulty lies in two particular truths; support would include a parts manager/chaser.

Monday morning. the first is for the majority of mines, The role of this individual is not only to ensure

At first glance this situation would seem to Operations are the king of the hill, the that the parts for planned work are ordered

be not much more than an inconvenience or masters of destiny as it were, when it comes to and on site as required but also to be the go

perhaps a loss of common sense, but not the how the maintenance department actually to person for parts required for the unplanned

symptom of a problem that plagues many functions. In some cases Maintenance is the or unforeseen. That role would also provide

mining operations around the world. As a rule, black sheep of the organisation its opinions part kits for standard jobs, to reduce delays in

a mine with a viable cost structure will most discounted or even ignored and yet they are part availability. One more thing as it relates to

likely have a fairly well run maintenance blamed when things are not running as parts; as the planning and implementation of

planning department. However, it would not expected. The second is that planning is maintenance improves, the parts for the NWL

be uncommon to have a manager say that we anything but and planners are the catch all for (Now What List) will be greatly reduced as

have a first rate planning department yet our most of the tasks that take place in breakdowns and unforeseen problems

cost structure leaves a great deal to be desired. Maintenance. For example they end up chasing diminish.

Upon closer inspection you will find that what parts for the planned and unplanned work; A standard work program should be

this manager has in reality is a department that they are usually the contact person for many developed to have the steps, parts and

has an 85% compliance to plan, while it has a of the vendors that supply the operations with resources required for each job laid out in such

breakdown rate of 35% or more. More than services related to maintenance; are expected a manner that each job can be better planned,

34 International Mining MARCH 2010

MAINTENANCE

understood and the quality of the work prosper when times are good from those who would also act as liaison to Operations in an

measured and not left to depend on the may not make it through those same hard effort to ensure that both Operations and

individual doing the work, to say nothing of times and hope for the best when times are Maintenance are playing on the same team.

ensuring that it is done safely. better. Maintenance planners are well versed Last, but certainly not least, upper

One of the key components to any plan is in the improvements needed to systems and management is the key required to tie all this

information about what actually needs to be equipment as they constantly have to do what together. It must engage the planners and

done and when. The inclusion of a PM they can to make them function as reliably as everyone who has a stake in the establishment

inspector in the planning support system is as possible. Any ideas for improvements are of a first class planning department, to listen

important, if not more so, than any other necessarily mixed in with all the planners to their concerns and to require that the

element required to make maintenance work other obligations. Some will do what they can information the planning department passes

as it should. This individual need not be the to make the improvements happen while along to management is based on facts not

most senior or even the most experienced others simply give up in the face of misguided standards. Upper management

person available but should have the ability to overwhelming demands on their time. A must commit to putting the support system in

use his or her experience to make decisions on person or office in place to support the place so that the planners can do what they

what work needs to be done and in what planning department in moving continuous need to do, above all else Plan and have

order as they inspect equipment in the improvement projects forward would pay for those plans become effective. The alternative is

assigned area so that the planner has eyes; itself many times over as these projects start what you will find in so many mines, where

ears and legs on the floor. It is also important to deliver benefits of reduced and unplanned front line maintenance manages to run

that the PM inspector works with the planner downtime. somewhat in spite of itself.

and no one else certainly not used to make It is said that if you cant beat them, join Of course, questions of how much this will

up shortfalls in manpower. This may mean that them. In the case of a well run and supported all cost in time and money will not take long

a particular crew or department may have to planning office it is a case of have them join, to arise. As many of us that have been in the

take a hit; but as the overall condition of the the them being Operations. This is done by mine maintenance business for any length of

maintenance system improves, the benefits will having an operations planner as part of the time know only too well, when it comes right

far outweigh any temporary inconvenience. maintenance planning office. Operations down to it quite often there is never enough

Continuous improvement is more than just a personnel have certain responsibilities when it time or money to do it right, but there always

phrase, it is the cornerstone to human comes to some maintenance jobs and it would seems to be plenty to do it over and over

evolution. When it comes to mining, be the task of the operations planner to ensure again. The bottom line is that to have a first

continuous improvement is the key factor that that these responsibilities are co-ordinated with rate planning system makes all the difference

separates those who weather hard times and the maintenance needs of the plan. They in the world. IM

in B Mee

Efciency in the hardest S t M u nA U M t u s

an

d N ich A 20 at

mining conditions o. 19 10

11 26

0,

Ha Apr

ll C il

2

DFM ZANAM-LEGMET designes machines

for different underground applications.

Our products comprise complete mining and

haulage systems and are successfully operated in

the whole production cycle.

Our mission is to deliver the most effective

solutions for mining. We produce the machines that

are easy to operate, reliable and examined in the

toughest mining conditions. LHDs with bucket volumes 1.6 8.5 m3

Haulage Trucks Vehicles for Ripping Drilling & Bolting Rigs Crushers

DFM ZANAM-LEGMET sp. z o.o.

ul. Kopalniana 7, 59-101 Polkowice, Poland

Trade Department Marketing Department

tel. (+48) 76 7468 481 tel. (+48) 76 8470 822, 823

trade@zanam-legmet.pl marketing@zanam-legmet.pl www.zanam-legmet.pl

MARCH 2010 International Mining 35

Potrebbero piacerti anche

- Creating a Project Management System: A Guide to Intelligent Use of ResourcesDa EverandCreating a Project Management System: A Guide to Intelligent Use of ResourcesNessuna valutazione finora

- Turnaround PlanDocumento9 pagineTurnaround PlanShaheen Parveen100% (2)

- The Central IssueDocumento3 pagineThe Central IssueJosé RodríguezNessuna valutazione finora

- Effective Preparation For TurnaroundsDocumento3 pagineEffective Preparation For Turnaroundsreguii100% (1)

- Strengthening The Business Continuity Process With Methodical DrillsDocumento5 pagineStrengthening The Business Continuity Process With Methodical DrillsHaroon RasheedNessuna valutazione finora

- Planning Flow-2003Documento9 paginePlanning Flow-2003juncos0729Nessuna valutazione finora

- 5 Ways To Break Out of The Reactive Maintenance Cycle of DoomDocumento5 pagine5 Ways To Break Out of The Reactive Maintenance Cycle of DoomElvis DiazNessuna valutazione finora

- 5 Reasons Why PM Plans Can Contribute To Poor Asset ReliabilityDocumento9 pagine5 Reasons Why PM Plans Can Contribute To Poor Asset ReliabilityYury FedichkinNessuna valutazione finora

- Releasing Project TeamDocumento3 pagineReleasing Project TeamChassel ParasNessuna valutazione finora

- Best Strategy For Asset Integrityweb 140129045704 Phpapp01Documento9 pagineBest Strategy For Asset Integrityweb 140129045704 Phpapp01cassindromeNessuna valutazione finora

- Availability-Based Maintenance Within An Asset Management ProgrammeDocumento12 pagineAvailability-Based Maintenance Within An Asset Management Programmeignite182Nessuna valutazione finora

- Maintenance Work Planning & SchedulingDocumento4 pagineMaintenance Work Planning & Schedulingcenk saral100% (1)

- Great Maintenance SupervisorsDocumento7 pagineGreat Maintenance SupervisorsJair T100% (1)

- Maintenance Frequency Optimization Tools and ProcessesDocumento19 pagineMaintenance Frequency Optimization Tools and Processesfzida8942Nessuna valutazione finora

- Why Asset Integrity Implementation FailsDocumento2 pagineWhy Asset Integrity Implementation Failsmohsen m.aghabeglouNessuna valutazione finora

- Why Asset Integrity Implementation FailsDocumento2 pagineWhy Asset Integrity Implementation Failsmohsen m.aghabeglouNessuna valutazione finora

- CEng Interview QuestionsDocumento17 pagineCEng Interview Questionsgyan100% (1)

- Six Sigma Yellow Belt Project PROJECTDocumento4 pagineSix Sigma Yellow Belt Project PROJECTSarweshwaranand PandeyNessuna valutazione finora

- TPM Newsletter Quarter 3 October 2016Documento7 pagineTPM Newsletter Quarter 3 October 2016Quality HosurNessuna valutazione finora

- Swift PursuitDocumento5 pagineSwift PursuitadamNessuna valutazione finora

- Pemeco Inc.: Rapid ERP DeploymentsDocumento5 paginePemeco Inc.: Rapid ERP DeploymentsLuis MalpartidaNessuna valutazione finora

- Operational ReadinessDocumento14 pagineOperational Readinesszubin orchasNessuna valutazione finora

- 10 Principles of ManufacturingDocumento4 pagine10 Principles of Manufacturingsarwan85806167% (3)

- Ammj July Ricky Smith Article W CoverDocumento5 pagineAmmj July Ricky Smith Article W CoverSrđan KrsteljNessuna valutazione finora

- How To Build An Electrical Maintenance ProgramDocumento5 pagineHow To Build An Electrical Maintenance ProgramJayson Jonson AraojoNessuna valutazione finora

- Maintenance Planning Is Too Hard in My WorkplaceDocumento4 pagineMaintenance Planning Is Too Hard in My WorkplaceambiabaNessuna valutazione finora

- Dbvisit Disaster Recovery Planning ChecklistDocumento2 pagineDbvisit Disaster Recovery Planning ChecklistAkram M. Almotaa100% (1)

- The Disaster Recovery Planning ProcessDocumento30 pagineThe Disaster Recovery Planning ProcessMuhammad JawadNessuna valutazione finora

- Disaster Recovery Management 10 Things Your Staff Is Afraid To Tell You MRP WPS 089Documento8 pagineDisaster Recovery Management 10 Things Your Staff Is Afraid To Tell You MRP WPS 089scapasNessuna valutazione finora

- Discussion Paper: Topic: Rating and Prioritizing An Organization's Functions For Continuity PlanningDocumento9 pagineDiscussion Paper: Topic: Rating and Prioritizing An Organization's Functions For Continuity PlanningasfawmNessuna valutazione finora

- Lean Leadership From The Shop Floor SupervisorDocumento4 pagineLean Leadership From The Shop Floor SupervisorVictor Estrada Díaz100% (1)

- Maintenance Planning Is Too HardDocumento4 pagineMaintenance Planning Is Too HarddachrydaxNessuna valutazione finora

- The Reliability Leaders Guide To Maintenance Strategy OptimizationDocumento11 pagineThe Reliability Leaders Guide To Maintenance Strategy OptimizationOmayr QureshiNessuna valutazione finora

- Principle of Planning and Control (PPIC) BingDocumento10 paginePrinciple of Planning and Control (PPIC) BingAngela Ayu DewiNessuna valutazione finora

- The Essential Guide To Predictive MaintenanceDocumento11 pagineThe Essential Guide To Predictive Maintenancezemed bamlakuNessuna valutazione finora

- Planning and Scheduling MaterialDocumento4 paginePlanning and Scheduling MaterialIrete FemiNessuna valutazione finora

- Session 1: Introduction To Production Planning and The Last Planner SystemDocumento7 pagineSession 1: Introduction To Production Planning and The Last Planner SystemMohamed AhmedNessuna valutazione finora

- Maintenance Planning Is To Hard To My WorklplaceDocumento4 pagineMaintenance Planning Is To Hard To My WorklplaceFery HartantoNessuna valutazione finora

- Temporary Shutdown's Five Phases Phase #1: PlanningDocumento3 pagineTemporary Shutdown's Five Phases Phase #1: PlanningParth PurandareNessuna valutazione finora

- Poor WeatherDocumento6 paginePoor Weather漡沁Nessuna valutazione finora

- The Value of PPM: 6 Proven Tools For Project SuccessDocumento5 pagineThe Value of PPM: 6 Proven Tools For Project Successkallolshyam.roy2811Nessuna valutazione finora

- Maintenance BacklogDocumento10 pagineMaintenance BacklogsarifinNessuna valutazione finora

- 10 Reasons Why Mntnce FailsDocumento7 pagine10 Reasons Why Mntnce FailsCyrix.OneNessuna valutazione finora

- Plant Enginerring ManagementDocumento4 paginePlant Enginerring ManagementTHEOPHILUS ATO FLETCHERNessuna valutazione finora

- Bringing Discipline To Project ManagementDocumento12 pagineBringing Discipline To Project ManagementRoyNessuna valutazione finora

- Turnaround ProcessDocumento24 pagineTurnaround Processiradanke100% (1)

- SERTICA - 7 Challenges in Technical Ship ManagementDocumento11 pagineSERTICA - 7 Challenges in Technical Ship ManagementSamuel ChanNessuna valutazione finora

- The Critical Chain DifferenceDocumento10 pagineThe Critical Chain Differencemy.nafi.pmp5283Nessuna valutazione finora

- The Disaster Recovery Planning ProcessDocumento30 pagineThe Disaster Recovery Planning ProcessSwethaNessuna valutazione finora

- AT Kearney ERP MythsDocumento11 pagineAT Kearney ERP MythsSamirNessuna valutazione finora

- BAIN BRIEF When The Front Line Should Lead A Major TransformationDocumento8 pagineBAIN BRIEF When The Front Line Should Lead A Major TransformationsilmoonverNessuna valutazione finora

- Project Mg. AssignmentDocumento4 pagineProject Mg. AssignmentMuhammad TayyabNessuna valutazione finora

- Angotti Product Development: Project ImprovementDocumento7 pagineAngotti Product Development: Project ImprovementTony MorrowNessuna valutazione finora

- Plant Management TafskillsDocumento4 paginePlant Management TafskillsTHEOPHILUS ATO FLETCHERNessuna valutazione finora

- Plant Management TafskillsDocumento4 paginePlant Management TafskillsTHEOPHILUS ATO FLETCHERNessuna valutazione finora

- TW98 The Project Management Top TenDocumento5 pagineTW98 The Project Management Top TenrproserpioNessuna valutazione finora

- Best Practices For Planners and Schedulers: WhitepaperDocumento4 pagineBest Practices For Planners and Schedulers: Whitepaperaaakengyahoo.comNessuna valutazione finora

- C1S - Shutdown Coordination White PaperDocumento4 pagineC1S - Shutdown Coordination White PaperNaresh GanisonNessuna valutazione finora

- 2012-21 Action Tracking v0Documento2 pagine2012-21 Action Tracking v0Aayushi AroraNessuna valutazione finora

- Disaster Recovery Project Plan SampleDocumento10 pagineDisaster Recovery Project Plan SampleRPNessuna valutazione finora

- MPS Day1 World Class Reliability PerformanceDocumento142 pagineMPS Day1 World Class Reliability Performancemelator100% (1)

- We Amp 2013Documento339 pagineWe Amp 2013Anonymous OuY6oAMggxNessuna valutazione finora

- Project Management ProcessDocumento18 pagineProject Management Processvineetkrs002Nessuna valutazione finora

- Senior Asset Planner - M&E (HDWKS)Documento8 pagineSenior Asset Planner - M&E (HDWKS)Anonymous OuY6oAMggxNessuna valutazione finora

- Mini-Fill Touch Manual v2 en 2016Documento30 pagineMini-Fill Touch Manual v2 en 2016Anonymous OuY6oAMggxNessuna valutazione finora

- Draw Now 30 Easy Exercises For BeginnersDocumento78 pagineDraw Now 30 Easy Exercises For BeginnersDanut Alexandru100% (1)

- Position Description - Reliability EngineerDocumento7 paginePosition Description - Reliability EngineerAnonymous OuY6oAMggxNessuna valutazione finora

- PROJECT MANAGERS Implementation ManualDocumento127 paginePROJECT MANAGERS Implementation ManualAnonymous OuY6oAMggxNessuna valutazione finora

- Position Description - Electrical Asset Engineer - February 2016Documento2 paginePosition Description - Electrical Asset Engineer - February 2016Anonymous OuY6oAMggxNessuna valutazione finora

- Position Description - Reliability EngineerDocumento7 paginePosition Description - Reliability EngineerAnonymous OuY6oAMggxNessuna valutazione finora

- NB604n Wireless Setup GuideDocumento33 pagineNB604n Wireless Setup GuideAnonymous OuY6oAMggxNessuna valutazione finora

- Senior Asset Planner - M&E (HDWKS)Documento8 pagineSenior Asset Planner - M&E (HDWKS)Anonymous OuY6oAMggxNessuna valutazione finora

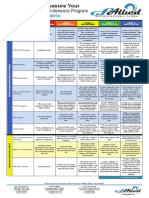

- Gpalliedmaturitymatrix8planning Scheduling1rev3 130926135255 Phpapp02 PDFDocumento2 pagineGpalliedmaturitymatrix8planning Scheduling1rev3 130926135255 Phpapp02 PDFAnonymous OuY6oAMggxNessuna valutazione finora

- Productflyer - 978 3 319 02677 0Documento1 paginaProductflyer - 978 3 319 02677 0Anonymous OuY6oAMggxNessuna valutazione finora

- MPS Day1 World Class Reliability PerformanceDocumento142 pagineMPS Day1 World Class Reliability Performancemelator100% (1)

- BobResume ReliabilityDocumento7 pagineBobResume ReliabilityAnonymous OuY6oAMggxNessuna valutazione finora

- Maturity Matrix: Preventive Maintenance ProgramDocumento2 pagineMaturity Matrix: Preventive Maintenance ProgramAnonymous OuY6oAMggx100% (1)

- Maturity Matrix: Preventive Maintenance ProgramDocumento2 pagineMaturity Matrix: Preventive Maintenance ProgramAnonymous OuY6oAMggx100% (1)

- 11 - 8 Steps To Success in Maintenance Planning and Scheduling PDFDocumento42 pagine11 - 8 Steps To Success in Maintenance Planning and Scheduling PDFmsaad19103564100% (2)

- Project Management "Made Simple": Using Technical and Behavioral Quick ConnectsDocumento30 pagineProject Management "Made Simple": Using Technical and Behavioral Quick ConnectsAnonymous OuY6oAMggxNessuna valutazione finora

- Maintenanceplanner PDFDocumento3 pagineMaintenanceplanner PDFAnonymous OuY6oAMggxNessuna valutazione finora

- Maintenance Planner Job DescriptionDocumento4 pagineMaintenance Planner Job Descriptionansar shafiiNessuna valutazione finora

- Maintenance Planner Role ResponsibilitiesDocumento2 pagineMaintenance Planner Role ResponsibilitiesAnonymous OuY6oAMggxNessuna valutazione finora

- Document 1Documento2 pagineDocument 1Anonymous OuY6oAMggxNessuna valutazione finora

- Document 1Documento5 pagineDocument 1Anonymous OuY6oAMggxNessuna valutazione finora

- VardonDocumento2 pagineVardonAnonymous OuY6oAMggxNessuna valutazione finora

- Document 1Documento5 pagineDocument 1Anonymous OuY6oAMggxNessuna valutazione finora

- Karma Cola LTD Credit Application FormDocumento4 pagineKarma Cola LTD Credit Application FormAnonymous OuY6oAMggxNessuna valutazione finora

- Karma Cola LTD Credit Application FormDocumento4 pagineKarma Cola LTD Credit Application FormAnonymous OuY6oAMggxNessuna valutazione finora

- Cognitive Coaching AdelaideDocumento3 pagineCognitive Coaching AdelaideBusiness-Edu100% (2)

- Skills Check Extra 2ADocumento1 paginaSkills Check Extra 2AVishmi JayawardeneNessuna valutazione finora

- Lesson 3 - Adaptation AssignmentDocumento3 pagineLesson 3 - Adaptation AssignmentEmmy RoseNessuna valutazione finora

- A List of 142 Adjectives To Learn For Success in The TOEFLDocumento4 pagineA List of 142 Adjectives To Learn For Success in The TOEFLchintyaNessuna valutazione finora

- 02 Laboratory Exercise 1Documento2 pagine02 Laboratory Exercise 1Mico Bryan BurgosNessuna valutazione finora

- Deictics and Stylistic Function in J.P. Clark-Bekederemo's PoetryDocumento11 pagineDeictics and Stylistic Function in J.P. Clark-Bekederemo's Poetryym_hNessuna valutazione finora

- Vicente BSC2-4 WhoamiDocumento3 pagineVicente BSC2-4 WhoamiVethinaVirayNessuna valutazione finora

- Market Structure and TrendDocumento10 pagineMarket Structure and TrendbillNessuna valutazione finora

- Jail Versus Substance Abuse TreatmentDocumento5 pagineJail Versus Substance Abuse Treatmentapi-240257564Nessuna valutazione finora

- 8A L31 Phiếu BTDocumento7 pagine8A L31 Phiếu BTviennhuNessuna valutazione finora

- Libel Arraignment Pre Trial TranscriptDocumento13 pagineLibel Arraignment Pre Trial TranscriptAnne Laraga LuansingNessuna valutazione finora

- Dreizler EDocumento265 pagineDreizler ERobis OliveiraNessuna valutazione finora

- 2015 Grade 4 English HL Test MemoDocumento5 pagine2015 Grade 4 English HL Test MemorosinaNessuna valutazione finora

- T2 Group4 English+for+BusinessDocumento8 pagineT2 Group4 English+for+Businessshamerli Cerna OlanoNessuna valutazione finora

- Major Stakeholders in Health Care SystemDocumento5 pagineMajor Stakeholders in Health Care SystemANITTA S100% (1)

- Smashing HTML5 (Smashing Magazine Book Series)Documento371 pagineSmashing HTML5 (Smashing Magazine Book Series)tommannanchery211Nessuna valutazione finora

- Chapter 3-CP For Armed Conflict SituationDocumento23 pagineChapter 3-CP For Armed Conflict Situationisidro.ganadenNessuna valutazione finora

- Description About Moon: Earth SatelliteDocumento6 pagineDescription About Moon: Earth SatellitePurva KhatriNessuna valutazione finora

- FBISE Grade 10 Biology Worksheet#1Documento2 pagineFBISE Grade 10 Biology Worksheet#1Moaz AhmedNessuna valutazione finora

- C7.5 Lecture 18: The Schwarzschild Solution 5: Black Holes, White Holes, WormholesDocumento13 pagineC7.5 Lecture 18: The Schwarzschild Solution 5: Black Holes, White Holes, WormholesBhat SaqibNessuna valutazione finora

- A Meta Analysis of The Relative Contribution of Leadership Styles To Followers Mental HealthDocumento18 pagineA Meta Analysis of The Relative Contribution of Leadership Styles To Followers Mental HealthOnii ChanNessuna valutazione finora

- MultiZone Limitations and HintsDocumento2 pagineMultiZone Limitations and HintsRubén Darío Becerra GalindoNessuna valutazione finora

- Diagnostic Test Everybody Up 5, 2020Documento2 pagineDiagnostic Test Everybody Up 5, 2020George Paz0% (1)

- Solitax SCDocumento8 pagineSolitax SCprannoyNessuna valutazione finora

- Duties and Responsibilities - Filipino DepartmentDocumento2 pagineDuties and Responsibilities - Filipino DepartmentEder Aguirre Capangpangan100% (2)

- Advantages of The CapmDocumento3 pagineAdvantages of The Capmdeeparaghu6Nessuna valutazione finora

- NHD Process PaperDocumento2 pagineNHD Process Paperapi-122116050Nessuna valutazione finora

- Kpolovie and Obilor PDFDocumento26 pagineKpolovie and Obilor PDFMandalikaNessuna valutazione finora

- ARHAM FINTRADE LLP - Company, Directors and Contact Details Zauba CorpDocumento1 paginaARHAM FINTRADE LLP - Company, Directors and Contact Details Zauba CorpArun SonejiNessuna valutazione finora

- Mystakidis2022 MetaverseDocumento13 pagineMystakidis2022 MetaverseVennela NandikondaNessuna valutazione finora