Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Qap Gate Valve

Caricato da

Ajit PatilCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Qap Gate Valve

Caricato da

Ajit PatilCopyright:

Formati disponibili

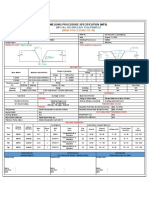

QUALITY ASSURANCE PLAN

QAP NO; CQa 0701 R1

Cast valve - GGC (Ctass 1f0/300/600) )ATE :15-07-200s

o

ts

CUSTOMER MANUFAcTURiR : KSB PUMPS LIMITTE

q

o P,O. No. SALES ORDER NO.

N 2I

PROJECT , MATERIAL oF corusrRucttoN : carbon/Anoy/staintess steet

I

(1, 11, (3) (4) (5) (6i (7) (8) (s) (1 0)

sr. Component & FOnnat Agency

Characteristic Quantum Reference Acceptance

Type of check of Remarks

d No. Operation of check Document Norms P w

Fsearr{ R

'1.0 RAW MATERIAL & BOUGHT OUT COMPONENTS

'1 I Body, Bonnet -

a) Chemical compositjon T.C. Review 1 / Heat ASTM std ASTM std MTC 1 ,1,

and Cover b) Mech. Properties T.C. Review 1 / Heat ASTM std ASTM std MTC 1 2,3

c) Surface finish Visual 100% MSS SP 55 IVSS SP 55 GR 12

d) Dimensional Measurement Sampling KSB drg. KSB drg. GR 1,2

qlby steel

fl NDT MT laoo/. ASTM E7O9 ASME 816.34 TR I 2

rnly

1.2 Trim Material a) Chemical composition T C. Review 1 / Heat ASTM std ASTM std vtTc 1 2

{Stem, disc , b) Mech. Properties T.C. Review 1 I Heat ASTM std ASTM Sld \/tTc 1 2

wedge,seat ) c) Surface finish Visual Sampling ASTM std ASTM std 3R 1,2

d) Dimensional Measurement Sampling KSB drg KSB drg JK

IJ Fasleners a) Chemical composition T.C. Review 1 / Heat ASTM std ASTM std MTC 1

Stud/Nut b) Mech. Properties T.C. Review 1 / Heat ASTM std ASTM Std !tTc 1

I

c) Surface finish Visual Sampling ASTM std ASTM std 3R 1,2

d) Dimensional Thread check Sampling ASME std ASME std JK \.2

t.9 Bought out itenis d, vuil tPlrdt rLtr LU. RCVIEW 'iiitem tvttr uul ilp. t u 1 z

Gland Facking b) Dimensional Measurement Sampling (SB drg KSB org GR 1.2

Gasket etc.

2.0 IN PROCESS

2.1 All machined a) Workmanship & finish Visual 100% KSB drg. KSB drg. POCR 2

components b) Drmensional Measurement Sampling KSB drg. KSB drg POCR 2

St6 surface &

2.2 a) Surface defects PT 100% ASTM E165 ASME 816,34 POCRTIR 2

Butt Weld Ends

Trim Hard Face t) Hardness Hardness check Sampling KSB Std KSB SId POCR/IR a

3,0 FINAL INSPECTION & TESTING

3.1 Assembied valve a) Assembly Visual 100% Run card Run card 2

Hydro / As per Drg /

b) lnlegrity /'festing 1000/o APt 598 vtc 2 )a Note

Pneumatic Test API 5S8 1

Manual / Motor /

c) Operation 100% As per Drg. As per Drg. vrc 2 I,J ta Note 1

Gear Box

d) Overall Dimensiorrs Measurement Sampling As per Drg. As per Drg. vtc ? ae Note 1

4.0 racking a) Packing quality Visual rca% KSB procedure KSB procedure 2

5.0 :inal a) Compilation oI Verification Pu rchase Purchase Release

locumentaiion Documents Order Order note

TR i IR - TEST REPORTI INSPECTION REPORT MT - MAGNETIC PARTICLE TEST P - PERFORMED BY

MTC. MATERIAL TEST CERTIFICATE PT. LIQUID PENETRANT TEST W. WITNESSED BY

POCR - PRODUCTION ORDER CONFIRMATION REPORT R - REVIEW BY

MIP. MATERIAL INSPECTION PLAN

VIC - VALVE INSPECTION CERTIFICATE 1 . SUPPLIER

GR - GOODS RECEIPT 2. MANUFACTURER

3 - III FARTY / CLIENT INSPECTION

Name Siqnatu re Date Note.l:

Prepared by R.SIVANESAN (.Annimrnrr 1 5^07-200{ a) Witness if speciiied in P.O. subject to 100/0 of Total qty

LL

Checked by M.SUBRAMANIAM ,\[[f,-- 1 5-07-200{ b) No Third Party / Client lnspection for IBR certified valves.

Approved by R.KUMAR rlllr. 1 5-07-200{

Potrebbero piacerti anche

- IRN - 18.07.2019 - Harshad Panchal - Revision-0 - Furnace Fabrica - JNK - PORVAIR - RIL PDFDocumento3 pagineIRN - 18.07.2019 - Harshad Panchal - Revision-0 - Furnace Fabrica - JNK - PORVAIR - RIL PDFsaptarshi jashNessuna valutazione finora

- Welding Procedure Specification (WPS) Pipeline: Lower Than PQR Preheat TempDocumento1 paginaWelding Procedure Specification (WPS) Pipeline: Lower Than PQR Preheat TempPanneer SelvamNessuna valutazione finora

- TDC 004 CS Fittings r0Documento1 paginaTDC 004 CS Fittings r0samkarthik47Nessuna valutazione finora

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Documento4 pagineAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- Test Certification PDFDocumento1 paginaTest Certification PDFDany ChlNessuna valutazione finora

- A106 Seamless Carbon Steel Pipe: Hydrostatic TestingDocumento7 pagineA106 Seamless Carbon Steel Pipe: Hydrostatic TestingTan Chee MingNessuna valutazione finora

- TDC - CS PipeDocumento1 paginaTDC - CS PipetrushalpanchalNessuna valutazione finora

- MSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryDocumento1 paginaMSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryMohd SaffririzalNessuna valutazione finora

- Wps MainlineDocumento5 pagineWps MainlineAlfian FebriansyahNessuna valutazione finora

- Fit - Up and Visual Examination Report: Attachment Drawing Joint DetailDocumento1 paginaFit - Up and Visual Examination Report: Attachment Drawing Joint DetailMuhammad Fitransyah Syamsuar Putra100% (1)

- Standard Inspection and Test Plan For Api6D Valves: A GSL Company - Quality EndorsedDocumento4 pagineStandard Inspection and Test Plan For Api6D Valves: A GSL Company - Quality EndorsednithyaNessuna valutazione finora

- Visual Examination ProcedureDocumento23 pagineVisual Examination ProcedureEdAlmNessuna valutazione finora

- Raw Material MTC - API 5L GR B PSL 2Documento3 pagineRaw Material MTC - API 5L GR B PSL 2ClarkFedele27Nessuna valutazione finora

- Curriculum Vitae: Total Experience 18.1 YearsDocumento7 pagineCurriculum Vitae: Total Experience 18.1 Yearskbpatel123Nessuna valutazione finora

- Material Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureDocumento1 paginaMaterial Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureMohamed RaafatNessuna valutazione finora

- ASME U & UM Stamp Certification ProcessDocumento11 pagineASME U & UM Stamp Certification ProcessMd Anamul HoqueNessuna valutazione finora

- WPS-PQR ListDocumento1 paginaWPS-PQR ListSandra SandersNessuna valutazione finora

- Welding Procedure Welding Procedure Specification SpecificationDocumento2 pagineWelding Procedure Welding Procedure Specification SpecificationHamid MansouriNessuna valutazione finora

- Form UT, MT, PT, RTDocumento5 pagineForm UT, MT, PT, RTLuong Ho Vu100% (1)

- Reliance Industries Limited Line History Sheet For CS Piping Without PWHTDocumento1 paginaReliance Industries Limited Line History Sheet For CS Piping Without PWHTRavi ShankarNessuna valutazione finora

- Nde Map & Nde Procedure (Sudah Di Revisi)Documento4 pagineNde Map & Nde Procedure (Sudah Di Revisi)Hardika SambilangNessuna valutazione finora

- Lot Inspection Report For LPG New CylindersDocumento3 pagineLot Inspection Report For LPG New CylindersJagannath MajhiNessuna valutazione finora

- Tuv India Private Limited: Inspection Visit ReportDocumento5 pagineTuv India Private Limited: Inspection Visit ReportAkhtar aliNessuna valutazione finora

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocumento3 pagineN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNessuna valutazione finora

- Requirement For Wn/Blind Flanges Astm A182 F316L/316L: INQ - 610 Rev.: A Page: 1 of 1 Doc NoDocumento1 paginaRequirement For Wn/Blind Flanges Astm A182 F316L/316L: INQ - 610 Rev.: A Page: 1 of 1 Doc Nonaveen_86Nessuna valutazione finora

- 1662 15Documento117 pagine1662 15RajamanikkamNessuna valutazione finora

- WELDING SPECIFICATION Rev BDocumento45 pagineWELDING SPECIFICATION Rev Bmurugesan0% (1)

- Safety Valve Qap 270622Documento2 pagineSafety Valve Qap 270622Pavul RajNessuna valutazione finora

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Documento4 pagineProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabNessuna valutazione finora

- 60 MM SA 516 GR 70 MTCDocumento21 pagine60 MM SA 516 GR 70 MTCgeoanburajaNessuna valutazione finora

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDocumento9 pagine2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanNessuna valutazione finora

- Werkszeugnis Altena Blech Vom 17.06.PDF 1Documento2 pagineWerkszeugnis Altena Blech Vom 17.06.PDF 1MuzammilNessuna valutazione finora

- Wps Mma PipeDocumento2 pagineWps Mma PipeDimitris NikouNessuna valutazione finora

- QAP Seamless PipeDocumento2 pagineQAP Seamless PipeashokkahirwarNessuna valutazione finora

- ITP 07-2 3LPP CS Rev.4 E0660-P10361121-H03-2001-05 (CODE 1) PDFDocumento29 pagineITP 07-2 3LPP CS Rev.4 E0660-P10361121-H03-2001-05 (CODE 1) PDFBlade ChannelTvNessuna valutazione finora

- SA 387 Grade 91 Class 2Documento4 pagineSA 387 Grade 91 Class 2briang-2Nessuna valutazione finora

- ThyssenDocumento0 pagineThyssenAbbas RizviNessuna valutazione finora

- T.C.L. Co. - Test & Control LaboratoriesDocumento2 pagineT.C.L. Co. - Test & Control LaboratoriesA. ΒρατσισταNessuna valutazione finora

- Material Traceability ProcedureDocumento12 pagineMaterial Traceability Procedureqamar qateebNessuna valutazione finora

- Circularity Inspection Report: Shell Course (LW) CW CWDocumento14 pagineCircularity Inspection Report: Shell Course (LW) CW CWaszlizaNessuna valutazione finora

- QAP For PQR'S - For Impact TestingDocumento3 pagineQAP For PQR'S - For Impact TestingDries VandezandeNessuna valutazione finora

- LPT Written ProcedureDocumento8 pagineLPT Written ProcedureManikantaSumanthNessuna valutazione finora

- Inspection Report: CPP-RM-PO-0180Documento4 pagineInspection Report: CPP-RM-PO-0180ANIL PLAMOOTTIL0% (1)

- Qap Sa420Documento3 pagineQap Sa420Abhishek NagNessuna valutazione finora

- Technical Data NRL 02301Documento8 pagineTechnical Data NRL 02301Attiq Ahmad ChoudhryNessuna valutazione finora

- Technical Delivery Condition: Applicable To Parts: Ring WCFN0055Documento4 pagineTechnical Delivery Condition: Applicable To Parts: Ring WCFN0055Balram JiNessuna valutazione finora

- Mechanical Test 1Documento21 pagineMechanical Test 1Manoranjan sharmaNessuna valutazione finora

- WPS ListDocumento2 pagineWPS ListAdeel OmerNessuna valutazione finora

- Inspection DishendDocumento5 pagineInspection DishendVarun MalhotraNessuna valutazione finora

- (732-Itp-40 (V-6905) 42000-SNG-69-42000P-MS-5733-504-0000-06Documento10 pagine(732-Itp-40 (V-6905) 42000-SNG-69-42000P-MS-5733-504-0000-06sathi11189Nessuna valutazione finora

- WPS PQR 12 PDFDocumento9 pagineWPS PQR 12 PDFVinay YadavNessuna valutazione finora

- Welders ManagementDocumento11 pagineWelders ManagementStanley AlexNessuna valutazione finora

- B H e L Limited RTDocumento13 pagineB H e L Limited RTbhavin17850% (2)

- TDC 003 - SS Pipes - r0Documento1 paginaTDC 003 - SS Pipes - r0samkarthik47Nessuna valutazione finora

- WI-INSP-07 R2 Work Instruction-Inspection of PumpsDocumento5 pagineWI-INSP-07 R2 Work Instruction-Inspection of PumpsRakesh MishraNessuna valutazione finora

- NSH-DALM-JERP-WPS-11-P2 Rev.00Documento10 pagineNSH-DALM-JERP-WPS-11-P2 Rev.00Alam MD SazidNessuna valutazione finora

- QAPDocumento31 pagineQAPlohitha100% (1)

- Pressure Vessel Plate InspectionDocumento5 paginePressure Vessel Plate InspectionSadashiw PatilNessuna valutazione finora

- GS Peb QapDocumento4 pagineGS Peb Qapshailendr12Nessuna valutazione finora

- Inspection and Test Plan / Ni-Al Bronze Manual Valves (Vendor Doc - No#: ITP-01-535)Documento4 pagineInspection and Test Plan / Ni-Al Bronze Manual Valves (Vendor Doc - No#: ITP-01-535)Muthazhagan SaravananNessuna valutazione finora

- Motions: of The EarthDocumento25 pagineMotions: of The EarthAjit PatilNessuna valutazione finora

- MahabharataDocumento217 pagineMahabharataIndia ForumNessuna valutazione finora

- Galvanizing GalvanizingDocumento6 pagineGalvanizing GalvanizingAjit PatilNessuna valutazione finora

- SR61 78Documento165 pagineSR61 78Ajit PatilNessuna valutazione finora

- 4-QAP Heat EXDocumento8 pagine4-QAP Heat EXAjit Patil100% (1)

- Welding of Boilers PDFDocumento16 pagineWelding of Boilers PDFValentin JonovNessuna valutazione finora

- Mechanical Books Url LinksDocumento6 pagineMechanical Books Url Linkskirankuma.jagtapNessuna valutazione finora

- Weldolet & SokoletDocumento9 pagineWeldolet & SokoletAjit PatilNessuna valutazione finora

- 12fishbone Cause and Effect AnalysisDocumento3 pagine12fishbone Cause and Effect AnalysisVasudeva CkshirasagarNessuna valutazione finora

- 088 - Hex NutDocumento1 pagina088 - Hex NutAjit PatilNessuna valutazione finora

- NdeDocumento11 pagineNdeAjit PatilNessuna valutazione finora

- Bobst PACKING ProcessDocumento1 paginaBobst PACKING ProcessAjit PatilNessuna valutazione finora

- Questions Related To Sec - Viii Div.1: Larsen & Toubro LimitedDocumento13 pagineQuestions Related To Sec - Viii Div.1: Larsen & Toubro LimitedAjit PatilNessuna valutazione finora

- SSGBDocumento8 pagineSSGBAjit PatilNessuna valutazione finora

- Filler Metal Matching PDFDocumento3 pagineFiller Metal Matching PDFchowhkNessuna valutazione finora

- Case StudyDocumento1 paginaCase StudyAjit PatilNessuna valutazione finora

- Shot Peening ProcessDocumento9 pagineShot Peening ProcessAjit PatilNessuna valutazione finora

- BWG To MM Conversion TableDocumento1 paginaBWG To MM Conversion TableAjit PatilNessuna valutazione finora

- Upsteam, Midstream and DownstreamDocumento1 paginaUpsteam, Midstream and DownstreamAjit PatilNessuna valutazione finora

- UT 01 Report FormatDocumento1 paginaUT 01 Report FormatAjit PatilNessuna valutazione finora

- NdeDocumento11 pagineNdeAjit PatilNessuna valutazione finora

- Standard For GalvanizingDocumento4 pagineStandard For GalvanizingA.K.A. HajiNessuna valutazione finora

- Zinc CoatingsDocumento12 pagineZinc CoatingsvvgdreamNessuna valutazione finora

- Part UWDocumento10 paginePart UWAjit PatilNessuna valutazione finora

- Fol SystemDocumento4 pagineFol SystemAjit PatilNessuna valutazione finora

- Heat TreatmentDocumento36 pagineHeat TreatmentAjit PatilNessuna valutazione finora

- ShimsDocumento16 pagineShimsAjit PatilNessuna valutazione finora

- Lube Oil MotorDocumento4 pagineLube Oil MotorAjit PatilNessuna valutazione finora

- TTS Expansion CalculationDocumento2 pagineTTS Expansion CalculationAjit PatilNessuna valutazione finora

- Utah State Hospital Policies and Procedures RadiologyDocumento9 pagineUtah State Hospital Policies and Procedures RadiologysultanarahmanNessuna valutazione finora

- D Fwxfs Fzô Fee F Fs Wû Àfiy°Ff WX' Af° F Ff°Fe W F FF 21 D F°Ff Izy QZVF FWX A FZ Afz FF FF 23Documento24 pagineD Fwxfs Fzô Fee F Fs Wû Àfiy°Ff WX' Af° F Ff°Fe W F FF 21 D F°Ff Izy QZVF FWX A FZ Afz FF FF 23Govind Chandra DwivediNessuna valutazione finora

- 12 C AdminstrationDocumento2 pagine12 C AdminstrationMuditNessuna valutazione finora

- Introduction To SCILABDocumento14 pagineIntroduction To SCILABMertwysef DevrajNessuna valutazione finora

- L8 Logistics ManagementDocumento41 pagineL8 Logistics ManagementShahmien SevenNessuna valutazione finora

- Krishna Yadav Cell#+91-9540308010: BjectiveDocumento6 pagineKrishna Yadav Cell#+91-9540308010: BjectiveIssac JohnNessuna valutazione finora

- IS301 P1 Theory June 2021 P1 TheoryDocumento20 pagineIS301 P1 Theory June 2021 P1 Theory50902849Nessuna valutazione finora

- Scope: Manufacture of High Precision and CloseDocumento1 paginaScope: Manufacture of High Precision and CloseAnuranjanNessuna valutazione finora

- Quiz 1 - Domain Modeling With Answer KeyDocumento5 pagineQuiz 1 - Domain Modeling With Answer Keyprincess100267% (3)

- MBridgeDocumento50 pagineMBridgeTsila SimpleNessuna valutazione finora

- CTA Case Digests - 07.23.2021Documento5 pagineCTA Case Digests - 07.23.2021Emrico CabahugNessuna valutazione finora

- Asmsc 1119 PDFDocumento9 pagineAsmsc 1119 PDFAstha WadhwaNessuna valutazione finora

- Hullabaloo (TV Series)Documento3 pagineHullabaloo (TV Series)ozNessuna valutazione finora

- RW01 Concrete Masonry - Reinforced Cantilever Retaining WallsDocumento81 pagineRW01 Concrete Masonry - Reinforced Cantilever Retaining WallshaixdproNessuna valutazione finora

- ''Adhibeo'' in LatinDocumento5 pagine''Adhibeo'' in LatinThriw100% (1)

- Gaps, Pro Versus NoviceDocumento2 pagineGaps, Pro Versus Novicertkiyous2947Nessuna valutazione finora

- Snmpwalk Westermo DSL ModemDocumento24 pagineSnmpwalk Westermo DSL ModemAexNessuna valutazione finora

- Communication To Offer-ContractsDocumento20 pagineCommunication To Offer-ContractsAarif Mohammad BilgramiNessuna valutazione finora

- 4th Party LogisticsDocumento3 pagine4th Party Logisticsch_salmanNessuna valutazione finora

- File 1379580604 PDFDocumento9 pagineFile 1379580604 PDFMuhammad Salik TaimuriNessuna valutazione finora

- 201805graphene PDFDocumento204 pagine201805graphene PDFMohammad RezkyNessuna valutazione finora

- Due Friday, February 21, 2014 by 5:00 P.M. To The AE312 MailboxDocumento3 pagineDue Friday, February 21, 2014 by 5:00 P.M. To The AE312 MailboxankstamanNessuna valutazione finora

- Shell Answer Book 07 The Driving Emergency BookDocumento8 pagineShell Answer Book 07 The Driving Emergency BookKenneth100% (2)

- Introduction To MAX InternationalDocumento48 pagineIntroduction To MAX InternationalDanieldoeNessuna valutazione finora

- Flexible, Dynamic VR Simulation of A Future River Lock Facilitates Prevention Through Design in Occupational Safety and HealthDocumento2 pagineFlexible, Dynamic VR Simulation of A Future River Lock Facilitates Prevention Through Design in Occupational Safety and HealthEdgar Alexander Hurtado MolochoNessuna valutazione finora

- Formal Methods Assignment PDFDocumento25 pagineFormal Methods Assignment PDFAdla FikriyahNessuna valutazione finora

- Agriculture Water Usage Poster ProjectDocumento1 paginaAgriculture Water Usage Poster Projectapi-339004071Nessuna valutazione finora

- 1.0 Design Andheri Khola Bridge, 1x25m 8.4m 3 GirderDocumento18 pagine1.0 Design Andheri Khola Bridge, 1x25m 8.4m 3 GirderManoj ChaudharyNessuna valutazione finora

- 1 - Pengenalan Enterprise ArchitectureDocumento37 pagine1 - Pengenalan Enterprise ArchitectureSILVERNessuna valutazione finora

- 10 Me 42 BDocumento144 pagine10 Me 42 BdineshNessuna valutazione finora