Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ballsim Direct

Caricato da

Anonymous TsKN7XZBCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ballsim Direct

Caricato da

Anonymous TsKN7XZBCopyright:

Formati disponibili

About the Ballsim_Direct Spreadsheet ...

Scope :

The Ballsim_Direct spreadsheet was designed to simulate the Size-by-Size Mass Balance around any given

Conventional Ball Mill grinding section, of the Direct configuration (see Flowsheet), operating under various conditions,

on the basis of well accepted mathematical models for the grinding and hydroclassification processes.

Theoretical Framework :

- The Grinding Model :

For the simulation of the ball mill response, this routine is based on the so called Modern Theory of Comminution. This

theory introduced two new sets of parameters : the Selection Function S and the Breakage Function B. The first set

also referred to as Grindability relates to the grinding kinetics of each independent particle and the second set also

referred to as Distribution of Primary Fragments characterizes the size distribution of the fragments produced as a

result of breakage events.

The Figure below helps define both concepts with greater clarity. Consider that at any given instant t, the size distribution

of the mineral charge in a hypothetical batch mill is quantified by the fractions f i (i = 1, n) retained on the n different screens

represented on the left of such Figure. After a time interval t, the resulting size distribution is represented on the right of

the same Figure. During this time interval, some particles will be fractured and their fragments redistributed to the lower

screens. For the particles retained on mesh i+1 (the i fraction), the Selection Function Si (min-1) denotes the fractional

breakage velocity; that is, the fraction of the particles in the size range [d i+1 , di] which are fractured, per unit of time.

Therefore, the product (Sit) represents the fraction of the material retained on mesh i+1, at time t, that will be fractured

by the action of the grinding media, during the following time period t. Complementarily, the Breakage Function bij

denotes the fraction, by weight, of the fragments arising from the breakage of the particles retained on mesh j+1 to be

retained on the lower i+1 mesh.

t =t t = t +t

(1-S 1t) f1

f1

2 S 1t f1 2

b21S1t f1

f2

3 (1-S 2t) f2 3

S2t f2

bi1S1t f1

fi

i +1 bi2S2t f2 i +1

bn1S1t f1

fn

bn2S2t f2

n +1

n +1

Moly-Cop Tools / 351528189.xls Page 1 04/13/2017 / 06:43:23

Moly-Cop Tools / 351528189.xls Page 2 04/13/2017 / 06:43:24

It is customary to define mesh 1 as the coarsest opening and n as the finest opening. Then, by definition :

i+1

Bij = bkj (1)

k=n

represents the cummulative fraction of fragments from the breakage of particles retained on mesh j that will become finer

than mesh i.

With reference to the Figure above, it is then possible to establish, for each size fraction i, the following population

balance of particles :

[Particles in fraction i at time (t+t)] = [Particles in fraction i at time t]

- [Particles in fraction i broken during the time interval t]

+ [New particles added to fraction i as a result of the breakage

of particles originally retained in the coarser fractions (j = 1, i-1)]

then, if H represents the total weight of ore in the mill :

fi(t+t) H = fi(t) H - Sitfi(t) H + bi1S1tf1(t) H + bi2S2tf2(t) H + + bi,i-1Si-1tfi-1(t) H ; for i = 1, 2, , n (2)

Considering the limiting condition when t approaches zero, the expression above reduces to the system of first order

differential equations :

1

d(fi)/dt = -Si fi + bij Sj fj ; for i = 1, 2, , n (3)

j = i-1

which constitutes the General Grinding Model, in its differential form.

The analytical solution of this complex system of differential equations is fortunately known, under the restrictive

assumption that the parameters S and B are invariant with time; so giving rise to particular solution of the general system

denoted Linear Model, which in its matrix form is expressed as :

f = ( T J T-1 ) f (4)

where :

f = {fi | i = 1, 2, , n} = vector containing the size distribution of the mill discharge (ground product),

f = {fi | i = 1, 2, , n} = vector containing the size distribution of the mill feed,

T = {Tij | i,j = 1, 2, , n} = lower triangular matrix of values Tij recursively defined as :

Tij = 0 ; when i < j

Tij = 1 ; when i = j

i-1

Tij = S ( bik Sk Tkj )/( Si Sj ) ; when i > j

k=j

Moly-Cop Tools / 351528189.xls Page 3 04/13/2017 / 06:43:24

J = {Jij | i,j = 1, 2, , n} = diagonal matrix of values Jij defined as :

Jij = exp (-Sit) ; when i = j ( batch grinding)

Jij = (1 + Si/N)-N ; when i = j (continuous grinding)

Jij = 0 ; in all other cases

and where - the average mean residence time - and N are parameters characteristic of the Residence Time Distribution

(RTD) of the mineral slurry in the mill, here represented by :

E(t) = [ NN (t/)N-1 / (N) ] exp (-Nt/) (5)

referred to as the N-Mixers in Series Model and where the parameter N may be approximated by the effective

(Lenght/Diameter) ratio of the mill.

The grinding model parameters (the Selection and Breakage parameters) are different for different particle sizes. Such

dependence is here represented by the following relationships :

- For the Selection Function :

Si = 0 (di*)1 / [ 1 + (di* / dcrit)2 ] (6)

with :

di* = (di di+1)0.5 = average particle size of the i-th fraction.

An expanded form of this expression - also available in this simulation routine - is given by :

Si = [1/(1+02/01)] { 01 (di*)11 / [ 1 + (di* / dcrit)2 ] + 02 (di*)12 } (6e)

- For the Breakage Function :

Bij = 0 (di/dj+1)1 + (1- 0) (di/dj+1)2 (7)

An expanded form of this expression - also available in this simulation routine - is obtained by replacing 0 in

Equation 7 by :

0j = 00(dj+1/1000) -01 , never > 1 (7e)

These expanded forms for Si and Bij are intended to provide the model greater descriptive flexibility when tuning

the model to actual specific grinding systems (see Files BallParam_Batch and BallParam_Open) but, since they

increment the total number of ore characteristic parameters to be estimated, its use should be avoided whenever

possible.

In any case, the proposed expanded forms reduce to the normal forms if 02 and 01 are set equal to zero.

Not considering the expanded forms, the above expressions considerably reduce the number of ore characteristic

parameters to a maximum of seven (0, 1, 2, dcrit, 0, 1 and 2) and simplify the computation of the (n-1) S is values and

the n(n-1)/2 Bijs values required for the evaluation of the model.

Moly-Cop Tools / 351528189.xls Page 4 04/13/2017 / 06:43:24

The critical role of the Specific Energy Consumption E (kWh/ton) becomes explicit in the above formulations through a

simple change of variables, when introducing the Specific Selection Function parameter as :

SiEballs = Si (H/Pballs) ; i = 1, 2, ..., n (8)

and recognizing that (see Equations 2 and 5) :

Eballs = t (Pballs/H) (batch grinding)

Eballs = (Pballs/H) (continuous grinding) (9)

where Pballs represents the contribution of the balls to the Net Mill Power Draw (kW) (see Mill Power_Ball Mills), it may

be concluded that :

SiEballs Eballs = Si t (batch grinding)

or : S iEballs Eballs = Si (continuous grinding) (10)

Therefore, it is enough to replace in Equations 4 above the products (S it) or (Si) by the product (SiEballsEballs) to obtain the

equations of the Linear Grinding Model in terms of the Specific Selection Function, S iEballs.

- The Hydrocyclone Model : (see Files Cyclosim_Single and Cyclobal_Single)

- Simulation of Grinding/Classification Circuits :

The mathematical simulation of the response of grinding/classification circuits, like the one represented here in Flowsheet,

requires the proper combination of the unit grinding and classification models. As a result of the circulating load stream,

both models can not be solved independently : the feed to the mill is affected by the cyclones discharge stream which

depends on the cyclones feed and this cyclones feed is affected by the mill discharge, which in turns depends on the mill

feed. Such interdependence condition implies that the system must be solved with the aid of numerical convergence

algorithms, starting from an initial guessed value for the Circulating Load ratio (defined as the ratio of the massflowrate of

solids in the cyclones discharge stream to the massflowrate of solids in the cyclones overflow stream). For such purposes,

the present Ballsim_Direct simulator makes use of the Goal Seek tool available in Microsoft Excel.

Data Input and Program Execution :

The data required by the simulator must be defined in each corresponding unprotected white background cell - inside the

red double-lined border - of the here attached Data_File worksheet. Gray background cells contain the results of the

corresponding formulas there defined and are protected to avoid any accidental editing.

In addition to the above, the user is requested to provide an initial guess of the Circulating Load ratio in Cell E21. Finally,

the system is solved by single clicking on the macro button Iterate, next to Cell E21.

Important Notice : Iterate ... must be clicked every time any element of input data gets to be modified. After clicking

ITERATE, Cell E23 must display a zero value; otherwise, the current outputs are not valid.

Moly-Cop Tools / 351528189.xls Page 5 04/13/2017 / 06:43:24

Calculation results are presented in the Reports worksheet and graphically summarized in the Flowsheet worksheet.

New Moly-Cop Tools users are invited to explore the brief comments inserted in each relevant cell, rendering the whole

utilization of the worksheets self-explanatory. Eventually, the user may wish to remove the view of the comments by

selecting Tools / Options / View / Comments / None.

Moly-Cop Tools / 351528189.xls Page 6 04/13/2017 / 06:43:24

Moly-Cop Tools / 351528189.xls Page 7 04/13/2017 / 06:43:24

ate the Size-by-Size Mass Balance around any given

onfiguration (see Flowsheet), operating under various conditions,

he grinding and hydroclassification processes.

s based on the so called Modern Theory of Comminution. This

ction Function S and the Breakage Function B. The first set

kinetics of each independent particle and the second set also

aracterizes the size distribution of the fragments produced as a

r clarity. Consider that at any given instant t, the size distribution

tified by the fractions f i (i = 1, n) retained on the n different screens

al t, the resulting size distribution is represented on the right of

s will be fractured and their fragments redistributed to the lower

raction), the Selection Function Si (min-1) denotes the fractional

he size range [d i+1 , di] which are fractured, per unit of time.

e material retained on mesh i+1, at time t, that will be fractured

ime period t. Complementarily, the Breakage Function bij

from the breakage of the particles retained on mesh j+1 to be

Moly-Cop Tools / 351528189.xls Page 8 04/13/2017 / 06:43:24

Moly-Cop Tools / 351528189.xls Page 9 04/13/2017 / 06:43:24

g and n as the finest opening. Then, by definition :

bkj (1)

he breakage of particles retained on mesh j that will become finer

establish, for each size fraction i, the following population

raction i at time t]

tion i broken during the time interval t]

dded to fraction i as a result of the breakage

nally retained in the coarser fractions (j = 1, i-1)]

f2(t) H + + bi,i-1Si-1tfi-1(t) H ; for i = 1, 2, , n (2)

ero, the expression above reduces to the system of first order

+ bij Sj fj ; for i = 1, 2, , n (3)

j = i-1

ferential form.

ntial equations is fortunately known, under the restrictive

th time; so giving rise to particular solution of the general system

essed as :

T-1 ) f (4)

size distribution of the mill discharge (ground product),

e size distribution of the mill feed,

atrix of values Tij recursively defined as :

Si Sj ) ; when i > j

Moly-Cop Tools / 351528189.xls Page 10 04/13/2017 / 06:43:24

ues Jij defined as :

when i = j ( batch grinding)

when i = j (continuous grinding)

in all other cases

are parameters characteristic of the Residence Time Distribution

by :

) ] exp (-Nt/) (5)

he parameter N may be approximated by the effective

akage parameters) are different for different particle sizes. Such

nships :

dcrit)2 ] (6)

size of the i-th fraction.

e in this simulation routine - is given by :

+ (di* / dcrit)2 ] + 02 (di*)12 } (6e)

0) (di/dj+1)2 (7)

e in this simulation routine - is obtained by replacing 0 in

, never > 1 (7e)

provide the model greater descriptive flexibility when tuning

iles BallParam_Batch and BallParam_Open) but, since they

ameters to be estimated, its use should be avoided whenever

e normal forms if 02 and 01 are set equal to zero.

ions considerably reduce the number of ore characteristic

1

and 2) and simplify the computation of the (n-1) Sis values and

model.

Moly-Cop Tools / 351528189.xls Page 11 04/13/2017 / 06:43:24

E (kWh/ton) becomes explicit in the above formulations through a

fic Selection Function parameter as :

; i = 1, 2, ..., n (8)

(batch grinding)

(continuous grinding) (9)

Net Mill Power Draw (kW) (see Mill Power_Ball Mills), it may

(batch grinding)

(continuous grinding) (10)

he products (S it) or (Si) by the product (SiEballsEballs) to obtain the

pecific Selection Function, S iEballs.

gle and Cyclobal_Single)

/classification circuits, like the one represented here in Flowsheet,

classification models. As a result of the circulating load stream,

to the mill is affected by the cyclones discharge stream which

affected by the mill discharge, which in turns depends on the mill

ystem must be solved with the aid of numerical convergence

Circulating Load ratio (defined as the ratio of the massflowrate of

rate of solids in the cyclones overflow stream). For such purposes,

Goal Seek tool available in Microsoft Excel.

ach corresponding unprotected white background cell - inside the

worksheet. Gray background cells contain the results of the

to avoid any accidental editing.

e an initial guess of the Circulating Load ratio in Cell E21. Finally,

on Iterate, next to Cell E21.

me any element of input data gets to be modified. After clicking

, the current outputs are not valid.

Moly-Cop Tools / 351528189.xls Page 12 04/13/2017 / 06:43:24

eet and graphically summarized in the Flowsheet worksheet.

ief comments inserted in each relevant cell, rendering the whole

, the user may wish to remove the view of the comments by

Moly-Cop Tools / 351528189.xls Page 13 04/13/2017 / 06:43:24

Moly-Cop Tools / 351528189.xls Page 14 04/13/2017 / 06:43:24

Moly-Cop Tools TM

BALLSIM : Conventional Closed Circuit Grinding Simulator

Circuit Type DIRECT (see Flowsheet) Simulation N 0

Remarks Base Case Example

Mill Dimensions and Operating Conditions 3348 Balls

Diameter Length Speed Charge Balls App. Dens. Interstitial Lift 0 Overfilling

ft ft % Critical Filling,% Filling,% ton/m3 Slurry, % Angle, () 536 Slurry

18.5 22.0 72.0 38.0 38.0 5.39 100.0 35.0 3885 Net kW

rpm 12.82 10.0 % Losses

4316 Gross kW

Cyclone Dimensions (inches) and Operating Conditions

Number Diameter Height Inlet Vortex Apex

10 20.0 75.0 3.50 7.50 3.67

% Solids O'flow 40.0

% Solids U'flow 76.0 Bond's

% Solids Mill Discharge 72.0 Main Simulated Outputs Feedrate

P80 150.0 for a

Circulating Load 3.057 (Guess) Wio 15.08 Target P80

3.057 (Actual) % Fines MD 18.84

0.000 (Delta) Iterate Q 1566 Target P80

Bpf 0.372 170.0

Ore Density, ton/m3 2.80 Pressure 8.0 ton/hr

Balls Density, ton/m3 7.75 Very Important : Sump Water 355.1 429.8

Simulation results are not valid until

the Iterate button has been clicked

Feedrate, ton/hr (dry) 400.0 after any input data changes.

Feed Moisture, % 5.0

Feed Size Distribution

i Mesh Opening Mid-Size ton/hr % Retained % Passing

1 1.05 25400 100.00

2 0.742 19050 21997 0.00 0.00 100.00

3 0.525 12700 15554 20.00 5.00 95.00

4 0.371 9500 10984 66.40 16.60 78.40

5 3 6700 7978 56.28 14.07 64.33

6 4 4750 5641 41.32 10.33 54.00

7 6 3350 3989 33.36 8.34 45.66

8 8 2360 2812 27.36 6.84 38.82

9 10 1700 2003 21.64 5.41 33.41

10 14 1180 1416 20.40 5.10 28.31

11 20 850 1001 15.60 3.90 24.41

12 28 600 714 14.16 3.54 20.87

13 35 425 505 12.04 3.01 17.86

14 48 300 357 10.36 2.59 15.27

15 65 212 252 8.84 2.21 13.06

16 100 150 178 7.52 1.88 11.18

17 150 106 126 6.48 1.62 9.56

18 200 75 89 5.52 1.38 8.18

19 270 53 63 4.72 1.18 7.00

20 400 38 45 3.40 0.85 6.15

21 -400 0 19 24.60 6.15 0.00

Selection Function Parameters : Expanded Form :

alpha0 alpha1 alpha2 dcrit alpha02 alpha12

0.00918 0.65 2.5 6532 0 1

0 1 Suggested Default Values

Breakage Function Parameters : Expanded Form :

beta0 beta1 beta2 beta01

0.2 0.25 4 0

0 Suggested Default Value

Classifier Constants :

a1 a2 a3 a4

9.680 1.401 54.964 0.523 0.950

9.680 1.401 54.964 0.523 0.950 Suggested Default Values

Moly-Cop Tools / 351528189.xls Page 15 04/13/2017 / 06:43:24

Moly-Cop Tools TM

Simulation N 0

Remarks Base Case Example

40.00 % Solids

60.29 % - Size 18

psi 7.98 150.0 P80

# of Cyclones 10

Vortex 7.50 Circ. Load 3.06

Apex 3.67 0.372 Bpf m3/hr 1566

0.392 Bpw

% Solids 76.00

Water,

m3/hr 355.1

ton/hr 400.0 Water, 223.9

F80 9795 m3/hr

Gross kW 4316.1

kWh/ton 10.79 % Balls 38.00

Wio 15.08 % Critical 72.00

% Solids 72.00

% Solids 62.20

Moly-Cop Tools / 351528189.xls / Flowsheet 04/13/2017 / 06:43:24

Moly-Cop Tools TM

Simulation N 0

BALLSIM

Conventional Closed Circuit Grinding Simulator

Remarks : Base Case Example

CIRCUIT MASS BALANCE

Configuration : DIRECT

Fresh Mill Mill Sump Cyclone Cyclone Cyclone

Feed Feed Discharge Water Feed U'flow O'flow

Ore, ton/hr 400.0 1622.7 1622.7 0.0 1622.7 1222.7 400.0

Water, m3/hr 21.1 407.2 631.1 355.1 986.1 386.1 600.0

Slurry, ton/hr 421.1 2029.9 2253.8 355.1 2608.8 1608.8 1000.0

Slurry, m3/hr 163.9 986.7 1210.6 355.1 1565.7 822.8 742.9

Slurry Dens., ton/m3 2.569 2.057 1.862 1.000 1.666 1.955 1.346

% Solids (by volume) 87.2 58.7 47.9 0.0 37.0 53.1 19.2

% Solids (by weight) 95.00 79.94 72.00 0.00 62.20 76.00 40.00

Particle Size Distributions (Cummulative % Passing)

i Mesh Opening

1 1.05 25400 100.00 100.00 100.00 0.00 100.00 100.00 100.00

2 0.742 19050 100.00 100.00 100.00 0.00 100.00 100.00 100.00

3 0.525 12700 95.00 97.65 98.88 0.00 98.88 98.51 100.00

4 0.371 9500 78.40 91.00 96.32 0.00 96.32 95.12 100.00

5 3 6700 64.33 85.02 93.81 0.00 93.81 91.79 100.00

6 4 4750 54.00 80.19 91.53 0.00 91.53 88.76 100.00

7 6 3350 45.66 75.76 89.16 0.00 89.16 85.61 100.00

8 8 2360 38.82 71.36 86.44 0.00 86.44 82.00 100.00

9 10 1700 33.41 66.87 83.28 0.00 83.28 77.81 100.00

10 14 1180 28.31 61.49 79.16 0.00 79.16 72.34 100.00

11 20 850 24.41 55.67 74.30 0.00 74.30 65.89 100.00

12 28 600 20.87 48.60 68.10 0.00 68.10 57.67 99.97

13 35 425 17.86 40.41 60.53 0.00 60.53 47.78 99.49

14 48 300 15.27 31.69 51.77 0.00 51.77 37.05 96.76

15 65 212 13.06 23.97 42.92 0.00 42.92 27.54 89.96

16 100 150 11.18 18.22 35.18 0.00 35.18 20.52 80.01

17 150 106 9.56 14.31 29.08 0.00 29.08 15.87 69.49

18 200 75 8.18 11.73 24.57 0.00 24.57 12.89 60.29

19 270 53 7.00 9.95 21.24 0.00 21.24 10.91 52.82

20 400 38 6.15 8.74 18.84 0.00 18.84 9.59 47.14

D80, microns 9795 4680 1273 0 1273 2022 150.0

Specific Energy Consumption : 10.79 kWh/ton (Gross)

Operational Work Index : 15.08 kWh/ton

Moly-Cop Tools / 351528189.xls Page 17 04/13/2017 / 06:43:24

Moly-Cop Tools TM

Simulation N 0

BALLSIM

Conventional Closed Circuit Grinding Simulator

Remarks : Base Case Example

CLASSIFIERS PERFORMANCE

Number of Cyclones : 10 Operating Conditions :

Cyclone Dimensions, in : Feed Flowrate, m3/hr 1565.7

Diameter 20.00 Pressure, psi 8.0

Height 75.00 D50 (corr.), microns 179.8

Inlet 3.50 Water By-Pass, % 39.2

Vortex 7.50 Solids By-Pass, % 37.2

Apex 3.67 Plitt's Parameter 1.62

Ore Density, ton/m3 2.80 Circulating Load, % 306

Mass Balance around the Classifiers

Size Distributions, % Passing Classifier Efficiency

i Mesh Opening Mid-Size Feed U'flow O'flow Actual Corrected

1 1.05 25400 21997 100.00 100.00 100.00 1.000 1.000

2 0.742 19050 15554 100.00 100.00 100.00 1.000 1.000

3 0.525 12700 10984 98.88 98.51 100.00 1.000 1.000

4 0.371 9500 7978 96.32 95.12 100.00 1.000 1.000

5 3 6700 5641 93.81 91.79 100.00 1.000 1.000

6 4 4750 3989 91.53 88.76 100.00 1.000 1.000

7 6 3350 2812 89.16 85.61 100.00 1.000 1.000

8 8 2360 2003 86.44 82.00 100.00 1.000 1.000

9 10 1700 1416 83.28 77.81 100.00 1.000 1.000

10 14 1180 1001 79.16 72.34 100.00 1.000 1.000

11 20 850 714 74.30 65.89 100.00 0.999 0.998

12 28 600 505 68.10 57.67 99.97 0.984 0.975

13 35 425 357 60.53 47.78 99.49 0.923 0.878

14 48 300 252 51.77 37.05 96.76 0.810 0.698

15 65 212 178 42.92 27.54 89.96 0.683 0.495

16 100 150 126 35.18 20.52 80.01 0.575 0.323

17 150 106 89 29.08 15.87 69.49 0.497 0.200

18 200 75 63 24.57 12.89 60.29 0.447 0.119

19 270 53 45 21.24 10.91 52.82 0.416 0.071

20 400 38 19 18.84 9.59 47.14 0.383 0.018

Ore, ton/hr 1622.7 1222.7 400.0 Classifier Constants

Water, m3/hr 986.1 386.1 600.0

Slurry, ton/hr 2608.8 1608.8 1000.0 a1 9.6796052

Slurry, m3/hr 1565.7 822.8 742.9 a2 1.4013309

Slurry Dens., ton/m3 1.666 1.955 1.346 a3 54.964028

% Solids (by volume) 37.0 53.1 19.2 a4 0.5229776

% Solids (by weight) 62.2 76.0 40.0 0.95

Moly-Cop Tools / 351528189.xls Page 18 04/13/2017 / 06:43:24

Moly-Cop Tools / 351528189.xls Page 19 04/13/2017 / 06:43:24

Moly-Cop Tools TM

Simulation N 0

BALLSIM

Conventional Closed Circuit Grinding Simulator

Remarks : Base Case Example

BALL MILL PERFORMANCE

Diameter, ft 18.5 Mill Power, kW (Gross) 4316

Length, ft 22.0 Mill Power, kW (Net) 3885

Speed, % Critical 72.0 Throughput, ton/hr 1622.7

App. Density, ton/m3 5.39 % Solids (by weight) 72.0

Charge Level, % 38.0 Sp. Energy, kWh/ton 2.66

Balls Filling, % 38.0 Reduction Ratio 3.68

Lift Angle, () 35.0

Size Distributions

Mill Mill

i Mesh Opening Mid-Size Feed Discharge

1 1.05 25400 21997 100.00 100.00

2 0.742 19050 15554 100.00 100.00

3 0.525 12700 10984 97.65 98.88

4 0.371 9500 7978 91.00 96.32

5 3 6700 5641 85.02 93.81

6 4 4750 3989 80.19 91.53

7 6 3350 2812 75.76 89.16

8 8 2360 2003 71.36 86.44

9 10 1700 1416 66.87 83.28

10 14 1180 1001 61.49 79.16

11 20 850 714 55.67 74.30

12 28 600 505 48.60 68.10

13 35 425 357 40.41 60.53

14 48 300 252 31.69 51.77

15 65 212 178 23.97 42.92

16 100 150 126 18.22 35.18

17 150 106 89 14.31 29.08

18 200 75 63 11.73 24.57

19 270 53 45 9.95 21.24

20 400 38 19 8.74 18.84

D80, microns 4680 1273

Selection Function Parameters Breakage Function Parameters

alpha01 alpha02 alpha11 alpha12 alpha2 Dcrit Beta00 Beta01 Beta1 Beta2

0.00918 0.0000000 0.650 1.000 2.50 6532 0.200 0.000 0.25 4.00

Moly-Cop Tools / 351528189.xls Page 20 04/13/2017 / 06:43:24

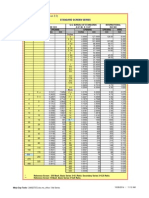

CONVENTIONAL BALL MILL POWER ESTIMATION

Hogg & Fuerstenau Model

Mill

Power, kW

Mill Dimensions and Operating Conditions 3348 Balls

Diameter Length Mill Speed Charge Balls Interstitial Lift 0 Overfilling

ft ft % Critical Filling,% Filling,% Slurry Filling,% Angle, () 536 Slurry

18.50 22.00 72.00 38.00 38.00 100.00 35.00 3885 Net Total

10.00 % Losses

4316 Gross Total

% Solids in the Mill 72.00 Charge Mill Charge Weight, tons Apparent

Ore Density, ton/m3 2.80 Volume, Ball Slurry Density

Slurry Density, ton/m3 1.86 m3 Charge Interstitial above Balls ton/m3

Balls Density, ton/m3 7.75 63.76 296.48 47.48 0.00 5.395

Moly-Cop Tools / 351528189.xls 04/13/2017 / 06:43:24

Potrebbero piacerti anche

- BallSim OpenDocumento44 pagineBallSim OpenGonzalo LopezNessuna valutazione finora

- Moly-Cop Tools Spreadsheet Simulates Vertical Mill GrindingDocumento51 pagineMoly-Cop Tools Spreadsheet Simulates Vertical Mill GrindingW ZuoNessuna valutazione finora

- SAGSim OpenDocumento124 pagineSAGSim OpenpolsiemprealdoNessuna valutazione finora

- C.18 Plate Filter Press OptimizationDocumento2 pagineC.18 Plate Filter Press OptimizationRatri Puspita WardaniNessuna valutazione finora

- Moly-Cop Tools: Mineral Slurry Characterization Extensive PropertiesDocumento2 pagineMoly-Cop Tools: Mineral Slurry Characterization Extensive PropertiesAnonymous TsKN7XZBNessuna valutazione finora

- Date: Project No: Purpose: Procedure: FeedDocumento5 pagineDate: Project No: Purpose: Procedure: FeedRogger Renato Salinas LopezNessuna valutazione finora

- Constrained Model Predictive Control in Ball Mill Grinding ProcessDocumento9 pagineConstrained Model Predictive Control in Ball Mill Grinding ProcessHumbulaniNessuna valutazione finora

- Solvent Extraction TechnologyDocumento7 pagineSolvent Extraction TechnologyBob ChaplinNessuna valutazione finora

- Scope:: About The Ballbal - Reverse Spreadsheet ..Documento15 pagineScope:: About The Ballbal - Reverse Spreadsheet ..julio carpio FrancoNessuna valutazione finora

- Moly-Cop Tools circuit simulatorDocumento1 paginaMoly-Cop Tools circuit simulatorDanny joaquinNessuna valutazione finora

- Cyclosim SingleDocumento9 pagineCyclosim SinglehadryanaNessuna valutazione finora

- Screw Screw Screw Screw Pump Pump Pump PumpDocumento2 pagineScrew Screw Screw Screw Pump Pump Pump PumpvictorvikramNessuna valutazione finora

- Research Report of Mineral Processing 2Documento17 pagineResearch Report of Mineral Processing 2MarcialNessuna valutazione finora

- A CIP Simulation Technique Using Excel Built-In FunctionalityDocumento4 pagineA CIP Simulation Technique Using Excel Built-In FunctionalityluischusNessuna valutazione finora

- TEMPLATE - New Product CharterDocumento1 paginaTEMPLATE - New Product CharterElise LenzNessuna valutazione finora

- Multistage Flowsheets Sabc1Documento204 pagineMultistage Flowsheets Sabc1alonsogonzalesNessuna valutazione finora

- Media Charge Wear Rod MillsDocumento3 pagineMedia Charge Wear Rod MillspolsiemprealdoNessuna valutazione finora

- Drilling parameters and pressure loss calculationsDocumento9 pagineDrilling parameters and pressure loss calculationsmehmetNessuna valutazione finora

- Crush - Reverse:: Moly-Cop Tools (Version 3.0)Documento8 pagineCrush - Reverse:: Moly-Cop Tools (Version 3.0)Gonzalo LopezNessuna valutazione finora

- SAGParam OpenEJEMPLO2Documento120 pagineSAGParam OpenEJEMPLO2polsiemprealdoNessuna valutazione finora

- Jacobs Calculations 2Documento2 pagineJacobs Calculations 2BhattNessuna valutazione finora

- Balance Mol Flot1Documento2 pagineBalance Mol Flot1Harry VirgoNessuna valutazione finora

- 35 Alex Doll - Formato PRM16Documento24 pagine35 Alex Doll - Formato PRM16rodrigoalcaino100% (1)

- 76 Mbar - 91 Mbar: CO - InertizationDocumento1 pagina76 Mbar - 91 Mbar: CO - InertizationKenny RuizNessuna valutazione finora

- Raw Water System Technical SpecsDocumento11 pagineRaw Water System Technical SpecsChandraNessuna valutazione finora

- Wilo Mather and Platt Pumps Pvt. LTD: Technical DatasheetDocumento3 pagineWilo Mather and Platt Pumps Pvt. LTD: Technical DatasheetViral ParmarNessuna valutazione finora

- Improvements in The Operation and Control of SAG Mills in PT Amman Mineral's Batu Hijau Operation Using Mill Load Soft SensorDocumento17 pagineImprovements in The Operation and Control of SAG Mills in PT Amman Mineral's Batu Hijau Operation Using Mill Load Soft SensorFernandoNessuna valutazione finora

- PB Filter Press Sidebar Me1500 Me2500 en Web DataDocumento8 paginePB Filter Press Sidebar Me1500 Me2500 en Web DataTiago J C MachadoNessuna valutazione finora

- Jacobs Engineering India Private Limited ProfileDocumento47 pagineJacobs Engineering India Private Limited ProfileBhattNessuna valutazione finora

- Operating Variables in Knelson ConcentratorDocumento13 pagineOperating Variables in Knelson Concentratorjoegb2919Nessuna valutazione finora

- Ball Mill ToolsDocumento2 pagineBall Mill ToolsCarlos Rafael Uriarte VasquezNessuna valutazione finora

- Scope:: About The Cyclosim - Single Spreadsheet ..Documento14 pagineScope:: About The Cyclosim - Single Spreadsheet ..Flia Diaz ZunigaNessuna valutazione finora

- Ball MillDocumento7 pagineBall MillAndres Acosta RozoNessuna valutazione finora

- SGS 6 Basic Iron Sulphate in POX Processing of Refractory GoldDocumento10 pagineSGS 6 Basic Iron Sulphate in POX Processing of Refractory Goldboanerges wino pattyNessuna valutazione finora

- Compilation of Mineral Processing Formulas PDFDocumento11 pagineCompilation of Mineral Processing Formulas PDFEmerald MasterNessuna valutazione finora

- Prob (Comminution) PDFDocumento3 pagineProb (Comminution) PDFanasabdullahNessuna valutazione finora

- Bench and Pilot Plant ProgramsDocumento10 pagineBench and Pilot Plant ProgramsNataniel LinaresNessuna valutazione finora

- Balance Celda X Celda Por MallasDocumento8 pagineBalance Celda X Celda Por MallasFlor Margarita Alfaro MiñanoNessuna valutazione finora

- Red MudDocumento24 pagineRed MudAfan Taufiq Faturohman100% (1)

- Spiral Brochure 3-2007Documento8 pagineSpiral Brochure 3-2007MikeWalsheNessuna valutazione finora

- Mechanical Centrifugal Air ClassifiersDocumento3 pagineMechanical Centrifugal Air ClassifiersBramJanssen76Nessuna valutazione finora

- Minerals Processing Engineering interview questionsDocumento15 pagineMinerals Processing Engineering interview questionsMohammad NuruzzamanNessuna valutazione finora

- Cyclone Separator Press DropDocumento2 pagineCyclone Separator Press DropnileshNessuna valutazione finora

- Fire Explosion Hazard SX-EWDocumento104 pagineFire Explosion Hazard SX-EWGeorgi SavovNessuna valutazione finora

- Spanish translation of BallParam_Batch documentDocumento16 pagineSpanish translation of BallParam_Batch documentAnonymous TsKN7XZBNessuna valutazione finora

- Letseng Diamonds Plant 2 DocumentationDocumento14 pagineLetseng Diamonds Plant 2 DocumentationKgotsofalang Kayson NqhwakiNessuna valutazione finora

- Cyclone - JK PDFDocumento49 pagineCyclone - JK PDFpaulandrevallee100% (2)

- UBC 4th Year Mining Engineering Trip Report: Visits to Brazilian Mines and Research FacilitiesDocumento50 pagineUBC 4th Year Mining Engineering Trip Report: Visits to Brazilian Mines and Research Facilitieskingskid22Nessuna valutazione finora

- Utilities - STD Sieve SeriesDocumento1 paginaUtilities - STD Sieve SeriespolsiemprealdoNessuna valutazione finora

- Cylcone Type Selection RouteDocumento75 pagineCylcone Type Selection RouteAnonymous pVoSWn8yh0Nessuna valutazione finora

- Performing Metallurgical Calculations on SpreadsheetsDocumento9 paginePerforming Metallurgical Calculations on SpreadsheetsJose Luis ValladaresNessuna valutazione finora

- Annexure - A: F:/Projects/Hpli/Obsc/Annex/Filter PressDocumento1 paginaAnnexure - A: F:/Projects/Hpli/Obsc/Annex/Filter Presssushant_jhawerNessuna valutazione finora

- Metal Accounting, The Core Responsibility of Process EngineersDocumento13 pagineMetal Accounting, The Core Responsibility of Process EngineersDirceu Nascimento100% (1)

- Mechanical Data Sheet For Rich Teg Carbon Filter (F-2003/3003), (F-2004/3004)Documento5 pagineMechanical Data Sheet For Rich Teg Carbon Filter (F-2003/3003), (F-2004/3004)AbdulBasitNessuna valutazione finora

- Color Code Manual for Water & Sewer Equipment IdentificationDocumento7 pagineColor Code Manual for Water & Sewer Equipment IdentificationpuniveinNessuna valutazione finora

- SAGSim OpenDocumento129 pagineSAGSim OpenFederico Hirsch EspinozaNessuna valutazione finora

- SAGSim RecycleDocumento157 pagineSAGSim RecycleFederico Hirsch EspinozaNessuna valutazione finora

- BallSim_Direct Spreadsheet Simulation ModelDocumento48 pagineBallSim_Direct Spreadsheet Simulation ModelluisNessuna valutazione finora

- SAGSim Spreadsheet Simulates SAG Mill Size-by-Size Mass BalanceDocumento129 pagineSAGSim Spreadsheet Simulates SAG Mill Size-by-Size Mass BalanceIrving Dirzo CarrilloNessuna valutazione finora

- Utilities Size Distribution FitDocumento2 pagineUtilities Size Distribution FitAnonymous TsKN7XZBNessuna valutazione finora

- Moly-Cop Tools Conversion Factors SheetDocumento4 pagineMoly-Cop Tools Conversion Factors SheetAnonymous TsKN7XZBNessuna valutazione finora

- Bond Mill ThroughputDocumento5 pagineBond Mill ThroughputAnonymous TsKN7XZBNessuna valutazione finora

- Spanish translation of BallParam_Batch documentDocumento16 pagineSpanish translation of BallParam_Batch documentAnonymous TsKN7XZBNessuna valutazione finora

- BallParam OpenDocumento15 pagineBallParam OpenAnonymous TsKN7XZBNessuna valutazione finora

- Aerophine 3418aDocumento2 pagineAerophine 3418aRaulNessuna valutazione finora

- BallParam OpenDocumento15 pagineBallParam OpenAnonymous TsKN7XZBNessuna valutazione finora

- Overflow (O/F) Alimento (F)Documento2 pagineOverflow (O/F) Alimento (F)Anonymous TsKN7XZBNessuna valutazione finora

- Flow SheetDocumento1 paginaFlow SheetAnonymous TsKN7XZBNessuna valutazione finora

- Bases Molino Vicus-ModelDocumento1 paginaBases Molino Vicus-ModelAnonymous TsKN7XZBNessuna valutazione finora

- Balance Metalurgico EbmDocumento2 pagineBalance Metalurgico EbmAnonymous TsKN7XZBNessuna valutazione finora

- Curriculum Vitae of Masilo ModibaDocumento11 pagineCurriculum Vitae of Masilo Modibalevy2011Nessuna valutazione finora

- BSC Ag Syllabus 5th DeanDocumento150 pagineBSC Ag Syllabus 5th Deansaurabh rNessuna valutazione finora

- Energy Monitoring With Ultrasonic Flow MetersDocumento35 pagineEnergy Monitoring With Ultrasonic Flow MetersViswa NathanNessuna valutazione finora

- Balance of Payment (BoP) Definition, Importance and ComponentsDocumento21 pagineBalance of Payment (BoP) Definition, Importance and ComponentsAnkita Sharma PandeyNessuna valutazione finora

- 10 Tips To Protect Yourself From Unhealthy AirDocumento2 pagine10 Tips To Protect Yourself From Unhealthy AirAnonymous XuFb6TNessuna valutazione finora

- Sap MRP ConfigDocumento23 pagineSap MRP Configsharadapurv100% (1)

- Understanding the Process of OogenesisDocumento52 pagineUnderstanding the Process of OogenesisBharat ThapaNessuna valutazione finora

- Captain Marvel (DC Comics) : Shazam! Navigation SearchDocumento34 pagineCaptain Marvel (DC Comics) : Shazam! Navigation SearchAce Orense Cupid Uranus Ace Sphinx Galzu Acetr444 son of Multiverses Chaos Gaeia Eros ACETR444Nessuna valutazione finora

- 405 Econometrics Odar N. Gujarati: Prof. M. El-SakkaDocumento27 pagine405 Econometrics Odar N. Gujarati: Prof. M. El-SakkaKashif KhurshidNessuna valutazione finora

- Tests On Cement: IS: 4031 Part 4 1988 (Indian Standards)Documento1 paginaTests On Cement: IS: 4031 Part 4 1988 (Indian Standards)Lorna BacligNessuna valutazione finora

- Assignment 1 Systems Analysis - EME5601Documento7 pagineAssignment 1 Systems Analysis - EME5601Travis GrantNessuna valutazione finora

- Word Trek Lesson OutlinesDocumento8 pagineWord Trek Lesson Outlinesapi-289048378Nessuna valutazione finora

- D-Glucitol (420i) Dextrose MonohydrateDocumento3 pagineD-Glucitol (420i) Dextrose MonohydrateSilvia Melendez HNessuna valutazione finora

- NPTEL Control Engineering Assignment 2 - SEO OptimizedDocumento4 pagineNPTEL Control Engineering Assignment 2 - SEO OptimizedGanesh RadharamNessuna valutazione finora

- Toxicology Compendium PDFDocumento602 pagineToxicology Compendium PDFJUANNessuna valutazione finora

- M.E. (Mechanical - Heat Power Engineering) SyllabusDocumento37 pagineM.E. (Mechanical - Heat Power Engineering) SyllabusKapil KotangaleNessuna valutazione finora

- Minicap FTC260, FTC262: Technical InformationDocumento20 pagineMinicap FTC260, FTC262: Technical InformationAmanda PorterNessuna valutazione finora

- Got 1000 Connect To Alpha 2Documento42 pagineGot 1000 Connect To Alpha 2supriyo110Nessuna valutazione finora

- Kodak Film StructureDocumento40 pagineKodak Film StructureThu Thu SheinNessuna valutazione finora

- Operation Manual: Impedance Audiometer AT235hDocumento102 pagineOperation Manual: Impedance Audiometer AT235hmendezoswaldoNessuna valutazione finora

- ADAMHAND8A4Documento11 pagineADAMHAND8A4Elker José Camargo100% (1)

- Lab 7 Activities Sheet Winter 2020Documento7 pagineLab 7 Activities Sheet Winter 2020Mareline MendietaNessuna valutazione finora

- Network FYPDocumento3 pagineNetwork FYPla tahzanNessuna valutazione finora

- Diversification in Flavoured Milk: A ReviewDocumento6 pagineDiversification in Flavoured Milk: A ReviewInternational Journal of Clinical and Biomedical Research (IJCBR)Nessuna valutazione finora

- Enzymatic Browning and Its Prevention-American Chemical Society (1995)Documento340 pagineEnzymatic Browning and Its Prevention-American Chemical Society (1995)danielguerinNessuna valutazione finora

- Picard's Existence and Uniqueness TheoremDocumento2 paginePicard's Existence and Uniqueness Theoremmanjoy dasNessuna valutazione finora

- Case CX210B Mine Crawler Excavator Tier 3 Parts Manual PDFDocumento701 pagineCase CX210B Mine Crawler Excavator Tier 3 Parts Manual PDFJorge Martinez100% (3)

- Caffeine Extraction 1 PDFDocumento25 pagineCaffeine Extraction 1 PDFShanay ShahNessuna valutazione finora

- Alimak AustraliancontractminingDocumento5 pagineAlimak AustraliancontractminingmanudemNessuna valutazione finora