Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Question Bank Vlsi Technology Eec-604

Caricato da

Sougata Ghosh100%(1)Il 100% ha trovato utile questo documento (1 voto)

348 visualizzazioni2 pagineThis document contains 20 questions from 5 units related to the subject of VLSI Technology for the 6th semester B.Tech course in Electronics and Communication Engineering. The questions cover topics like crystal growth techniques, epitaxy processes, wafer preparation, defects in silicon, oxide growth modeling, photoresist materials and properties, lithography techniques, diffusion modeling and processes, metallization and patterning techniques like etching.

Descrizione originale:

ccxx

Copyright

© © All Rights Reserved

Formati disponibili

DOC, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document contains 20 questions from 5 units related to the subject of VLSI Technology for the 6th semester B.Tech course in Electronics and Communication Engineering. The questions cover topics like crystal growth techniques, epitaxy processes, wafer preparation, defects in silicon, oxide growth modeling, photoresist materials and properties, lithography techniques, diffusion modeling and processes, metallization and patterning techniques like etching.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

348 visualizzazioni2 pagineQuestion Bank Vlsi Technology Eec-604

Caricato da

Sougata GhoshThis document contains 20 questions from 5 units related to the subject of VLSI Technology for the 6th semester B.Tech course in Electronics and Communication Engineering. The questions cover topics like crystal growth techniques, epitaxy processes, wafer preparation, defects in silicon, oxide growth modeling, photoresist materials and properties, lithography techniques, diffusion modeling and processes, metallization and patterning techniques like etching.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

Total 20 Questions

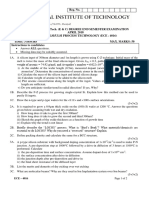

Course: B.Tech (Electronics & Communication Engineering)

Subject: Vlsi Technology

Paper Code: EEC-604

Semester: VI

Questions from Unit I

Q.1. Explain CZ technique of crystal growth.

Q.2. A silicon ingot with 0.5 x 1016 boron atoms/cm3 is to be grown by CZ method. What should be

the concentration of boron in the melt to obtain the required doping concentration? The segregation

coefficient of boron is 0.8.

Q.3. Discuss Molecular beam epitaxy process.

Q.4.(a) Explain vapor phase epitaxy.

(b) What are the sources of silicon in vapor phase epitaxy?

Q.5. Discuss different steps in preparing wafers from raw silicon.

Q.6. What are different defects that occur in silicon?

Questions from Unit II

Q.1. Derive the expression of oxide thickness using Deal-Grove model.

Q.2. Show that to grow an oxide layer of SiO2 layer of thickness x, a thickness of 0.44x of silicon is

consumed.

Q.3. What are PR materials?Describe all types of PR.What are the properties of good PR?

Q.4. Compare X-ray and ion-beam lithography process.

Q.5. Explain the working of CVD reactors in detail.

Q.6. Give the process of silicon vapor deposition.

Questions from Unit III

Q.1. If the measured phosphorous profile is represented by a Gaussian function with a diffusivity

D=2.3 x 10-13 cm2/s, the measured surface concentration is 1 x1018 atoms/cm3 and the measured

junction depth is 1 m at a substrate concentration of 1 x 1015 atoms/cm3.Calculate diffusion time and

the total dopant in the diffused layer.

Q.2.What is Ficks law? Explain its importance in theory of diffusion.

Q.3.What are the process variables that affect the diffusion process? Explain.

Q.4. Compare ion implantation process with diffusion.

Q.5.What do you mean by annealing and why it is required in IC fabrication process?

Q.6. Explain solid source diffusion of Boron.

Questions from Unit IV

Q.1. Describe step converge with CVD processes. Explain how gas pressure and surface temperature

may influence these different profiles.

Q.2. Explain the metallization and also describe the problems associated with the process. Explain dc

sputtering method of metallization.

Q.3. Explain proximity printing and projection printing and compare these two.

Q.4. What is etching? Explain its different types and write advantages and disadvantages of each.

Q.5.List all process steps of pattern transfer with diagram.

Q.6. Explain the reactive ION Beam Etching with suitable diagram.

Questions from Unit V

Q.1. Discuss all the steps involved in fabrication of CMOS.

Q.2. Why cleaning of silicon wafers is necessary before any processing steps? What are clean room

standards.

Q.3.Why (100) orientation is preferred over (111) orientation for starting material in NMOS/CMOS

ICS fabrication? Explain the application of SiO2 layer in IC fabrication.

Q.4. A silicon wafer with p type doping of 1015 is heated at 10000C for 1 hour in a day with oxygen.

How much oxide has been grown?

Q.5.Explain the following terms:

(a) Dry Oxidtion

(b)Wet Oxidation

(c)Plasma Oxidation

Q.6.Explain the difference between Dry and Wet Etching.

Potrebbero piacerti anche

- SPLNPROC Word 2010-2016 Technical InstructionsDocumento9 pagineSPLNPROC Word 2010-2016 Technical InstructionsMartín Montes RiveraNessuna valutazione finora

- OxidationDocumento47 pagineOxidationskgarg04100% (1)

- Ece-V-fundamentals of Cmos Vlsi (10ec56) - SolutionDocumento41 pagineEce-V-fundamentals of Cmos Vlsi (10ec56) - SolutionSanthosh Chandu C100% (2)

- Fluid Mechanics and HydraulicsDocumento2 pagineFluid Mechanics and Hydraulicsjcruzada50% (2)

- BiCMOS TechnologyDocumento21 pagineBiCMOS TechnologyMohd YasirNessuna valutazione finora

- VL5301 Analog To Digital InterfacesDocumento1 paginaVL5301 Analog To Digital InterfacesRam MurthyNessuna valutazione finora

- Presentation: Thin Film TransistorDocumento9 paginePresentation: Thin Film TransistorMayankSharma100% (1)

- VLSI Technology: History, Usage and Design ProcessDocumento3 pagineVLSI Technology: History, Usage and Design ProcessLearnyzenNessuna valutazione finora

- Basic Planar ProcessDocumento15 pagineBasic Planar ProcessSmitha KollerahithluNessuna valutazione finora

- Float Zone & Bridgman Crystal Growth Techniques: Abu Syed Md. Jannatul Islam Lecturer, Dept. of EEE, KUET, BDDocumento27 pagineFloat Zone & Bridgman Crystal Growth Techniques: Abu Syed Md. Jannatul Islam Lecturer, Dept. of EEE, KUET, BDBomkesh SardarNessuna valutazione finora

- A Seminar Report On Vlsi FloorplanningDocumento17 pagineA Seminar Report On Vlsi FloorplanningPARAG100% (1)

- Electro LuminescenceDocumento5 pagineElectro LuminescenceKush SharmaNessuna valutazione finora

- R.M.K. College of Engineering and TechnologyDocumento2 pagineR.M.K. College of Engineering and TechnologysankarsadaNessuna valutazione finora

- Chip MorphingDocumento3 pagineChip MorphingSriram Ramachandran100% (1)

- Transistor Biasing & Thermal Stability: Prepared By: Mr. Gaurav Verma Asst. Prof. ECE Dept. NiecDocumento80 pagineTransistor Biasing & Thermal Stability: Prepared By: Mr. Gaurav Verma Asst. Prof. ECE Dept. NiecAbhishek abhishekNessuna valutazione finora

- Subsystem Design: Architectural IssuesDocumento26 pagineSubsystem Design: Architectural IssuesSanjana M PNessuna valutazione finora

- Sample Question Paper Applied ElectronicsDocumento4 pagineSample Question Paper Applied Electronicssachin barge100% (1)

- Organic Light Emitting Diode - Material Process and DevicesDocumento332 pagineOrganic Light Emitting Diode - Material Process and DevicesMelissa FletcherNessuna valutazione finora

- Laser and OpticsDocumento2 pagineLaser and OpticsFish AppearNessuna valutazione finora

- VLSI Fabrication Process PDFDocumento6 pagineVLSI Fabrication Process PDFkitcha5555100% (1)

- EE8461-Linear and Digital Integrated Circuits-Lab ManualDocumento96 pagineEE8461-Linear and Digital Integrated Circuits-Lab ManualSETNHILNessuna valutazione finora

- Linear Integrated Circuits - EC2254Documento77 pagineLinear Integrated Circuits - EC2254Muthu LakiNessuna valutazione finora

- Nanolithography - Processing Methods PDFDocumento10 pagineNanolithography - Processing Methods PDFNilesh BhardwajNessuna valutazione finora

- Types of Rapid PrototypingDocumento65 pagineTypes of Rapid PrototypingNurhuda Hayati0% (1)

- EE2254 - Linear Integrated Circuits and ApplicationsDocumento32 pagineEE2254 - Linear Integrated Circuits and ApplicationsBalaji .sNessuna valutazione finora

- ET7014-Application of MEMS Technology PDFDocumento4 pagineET7014-Application of MEMS Technology PDFSaran ArunNessuna valutazione finora

- Vlsi Basic Viva Questions and Answers PDFDocumento12 pagineVlsi Basic Viva Questions and Answers PDFAnonymous BVp7iZNessuna valutazione finora

- Industrial Automation PDFDocumento4 pagineIndustrial Automation PDFRohit Shinde RSNessuna valutazione finora

- Final PPT Hand GestureDocumento23 pagineFinal PPT Hand GestureLalitha YentiNessuna valutazione finora

- Chapter 1 IC FabricationDocumento35 pagineChapter 1 IC FabricationAiman NamakuNessuna valutazione finora

- EE6007-MEMS Rejinpaul Important Questions PDFDocumento2 pagineEE6007-MEMS Rejinpaul Important Questions PDFGopi ChandNessuna valutazione finora

- Bi Cmos TechnologyDocumento27 pagineBi Cmos Technologymbiswasray_iter100% (1)

- Artificial Intelligence Substation ControllerDocumento3 pagineArtificial Intelligence Substation ControllerJITHINRAJ35100% (1)

- Chapter 4 Clean Room Wafer Cleaning and GetteringDocumento31 pagineChapter 4 Clean Room Wafer Cleaning and GetteringBablu VermaNessuna valutazione finora

- 15ecl48 VTU Raghudathesh RC Wein Bridge OscillatorsDocumento7 pagine15ecl48 VTU Raghudathesh RC Wein Bridge OscillatorsraghudatheshgpNessuna valutazione finora

- Metalization ProcessDocumento24 pagineMetalization Processsowbarniga soundararajanNessuna valutazione finora

- BSC Electronics Syllabus Kerala UniversityDocumento64 pagineBSC Electronics Syllabus Kerala UniversityVarunRaj67% (3)

- Electronic Devices Model Question PapersDocumento2 pagineElectronic Devices Model Question Papersk_kunarajNessuna valutazione finora

- Ee 2254 Linear Integrated Circuits and Applications Anna University Previous Year Question PaperDocumento2 pagineEe 2254 Linear Integrated Circuits and Applications Anna University Previous Year Question Paperkibrom atsbhaNessuna valutazione finora

- Seminar On CmosDocumento8 pagineSeminar On CmosRoberto HoodNessuna valutazione finora

- Atal FDP On Sensor Technology - 2Documento3 pagineAtal FDP On Sensor Technology - 2Rameshkumar JayaramanNessuna valutazione finora

- Introduction To VLSI Fabrication Technologies: Emanuele BaravelliDocumento38 pagineIntroduction To VLSI Fabrication Technologies: Emanuele BaravelliNelarapuMaheshNessuna valutazione finora

- EDC BitsDocumento12 pagineEDC BitsKumar Goud.K0% (1)

- Chapter 2.coaxial and Fiber Optic CableDocumento32 pagineChapter 2.coaxial and Fiber Optic CableSwapnil Shinde100% (1)

- Cmos Analog Ic Design Course Plan NewDocumento9 pagineCmos Analog Ic Design Course Plan Newjim2001Nessuna valutazione finora

- Vlsi Tech QBDocumento5 pagineVlsi Tech QBanupvasuNessuna valutazione finora

- EE8451, EE6303 Linear Integrated Circuits and Applications LICA - 2 Marks With Answers 2Documento47 pagineEE8451, EE6303 Linear Integrated Circuits and Applications LICA - 2 Marks With Answers 2manoj kumarNessuna valutazione finora

- Ee503 - Ic Fabrication and Packaging TechnologyDocumento34 pagineEe503 - Ic Fabrication and Packaging TechnologyPrevenaManiamNessuna valutazione finora

- MEMS FabricationDocumento23 pagineMEMS FabricationPardha Saradhi DamarlaNessuna valutazione finora

- VLSI - Silicon Gate TechnologyDocumento18 pagineVLSI - Silicon Gate TechnologyK.R.RaguramNessuna valutazione finora

- Steps For IC Manufacturing - VLSI Tutorials - MepitsDocumento6 pagineSteps For IC Manufacturing - VLSI Tutorials - MepitsAbhiNessuna valutazione finora

- Qca Project PPTDocumento20 pagineQca Project PPTPandu KNessuna valutazione finora

- Ebe Final PHD For 1 DC MeetingDocumento19 pagineEbe Final PHD For 1 DC MeetingBramwell Samuel KumarNessuna valutazione finora

- of Phase 1Documento33 pagineof Phase 1Gouthamraman SegarNessuna valutazione finora

- Chemical - Mechanical PolishingDocumento7 pagineChemical - Mechanical PolishingMorcos Nashaat Daneil100% (1)

- EC8095-VLSI DesignDocumento11 pagineEC8095-VLSI DesignfayikaliNessuna valutazione finora

- Question Bank Fundamentals of CMOS VLSI-10EC56 15-16Documento10 pagineQuestion Bank Fundamentals of CMOS VLSI-10EC56 15-16Pranav KpNessuna valutazione finora

- Modern Intelligent Instruments - Theory and ApplicationDa EverandModern Intelligent Instruments - Theory and ApplicationNessuna valutazione finora

- Mec010 Vlsi TechnologyDocumento1 paginaMec010 Vlsi TechnologySougata GhoshNessuna valutazione finora

- Assignment 2: Assignments#1 For Vlsi TechnologyDocumento5 pagineAssignment 2: Assignments#1 For Vlsi TechnologyRajesh BathijaNessuna valutazione finora

- LPVD 2018Documento2 pagineLPVD 2018Aniruddh AndeNessuna valutazione finora

- Chapter 6 Thermal Oxidation - I Bo CuiDocumento23 pagineChapter 6 Thermal Oxidation - I Bo CuisbotacondNessuna valutazione finora

- JFET Characteristics PDFDocumento9 pagineJFET Characteristics PDFSougata GhoshNessuna valutazione finora

- Asynchronous Using D FlipflopDocumento3 pagineAsynchronous Using D FlipflopSougata GhoshNessuna valutazione finora

- Lamda Rules Layout TutorialDocumento15 pagineLamda Rules Layout TutorialSougata GhoshNessuna valutazione finora

- Montecarlo PDFDocumento7 pagineMontecarlo PDFSougata GhoshNessuna valutazione finora

- CCPastStatement03 12 2018 PDFDocumento1 paginaCCPastStatement03 12 2018 PDFSougata GhoshNessuna valutazione finora

- Quick Start PDFDocumento1 paginaQuick Start PDFSougata GhoshNessuna valutazione finora

- Akhbari Hosiyarpur PaperDocumento8 pagineAkhbari Hosiyarpur PaperSougata GhoshNessuna valutazione finora

- IIT Kanpur L20 - Class - AB PDFDocumento33 pagineIIT Kanpur L20 - Class - AB PDFSougata GhoshNessuna valutazione finora

- 03amplitude ModulationDocumento50 pagine03amplitude ModulationSougata GhoshNessuna valutazione finora

- 7th LessonDocumento54 pagine7th LessonSougata GhoshNessuna valutazione finora

- Chapter - 3Documento40 pagineChapter - 3Sougata Ghosh100% (1)

- Abstract-The Enhancement of Recycling Folded Cascode (RFC)Documento2 pagineAbstract-The Enhancement of Recycling Folded Cascode (RFC)Sougata GhoshNessuna valutazione finora

- Comm 03 Amplitude ModulationDocumento47 pagineComm 03 Amplitude ModulationHazem Abu RamadanNessuna valutazione finora

- New DSP LabDocumento31 pagineNew DSP LabSougata GhoshNessuna valutazione finora

- 1501137243609Documento2 pagine1501137243609Sougata Ghosh0% (1)

- Quiz Basic ElectronicsDocumento2 pagineQuiz Basic ElectronicsSougata GhoshNessuna valutazione finora

- Front PageDocumento14 pagineFront PageSougata GhoshNessuna valutazione finora

- IndexDocumento4 pagineIndexSougata GhoshNessuna valutazione finora

- Chapter - 11Documento48 pagineChapter - 11Sougata GhoshNessuna valutazione finora

- DESIGN of FIR FILTER Low Pass & High Pass FilterDocumento4 pagineDESIGN of FIR FILTER Low Pass & High Pass FilterSougata GhoshNessuna valutazione finora

- How To Have A Healthy BabyDocumento5 pagineHow To Have A Healthy BabySougata GhoshNessuna valutazione finora

- Simulation Lab FileDocumento42 pagineSimulation Lab FileSougata GhoshNessuna valutazione finora

- Chapter - 10Documento20 pagineChapter - 10Sougata GhoshNessuna valutazione finora

- Chapter - 2Documento14 pagineChapter - 2Sougata GhoshNessuna valutazione finora

- Chapter - 1Documento34 pagineChapter - 1Sougata GhoshNessuna valutazione finora

- Chapter - 4Documento58 pagineChapter - 4Sougata GhoshNessuna valutazione finora

- Vlsi Technology 10 QuestionsDocumento1 paginaVlsi Technology 10 QuestionsSougata GhoshNessuna valutazione finora

- Phrasal Verbs List PDFDocumento20 paginePhrasal Verbs List PDFNelly Vicky CruzNessuna valutazione finora

- Jahn Teller Theorm 5th ChemDocumento10 pagineJahn Teller Theorm 5th ChemMuhammad ArhamNessuna valutazione finora

- AspenTech HYSYS Pipe ModelsDocumento23 pagineAspenTech HYSYS Pipe ModelswidhisaputrawijayaNessuna valutazione finora

- Docu Tips-24972ukqualsgcebiologyas804224972Documento52 pagineDocu Tips-24972ukqualsgcebiologyas804224972Rafid HaqNessuna valutazione finora

- Essay On Corrosion - Baimourne BournebeDocumento4 pagineEssay On Corrosion - Baimourne BournebeBAIMOURNE BOURNEBENessuna valutazione finora

- HAZOP For Blasting ChamberDocumento5 pagineHAZOP For Blasting Chambersepri manerson sinaga0% (1)

- OTRDocumento51 pagineOTRNithi AnandNessuna valutazione finora

- Chapter 5: Analytic Techniques: by Julia C. Drees, Matthew S. Petrie, Alan H.B. WuDocumento15 pagineChapter 5: Analytic Techniques: by Julia C. Drees, Matthew S. Petrie, Alan H.B. WuTanveerNessuna valutazione finora

- ATR MRFDocumento24 pagineATR MRFnasser ondilloNessuna valutazione finora

- Lettre MotivationDocumento2 pagineLettre MotivationSalhi SiwarNessuna valutazione finora

- A744 A744m 07Documento6 pagineA744 A744m 07arunrathikaNessuna valutazione finora

- CL ALOX enDocumento2 pagineCL ALOX enmikael8118Nessuna valutazione finora

- Catalog Precisa PDFDocumento27 pagineCatalog Precisa PDFmbilalk315Nessuna valutazione finora

- (PDF) a General LC-MS - MS Method for Monitoring Potential Β-Lactam Contamination in Drugs and Drug-Manufacturing SurfacesDocumento16 pagine(PDF) a General LC-MS - MS Method for Monitoring Potential Β-Lactam Contamination in Drugs and Drug-Manufacturing SurfacessppNessuna valutazione finora

- NTSE Question Bank & Solutions (Complete Syllabus) PDFDocumento7 pagineNTSE Question Bank & Solutions (Complete Syllabus) PDFSaksham50% (2)

- Shin 2016Documento8 pagineShin 2016pur bNessuna valutazione finora

- Aiats Aieee 2012 Test-1 SolutionDocumento10 pagineAiats Aieee 2012 Test-1 Solutionblue_l1Nessuna valutazione finora

- SoilMech Ch8 EC7 RequirementsDocumento10 pagineSoilMech Ch8 EC7 RequirementsarslanpasaNessuna valutazione finora

- Flavor ChemistryDocumento1 paginaFlavor ChemistryMVNessuna valutazione finora

- Photosynthesis in PlantsDocumento5 paginePhotosynthesis in Plantskay69max47Nessuna valutazione finora

- s20mdl1sm PDFDocumento31 pagines20mdl1sm PDFvegamarco80Nessuna valutazione finora

- Scale Up ArticleDocumento8 pagineScale Up ArticleAndrek QueckNessuna valutazione finora

- Xpress 500 Changeover TimeDocumento3 pagineXpress 500 Changeover Timeltrevino100Nessuna valutazione finora

- Chemical Process Calculations: Autumn 2021Documento23 pagineChemical Process Calculations: Autumn 2021Ujjwal AnandNessuna valutazione finora

- Laf Foon 1951Documento10 pagineLaf Foon 1951ShivakrishnaNessuna valutazione finora

- Piercing Extrusion of Long Hollow Component With Subsidiary TensionDocumento4 paginePiercing Extrusion of Long Hollow Component With Subsidiary TensionDhan CNessuna valutazione finora

- Vessel Manways, Handholes Pose Special Sealing Challenges: Flanged PlatesDocumento6 pagineVessel Manways, Handholes Pose Special Sealing Challenges: Flanged PlatesalokbdasNessuna valutazione finora

- Dye Penetrant TestingDocumento2 pagineDye Penetrant TestingshreeambhasankaranNessuna valutazione finora

- Texture 160203172810Documento28 pagineTexture 160203172810NainaNessuna valutazione finora

- Schultz 1987Documento18 pagineSchultz 1987Ruiz ManuelNessuna valutazione finora