Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Danfoss 1 NL73FT - Oc - R134a - 220v - 50hz - 08-2004 - Ed400q102

Caricato da

Hikmat KtkTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Danfoss 1 NL73FT - Oc - R134a - 220v - 50hz - 08-2004 - Ed400q102

Caricato da

Hikmat KtkCopyright:

Formati disponibili

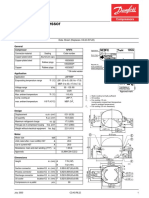

NL7.

3FT

Tropical Compressor Application

NL7.3FT 105G

R134a R134a

220-240V 50Hz Blue stripe

6731

Approvals

8282-11

Barcode on

General white background

DANFOSS COMPRESSORS

Yellow background

Code number 105G6731

Approvals EN 60335-2-34

Compressors on pallet 80

Application

Application LBP

Frequency Hz 50 60

Evaporating temperature C -35 to -10

Voltage range V 187 - 254

Max. condensing temperature continuous (short) C 60 (70)

Max. winding temperature continuous (short) C 125 (135)

Cooling requirements at max. ambient temperature

Frequency Hz 50 60 S = Static cooling normally sufficient

O = Oil cooling

Application LBP MBP HBP LBP MBP HBP

F1 = Fan cooling 1.5 m/s

32C S (compressor compartment temperature

38C S equal to ambient temperature)

F2 = Fan cooling 3.0 m/s necessary

43C O

SG = Suction gas cooling normally sufficent

Remarks on application: In capillary tube systems where non-equalized pressures may occur = not applicable in this area

at compressor start, or in areas with short power supply drop-outs, a starting capacitor can be

used for ensuring a successful start (CSIR).

Motor

Motor type RSIR/CSIR

LRA (rated after 4 sec. UL984), HST | LST A 8.4 6.7 204

Cut in Current, HST | LST A 8.4 11.3 170

Resistance, main | start winding (25C) 11.2 16.2

Design

100

Displacement cm3 7.27

70

Oil quantity (type) cm3 270 (polyolester)

Maximum refrigerant charge g 400 16

Free gas volume in compressor cm 3

2180

178

Weight without electrical equipment kg 9.3 D 205

E

Dimensions C

Height mm A 188

B 182

25

35

B1 A B

15

B2

93.5

102.5

75.5

Suction connector location/I.D. mm | angle C 6.2 | 15

40

material | comment Cu-plated steel | Al caps

254

Process connector location/I.D. mm | angle D 6.2 | 25 F

material | comment Cu-plated steel | Al caps 8249

Discharge connector location/I.D. mm | angle E 5.0 | 35

material | comment Cu-plated steel | Al caps

60.5

166

Oil cooler connector location/I.D. mm | angle F 5.0 | 35

40

51 27

47

54

material | comment Copper | Rubber caps

72

78

Connector tolerance I.D. mm 0.09, on 5.0 +0.12/+0.20

Remarks: stamp on cover only Danfoss 113 119

127

August 2004 DEHC.ED.400.Q1.02 1/2

EN 12900 Household (CECOMAF) 220V, 50Hz, 2 W PTC consumption incl., static cooling

Evap. temp. in C -45 -40 -35 -30 -25 -23.3 -20 -15 -10 -6.7 -5 0 5 7.2 10 15 20

Capacity in W 71 100 136 150 181 235 299

Power cons. in W 108 124 145 152 168 194 220

Current cons. in A 0.86 0.88 0.94 0.96 1.01 1.11 1.21

COP in W/W 0.66 0.81 0.94 0.99 1.07 1.21 1.36

ASHRAE LBP 220V, 50Hz, 2 W PTC consumption incl., static cooling

Evap. temp. in C -45 -40 -35 -30 -25 -23.3 -20 -15 -10 -6.7 -5 0 5 7.2 10 15 20

Capacity in W 87 123 168 185 222 289 369

Power cons. in W 108 124 145 152 168 194 220

Current cons. in A 0.86 0.88 0.94 0.96 1.01 1.11 1.21

COP in W/W 0.81 0.99 1.16 1.21 1.32 1.49 1.68

LST HST

c

g

b

8217

b

a1

8219-5

d a2

Main winding a1 Start winding d

N

c

10 11

N L 12 13

C

14

Winding protector Main winding Winding protector Start winding

Accessories Figure Code number Test conditions EN 12900/CECOMAF ASHRAE

PTC starting device 6.3 mm spade connectors 103N0011 Condensing temperature 55C 54.4C

4.8 mm spade connectors a1 103N0018 Ambient temperature 32C 32C

ePTC starting device 4.8 mm spade connectors Suction gas temperature 32C 32C

Starting relay 6.3 mm spade connectors a2 117U6001 Liquid temperature no subcooling 32C

Start. capacitor 80 F 6.3 mm spade connectors c 117U5015

Cover b 103N2010

Cord relief d 103N1010 Mounting accessories Code number

Run capacitor 4 F 6.3 mm spade connectors Bolt joint for one compressor : 16 mm 118-1917

e

(optional) 4.8 mm spade connectors Bolt joint in quantities : 16 mm 118-1918

Protection screen for PTC g 103N0476 Snap-on in quantities : 16 mm 118-1919

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already

on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

2/2 DEHC.ED.400.Q1.02 August 2004

Potrebbero piacerti anche

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDa EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsValutazione: 5 su 5 stelle5/5 (1)

- SC 18 MLDocumento2 pagineSC 18 MLmarco adolfo escobar garcíaNessuna valutazione finora

- bd35f 101z0204 R134a 12-24vdc 05-2016 Desd100p522 PDFDocumento2 paginebd35f 101z0204 R134a 12-24vdc 05-2016 Desd100p522 PDFSilvaNessuna valutazione finora

- bd35f 101z0204 R134a 12-24vdc 05-2016 Desd100p522Documento2 paginebd35f 101z0204 R134a 12-24vdc 05-2016 Desd100p522SilvaNessuna valutazione finora

- NL10MF Standard Compressor R134a 220-240V 50Hz & 208-230V 60HzDocumento2 pagineNL10MF Standard Compressor R134a 220-240V 50Hz & 208-230V 60HzHumberto Cadori FilhoNessuna valutazione finora

- SC21CL Compressor Data SheetDocumento2 pagineSC21CL Compressor Data SheetOscar MendozaNessuna valutazione finora

- Compresseur Danfoss Secop sc21cl PDFDocumento2 pagineCompresseur Danfoss Secop sc21cl PDFOscar MendozaNessuna valutazione finora

- SC21CL Compressor Data SheetDocumento2 pagineSC21CL Compressor Data SheetMohamed SaifiNessuna valutazione finora

- bd80f 101z0280 R134a 12-24vdc 03-2023 Desd100d402Documento2 paginebd80f 101z0280 R134a 12-24vdc 03-2023 Desd100d402Boudjakdji SamirNessuna valutazione finora

- Nf9Fx Standard Compressor R134a 115-127V 60Hz: CompressorsDocumento2 pagineNf9Fx Standard Compressor R134a 115-127V 60Hz: CompressorsGregory Hernandez0% (1)

- Danfoss Sc18clDocumento2 pagineDanfoss Sc18clYosephanderNessuna valutazione finora

- Sc18cl Comp Unicond EnfriadorDocumento2 pagineSc18cl Comp Unicond EnfriadorDante Víctor Flores HerbasNessuna valutazione finora

- NF7FX R134a 115V 60Hz 07-03 Cg43x422Documento2 pagineNF7FX R134a 115V 60Hz 07-03 Cg43x422Sixto AgueroNessuna valutazione finora

- Htk12Aa KAPPA LBP Compressor Top Efficiency R600a 220-240V 50HzDocumento2 pagineHtk12Aa KAPPA LBP Compressor Top Efficiency R600a 220-240V 50HzTunaNessuna valutazione finora

- SC18G R134a 115V 60Hz 10-03 Cg44h422Documento2 pagineSC18G R134a 115V 60Hz 10-03 Cg44h422Jesus Maria Medina SanchezNessuna valutazione finora

- SC15CL LBP/MBP Compressor R404A/R507 220-240V 50Hz: CompressorsDocumento2 pagineSC15CL LBP/MBP Compressor R404A/R507 220-240V 50Hz: CompressorsMarisol SaavedraNessuna valutazione finora

- TTY5F R134a 115V 60Hz 01-04 Cd42v522Documento2 pagineTTY5F R134a 115V 60Hz 01-04 Cd42v522salvadorNessuna valutazione finora

- CPDAS343Documento2 pagineCPDAS343ali.mamuti.36Nessuna valutazione finora

- NF10FX Standard Compressor R134a 115-127V 60Hz: CompressorsDocumento2 pagineNF10FX Standard Compressor R134a 115-127V 60Hz: CompressorsPaul Antonio Quero PolancoNessuna valutazione finora

- SC12DL MBP/HBP Compressor R404A/R507 & R407C 220-240V 50Hz: GeneralDocumento2 pagineSC12DL MBP/HBP Compressor R404A/R507 & R407C 220-240V 50Hz: GeneralDanieleNessuna valutazione finora

- Kompressor Nle11cnl LBP Datablad Kruff AbDocumento2 pagineKompressor Nle11cnl LBP Datablad Kruff Abpadilla.marcos.420Nessuna valutazione finora

- BD35F-HD Heavy Duty Direct Current Compressor R134a, 12-24V DCDocumento2 pagineBD35F-HD Heavy Duty Direct Current Compressor R134a, 12-24V DCNaba94Nessuna valutazione finora

- NL7.3FT Tropical Compressor R134a 220-240V 50Hz: GeneralDocumento2 pagineNL7.3FT Tropical Compressor R134a 220-240V 50Hz: Generalbram samyNessuna valutazione finora

- Danfoss BD35F CompressorDocumento2 pagineDanfoss BD35F CompressorsaxonpirateNessuna valutazione finora

- TFS4.5FT Tropical Compressor R134a 115-127V 60Hz: CompressorsDocumento2 pagineTFS4.5FT Tropical Compressor R134a 115-127V 60Hz: CompressorsMarcos GuardiaNessuna valutazione finora

- sc12clx2 104l2699 R404a-R507 220v 60hz 01-2020 Desd461z302-22Documento4 paginesc12clx2 104l2699 R404a-R507 220v 60hz 01-2020 Desd461z302-22Shan AhmadNessuna valutazione finora

- Direct Current CompressorDocumento2 pagineDirect Current Compressorcbdk71Nessuna valutazione finora

- bd35k 101z0211 R600a 12-24vdc 07-2013 Dehced100f502Documento2 paginebd35k 101z0211 R600a 12-24vdc 07-2013 Dehced100f502AshwinNessuna valutazione finora

- sc12g 8240Documento2 paginesc12g 8240Rivera DanielNessuna valutazione finora

- Kompresor Secop Nl9f Za ZamrzivačDocumento2 pagineKompresor Secop Nl9f Za ZamrzivačSrećkoNessuna valutazione finora

- Sc12Mlx MBP Compressor R404A/R507 208-230V 60Hz & 220-240V 50HzDocumento2 pagineSc12Mlx MBP Compressor R404A/R507 208-230V 60Hz & 220-240V 50HzFRIER RefrigeraciónNessuna valutazione finora

- Doc087986422029 PDFDocumento2 pagineDoc087986422029 PDFGalih EndrayanaNessuna valutazione finora

- NF5.5FX Standard Compressor R134a 115-127V 60Hz: CompressorsDocumento2 pagineNF5.5FX Standard Compressor R134a 115-127V 60Hz: CompressorsMiguel CamposNessuna valutazione finora

- SC15G Standard Compressor R134a 208 A 230V 60HzDocumento2 pagineSC15G Standard Compressor R134a 208 A 230V 60Hzgabriel_stachNessuna valutazione finora

- SC18CLX.2 LBP Compressor R404A/R507 220-240V 50Hz: GeneralDocumento2 pagineSC18CLX.2 LBP Compressor R404A/R507 220-240V 50Hz: Generalأبو زينب المهندسNessuna valutazione finora

- Energy-optimized 115V 60Hz R134a compressor data sheetDocumento2 pagineEnergy-optimized 115V 60Hz R134a compressor data sheetElectronicaPictronicNessuna valutazione finora

- Danfoss Secop FR7GHDocumento2 pagineDanfoss Secop FR7GHwinNessuna valutazione finora

- NL11MF Standard Compressor R134a 220-240V 50Hz: GeneralDocumento2 pagineNL11MF Standard Compressor R134a 220-240V 50Hz: GeneralTrkulja GoranNessuna valutazione finora

- NL8.4MF Standard Compressor R134a 220-240V 50Hz & 208-230V 60HzDocumento2 pagineNL8.4MF Standard Compressor R134a 220-240V 50Hz & 208-230V 60HzRabah RebouhNessuna valutazione finora

- Tly4kk3 102h4442 R600a 220v 50hz 11-2011 Desd503u102Documento2 pagineTly4kk3 102h4442 R600a 220v 50hz 11-2011 Desd503u102zach yvesNessuna valutazione finora

- Gs26Mlx MBP Compressor R404A/R507 220-240V 50Hz: GeneralDocumento2 pagineGs26Mlx MBP Compressor R404A/R507 220-240V 50Hz: GeneralMd. Matiur RahmanNessuna valutazione finora

- CPDAS218Documento2 pagineCPDAS218issiaka dialloNessuna valutazione finora

- TL2.5F Standard Compressor R134a 115V 60Hz: GeneralDocumento2 pagineTL2.5F Standard Compressor R134a 115V 60Hz: GeneraljessahelbrandtNessuna valutazione finora

- bd35k-b 101z0214 R600a 12-24vdc 03-2023 Desd101u202Documento2 paginebd35k-b 101z0214 R600a 12-24vdc 03-2023 Desd101u202Alexis OrganisNessuna valutazione finora

- Nle11cnl 105h6174 r290 220v 50hz 09-2019 DsDocumento6 pagineNle11cnl 105h6174 r290 220v 50hz 09-2019 Dspadilla.marcos.420Nessuna valutazione finora

- Gs26Clx LBP Compressor R404A/R507 220-240V 50Hz: GeneralDocumento2 pagineGs26Clx LBP Compressor R404A/R507 220-240V 50Hz: GeneralmustafaNessuna valutazione finora

- nl73mf 105g6772 R134a 220v 50hz 60hz 10-2019 Desd400w402Documento2 paginenl73mf 105g6772 R134a 220v 50hz 60hz 10-2019 Desd400w402tiếm nguyễnNessuna valutazione finora

- R134a Standard Compressor 220-240V 50Hz Technical SpecificationsDocumento2 pagineR134a Standard Compressor 220-240V 50Hz Technical SpecificationsVladimir FloresNessuna valutazione finora

- Sc21Ftx Tropical Compressor R134a 220-240V 50Hz: GeneralDocumento2 pagineSc21Ftx Tropical Compressor R134a 220-240V 50Hz: GeneralJulio Cesar Medina PanaNessuna valutazione finora

- Tl4G Universal Compressor R134a 220-240V 50/60Hz: GeneralDocumento2 pagineTl4G Universal Compressor R134a 220-240V 50/60Hz: GeneralMaria MartinNessuna valutazione finora

- TFS4.5FT Tropical Compressor R134a 115-127V 60Hz: GeneralDocumento2 pagineTFS4.5FT Tropical Compressor R134a 115-127V 60Hz: GeneralEstebanLiNessuna valutazione finora

- Catál Compr DANFOSS TL4FDocumento2 pagineCatál Compr DANFOSS TL4FDanielNessuna valutazione finora

- With 105N4710 & 105N4760 ControllersDocumento3 pagineWith 105N4710 & 105N4760 ControllersHarold ReyesNessuna valutazione finora

- fr85cl 103u2890 R404a-R507 220v 50hz 08-2011 Desd460l102Documento2 paginefr85cl 103u2890 R404a-R507 220v 50hz 08-2011 Desd460l102arie 8989Nessuna valutazione finora

- SC 12 CLDocumento2 pagineSC 12 CLFRACHESKA RUBIONessuna valutazione finora

- Bd50f CompressorDocumento2 pagineBd50f CompressorluisNessuna valutazione finora

- NF6.1FX.2 Standard Compressor R134a 115-127V 60Hz: GeneralDocumento2 pagineNF6.1FX.2 Standard Compressor R134a 115-127V 60Hz: GeneralAntonio JarquiinNessuna valutazione finora

- MBP Compressor R404A/R507 115V 60Hz SpecsDocumento2 pagineMBP Compressor R404A/R507 115V 60Hz SpecsComercializadora Agroindustrial FecusacNessuna valutazione finora

- SC15G Universal Compressor R134a 220-240V 50/60Hz: GeneralDocumento2 pagineSC15G Universal Compressor R134a 220-240V 50/60Hz: GeneralSergiu RusuNessuna valutazione finora

- Pending JobsDocumento1 paginaPending JobsHikmat KtkNessuna valutazione finora

- ConsignmentsDocumento3 pagineConsignmentsHikmat KtkNessuna valutazione finora

- Feedback Report For New ModelDocumento2 pagineFeedback Report For New ModelHikmat KtkNessuna valutazione finora

- Pending JobsDocumento1 paginaPending JobsHikmat KtkNessuna valutazione finora

- Sample Report For InformationDocumento16 pagineSample Report For InformationHikmat KtkNessuna valutazione finora

- Guidet-Tour-data KSB PumpDocumento23 pagineGuidet-Tour-data KSB PumpHikmat KtkNessuna valutazione finora

- Data RequiredDocumento1 paginaData RequiredHikmat KtkNessuna valutazione finora

- ATA55 CatalogueDocumento5 pagineATA55 CatalogueHikmat KtkNessuna valutazione finora

- Summary For LinkedIDocumento2 pagineSummary For LinkedIHikmat KtkNessuna valutazione finora

- How Does PMO Project Management Officer and PMS Project Management System Effect Project?Documento1 paginaHow Does PMO Project Management Officer and PMS Project Management System Effect Project?Hikmat KtkNessuna valutazione finora

- Complressor R134aDocumento2 pagineComplressor R134aHikmat KtkNessuna valutazione finora

- EverExceed Hybrid Solar SystemDocumento0 pagineEverExceed Hybrid Solar Systemasr2972Nessuna valutazione finora

- Previous ResearchDocumento2 paginePrevious ResearchsudhakarNessuna valutazione finora

- Lecture Compounding in Impulse TurbineDocumento8 pagineLecture Compounding in Impulse TurbineAbdul Sami Abdul LatifNessuna valutazione finora

- For Turbine: T T T T T TDocumento1 paginaFor Turbine: T T T T T TZakir HussainNessuna valutazione finora

- Airplane - NotesDocumento2 pagineAirplane - NotesVikram MaliNessuna valutazione finora

- WEG Guide To Explosive Atmospheres Wallchart 50042119 Quick Guide EnglishDocumento1 paginaWEG Guide To Explosive Atmospheres Wallchart 50042119 Quick Guide EnglishDave CNessuna valutazione finora

- Six Stroke EngineDocumento36 pagineSix Stroke EngineAmandeep Tanwar100% (2)

- Vittotronic 100 HC1B and 300-KDocumento64 pagineVittotronic 100 HC1B and 300-Kmishu35Nessuna valutazione finora

- 04 PPP TTE API 570 Piping InspnDocumento35 pagine04 PPP TTE API 570 Piping InspnRavindra S. Jivani100% (8)

- BSRIA-Check List - Cold WaterDocumento3 pagineBSRIA-Check List - Cold WaterSawar NaheelNessuna valutazione finora

- Alstom New Designs PDFDocumento18 pagineAlstom New Designs PDF55312714100% (1)

- Fans Blowers and CompressorsDocumento7 pagineFans Blowers and CompressorsChristina SignioNessuna valutazione finora

- Lecture 5 CondenserDocumento37 pagineLecture 5 CondenserWalid MohammedNessuna valutazione finora

- Accepted Manuscript: Renewable EnergyDocumento38 pagineAccepted Manuscript: Renewable EnergyPrivateNessuna valutazione finora

- Su Pompasi Ve Disli 123Documento4 pagineSu Pompasi Ve Disli 123ВЛАДИМИРNessuna valutazione finora

- Thermal Power - WikipediaDocumento24 pagineThermal Power - WikipediaEusebia MaedzwaNessuna valutazione finora

- S225LC-V Bomba de InyeccionDocumento2 pagineS225LC-V Bomba de InyeccionGonzalo Orlandini Lazcano0% (1)

- The Power of Steam: Planing and Sales Certuss Dampfautomaten GMBH & Co. KGDocumento24 pagineThe Power of Steam: Planing and Sales Certuss Dampfautomaten GMBH & Co. KGPrisca Rojas CandelarioNessuna valutazione finora

- Me8595 Te II Steam Turbines Unit III-2022 - 23Documento175 pagineMe8595 Te II Steam Turbines Unit III-2022 - 23CAD With RaoNessuna valutazione finora

- MATLAB An Introduction With Applications by Amos Gilat (5th Edition)Documento53 pagineMATLAB An Introduction With Applications by Amos Gilat (5th Edition)John TauloNessuna valutazione finora

- PDF ChillerDocumento41 paginePDF ChillerTariqNessuna valutazione finora

- Control Valves in Split RangesDocumento6 pagineControl Valves in Split RangesGaurav MishraNessuna valutazione finora

- NRC Generic Letter 98-04Documento21 pagineNRC Generic Letter 98-04jbasdNessuna valutazione finora

- Steam Power Plant: (Coal-Fired)Documento94 pagineSteam Power Plant: (Coal-Fired)Gabriel ApolonioNessuna valutazione finora

- Data Sheet Ejector PDFDocumento2 pagineData Sheet Ejector PDFSuryaprakashNessuna valutazione finora

- Diagramas Electricos P.V 3ra EdiciónDocumento99 pagineDiagramas Electricos P.V 3ra EdiciónNéstor Miranda Marin100% (1)

- Performance of Simple Gas Turbine Cycle Performance of Simple Gas Turbine CycleDocumento25 paginePerformance of Simple Gas Turbine Cycle Performance of Simple Gas Turbine CycleVenkatesh Vakalapudi100% (1)

- RRI School of Performance Air-Fuel RatiosDocumento4 pagineRRI School of Performance Air-Fuel RatiosAntonio Renato CrespoNessuna valutazione finora

- Brown University Facilities Management Building Input Data Form InventoryDocumento40 pagineBrown University Facilities Management Building Input Data Form InventoryMuthana JalladNessuna valutazione finora

- UNIT 16 - Prime Movers and Engines (Q121) PDFDocumento22 pagineUNIT 16 - Prime Movers and Engines (Q121) PDFRajesh Gupta100% (1)