Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Via Fill & via-In-Pad - Heros Electronics

Caricato da

Heros ElectronicsCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Via Fill & via-In-Pad - Heros Electronics

Caricato da

Heros ElectronicsCopyright:

Formati disponibili

2017328 ViaFill&ViaInPadHerosElectronics

+867552749 5167 Ext. 806 sales@heroselectronics.com

Home Capacities Products News Contact Request A Quote

Home / Capacities / Via Fill & ViaInPad

ViaFill&ViaInPad

ViaFill&ViaInPad

PCB Assembly Capacities

Via Fill

Leadfree Assembly

Rigid PCB Capacities

As a refresher, a via is a copper plated hole that is used to connect two or more layers within a PCB together. Via Fill is a special PCB

File Package Information

manufacturing technique used to selectively and completely close via holes with epoxy. There are many instances in which a PCB

PCB Materials

designer might want to have a via filled. Some key benefits are:

PCB Equipments

PCBA Equipments

More reliable surface mounts

PCB & PCBA Services

Increased assembly yields

Via Fill & ViaInPad

Improved reliability by decreasing the probability of trapped air or liquids.

ViaInPad

Perhaps one of the greatest benefits of via fill is the option to implement Via InPad. This process is becoming more and more popular

and preferred as opposed to using the traditional "dog bone" method to transfer signal from the BGA, through the via, and on to inner

layers. In this process, also known as active pad, vias are filled, planarized, plated over with copper. While the ViaInPad process does

increase cost there can be significant benefits over conventional through hole technology.

Some key benefits are:

Tighter BGA pitches

Increased thermal dissipation

Reduced layer count or board size, which ultimately may reduce cost

Improved routing density (higher density per layer)

Strengthening Pad attachment

Gives high frequency designs the shortest possible route to bypass capacitors

Overcomes high speed design issues and constraints such as low inductance

Conductive vs. NonConductive Via Fill

NonConductive Via Fill, sometimes confused with Via Plug, still has copper plated vias to conduct power and heat. The via, however, is

filled with a special low shrinkage epoxy specially formulated for this application. Conductive via fill has silver of copper particles

distributed throughout the epoxy to provide extra thermal and electrical conductivity.

NonConductive fill has a thermal conductivity of 0.25 W/mK whereas Conductive pastes have a thermal conductivity anywhere from

3.515 W/mK. In contrast, electroplated copper has a thermal conductivity of more than 250W/mK.

So while Conductive via fill can offer needed conductivity in some applications more often than not it is possible to use nonconductive

paste and add additional vias. Often this results in superior thermal and electrical conductivity with minimal cost impact.

Contact Our Features News Click to send mail

Tel: PCB Assembly Capacities Introduction of PCB Materials Get PCB and PCBA quick quote!

+867552749 5167 Ext. 806

Rigid PCB Capacities DFM From Gerber files to PCB Production

Email: Data Send Email

sales@heroselectronics.com File Package Information

Skype: Blind & Buried Via Technology in HDI PCB

130Layer FR4 PCB

alan@heroselectronics.com

Aluminum PCB Controlled Impedance Printed Circuit

Address: Board

3F, A4 Building, Junfeng Industrial Car Devices

Park, Chongqing Road, Fuyong Computer

Street, Bao'an District, Shenzhen

518103, China.

http://heroselectronics.com/en/ViaFillViaInPad880568959a8313fac32f11b0/ 1/1

Potrebbero piacerti anche

- Shengyi FR4 S7136 High Frequency PCB For Communication Antenna - High Frequency PCB - Heros ElectronicsDocumento3 pagineShengyi FR4 S7136 High Frequency PCB For Communication Antenna - High Frequency PCB - Heros ElectronicsHeros ElectronicsNessuna valutazione finora

- RoHS Compliant Printed Board Assembly With Guaranteed - Power - Heros ElectronicsDocumento3 pagineRoHS Compliant Printed Board Assembly With Guaranteed - Power - Heros ElectronicsHeros ElectronicsNessuna valutazione finora

- 2 Layer Cheap RO3003 PCB Rogers High Frequency PCB Fabrication - High Frequency PCB - Heros Electronics PDFDocumento3 pagine2 Layer Cheap RO3003 PCB Rogers High Frequency PCB Fabrication - High Frequency PCB - Heros Electronics PDFHeros ElectronicsNessuna valutazione finora

- 2L High Frequency Circuit Board Arlon AD1000 PCB With Immersion Silver - High Frequency PCB - Heros ElectronicsDocumento3 pagine2L High Frequency Circuit Board Arlon AD1000 PCB With Immersion Silver - High Frequency PCB - Heros ElectronicsHeros ElectronicsNessuna valutazione finora

- 2 Layer Next Day PCB Prototype Shenzhen - PCB Prototype Board - Heros Electronics PDFDocumento3 pagine2 Layer Next Day PCB Prototype Shenzhen - PCB Prototype Board - Heros Electronics PDFHeros ElectronicsNessuna valutazione finora

- 12L High Frequency RO4005B Rogers PCB With Selective Solder Mask - High Frequency PCB - Heros ElectronicsDocumento3 pagine12L High Frequency RO4005B Rogers PCB With Selective Solder Mask - High Frequency PCB - Heros ElectronicsHeros ElectronicsNessuna valutazione finora

- 1W/mK Aluminium PCB Fabrication - Aluminum PCB - Heros ElectronicsDocumento4 pagine1W/mK Aluminium PCB Fabrication - Aluminum PCB - Heros ElectronicsHeros ElectronicsNessuna valutazione finora

- SMT & DIP PCB Prototype Assembly - Consumer Electronics - Heros ElectronicsDocumento3 pagineSMT & DIP PCB Prototype Assembly - Consumer Electronics - Heros ElectronicsHeros ElectronicsNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Mastertop 1230 Plus PDFDocumento3 pagineMastertop 1230 Plus PDFFrancois-Nessuna valutazione finora

- Prelim Examination MaternalDocumento23 paginePrelim Examination MaternalAaron ConstantinoNessuna valutazione finora

- BMOM5203 Full Version Study GuideDocumento57 pagineBMOM5203 Full Version Study GuideZaid ChelseaNessuna valutazione finora

- Aptitude Number System PDFDocumento5 pagineAptitude Number System PDFharieswaranNessuna valutazione finora

- Evaluation TemplateDocumento3 pagineEvaluation Templateapi-308795752Nessuna valutazione finora

- Digital MetersDocumento47 pagineDigital MetersherovhungNessuna valutazione finora

- Borang Ambulans CallDocumento2 pagineBorang Ambulans Callleo89azman100% (1)

- Strucure Design and Multi - Objective Optimization of A Novel NPR Bumber SystemDocumento19 pagineStrucure Design and Multi - Objective Optimization of A Novel NPR Bumber System施元Nessuna valutazione finora

- Chapter 1 ClassnotesDocumento35 pagineChapter 1 ClassnotesAllison CasoNessuna valutazione finora

- PED003Documento1 paginaPED003ely mae dag-umanNessuna valutazione finora

- Agnes de MilleDocumento3 pagineAgnes de MilleMarie-Maxence De RouckNessuna valutazione finora

- LetrasDocumento9 pagineLetrasMaricielo Angeline Vilca QuispeNessuna valutazione finora

- Ito Na Talaga Yung FinalDocumento22 pagineIto Na Talaga Yung FinalJonas Gian Miguel MadarangNessuna valutazione finora

- Pivot TableDocumento19 paginePivot TablePrince AroraNessuna valutazione finora

- Sam Media Recruitment QuestionnaireDocumento17 pagineSam Media Recruitment Questionnairechek taiNessuna valutazione finora

- Environmental Economics Pollution Control: Mrinal Kanti DuttaDocumento253 pagineEnvironmental Economics Pollution Control: Mrinal Kanti DuttashubhamNessuna valutazione finora

- An Exploration of The Ethno-Medicinal Practices Among Traditional Healers in Southwest Cebu, PhilippinesDocumento7 pagineAn Exploration of The Ethno-Medicinal Practices Among Traditional Healers in Southwest Cebu, PhilippinesleecubongNessuna valutazione finora

- Vendor Information Sheet - LFPR-F-002b Rev. 04Documento6 pagineVendor Information Sheet - LFPR-F-002b Rev. 04Chelsea EsparagozaNessuna valutazione finora

- Origami Oso HormigueroDocumento9 pagineOrigami Oso HormigueroRogelio CerdaNessuna valutazione finora

- User S Manual AURORA 1.2K - 2.2KDocumento288 pagineUser S Manual AURORA 1.2K - 2.2KEprom ServisNessuna valutazione finora

- ME Eng 8 Q1 0101 - SG - African History and LiteratureDocumento13 pagineME Eng 8 Q1 0101 - SG - African History and Literaturerosary bersanoNessuna valutazione finora

- SMR 13 Math 201 SyllabusDocumento2 pagineSMR 13 Math 201 SyllabusFurkan ErisNessuna valutazione finora

- QP December 2006Documento10 pagineQP December 2006Simon ChawingaNessuna valutazione finora

- RTDM Admin Guide PDFDocumento498 pagineRTDM Admin Guide PDFtemp100% (2)

- 2009 2011 DS Manual - Club Car (001-061)Documento61 pagine2009 2011 DS Manual - Club Car (001-061)misaNessuna valutazione finora

- SMC 2D CADLibrary English 1Documento590 pagineSMC 2D CADLibrary English 1Design IPGENessuna valutazione finora

- TCL LD24D50 - Chassis MS09A-LA - (TKLE2413D) - Manual de Servicio PDFDocumento41 pagineTCL LD24D50 - Chassis MS09A-LA - (TKLE2413D) - Manual de Servicio PDFFabian OrtuzarNessuna valutazione finora

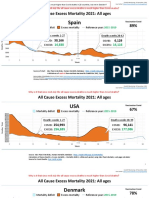

- Countries EXCESS DEATHS All Ages - 15nov2021Documento21 pagineCountries EXCESS DEATHS All Ages - 15nov2021robaksNessuna valutazione finora

- Marketing FinalDocumento15 pagineMarketing FinalveronicaNessuna valutazione finora

- Leak Detection ReportDocumento29 pagineLeak Detection ReportAnnMarie KathleenNessuna valutazione finora