Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

30 GNI Trigeneration Case Study

Caricato da

sahat0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

30 visualizzazioni5 pagineac

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoac

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

30 visualizzazioni5 pagine30 GNI Trigeneration Case Study

Caricato da

sahatac

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 5

Case Study

Trigeneration Technology helps Rochestown Park Hotel to do it again

Located in Douglas, Cork, the Rochestown Park Hotel offers 149 guest bedrooms, a

health club, swimming pools, 12 conference and banqueting suites with the capacity

to cater for 700 guests. In the mid-90s this hotel invested in Combined Heat and

Power (CHP) technology to reduce their operating costs.

Following the 2008 investment of 18 million to refurbish the hotel, managements

focus was to get even further returns from their best-in-class technical energy

solution which had proven to be extremely cost effective over the previous 13 years.

By adding 50 new bedrooms, a new bar, restaurant and a larger reception area,

energy requirements increased significantly. With knowledge and experience of the

savings that could be earned from CHP technology, managements strategy was to

invest in a larger CHP system, coupled with an absorption chiller providing air-

conditioning, to cater for the increase in energy requirements, and gain further

energy efficiencies and financial savings.

Since the hotels original investment in CHP technology, Rochestown Park Hotel has

enjoyed annual energy cost savings of over 40%, significantly lower carbon

emissions, a reliable energy solution with the security of a natural gas supply and

independent on-site generation of electricity. This encouraged management of the

hotel to look again towards CHP technology to meet their future energy needs.

Results

Annual energy savings of circa 115,000

Approximately 2 year payback on investment

Enhanced security of energy supply

Reduced Carbon Emissions of 278 tonnes CO2 per annum

Increased competitiveness through additional facilities and cost savings.

The solution developed included:

Natural gas to fuel the CHP equipment

CHP to generate electricity

Heat from CHP harnessed for hotel and leisure centre

Additional heat from CHP used through absorption chillers for efficient air

conditioning

Heat recovery system

Building Energy Management System (BEMS).

Hotel Goals/Objectives

With the refurbishment, the hotels energy requirements increased accordingly.

Positive experience with CHP warranted further investment in this technology and an

absorption chiller was introduced to provide air conditioning during the summer

months. Due to its low cost and greater efficiency, natural gas was chosen to fuel the

appliance again.

What is CHP?

CHP, also known as Co-Generation is the simultaneous production of electricity

and heat usually in the form of hot water or steam from a primary fuel such as

natural gas (see Figure 1 Inside a Combined Heat and Power Unit). Electricity is

generated on site by using natural gas to drive an alternator connected to the

engine. The heat from exhaust fumes generated by the engine is harvested to

provide heating and hot water for the building, while some of the energy within the

hot water can also be used to provide cooling and air conditioning by using

absorption chillers.

Why CHP?

Due to potential inefficiencies in electricity generation and the resulting cost of

electricity from energy suppliers, significant savings can be made by generating

electricity to meet requirements on your own site.

The financial benefits of onsite electricity generation (using natural gas to power the

electricity generator) are evident by comparing daytime electricity prices in Ireland of

circa 13.9 cent/kWh with market natural gas prices of circa 4.5cent/kWh (SEAI

figures, July 2013).

Trigeneration

Trigeneration takes cogeneration one step further. Trigeneration is the simultaneous

production of electricity and heat with the additional transfer of thermal energy to

provide cooling for practical use (see Fig 3 Principles of Natural Gas

Trigeneration).

Heat generated from the CHP system is converted using an absorption chiller to

provide cold water to cool the building. By adding the absorption chiller into a CHP

system the user can increase the equipments operational hours, maximising the

utilisation of the energy, which is of particular benefit in summer periods, thus

reducing dependence on the more costly electrical air conditioning.

Rochestown Park Hotel have enjoyed these benefits since introducing a natural gas

trigeneration system.

Benefits

Significant reduction in energy costs

CO2 emissions reduced

Lower carbon tax

Security and continuity of power supply

Conservation of valuable fuel resources

Rochestown Park Hotel trigeneration technical details:

Equipment: CHP consultant Tony Lyons designed the new energy system and

oversaw the entire project. All equipment used was supplied and commissioned by

Temp Technology and installed by MBS. The CHP system installed was the ENER-G

310 generating 306kWh of electricity and 357kWh of heat (see Fig 2).

A standard Trigeneration installation includes:

Prime mover

Electrical generator / alternator

Heat recovery system

Absorption chillers

Electrical Safety and monitoring controls

Prime Mover: A prime mover is a gas reciprocating engine, derived from

commercially proven diesel engines. Modifications are made to provide the spark

ignition for the fuel and to reduce the cylinder compression ratio resulting in a strong

reliable and resistant engine. In a CHP system the prime mover / engine is used to

drive an electrical generator or alternator to generate electricity.

Electrical Generator/Alternator: This is an electromechanical device used to convert

mechanical energy to electrical energy in the form of alternating current (AC). The

generator is driven by the Prime Mover engine and generates the required electricity

which can be used directly on site, displacing some or all of the electricity purchased

from the local supply network.

Heat Recovery System: A heat recovery system is designed into the CHP Unit and

takes waste heat from the prime mover engine, harvesting that heat for use locally

in the form of hot water, steam etc. The heat from the engine comes from the

exhaust fumes generated by the engine during the internal combustion process. A

suitable inbuilt heat recovery system ensures that much of the energy contained in

this exhaust heat is not lost. The Rochestown Park Hotel recovered further heat by

fitting an additional external heat recovery system to the CHP unit, to provide hot

water from the waste exhaust.

Absorption Chillers: Absorption chillers are designed to be supplied with steam or hot

water. Through a series of chemical reactions, the energy in hot water is converted

to produce chilled water which is used for space cooling / air conditioning. The

addition of absorption chillers into a CHP system results in the generation of cooling

indirectly from natural gas and reduces the need for costly electric air conditioning

(see Fig 4 CHP and Chillers).

Management Perspective

Having seen the significant savings achieved by generating electricity on-site using

CHP Technology, it was obvious that further investment to achieve even greater

savings was the only solution to meet our hotels greater energy requirements. The

ability to independently generate electricity onsite, at a cost almost 70% less than

grid market costs, gives our business a significantly lower cost base to help us drive

profitability.

John Donovan, Financial Controller

Trigeneration Technology and Rochestown Park Hotel Results

Running costs reduced

Estimated Annual energy cost savings of circa 115,000 were achieved through the

use of the Trigeneration solution.

Project payback

Payback on this project was approximately 2 years on the CHP installation based on

the above savings and an approximate investment of around 240,000.

Emissions reduced

A reduction of 33% on the hotels emissions resulted in a decrease of 77 tonnes of

carbon and 278 tonnes of CO2 being emitted to atmosphere equivalent to

removing 150 cars from the nations roads every year.

Continuity of energy supply

Because the Rochestown Park Hotel generates a large portion of its electrical

demand on site, it is assured of a constant supply of electricity, even in the event of

grid power outages in the region.

Technical Team

Consultant CHP Design Engineer

Tony Lyons

Origen Energy Ltd.

South Ring West Business Park, Tramore Road, Cork

Tel 087 630 4612

Email tonylyons@origen.ie

CHP Maintenance Contractors

Temptech

Unit 9, Childers Road Industrial Estate, Limerick.

Declan Ryan

Tel 086 811 6266

Email declan@temptech.ie

www.temptech.ie

Absorption Chillers Maintenance Contractors

Comfort Cooling Ltd

Unit 7, Airport East Business Park, Cork.

Tom OLeary

Tel 087 254 9468

Email tom@comfortcooling.ie

www.comfortcooling.ie

Contact Information

Rochestown Park Hotel

Rochestown Road, Douglas, Cork.

Tel 021 489 0800 Email res@rochestownpark.com www.rochestownpark.com

The contact details for Gas Networks Ireland are:

Networks Services Centre, St. Margarets Road, Finglas, Dublin 9.

Businesslink: 1850 411 511

Site Drawings: plans@bge.ie

networksinfo@gasnetworks.ie @GasNetIRL

gasnetworks.ie

This information is only a guideline to the different products available for use with

natural gas in new development construction. Users should ensure that products are

suitable for the specific circumstances in which they seek to apply them. Contact the

supplier or manufacturer directly for specific information on building requirements

and materials needed for installation. Professional advice specific to the project

should always be sought. The current Irish Gas Standards and Technical Guidance

Documents (Building Regulations) override all contents. Users should ensure they

always have the most up to date information.

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- A Tuna ChristmasDocumento46 pagineA Tuna ChristmasMark100% (3)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

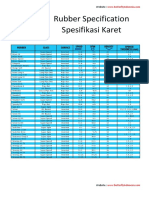

- Rubber Specification Spesifikasi Karet: WebsiteDocumento2 pagineRubber Specification Spesifikasi Karet: WebsitesahatNessuna valutazione finora

- DoorDocumento120 pagineDoorsahatNessuna valutazione finora

- Smart Building GPON by Microduct PT CsiDocumento16 pagineSmart Building GPON by Microduct PT CsisahatNessuna valutazione finora

- VRF Systems Versus Geothermal SystemsDocumento56 pagineVRF Systems Versus Geothermal SystemssahatNessuna valutazione finora

- Catalogue of CCP Publications 2021Documento75 pagineCatalogue of CCP Publications 2021marcheinNessuna valutazione finora

- Review Test 4 - Units 7-8, Real English B1, ECCEDocumento2 pagineReview Test 4 - Units 7-8, Real English B1, ECCEΜαρία ΒενέτουNessuna valutazione finora

- I YOU HE SHE IT WE YOU They: Personal Pronouns in Your Language (In Limba Ta)Documento1 paginaI YOU HE SHE IT WE YOU They: Personal Pronouns in Your Language (In Limba Ta)Alina SardariuNessuna valutazione finora

- 173 RevDocumento131 pagine173 Revmomo177sasaNessuna valutazione finora

- Tales From The SSRDocumento48 pagineTales From The SSRBrad GlasmanNessuna valutazione finora

- Chapter 10 E-Commerce: Digital Markets, Digital GoodsDocumento9 pagineChapter 10 E-Commerce: Digital Markets, Digital Goodsabdalla jaradatNessuna valutazione finora

- Employee Engagement ReportDocumento51 pagineEmployee Engagement Reportradhika100% (1)

- Financial Management Model Question PaperDocumento2 pagineFinancial Management Model Question PaperdvraoNessuna valutazione finora

- Soal Asking and Giving OpinionDocumento2 pagineSoal Asking and Giving OpinionfitriaNessuna valutazione finora

- Case Digest: Dante O. Casibang vs. Honorable Narciso A. AquinoDocumento3 pagineCase Digest: Dante O. Casibang vs. Honorable Narciso A. AquinoMaria Cherrylen Castor Quijada100% (1)

- Time ClockDocumento21 pagineTime ClockMarvin BrunoNessuna valutazione finora

- 24 BL-BK SP List (2930130900)Documento56 pagine24 BL-BK SP List (2930130900)CapricorniusxxNessuna valutazione finora

- 04 Chapter 3Documento13 pagine04 Chapter 3Danica Marie Baquir PadillaNessuna valutazione finora

- Project - 2-2Documento17 pagineProject - 2-2Fareeha KhanNessuna valutazione finora

- Career Development Cell: Kamla Nehru Institute of TechnologyDocumento1 paginaCareer Development Cell: Kamla Nehru Institute of TechnologypiyushNessuna valutazione finora

- DomOrlando Corporate Resume000Documento3 pagineDomOrlando Corporate Resume000domorlando1Nessuna valutazione finora

- Configuring Srewquid Proxy ServerDocumento4 pagineConfiguring Srewquid Proxy ServerPendekar BlankNessuna valutazione finora

- Kansai Survival Manual CH 15Documento2 pagineKansai Survival Manual CH 15Marcela SuárezNessuna valutazione finora

- Double JeopardyDocumento5 pagineDouble JeopardyDeepsy FaldessaiNessuna valutazione finora

- Vasco Menu - Monthly Festive Dinner 2023Documento4 pagineVasco Menu - Monthly Festive Dinner 2023Heamalatha Raja ManickamNessuna valutazione finora

- Oracle IRecruitment Setup V 1.1Documento14 pagineOracle IRecruitment Setup V 1.1Irfan AhmadNessuna valutazione finora

- Oscam FilesDocumento22 pagineOscam Filesvalievabduvali2001Nessuna valutazione finora

- 35 Childrens BooksDocumento4 pagine35 Childrens Booksapi-710628938Nessuna valutazione finora

- Purpose of Schooling - FinalDocumento8 paginePurpose of Schooling - Finalapi-257586514Nessuna valutazione finora

- ObliconDocumento3 pagineObliconMonica Medina100% (2)

- Q2 - Week 7 8Documento4 pagineQ2 - Week 7 8Winston MurphyNessuna valutazione finora

- United States v. Fiasconaro, 315 F.3d 28, 1st Cir. (2002)Documento11 pagineUnited States v. Fiasconaro, 315 F.3d 28, 1st Cir. (2002)Scribd Government DocsNessuna valutazione finora

- Catalogu PDFDocumento24 pagineCatalogu PDFFer GuNessuna valutazione finora

- MidtermDocumento30 pagineMidtermRona CabuguasonNessuna valutazione finora