Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Darcy Business Challenge Submission - Utopians

Caricato da

Priyanka PanigrahiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Darcy Business Challenge Submission - Utopians

Caricato da

Priyanka PanigrahiCopyright:

Formati disponibili

ABSTRACT

Development of Avalon

Profit in Baltia's

Field offshore

163.33

developmentmil. Less than case 1

field of Agartha has

development been planned.

dollars D. Prod. Of

& 3 for Avalon E. Agartha's F. Kolob's G. Ship planning

profit:Agartha

B.

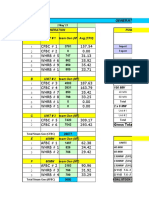

A.Year

No. C. No. of wells on prod. each sale(Mm3) sale(Mm3)(70% to Agartha only

of year(Mm3) (30%of D.) of D.) (Capacity, Trips)

No.

wells

Economic analysis

Target

WellMarkets

Count &&plan Q2 oftimeline

development

of transportation

Q1 Q3 Q4

1 the prominent0 cases:

1 3 5 19.77 5.931 13.839 (11,1)

2 Case 5 1. FLNG

8 11re- 14 17 109.35 32.805 76.545 (11,5)

gasified in Agartha

3 17 20 23 26 29 210.045 63.0135 147.0315 (11,10)

and set via buried

4 pipeline

29 to Kolob

32 35 38 41 312.78 93.834 218.946 (11,14),(3.3,1)

5 Case41 2. 44Pipeline

47 50 53 411.72 123.516 288.204 (11,19)

6 (subsea)

53 to 56 56 & 56

Agartha 56 468.825 140.6475 328.1775 (11,21),(3.3,1)

7 sent 56 via 57 buried

57 57 58 469.465 140.8395 328.6255 (11,21),(3.3,1)

8 pipeline

58 to Kolob

58 58 58 59 467.89 140.367 327.523 (11,21),(3.3,1)

9 Case593. Pipeline

59 59for 60 60 468.664 140.5992 328.0648 (11,21),(3.3,1)

10 Kolob60and 60

FLNG60for 60 60 462.1275 138.6383 323.48925 (11,21)

11 Agartha

60 shows:

60 60 60 60 451.0675 135.3203 315.74725 (11,21)

12 60 60 60 60 60 440.025 132.0075 308.0175 (11,20)

Subsea pipeline(Avalon-Kolob)

4291.729 ~241 mil. $ ~779 mil. $

Surface facilities Capacities

Total Rev. = 1020 mil. $

Subsea Pipeline(on 0.91

Seabed) Mm3/day

0.91

Gas Processing Plant Mm3/day

Surface Facilities placement for Case 3 economics

600

400

Production Rate (million m3/year)

FLNG 200 Avalon for Agartha

from

0

Surface facilities Capacities

10

FLNG Processing

0 0.39 Mm3/day

Plant(offshore)

Years 11,000 m3 &

Still in plateau Period of Ships 3300 m3

production Regasifiation 11,000 m 3

Cases Profit

Key risks technical and non-tehnical and577

Plant(onshore) theirmil

mitigation steps

Case 1

$

17 mil.

Case 2

Risks $ Mitigation Steps

Storage and handling of cryogenic fluid at -1600C. Intensive monitoring and control is required for

325

Case 3

mil. $processing and transportation of LNG.

Fluid is odourless, hence, difficult to detect leaks on Installation of fire-fighting facilities and proper

personnel basis. communication with Coast Guards.

Technical

Fire hazards while handling flammable LNG. Use of PPE(Personal Protective Equipment) to

Can cause cryogenic burns to operating personnel. avoid injuries.

LNG spill and its sudden vapour conversion can cause

explosion, thus damaging oceans pristine ecology.

Corrosion & Leakage is difficult to control in deep sub- Surveillance of sub-sea pipeline for leakage

sea pipeline. detection.

Consensus with Agartha government.

Technical

Geopolitical risk- Contractual agreement with Kolob

Non-

Laying sub-sea pipeline in International waters. government allowing uninterrupted gas

import of at least 330 million m3 per year

irrespective of relations with Agartha.

Key stakeholders and their management

Stakeholder Management

Government and people of Establishing training institutes and conducting workshops to develop skilled

Agartha human resource.

Local fishing community Job opportunities to fishing community and local people in production and

marketing sectors.

Local Contractors Involving local contractors in infrastructure development and production.

Kolob Government Developing Kolob gas market through gas imports.

Company shareholders and Optimum wages and dividends.

Employees

Potrebbero piacerti anche

- Discharge Test at Source S.No Time (Second) Discharge (G) : Yield of Source Is Feasible For DesigningDocumento11 pagineDischarge Test at Source S.No Time (Second) Discharge (G) : Yield of Source Is Feasible For DesigningTariq KhanNessuna valutazione finora

- Longwall Mining at Shallow Depth of Cover in IndiaDa EverandLongwall Mining at Shallow Depth of Cover in IndiaNessuna valutazione finora

- 2 Ships Particulas MV HC Jette-MaritDocumento2 pagine2 Ships Particulas MV HC Jette-MaritWILLINTON HINOJOSA100% (2)

- 09EB T T Definicion Preliminar v2 BRDocumento4 pagine09EB T T Definicion Preliminar v2 BRDanielNessuna valutazione finora

- Bridge and Roof Co. (I) LTDDocumento8 pagineBridge and Roof Co. (I) LTDRISHABH RATHORNessuna valutazione finora

- A Water ResourcesDocumento11 pagineA Water ResourcesChristel ContrerasNessuna valutazione finora

- CPT For Soft Sediments and Deepwater InvestigationsDocumento8 pagineCPT For Soft Sediments and Deepwater InvestigationsSajid IqbalNessuna valutazione finora

- B.delta64 - Spreadsheet 18 May 2011 - BRS Standard Bulk TransportDocumento1 paginaB.delta64 - Spreadsheet 18 May 2011 - BRS Standard Bulk TransportGeorge KanellakisNessuna valutazione finora

- AD-G34-1041-R2734 - Seafox 8 at ZULF GOSP-2 ACPDocumento8 pagineAD-G34-1041-R2734 - Seafox 8 at ZULF GOSP-2 ACPSinojKumarMalipronNessuna valutazione finora

- ATS 19 673 P 001 002 Stamped PlansDocumento33 pagineATS 19 673 P 001 002 Stamped Planswilliam sykes100% (1)

- Model Hydrostatics - MCB - 3-20-19Documento10 pagineModel Hydrostatics - MCB - 3-20-19Jg bzNessuna valutazione finora

- Founding Level (-) 11.198 L.W.L 15.135 Grade of Concrete M35 Reinforcements 20-25φ verticalsDocumento7 pagineFounding Level (-) 11.198 L.W.L 15.135 Grade of Concrete M35 Reinforcements 20-25φ verticalsRISHABH RATHORNessuna valutazione finora

- Earthing System Calculation: Bazian Steel Factory S/S 132/11kV, 1x30/40 MVADocumento29 pagineEarthing System Calculation: Bazian Steel Factory S/S 132/11kV, 1x30/40 MVASiraj nse NseNessuna valutazione finora

- Bazian Steel Factory Earthing CalculationDocumento29 pagineBazian Steel Factory Earthing Calculationsahli medNessuna valutazione finora

- Item No. Description Unit Quantity Minimum Number of Test: 1 Set Concrete Beam Sample/day of Pouring 7 Set MinDocumento23 pagineItem No. Description Unit Quantity Minimum Number of Test: 1 Set Concrete Beam Sample/day of Pouring 7 Set MinMae Ann GonzalesNessuna valutazione finora

- STABILITY REPORT23Documento43 pagineSTABILITY REPORT23Vamsi GuptaNessuna valutazione finora

- Kentledge Design SpreadsheetDocumento4 pagineKentledge Design SpreadsheetUtaya Kumar Veelmurugan100% (1)

- Consultants: G3 Engineering Consultants (PVT) LTD Contractor: Tameer Associates - Hasas (JV)Documento9 pagineConsultants: G3 Engineering Consultants (PVT) LTD Contractor: Tameer Associates - Hasas (JV)Yasin ShahNessuna valutazione finora

- Pipe Mill ReportDocumento19 paginePipe Mill ReportArslan AbbasNessuna valutazione finora

- HYDRANT System Demand: Full Unit: Annexure - 1 Fire Water Demand Calculation For SUG Facilities Fire Fighting SystemDocumento11 pagineHYDRANT System Demand: Full Unit: Annexure - 1 Fire Water Demand Calculation For SUG Facilities Fire Fighting SystemJMVNessuna valutazione finora

- D18a Under Keel Clearance Calculation r5Documento6 pagineD18a Under Keel Clearance Calculation r5paul John castroverdeNessuna valutazione finora

- Area Type Tonnage: Aggreko Fixed (SQ.M) Aggreko Variable (SQ.M) 9304 10374 0 1092Documento20 pagineArea Type Tonnage: Aggreko Fixed (SQ.M) Aggreko Variable (SQ.M) 9304 10374 0 1092Rahul BhatnagarNessuna valutazione finora

- Rehabilitation and upgrade of Stallionaire tank farmDocumento4 pagineRehabilitation and upgrade of Stallionaire tank farmorode franklynNessuna valutazione finora

- Marine Gyrocompass OperationsDocumento8 pagineMarine Gyrocompass OperationsJazib YaseenNessuna valutazione finora

- Langkawi Msma - Osd 75%Documento2 pagineLangkawi Msma - Osd 75%FARHANAH AFIQAH RAZMANNessuna valutazione finora

- Afe UdangDocumento8 pagineAfe UdangDwiki RamadhaniNessuna valutazione finora

- Airflow Equipment ReqDocumento2 pagineAirflow Equipment ReqAjy SetiawanNessuna valutazione finora

- Project Presentation: School of Mines and Petroleum Engineering Department of Mining and Mineral ProcessingDocumento24 pagineProject Presentation: School of Mines and Petroleum Engineering Department of Mining and Mineral ProcessingIsrael MwanyeleleNessuna valutazione finora

- Mechanised Blending and Laying of Blanketing MaterialDocumento27 pagineMechanised Blending and Laying of Blanketing Materialj krishnanNessuna valutazione finora

- LombokStrait LRDocumento4 pagineLombokStrait LRJeffrey Jan PerezNessuna valutazione finora

- Statoil Aldbrough Gas Storage Project Rig RequirementsDocumento14 pagineStatoil Aldbrough Gas Storage Project Rig RequirementsSamuel OkezieNessuna valutazione finora

- Sizing LV CableDocumento7 pagineSizing LV CableGireeshNessuna valutazione finora

- Status of TestDocumento271 pagineStatus of TestMichael LabayoNessuna valutazione finora

- Militar, Canada - B-gl-332-006 Fp-001 - Insert - Enginners (v2.4) - 01!03!2000Documento159 pagineMilitar, Canada - B-gl-332-006 Fp-001 - Insert - Enginners (v2.4) - 01!03!2000brunoNessuna valutazione finora

- Hydraulic Analysis On Highway CulvertDocumento8 pagineHydraulic Analysis On Highway CulvertWai linn zawNessuna valutazione finora

- Annexure-1 /OFFER LIST: Bill of Material For Ipbd (Unit-1) TotalDocumento3 pagineAnnexure-1 /OFFER LIST: Bill of Material For Ipbd (Unit-1) Totalsanjayprakash1979Nessuna valutazione finora

- 8 OffshoreliftingDocumento29 pagine8 OffshoreliftingBagus PanuntunNessuna valutazione finora

- 132 KV Grid StationDocumento14 pagine132 KV Grid StationWaqas AhmedNessuna valutazione finora

- Steam generation and power output dataDocumento8 pagineSteam generation and power output dataBhuvanesh MahendranNessuna valutazione finora

- apr09_stabDocumento3 pagineapr09_stabssabih75Nessuna valutazione finora

- ALMagd C-86-C Drilling Program v1Documento46 pagineALMagd C-86-C Drilling Program v1Anonymous XbmoAFtI100% (2)

- Condensate Production Optimization in The Arun GAs FieldDocumento5 pagineCondensate Production Optimization in The Arun GAs FieldTeddy GeovanieNessuna valutazione finora

- Wind Load & Blow Off Calculation NMML1Documento14 pagineWind Load & Blow Off Calculation NMML1Ankit AgarwalNessuna valutazione finora

- SEO-Optimized Title for Muck Disposal Plan ChapterDocumento11 pagineSEO-Optimized Title for Muck Disposal Plan ChaptertchangmaiNessuna valutazione finora

- Executive Summary RSM 221204Documento30 pagineExecutive Summary RSM 221204bimonurainiNessuna valutazione finora

- ACCEPTANCE LETTER JAMPUR DISTYDocumento5 pagineACCEPTANCE LETTER JAMPUR DISTYAccounts BranchNessuna valutazione finora

- Click To View Illustrations in PDF Format: Bu Hasa DiscoveryDocumento10 pagineClick To View Illustrations in PDF Format: Bu Hasa DiscoveryYouzhnyNessuna valutazione finora

- Coating and Stripping of Bitumen - Aggregate MixtureDocumento13 pagineCoating and Stripping of Bitumen - Aggregate MixtureCE PassajNessuna valutazione finora

- Item No. Description Unit Quantity Minimum Number of Test: 1 Set Concrete Beam Sample/day of Pouring 7 Set MinDocumento1 paginaItem No. Description Unit Quantity Minimum Number of Test: 1 Set Concrete Beam Sample/day of Pouring 7 Set MinMae Ann GonzalesNessuna valutazione finora

- Wave Modeling New Orleans - Mississippi River Gulf Outlet: Hurricane Katrina August 2005Documento46 pagineWave Modeling New Orleans - Mississippi River Gulf Outlet: Hurricane Katrina August 2005KatrinaDocsNessuna valutazione finora

- نرم افزار محاسبات خط لولهDocumento2 pagineنرم افزار محاسبات خط لولهMostafa SarvariNessuna valutazione finora

- Index To AerodromesDocumento15 pagineIndex To AerodromesIbrahim AbudabbusNessuna valutazione finora

- WaterDocumento5 pagineWaterRAMSNessuna valutazione finora

- Img 20220802 0001Documento1 paginaImg 20220802 0001Ralph BaltazarNessuna valutazione finora

- D9L Vs D9RDocumento6 pagineD9L Vs D9RSandyNessuna valutazione finora

- Pipe Mill Machine Project: Boss Moulded Furniture, PakistanDocumento13 paginePipe Mill Machine Project: Boss Moulded Furniture, PakistanArslan AbbasNessuna valutazione finora

- Volume Pekerjaan: Kepada: Bapak Ir.H.Heriwatno SE - Ak.MMDocumento2 pagineVolume Pekerjaan: Kepada: Bapak Ir.H.Heriwatno SE - Ak.MMdeviNessuna valutazione finora

- District CouncilBahawalnagarDocumento880 pagineDistrict CouncilBahawalnagarmuhammad iqbalNessuna valutazione finora

- Magazine December 2023 2 SDocumento28 pagineMagazine December 2023 2 SPriyanka PanigrahiNessuna valutazione finora

- Trump's Supporters See U.S. Victory in China Trade Deal - The New York TimesDocumento2 pagineTrump's Supporters See U.S. Victory in China Trade Deal - The New York TimesPriyanka PanigrahiNessuna valutazione finora

- Comparative Analysis of Biodiesel Feedstocks in India, Bangladesh and MalaysiaDocumento12 pagineComparative Analysis of Biodiesel Feedstocks in India, Bangladesh and MalaysiaPriyanka PanigrahiNessuna valutazione finora

- Comparative Analysis of Biodiesel Feedstocks in India, Bangladesh and MalaysiaDocumento12 pagineComparative Analysis of Biodiesel Feedstocks in India, Bangladesh and MalaysiaPriyanka PanigrahiNessuna valutazione finora

- Clause-By-Clause Explanation of ISO 9001:2015: White PaperDocumento21 pagineClause-By-Clause Explanation of ISO 9001:2015: White PaperbiskaalNessuna valutazione finora

- Comparative Analysis of Biodiesel Feedstocks in India, Bangladesh and MalaysiaDocumento12 pagineComparative Analysis of Biodiesel Feedstocks in India, Bangladesh and MalaysiaPriyanka PanigrahiNessuna valutazione finora

- Comparative Analysis of Biodiesel Feedstocks in India, Bangladesh and MalaysiaDocumento12 pagineComparative Analysis of Biodiesel Feedstocks in India, Bangladesh and MalaysiaPriyanka PanigrahiNessuna valutazione finora

- KECBrochureDocumento20 pagineKECBrochurePriyanka PanigrahiNessuna valutazione finora

- Groceries Take-out/Delivery Restaurant Non-Food Child Products Household Supplies Personal-Care Products Skin Care & Make-UpDocumento2 pagineGroceries Take-out/Delivery Restaurant Non-Food Child Products Household Supplies Personal-Care Products Skin Care & Make-UpPriyanka PanigrahiNessuna valutazione finora

- Downstream Team3Documento22 pagineDownstream Team3Priyanka PanigrahiNessuna valutazione finora

- Downstream Team3Documento22 pagineDownstream Team3Priyanka PanigrahiNessuna valutazione finora

- SPE DL Check ListDocumento9 pagineSPE DL Check ListPriyanka PanigrahiNessuna valutazione finora

- Wax Deposition Characterization and PreventionDocumento11 pagineWax Deposition Characterization and PreventionPriyanka PanigrahiNessuna valutazione finora

- Comparative Analysis of Biodiesel Feedstocks in India, Bangladesh and MalaysiaDocumento12 pagineComparative Analysis of Biodiesel Feedstocks in India, Bangladesh and MalaysiaPriyanka PanigrahiNessuna valutazione finora

- Downstream Team3Documento22 pagineDownstream Team3Priyanka PanigrahiNessuna valutazione finora

- Comparative Analysis of Biodiesel Feedstocks in India, Bangladesh and MalaysiaDocumento12 pagineComparative Analysis of Biodiesel Feedstocks in India, Bangladesh and MalaysiaPriyanka PanigrahiNessuna valutazione finora

- Wax Deposition Characterization and PreventionDocumento11 pagineWax Deposition Characterization and PreventionPriyanka PanigrahiNessuna valutazione finora

- Comparative Analysis of Biodiesel Feedstocks in India, Bangladesh and MalaysiaDocumento12 pagineComparative Analysis of Biodiesel Feedstocks in India, Bangladesh and MalaysiaPriyanka PanigrahiNessuna valutazione finora

- Downstream Team3Documento22 pagineDownstream Team3Priyanka PanigrahiNessuna valutazione finora

- Wax Deposition Characterization and PreventionDocumento11 pagineWax Deposition Characterization and PreventionPriyanka PanigrahiNessuna valutazione finora

- Quantifying The Results of Horizontal MuMultistage Development in Tight Oil Reservoirs of The Western Canadian Sedimentary BasinSPE-149000-MS-PDocumento46 pagineQuantifying The Results of Horizontal MuMultistage Development in Tight Oil Reservoirs of The Western Canadian Sedimentary BasinSPE-149000-MS-PPriyanka PanigrahiNessuna valutazione finora

- How Covid Changed Online Food Shopping in ItalyDocumento19 pagineHow Covid Changed Online Food Shopping in ItalyAsHish KasHyapNessuna valutazione finora

- Womens Film Audio - Reduction - CutDocumento2 pagineWomens Film Audio - Reduction - CutPriyanka PanigrahiNessuna valutazione finora

- Strategy of Development of Hard-To-Recover Reserves of Tyumen Suite Mayskoye Oil fieldSPE-138068-MSP UnlockedDocumento15 pagineStrategy of Development of Hard-To-Recover Reserves of Tyumen Suite Mayskoye Oil fieldSPE-138068-MSP UnlockedPriyanka PanigrahiNessuna valutazione finora

- Draft Speech 26 Jan 2021Documento3 pagineDraft Speech 26 Jan 2021Priyanka PanigrahiNessuna valutazione finora

- SHP SelfCareJournal 052020Documento42 pagineSHP SelfCareJournal 052020Priyanka Panigrahi100% (12)

- Production Enhancement by Redevelopment Through Multilateral Well Drilling in Tight Clastic Reservoirs With Low Primary RecoveryPETSOC-2001-027-PDocumento10 pagineProduction Enhancement by Redevelopment Through Multilateral Well Drilling in Tight Clastic Reservoirs With Low Primary RecoveryPETSOC-2001-027-PPriyanka PanigrahiNessuna valutazione finora

- Fresh Produce Supply Chain StrategiesDocumento31 pagineFresh Produce Supply Chain StrategiesPriyanka PanigrahiNessuna valutazione finora

- MBAL - User GuideDocumento366 pagineMBAL - User GuidePriyanka Panigrahi100% (1)

- How To Install MBal in PCDocumento1 paginaHow To Install MBal in PCPriyanka PanigrahiNessuna valutazione finora

- Chem103 Exam3Documento8 pagineChem103 Exam3MrPI PandesNessuna valutazione finora

- Topic 2.4 - Momentum and ImpulseDocumento38 pagineTopic 2.4 - Momentum and ImpulseKhánh NguyễnNessuna valutazione finora

- Hydraulic efficiency η h= Power output Energy available ∈the jet PDocumento3 pagineHydraulic efficiency η h= Power output Energy available ∈the jet Pkimlouie petateNessuna valutazione finora

- Bobcat Battery Reference GuideDocumento2 pagineBobcat Battery Reference GuideFrancisco Godoy Kutzbach67% (3)

- Underground Facilities for Better Environment and Safety - IndiaDocumento8 pagineUnderground Facilities for Better Environment and Safety - Indiafini1968Nessuna valutazione finora

- Zenit Compact Setup Manual En3Documento26 pagineZenit Compact Setup Manual En3Garage Lifestyle BVGNessuna valutazione finora

- Specification FOR Reciprocating Compressors: National Iranian South Oil-Fields Company (NISOC)Documento27 pagineSpecification FOR Reciprocating Compressors: National Iranian South Oil-Fields Company (NISOC)Mehrshad ShakibNessuna valutazione finora

- SS 578 2012 Portable Fire Extinguishers (Formerly CP55)Documento45 pagineSS 578 2012 Portable Fire Extinguishers (Formerly CP55)Andreas Indrakusuma100% (1)

- Упражнения на отработку Second ConditionalDocumento6 pagineУпражнения на отработку Second ConditionalНаргиля ГаджиеваNessuna valutazione finora

- Dual Cab Locomotive HandbookDocumento80 pagineDual Cab Locomotive HandbookRah Mli80% (5)

- 450 Kva Diesel Generator Set Model HG 450Documento1 pagina450 Kva Diesel Generator Set Model HG 450ghostshotNessuna valutazione finora

- FertiOne Manual (30.11.15)Documento36 pagineFertiOne Manual (30.11.15)YacineNessuna valutazione finora

- Exer 2 - PH and BuffersDocumento4 pagineExer 2 - PH and BuffersAsi JenNessuna valutazione finora

- DHA Anita MHA2 Paper2 Unit 3.1Documento34 pagineDHA Anita MHA2 Paper2 Unit 3.1Priyan TripathiNessuna valutazione finora

- Response of Water Resources Systems To Climate ChangeDocumento355 pagineResponse of Water Resources Systems To Climate ChangePat Prodanovic100% (5)

- EBARA Company ProfileDocumento11 pagineEBARA Company ProfileMohamed IbrahimNessuna valutazione finora

- STW21NM50N MosfetDocumento16 pagineSTW21NM50N MosfetrigowNessuna valutazione finora

- Coupling and ApplicationDocumento4 pagineCoupling and Applicationekobudi94Nessuna valutazione finora

- Cambridge International AS Level: Environmental Management 8291/12Documento12 pagineCambridge International AS Level: Environmental Management 8291/12zohaibNessuna valutazione finora

- Improved procedures for separating crystals from the meltDocumento10 pagineImproved procedures for separating crystals from the meltAna Mariel VenturaNessuna valutazione finora

- Parts Book D85ess-2 - Lepbd08205Documento325 pagineParts Book D85ess-2 - Lepbd08205Frengki Pangaribuan100% (2)

- Toshiba 4550: Service Manual Service HandbookDocumento499 pagineToshiba 4550: Service Manual Service Handbookصلاح هزاعNessuna valutazione finora

- Solar Water HeaterDocumento27 pagineSolar Water HeaterSantosh ThapaNessuna valutazione finora

- The Sun As The AxisDocumento20 pagineThe Sun As The AxisNeb Nyansapo Noopooh100% (2)

- Diesel Engine Technical SpecificationsDocumento3 pagineDiesel Engine Technical SpecificationsFahad MohammedNessuna valutazione finora

- Online Test of Physics On Magnetic Effect of Current and Magnetism PDFDocumento2 pagineOnline Test of Physics On Magnetic Effect of Current and Magnetism PDFrvignesh2809Nessuna valutazione finora

- Master Plumber Review Material 2Documento4 pagineMaster Plumber Review Material 2Marvin KalnganNessuna valutazione finora

- Magnetism and Heat Transfer Test Answers RevealedDocumento6 pagineMagnetism and Heat Transfer Test Answers RevealedMaryHazelClaveBeniga100% (1)

- Submissions - MMC Safety Program, MBFHI & Breastfeeding in The Workplace Orientation - Learning CheckDocumento1 paginaSubmissions - MMC Safety Program, MBFHI & Breastfeeding in The Workplace Orientation - Learning CheckAbis JohnNessuna valutazione finora

- BOSL Controllers Standard-1Documento82 pagineBOSL Controllers Standard-1Anonymous bnhNfqZXaNessuna valutazione finora