Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

E-415 - Practical Aspects of Well Planning & Costing: 10 Days For/Pawpce

Caricato da

mohanned salahTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

E-415 - Practical Aspects of Well Planning & Costing: 10 Days For/Pawpce

Caricato da

mohanned salahCopyright:

Formati disponibili

E-415 - Practical Aspects of Well Planning & Costing

10 Days FOR/PAWPCE

Overview

LEVEL

Foundation

AUDIENCE

Young engineers, drilling and completion superintendents already, or about to be involved in well design and

planning

PURPOSE

To provide a comprehensive overview of all steps one should take to properly plan and budget oil and gas

exploration or development wells, from pre-planning with geoscientists all the way to delivery

LEARNING OBJECTIVES

To review the different parameters involved in oil or gas well planning

To identify major concerns and plan for dealing with them

To understand procedures and methods for designing oil or gas wells and preparing drilling programs

To learn how to estimate drilling time and costs, along with corresponding margins of error

To grasp importance of effective well engineering and planning

To follow efficiently well planning and costing sequences

WAYS AND MEANS

Interactive course with case studies and practical exercises

A well case history will be used to build an AFE and a time drilling curve as a model for each section of this course

Agenda

WELL OBJECTIVES AND INPUTS TO THE DRILLING PROGRAM 0.5 d

Typical objectives and inputs to an exploration or/and a development well program

Pore and fracturation pressure evaluation

Criteria to consider for the well design

CASING DESIGN: SHOE POSITIONING 0.5 d

Swab and surge considerations, kick tolerance, hypothesis selection

Selection of mud weights, additional constraints, exercises with different hypothesis

CASING DESIGN: CASING SELECTION 1.5 d

Physical and mechanical properties of casings and casing connections

Use of the drilling data handbook

Casing string calculation, selection

WELLHEAD DESIGN AND SELECTION 0.5 d

Different wellheads in onshore and offshore environments, wellhead and BOP program

BITS PROGRAM 0.5 d

Contact us : fp.pau@ifptraining.com www.ifptraining.com

Different types of bits, bit selection: bit records, cost per foot, bit hydraulics

DRILL STRING, COMPONENTS AND SELECTION 1d

BHA components and design criteria; drill string design criteria

Torque and drag modeling, hydraulic and pumping requirements

MUD AND CEMENT PROGRAM 2d

Drilling fluid types and characteristics, mechanical treatment equipment

Selection of mud program according to the well construction criteria

Cementing technology and procedures, cement and slurry design

Cementing program, cementing quality control

FORMATION EVALUATION PROGRAM 0.5 d

Mud logging and cutting sampling, electrical logging, logging services requirements

Coring tools, procedures and coring program

DEVIATED WELLS DESIGN: DIRECTIONAL DRILLING METHODS AND 1d

TECHNOLOGY

Surveying tools and technology, basic behavior of rotary assemblies

Directional drilling tools and technology, directional program

Surveying methods, trajectory calculation methods, uncertainty evaluation

Surveying tools and technology, basic behavior of rotary assemblies

RIG SELECTION 1d

Main drilling rig functions

Types of rigs, rig selection criteria

TIME ESTIMATE AND PROVISIONAL PROGRESS CURVE 0.5 d

Typical rig times required for the different operations, drilling and tripping time, contingencies

Analysis of time curve plan for the case study

COST ESTIMATE AND AFE 0.5 d

Drilling, formation evaluation and logistics contracts

Intangible costs, tangible costs, and contingencies

Establishing the well budget and AFE for case study well

Information / Registration

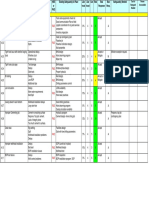

2015 course calendar

DATES LOCATION FEES BY EMAIL

EN Jun 15 - 26 Rueil 6,380 fp.pau@ifptraining.com

EN Nov 16 - 27 Rueil 6,380 fp.pau@ifptraining.com

2016 course calendar

DATES LOCATION FEES BY EMAIL

EN Jun 13 - 24 Rueil 6,380 fp.pau@ifptraining.com

EN Nov 14 - 25 Rueil 6,380 fp.pau@ifptraining.com

To organize an in-house course for your company at any location, contact us today

Potrebbero piacerti anche

- Onshore Pipeline Design Course BrochureDocumento6 pagineOnshore Pipeline Design Course Brochureilze86Nessuna valutazione finora

- Abdelatif Belmamoune - CV - Feb 2023Documento6 pagineAbdelatif Belmamoune - CV - Feb 2023Abdelatif BelmamouneNessuna valutazione finora

- CSU728 - AFS09 EX NGC ZZ ZZ XX MS SW 00002 00 - Ver2Documento43 pagineCSU728 - AFS09 EX NGC ZZ ZZ XX MS SW 00002 00 - Ver2Anonymous swFolM3gXNessuna valutazione finora

- 3 Reservoir Engineering GBDocumento24 pagine3 Reservoir Engineering GBpegeo09Nessuna valutazione finora

- Sep 2019 MDB4413Z ME Universiti Teknologi PETRONAS Plant Facilities & TransportDocumento3 pagineSep 2019 MDB4413Z ME Universiti Teknologi PETRONAS Plant Facilities & TransportAisar AmireeNessuna valutazione finora

- Course File Jigs & FixturessDocumento18 pagineCourse File Jigs & FixturessYogendra KumarNessuna valutazione finora

- Split Case Pump MosDocumento10 pagineSplit Case Pump MosFakhreddine Ezzahi100% (1)

- CV-Modeler 3Documento8 pagineCV-Modeler 3adarsh tNessuna valutazione finora

- ECVN Company ProfileDocumento22 pagineECVN Company ProfilethanhluanvtNessuna valutazione finora

- Cs Anil Piping Design ResumeDocumento9 pagineCs Anil Piping Design ResumeANIL KUMARNessuna valutazione finora

- Florin Cristea CV 2013Documento11 pagineFlorin Cristea CV 2013Zhoudq DqNessuna valutazione finora

- Wasif CVDocumento2 pagineWasif CVTalha BaigNessuna valutazione finora

- CV-Modeler 2Documento8 pagineCV-Modeler 2adarsh tNessuna valutazione finora

- Piping Design & Arrangement: Course Duration: 5 DaysDocumento6 paginePiping Design & Arrangement: Course Duration: 5 DaysSteven TrigoNessuna valutazione finora

- Les08 UndergroundDocumento96 pagineLes08 UndergroundFaisal AwadNessuna valutazione finora

- IIT Piping EnggDocumento7 pagineIIT Piping EnggSikander GirgoukarNessuna valutazione finora

- Mineral Exploration Drilling Sampling AnDocumento63 pagineMineral Exploration Drilling Sampling AnmilkyasNessuna valutazione finora

- Well Drilling Planning and Construction CourseDocumento2 pagineWell Drilling Planning and Construction CourseYadulla MemmedovNessuna valutazione finora

- Estimator Cum Draughtsman ResumeDocumento2 pagineEstimator Cum Draughtsman Resumemohan0% (1)

- Well Test Operation: Course ContentDocumento1 paginaWell Test Operation: Course Contentabnou_223943920Nessuna valutazione finora

- Shahbaz Ahmad CVDocumento8 pagineShahbaz Ahmad CVShahbaz AhmadNessuna valutazione finora

- Eng. Farhan CV 2Documento2 pagineEng. Farhan CV 2farhan faizNessuna valutazione finora

- Process Team Leader - Mohamed Eldib ResumeDocumento11 pagineProcess Team Leader - Mohamed Eldib ResumeMohamed AldeebNessuna valutazione finora

- Inspection Engineer - Senior Welding - Arunkumar Andavar - CVDocumento7 pagineInspection Engineer - Senior Welding - Arunkumar Andavar - CVArun KumarNessuna valutazione finora

- Kalyanasundaram Palaniappan BLK 468A Admiralty Drive, #04-129 SINGAPORE - 751468. H/P: 81691165 Singapore PR (S7564808A)Documento7 pagineKalyanasundaram Palaniappan BLK 468A Admiralty Drive, #04-129 SINGAPORE - 751468. H/P: 81691165 Singapore PR (S7564808A)GomathyselviNessuna valutazione finora

- Course FOPS - FIELDENG E-554C - Field Operations Engineer Certification - Ifp TrainingDocumento5 pagineCourse FOPS - FIELDENG E-554C - Field Operations Engineer Certification - Ifp TrainingCHO ACHIRI HUMPHREYNessuna valutazione finora

- Chapter 4 - Project Cash Flows NRR Oct2017Documento44 pagineChapter 4 - Project Cash Flows NRR Oct2017adib assoliNessuna valutazione finora

- Sandiip Rathod Resume Cost Estimation Engineer Updated ShellDocumento6 pagineSandiip Rathod Resume Cost Estimation Engineer Updated ShellSandiip RathodNessuna valutazione finora

- Curriculum Vitae: Total Years of Experience - 12 YearsDocumento4 pagineCurriculum Vitae: Total Years of Experience - 12 YearsnandakumarNessuna valutazione finora

- 2006 Blended Learning ProgramsDocumento2 pagine2006 Blended Learning Programsmohamed yehiaNessuna valutazione finora

- Shubham Kapoor ResumeDocumento2 pagineShubham Kapoor ResumeRANJITH K PNessuna valutazione finora

- People Edge - Mohammed AbdullahDocumento3 paginePeople Edge - Mohammed AbdullahahmedalishNessuna valutazione finora

- Home: +91: M.Ravi Sankar - 9003140214Documento4 pagineHome: +91: M.Ravi Sankar - 9003140214rasaNessuna valutazione finora

- 20me702 - Process Planning and Cost Estimation Unit 4 2023-24Documento64 pagine20me702 - Process Planning and Cost Estimation Unit 4 2023-24CAD With RaoNessuna valutazione finora

- Ce Law Presentation G 4 1Documento43 pagineCe Law Presentation G 4 1Hazel Shane Terren AzadaNessuna valutazione finora

- Raja Rizwan AhmadDocumento5 pagineRaja Rizwan AhmadSyed Tahreem AhmadNessuna valutazione finora

- Kiran Jose Paul Raj - OldDocumento4 pagineKiran Jose Paul Raj - OldArun MurugaiyanNessuna valutazione finora

- Design Index - A Systematic Method of PDC Drill Bit SelectionDocumento15 pagineDesign Index - A Systematic Method of PDC Drill Bit SelectionAzri HamimNessuna valutazione finora

- 20me702 - Process Planning and Cost Estimation Unit 1 2023-24Documento61 pagine20me702 - Process Planning and Cost Estimation Unit 1 2023-24CAD With RaoNessuna valutazione finora

- Mechanical - Pipeline Project EngineerDocumento5 pagineMechanical - Pipeline Project EngineerMorad M SwidNessuna valutazione finora

- 20me702 - Process Planning and Cost Estimation Unit 5 2023-24Documento65 pagine20me702 - Process Planning and Cost Estimation Unit 5 2023-24CAD With RaoNessuna valutazione finora

- Drilling Engineering (1) : M. Moarefian Azad University - Marvdasht Campus Fall 2006Documento19 pagineDrilling Engineering (1) : M. Moarefian Azad University - Marvdasht Campus Fall 2006HunterNessuna valutazione finora

- CV - Rahul Kumar - KuwaitDocumento3 pagineCV - Rahul Kumar - Kuwaitadarsh tNessuna valutazione finora

- Pvp2019 Long CFP r05Documento5 paginePvp2019 Long CFP r05Madhubalan PNessuna valutazione finora

- Special Edition, February 2015: 2015 Training and Development GuideDocumento20 pagineSpecial Edition, February 2015: 2015 Training and Development GuideEbby OnyekweNessuna valutazione finora

- NAAC PRT Visit ChecklistDocumento8 pagineNAAC PRT Visit ChecklistHOD ECE SVCETNessuna valutazione finora

- Swarnandhra College of Engineering & Technology Department of Mechanical Engineering Course Information SheetDocumento9 pagineSwarnandhra College of Engineering & Technology Department of Mechanical Engineering Course Information SheetgopichandallakaNessuna valutazione finora

- Sr. Piping Designer Ali Azzam CVDocumento5 pagineSr. Piping Designer Ali Azzam CVAli AzzamNessuna valutazione finora

- SHAHBAZ Updated CVDocumento4 pagineSHAHBAZ Updated CVShahbazNessuna valutazione finora

- RICSNew Rulesof Measurement PLPPresentation 20090520Documento30 pagineRICSNew Rulesof Measurement PLPPresentation 20090520Kevin DonNessuna valutazione finora

- Rizwana Barket - CVDocumento7 pagineRizwana Barket - CVRizwanaNessuna valutazione finora

- 1.MS - GRP PipesDocumento12 pagine1.MS - GRP Pipes721917114 47Nessuna valutazione finora

- Method Statement For Initial and Routine Load Test - TP1-10.06.2019Documento27 pagineMethod Statement For Initial and Routine Load Test - TP1-10.06.2019Manas BeheraNessuna valutazione finora

- Curriculum Vitae: Name: Upendra KumarDocumento6 pagineCurriculum Vitae: Name: Upendra KumarNitin KarboNessuna valutazione finora

- Piping Design CourseDocumento5 paginePiping Design CourseClaudio SotoNessuna valutazione finora

- CV - Dhananjai Kumar Gupt. 50Documento5 pagineCV - Dhananjai Kumar Gupt. 50Geevarghese Mammen KoyippallyNessuna valutazione finora

- Process Plant Layout and Piping System DesignDocumento117 pagineProcess Plant Layout and Piping System Designdelta_scope100% (2)

- OpopopopooooDocumento6 pagineOpopopopooookarthick rajaNessuna valutazione finora

- New Code of Estimating PracticeDa EverandNew Code of Estimating PracticeNessuna valutazione finora

- Subsea Rigid Pipelines – Methods of InstallationDa EverandSubsea Rigid Pipelines – Methods of InstallationValutazione: 5 su 5 stelle5/5 (1)

- Batch2 Mid-TermDocumento4 pagineBatch2 Mid-Termmohanned salahNessuna valutazione finora

- Causes of AbsenceDocumento19 pagineCauses of Absencemohanned salahNessuna valutazione finora

- Batch2 Mid-TermDocumento4 pagineBatch2 Mid-Termmohanned salahNessuna valutazione finora

- Ammended Chapt1 2021Documento23 pagineAmmended Chapt1 2021mohanned salahNessuna valutazione finora

- INTRODUCTIONDocumento9 pagineINTRODUCTIONmohanned salahNessuna valutazione finora

- HypothesisDocumento1 paginaHypothesismohanned salahNessuna valutazione finora

- Vargas Orlando Thesis 2018Documento24 pagineVargas Orlando Thesis 2018mohanned salahNessuna valutazione finora

- ConclusionsDocumento1 paginaConclusionsmohanned salahNessuna valutazione finora

- Successful Horizontal Well Placement in Shallow Unconsolidated Viscous Oil Field Block#6 Fulla North East Field (FNE)Documento1 paginaSuccessful Horizontal Well Placement in Shallow Unconsolidated Viscous Oil Field Block#6 Fulla North East Field (FNE)mohanned salahNessuna valutazione finora

- Microsoft Word - Striping XXDocumento37 pagineMicrosoft Word - Striping XXmohanned salahNessuna valutazione finora

- Microsoft Word - Horezontal Well ControlDocumento20 pagineMicrosoft Word - Horezontal Well Controlmohanned salahNessuna valutazione finora

- IMPACT of AbsenteesimDocumento4 pagineIMPACT of Absenteesimmohanned salahNessuna valutazione finora

- Cost Per MeterDocumento6 pagineCost Per Metermohanned salahNessuna valutazione finora

- Cementing Calculation of SchlumbergerDocumento14 pagineCementing Calculation of Schlumbergermohanned salah100% (1)

- HRM - Mr.S. VinothKumarDocumento22 pagineHRM - Mr.S. VinothKumarmohanned salahNessuna valutazione finora

- Barriers of TQMDocumento3 pagineBarriers of TQMChelliah Karthick Thevan100% (3)

- Cementing Calculation-Joknyang C-1 (9-5)Documento1 paginaCementing Calculation-Joknyang C-1 (9-5)mohanned salahNessuna valutazione finora

- Cementing Calculation of SchlumbergerDocumento14 pagineCementing Calculation of Schlumbergermohanned salah100% (1)

- Drilling Abstract FinalDocumento1 paginaDrilling Abstract Finalmohanned salahNessuna valutazione finora

- GMT ConversionDocumento1 paginaGMT Conversionmohanned salahNessuna valutazione finora

- 04 Monte CarloDocumento6 pagine04 Monte Carlomohanned salahNessuna valutazione finora

- PMP Exam With Answerforu3Documento26 paginePMP Exam With Answerforu3Scr2211100% (3)

- 01 Random NumbersDocumento1 pagina01 Random Numbersmohanned salahNessuna valutazione finora

- 05 Examples Monte CarloDocumento4 pagine05 Examples Monte CarloMohanad SulimanNessuna valutazione finora

- 03 Handling DistributionsDocumento4 pagine03 Handling DistributionsMohanad SulimanNessuna valutazione finora

- 03 Handling DistributionsDocumento4 pagine03 Handling DistributionsMohanad SulimanNessuna valutazione finora

- Problem Set (1) - StatisticsDocumento6 pagineProblem Set (1) - StatisticsMohanad SulimanNessuna valutazione finora

- 02 Distributions Revisions-1Documento7 pagine02 Distributions Revisions-1Mohanad SulimanNessuna valutazione finora

- 01 Random NumbersDocumento1 pagina01 Random Numbersmohanned salahNessuna valutazione finora

- 02 Distributions Revisions-1Documento11 pagine02 Distributions Revisions-1mohanned salahNessuna valutazione finora

- IPM-PR-WCI-001 Well Construction and Intervention Procedure PDFDocumento16 pagineIPM-PR-WCI-001 Well Construction and Intervention Procedure PDFOscarCajamarcaNessuna valutazione finora

- Risk Assesment 1Documento1 paginaRisk Assesment 1Leon MonsalveNessuna valutazione finora

- 41000e Casing Drive SystemDocumento4 pagine41000e Casing Drive SystemjulioramcaNessuna valutazione finora

- Downhole Tubing/casingDocumento6 pagineDownhole Tubing/casingDwiki RamadhaniNessuna valutazione finora

- 02 Drilling CalculationDocumento53 pagine02 Drilling CalculationMohammad Kamal Habbaba100% (2)

- Macondo Report 20042011Documento33 pagineMacondo Report 20042011Dr K GallowglaichNessuna valutazione finora

- FDP Final PresentationDocumento109 pagineFDP Final PresentationKhairil IkramNessuna valutazione finora

- DownloadDocumento2 pagineDownloadAHMED KAMESHNessuna valutazione finora

- P1M6100 Drilling Design ManualDocumento230 pagineP1M6100 Drilling Design Manualsaeed65100% (1)

- Perforations With PictureDocumento11 paginePerforations With PictureSagar PatelNessuna valutazione finora

- Training Report Down HoleDocumento36 pagineTraining Report Down HolePulkit GururaniNessuna valutazione finora

- Petrobowl 2015 (1) Flashcards - QuizletDocumento29 paginePetrobowl 2015 (1) Flashcards - Quizlethenry christian wontumiNessuna valutazione finora

- 3..oil Field TubularsDocumento32 pagine3..oil Field TubularsDarshan SharmaNessuna valutazione finora

- Boq-Well Drilling at Rang Ayan PDFDocumento1 paginaBoq-Well Drilling at Rang Ayan PDFAllen MendozaNessuna valutazione finora

- Drilling WorksheetDocumento61 pagineDrilling WorksheetKaton AntariksaNessuna valutazione finora

- Petroleum Production Technology Chapter 1Documento40 paginePetroleum Production Technology Chapter 1YERANessuna valutazione finora

- PIPESIM 2019: Steady-State Multiphase Flow SimulatorDocumento32 paginePIPESIM 2019: Steady-State Multiphase Flow SimulatorHafiz AkhtarNessuna valutazione finora

- Basic Drilling TechnologyDocumento553 pagineBasic Drilling TechnologyAhmed AdilNessuna valutazione finora

- GLOSAR TEHNIC Petrom Translation TeamDocumento912 pagineGLOSAR TEHNIC Petrom Translation TeamBojoaga Theo100% (4)

- IADC/SPE 35084 New Tool Improves Success Ratio For Balanced Plug CementingDocumento8 pagineIADC/SPE 35084 New Tool Improves Success Ratio For Balanced Plug CementingpaimanNessuna valutazione finora

- Pipe Handling Equipment: General Catalog Handling ToolsDocumento96 paginePipe Handling Equipment: General Catalog Handling ToolsengmuhmudNessuna valutazione finora

- Grouting and Its Application in Tunneling: January 2008Documento11 pagineGrouting and Its Application in Tunneling: January 2008purple agmjNessuna valutazione finora

- 10 WellsDocumento86 pagine10 WellsFelipe Rezende SantosNessuna valutazione finora

- FHWA Drilled Shafts LRFD Design MethodsDocumento972 pagineFHWA Drilled Shafts LRFD Design Methodsshsiavash100% (1)

- H - Tripping and Hole Fill Up Procedure PDFDocumento11 pagineH - Tripping and Hole Fill Up Procedure PDFMohamed MahmoudNessuna valutazione finora

- Premium Connection SummaryOKDocumento12 paginePremium Connection SummaryOKSebas DazaNessuna valutazione finora

- Casing Design ManualDocumento124 pagineCasing Design Manualfaraj0% (1)

- Drilling ReportDocumento45 pagineDrilling ReportFreddy Mendoza CoronelNessuna valutazione finora

- Development of A Simulation Method For The Subsea Production SystemDocumento14 pagineDevelopment of A Simulation Method For The Subsea Production Systemthlim19078656Nessuna valutazione finora

- Kick Tolerance Paper 3Documento9 pagineKick Tolerance Paper 3Diego AraqueNessuna valutazione finora