Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Nitrobenzene Sulfur Trioxide Nitrobenzene Nitrobenzene

Caricato da

vinoth0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

61 visualizzazioni1 pagina123 g of nitrobenzene are added to 375 g of oleum and heated to 110-115°C to sulfonate the nitrobenzene. The mixture is heated until tests in water no longer detect nitrobenzene odor. If sulfonation is incomplete, more oleum is added. The reaction mixture is cooled and added to ice with stirring. Sodium chloride is added, causing sodium 3-nitrobenzenesulfonate to separate out as a paste. After filtering and recrystallization, purified sodium 3-nitrobenzenesulfonate is obtained, which can be neutralized to yield 3-nitrobenzenesulfonic acid.

Descrizione originale:

hiii

Titolo originale

m Nitrobenzene

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documento123 g of nitrobenzene are added to 375 g of oleum and heated to 110-115°C to sulfonate the nitrobenzene. The mixture is heated until tests in water no longer detect nitrobenzene odor. If sulfonation is incomplete, more oleum is added. The reaction mixture is cooled and added to ice with stirring. Sodium chloride is added, causing sodium 3-nitrobenzenesulfonate to separate out as a paste. After filtering and recrystallization, purified sodium 3-nitrobenzenesulfonate is obtained, which can be neutralized to yield 3-nitrobenzenesulfonic acid.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

61 visualizzazioni1 paginaNitrobenzene Sulfur Trioxide Nitrobenzene Nitrobenzene

Caricato da

vinoth123 g of nitrobenzene are added to 375 g of oleum and heated to 110-115°C to sulfonate the nitrobenzene. The mixture is heated until tests in water no longer detect nitrobenzene odor. If sulfonation is incomplete, more oleum is added. The reaction mixture is cooled and added to ice with stirring. Sodium chloride is added, causing sodium 3-nitrobenzenesulfonate to separate out as a paste. After filtering and recrystallization, purified sodium 3-nitrobenzenesulfonate is obtained, which can be neutralized to yield 3-nitrobenzenesulfonic acid.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

123 g of nitrobenzene are added into 375 g of oleum (25 % free sulfur

trioxide) at 70 C. The mixture warms up rapidly to 100-110 C, but must not

be allowed to rise any higher. When all nitrobenzene has been added,

the mixture is heated at 110-115 C until a test portion poured into water no

longer gives any odor of nitrobenzene. If complete sulfonation has not

occurred within half an hour, then insufficient amount of oleum has been

used. In this case 50 g more oleum are added drop by drop, and if necessary

a further quantity after half an hour more. The reaction mixture is then

allowed to cool, and is poured on to 500 g ice with good mechanical stirring.

The nitrobenzene sulfonic acid goes completely into solution with the

exception of a small proportion of side product bis(3-nitrophenyl)

sulfone. 200 g of sodium chloride, in small quantities at a time, are

added with continuous stirring. The sodium salt of 3-nitrobenzenesulfonic

acid separates out as a thick paste, and stirring must be continued for some

time, until the mass again liquefies. After about 10 hours the solid is filtered

yielding the crude sodium 3-nitrobenzenesulfonate, which may be obtained

purified by recrystallization from water. 3-nitrobenzenesulfonic acid is

obtained by neutralizing sodium 3-nitrobenzenesulfonate with stereochemical

amount of dilute sulfuric acid.

Potrebbero piacerti anche

- Drugs - How To Make Cocaine (Synthetically)Documento5 pagineDrugs - How To Make Cocaine (Synthetically)jsssh80% (5)

- Amphetamine Sulphate SynthesisDocumento6 pagineAmphetamine Sulphate Synthesiskaikai25883% (6)

- Amphetamine SynteticDocumento1 paginaAmphetamine SynteticTim Wayne100% (2)

- Nitrazepam (Synth)Documento4 pagineNitrazepam (Synth)clyro27Nessuna valutazione finora

- Amphetamine Sulphate Synthesis PDFDocumento9 pagineAmphetamine Sulphate Synthesis PDFMemória Craft50% (2)

- Piperonal and Safrole From Vanillin and EugenolDocumento9 paginePiperonal and Safrole From Vanillin and EugenolSmokeNessuna valutazione finora

- Making Meth: NotesDocumento7 pagineMaking Meth: Notesshakarn7Nessuna valutazione finora

- Lab 4 - P-NitroacetanilideDocumento5 pagineLab 4 - P-Nitroacetanilidechamanyusuff100% (2)

- Amphetamine Sulphate SynthesisDocumento11 pagineAmphetamine Sulphate SynthesisMax Foix OrtizNessuna valutazione finora

- Phenylacetic Acid From Benzyl CyanideDocumento3 paginePhenylacetic Acid From Benzyl CyanideriskobinskoNessuna valutazione finora

- Synthesis of NitrazepamDocumento3 pagineSynthesis of Nitrazepamjiskate77100% (1)

- Sodium Azide PreparationDocumento3 pagineSodium Azide Preparationpamos1111100% (1)

- Synthesis of Adrafinil & ModafinilDocumento2 pagineSynthesis of Adrafinil & ModafinildjavahkNessuna valutazione finora

- Daddy SynthesusDocumento11 pagineDaddy SynthesusBarta BenceNessuna valutazione finora

- BZP SynthesisDocumento3 pagineBZP SynthesisScientology1Nessuna valutazione finora

- Síntese Sulfato de Anfetamina (Amphetamine Sulphate Synthesis)Documento11 pagineSíntese Sulfato de Anfetamina (Amphetamine Sulphate Synthesis)Caio Rocha100% (1)

- Total Nitrogen in Composts: ProcedureDocumento1 paginaTotal Nitrogen in Composts: ProcedureAnriansyah RenggamanNessuna valutazione finora

- Preparation of TNTDocumento1 paginaPreparation of TNTAndrés DezzuttoNessuna valutazione finora

- 2,4-Dimethyl-3,5-Dicarbethoxypyrrole: 2,4-Pyrroledicarboxylic Acid, 3,5-Dimethyl-, Diethyl EsterDocumento3 pagine2,4-Dimethyl-3,5-Dicarbethoxypyrrole: 2,4-Pyrroledicarboxylic Acid, 3,5-Dimethyl-, Diethyl EsterlibretasviejasNessuna valutazione finora

- Preparation of M-Nitroaniline From Sodium PolysulfideDocumento2 paginePreparation of M-Nitroaniline From Sodium Polysulfideprincesengar37Nessuna valutazione finora

- Chemistry - How To Make TNTDocumento1 paginaChemistry - How To Make TNTKarthik ChallaNessuna valutazione finora

- Gelatin Bloom StrengthDocumento3 pagineGelatin Bloom StrengthmeongNessuna valutazione finora

- I Hate The Antichrist.Documento1 paginaI Hate The Antichrist.hicksjay994Nessuna valutazione finora

- Experiment No: - 1Documento8 pagineExperiment No: - 1Mrinal SinghaNessuna valutazione finora

- Hymetellose: Hymetellose Is A Partly O - (Methylated) and O - (2-Hydroxyethylated) CelluloseDocumento3 pagineHymetellose: Hymetellose Is A Partly O - (Methylated) and O - (2-Hydroxyethylated) CelluloseKakon AhmedNessuna valutazione finora

- Experiment 4Documento8 pagineExperiment 4Botlhe Kgotla SamNessuna valutazione finora

- Preparation of SalicylaldehydeDocumento2 paginePreparation of Salicylaldehydeashanul haque100% (1)

- Anaranjado de MetiloDocumento2 pagineAnaranjado de MetiloLuis GbNessuna valutazione finora

- AnalysisofRiceStraw PDFDocumento3 pagineAnalysisofRiceStraw PDFyeshiduNessuna valutazione finora

- AnalysisofRiceStraw PDFDocumento3 pagineAnalysisofRiceStraw PDFyeshiduNessuna valutazione finora

- 2.5.5. Peroxide ValueDocumento4 pagine2.5.5. Peroxide ValuejjtedyNessuna valutazione finora

- Sodium Lauryl SulfatDocumento3 pagineSodium Lauryl SulfatTuti Agustia SafariNessuna valutazione finora

- Sintesis de FenilhidrazinaDocumento3 pagineSintesis de FenilhidrazinaManuel I. Faundez Parraguez0% (1)

- (Tri-Nitrate Toluene) ) (: TNT Acid PreparationDocumento6 pagine(Tri-Nitrate Toluene) ) (: TNT Acid Preparationasdsa asdsdNessuna valutazione finora

- Process of para Hydroxy Phenyl AcetamideDocumento1 paginaProcess of para Hydroxy Phenyl AcetamideBhargav PatelNessuna valutazione finora

- 2.5.5. SOP Peroxide ValueDocumento2 pagine2.5.5. SOP Peroxide ValueDhoni W Fadliansyah100% (1)

- AOAC 920 - 87 - Kjeldahl HarinasDocumento1 paginaAOAC 920 - 87 - Kjeldahl HarinasMaría De Los Ángeles SuárezNessuna valutazione finora

- 5328-5337 Volumetric SolutionsDocumento10 pagine5328-5337 Volumetric Solutionsismail khurshidNessuna valutazione finora

- Jurnal PPKODocumento4 pagineJurnal PPKONurlaeli NaelulmunaNessuna valutazione finora

- Discussion: Nickel Is Precipitated by The Addition of An Ethanolic Solution of DimethylglyoximeDocumento1 paginaDiscussion: Nickel Is Precipitated by The Addition of An Ethanolic Solution of DimethylglyoximeSubhash DhungelNessuna valutazione finora

- Synthesis of Benzoic AcidDocumento2 pagineSynthesis of Benzoic AcidVarun JogiNessuna valutazione finora

- Be Nazo CaineDocumento2 pagineBe Nazo Cainedhungelsubhash8154Nessuna valutazione finora

- Additive 250 m4 PDFDocumento4 pagineAdditive 250 m4 PDFJustine May Balinggan DelmasNessuna valutazione finora

- Synthesis of Sulfanilamide From NitrobenzeneDocumento11 pagineSynthesis of Sulfanilamide From Nitrobenzenecrazybobblaskey33% (3)

- Acidul Sulfanilic: Teoria Si Modul de LucruDocumento3 pagineAcidul Sulfanilic: Teoria Si Modul de LucruGabriel100% (1)

- P-Aminobenzoic Acid DiazotizationDocumento3 pagineP-Aminobenzoic Acid DiazotizationAliİnce50% (2)

- SamsynfrDocumento6 pagineSamsynfrkjvshahNessuna valutazione finora

- Preperatory TechniquesDocumento24 paginePreperatory TechniquessundaasNessuna valutazione finora

- American Government 13th Edition Volkomer Test Bank Full Chapter PDFDocumento22 pagineAmerican Government 13th Edition Volkomer Test Bank Full Chapter PDFnicholassmithyrmkajxiet100% (14)

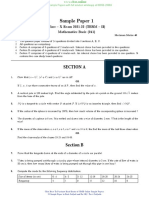

- Mock Test 8Documento27 pagineMock Test 8vinothNessuna valutazione finora

- Advt Cemil Ac 07092022Documento12 pagineAdvt Cemil Ac 07092022vinothNessuna valutazione finora

- Mock Test 10Documento28 pagineMock Test 10vinothNessuna valutazione finora

- Jembspsu 01Documento3 pagineJembspsu 01vinothNessuna valutazione finora

- ElectricDocumento4 pagineElectricvinothNessuna valutazione finora

- Materials Research Bulletin: M. Houshiar, L. JamilpanahDocumento6 pagineMaterials Research Bulletin: M. Houshiar, L. JamilpanahvinothNessuna valutazione finora

- Journal of Magnetism and Magnetic Materials: SciencedirectDocumento4 pagineJournal of Magnetism and Magnetic Materials: SciencedirectvinothNessuna valutazione finora

- UNIT - 1 Formula and ProcedureDocumento4 pagineUNIT - 1 Formula and ProcedurevinothNessuna valutazione finora

- 6th To 12th EC LOYOLA Guide 2022-23Documento1 pagina6th To 12th EC LOYOLA Guide 2022-23vinothNessuna valutazione finora

- 3 Hamdaoui 2019Documento7 pagine3 Hamdaoui 2019vinothNessuna valutazione finora

- Pressure Switch MFDDocumento2 paginePressure Switch MFDvinothNessuna valutazione finora

- Step 1: What You NeedDocumento5 pagineStep 1: What You NeedvinothNessuna valutazione finora

- Journal of Magnetism and Magnetic Materials: Research ArticlesDocumento7 pagineJournal of Magnetism and Magnetic Materials: Research ArticlesvinothNessuna valutazione finora

- Ceramics International: Li-An Han, Wan-Lin Zhai, Bing Bai, Hua-Ze Zhu, Jing Yang, Zheng-Xin Yan, Tao Zhang TDocumento5 pagineCeramics International: Li-An Han, Wan-Lin Zhai, Bing Bai, Hua-Ze Zhu, Jing Yang, Zheng-Xin Yan, Tao Zhang TvinothNessuna valutazione finora

- MCCP Matthews Symbols PDFDocumento9 pagineMCCP Matthews Symbols PDFvinothNessuna valutazione finora

- PG 15th Convocation ListDocumento25 paginePG 15th Convocation ListvinothNessuna valutazione finora

- ReferenceDocumento1 paginaReferencevinothNessuna valutazione finora

- Synchronous Detector: Apparatus RequiredDocumento3 pagineSynchronous Detector: Apparatus RequiredvinothNessuna valutazione finora

- Ex. No.: 01 Seven Segment Display Interface 04-11-2016Documento18 pagineEx. No.: 01 Seven Segment Display Interface 04-11-2016vinothNessuna valutazione finora

- Optical FiberDocumento67 pagineOptical FibervinothNessuna valutazione finora

- AMP Module I & IIDocumento69 pagineAMP Module I & IIvinothNessuna valutazione finora

- Chapter 6Documento136 pagineChapter 6vinothNessuna valutazione finora