Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Paint Cycle Electric Motors Types 1MB10 - 1MB15

Caricato da

jjermanDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Paint Cycle Electric Motors Types 1MB10 - 1MB15

Caricato da

jjermanCopyright:

Formati disponibili

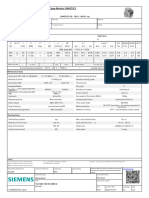

SEM MOTOR SURFACE PROTECTION PTN 143.

1

Mohelnice in standard modification C1 C6 Pages: 6 Page: 1

Former editions: 06/66; 02/67; 09/70; 03/77; 11/82; 03/86; 01/91; 08/93; 02/97; 01/99;

01-01/2004; 01-16/2004; 02/2005; 09/2005

Changes: completely overwrought PTN

1. Generally:

Motor surface protection is prescribed by order, data sheet and by the assembly drawing. This PTN specified

the selection of appropriate painting system and thickness parameter by product using purpose with reference to

production plant technology possibilities. This PTN embody option and marks assign. (This PTN isnt intended

(adopt) like production instruction)

2. Surface protection with paint

2.1 The parts intended for surfacing shall be prepare in according to EN ISO 12944-4

2.2 Climate aggressivity is assess by EN ISO 12944-2

C1 very low

C2 low

C3 medium

C4 high

C5-I very high industrial

C5-M very high - seaside

2.3 Motors for standard modification shall have separate components and final surface after assembly protected

in accordance with Table 1, C2.

2.4 Total thickness of painting shall be assess by ISO19840

o Arithmetic mean of dry surfaces measured thicknesses shall be minimum of required value

o Minimum measured value shall be equal or more than 80% required value.

o Frequency of measured thicknesses occurrence in range 80-100% shall be less than 20% number of

measuring.

o Maximum measured value shall be less than 3 times of required value.

2.5 On customers request should be motors with other final painting delivered (The treatment for export UPE)

3. Surface treatment with metal coating

The metal coating of motor parts for the standard modification shall be carried out in accordance with Table 2.

Hot dip galvanized coating SN EN ISO 1461 and thermal spraying SN EN 14616.

The minimum thickness of the coating on steel or brass parts shall be 5 m.

The minimum thickness of the coating on connecting components up to the size M5 shall be 5 m, over M5 it

shall be 8 m. To keep the ability of the components to be screwed, the metal coating thickness tolerance shall

be +2 m.

4. Impregnation of winding

TP 417 Technological Process is valid for the impregnation of winding.

5. Motors in modification without paint (K23, BN)

K23 the prime is applying on cast iron parts and fan cover in accordance with table 1. Cast iron schield and

free end of shaft are protected against corrosion in accordance with table 2. The painting is applying on schield

offset PS, ZS in accordance with table 2. BN mechanically clear surface.

Changes: completely overwrought PTN

Issued on: Worked out by: TPN: Approved by: Substitutes:

2011-11-24 Ing.ervinka M. Ing.ervinka M. Ing. Pnika M. PTN 143.1

of 20-01-1999

GENERAL DIVIDING TO THE CLIMATE CLASS

Table 1

Special paint resistant to Special paint for surround with very

sea - air C4 high aggressivity C5

Part

Motor type 1MB10 ( Option S03 ) Motor type 1MB15 ( Option S04 ) Used color

NDE shield from gray cast 30m base +60m -2x spray painting 50-100m ZN without spray painting WECO-FAN 1K - base

iron ( Under the fan cover ) WECO-FAN 2K

Fan

Plasic Ne Ne

AL Ne Ne

weldment 30m base + 90m-2x spray painting 50-100m ZN without spray painting WECO-FAN 2K

Fan cover internal side

Plasic

Zinc coating Ne Ne

Sheet metal Ne Ne WECO-FAN 1K - base

30m base + 90m 50-100m ZN WECO-FAN 2K

1-2x spray painting without spray painting

Completed motor final

spray painting WECO-FAN 2K

AL 120m 3x spray painting

Litina 50-100mZN+120m 3x spray

painting

Boundary between frame

and shiel Ne 30m color 1x painting WECO Therm

Cast iron

Machined external parts of 30m color 1x painting WECO Therm

motor

- recommended for internal and external - recommended for internal and external

surround , Where is the appliance directly surround, where the motors are directly

Using expose to clime. expose to clime.

- Industrial clime with mild level of - Industrial clime with mild level of

pullution SO2, seaside clime off coast. pullution SO2 and seaside clime and

However nay seaside clime on open sea; open sea. (e.g..for crane drive)

appropriate e.g. for crane drive and for - Conform to test specifications according

paper industry. to DIN EN ISO 12944-2 corrosion

- Conform to test specifications according category C5

to DIN EN ISO 12944-2 corrosion category

C4

- 1MB10 (code S03) - 1MB15 (code S04)

Types

Part Notes Applied color

Rotor - shaft Paint the shaft machined part from bearing WECO-FAN 1K

to rotor short-circuiting ring throughout WECO-FAN 2K

perimeter

Paint thickness 30m

Abbrev. N92

Winding overhang paint the winding overhang S 2352

Abbrev. Y92 (PTN 143.4)

Frame Paint frame machined part from offset to WECO-FAN 1K

lamination WECO-FAN 2K

Paint thickness 30m

Abbrev. N92

Flange Spray painting of flange external inclusive WECO-FAN 2K

worked surfaces, ruber sealing and holes

with threads in v flange protected aganist

painting by plastic cap

Abbrev.-NPO, PKN, OSPON,

Flange between shaft and centering coat

with paint Abbrev.- PLAK

Cover internal side Paint all the internal surface, minimum paint WECO-FAN 2K

thickness is 30m

Dont paint the part witch are modified by

hot dip zinc .-VNS

Terminal block internal side Paint all the internal surface, minimum paint WECO-FAN 2K

thickness is 30m

Dont paint the part witch are modified by

hot dip zinc. Abbrev.-VNS

Terminal flenge internal side Paint all the internal surface, minimum paint WECO-FAN 2K

thickness is 30m

Dont paint the part witch are modified by

hot dip zinc Abbrev.-VNS

Stator core internal diameter Spray painting internal diameter of stator S 2352

core. Spray painting thickness 20-30m

Apply after pressing to frame due to rolling

According to customers requirement Abbrev.-

RVN, P27

Brake Spray painting the external cast-iron case of WECO-FAN 2K

brake after the installation according to

customers request about total thickness

Part Carried out on Surfacing

Terminals of connection box (steel) Zink coating + chromating

All the small parts barring keys All version Zink coating

Connecting material Steel - zink coating + chromating

Brass - without surfacing

Centrifugal Brass and copper bating and passivate

switch conductive parts

Head of driven rivet All sizes Without surfacing

Steel parts Zink coating

Hub of rotation parts Without surfacing

Springs Phosphatize Synft 1220, improve by heat

Nameplate nail All version Nickeling

Potrebbero piacerti anche

- Paint Specification 1phDocumento5 paginePaint Specification 1phNhien ManNessuna valutazione finora

- Ciclo Di Verniciatura: Painting CycleDocumento1 paginaCiclo Di Verniciatura: Painting CycleMaffone NumerounoNessuna valutazione finora

- TL - 260 - en 2015Documento11 pagineTL - 260 - en 2015hand42100% (1)

- 1LE1003 1DA43 4AB4 Datasheet enDocumento1 pagina1LE1003 1DA43 4AB4 Datasheet enElio TavaresNessuna valutazione finora

- No35-Inclined Roof SystemDocumento24 pagineNo35-Inclined Roof SystemKitanovic NenadNessuna valutazione finora

- Roof System Trimoterm SNV 16526Documento20 pagineRoof System Trimoterm SNV 16526Vojin RodićNessuna valutazione finora

- XN90 N1 038Documento2 pagineXN90 N1 038ashleyNessuna valutazione finora

- Cable Marker - WMT 2,4 (15X4) R - 0816281: Key Commercial DataDocumento3 pagineCable Marker - WMT 2,4 (15X4) R - 0816281: Key Commercial DataVlad MaziluNessuna valutazione finora

- Corro-Coat PE-F Façade: Series 1301, 1303, 1307 and 1308Documento2 pagineCorro-Coat PE-F Façade: Series 1301, 1303, 1307 and 1308girlie fabroNessuna valutazione finora

- Paint System: Cargotec Finland Oy TampereDocumento1 paginaPaint System: Cargotec Finland Oy TampereEdward Erney Salas ValenzuelaNessuna valutazione finora

- Fireproof ROOF Panels Technical InformationDocumento4 pagineFireproof ROOF Panels Technical InformationMarko MiticNessuna valutazione finora

- Volute Casing Centrifugal Pumps of Block Design Series NB: VM 528 GB/2012.06 - Ident No. 795 261Documento20 pagineVolute Casing Centrifugal Pumps of Block Design Series NB: VM 528 GB/2012.06 - Ident No. 795 261safwan azizNessuna valutazione finora

- Attachment #6 1 - Schedule of Quantities FDC 22.09.21Documento119 pagineAttachment #6 1 - Schedule of Quantities FDC 22.09.21El Charasquiada CharroNessuna valutazione finora

- Coating Systems For The Series Version of Standard Trucks As Well As For Bus Components and AttachmentsDocumento24 pagineCoating Systems For The Series Version of Standard Trucks As Well As For Bus Components and AttachmentsAkmal NizametdinovNessuna valutazione finora

- 2.1.4 Technical Details 100 - 100KDocumento1 pagina2.1.4 Technical Details 100 - 100KMike Vergel de DiosNessuna valutazione finora

- Extreme - PVC SportivDocumento1 paginaExtreme - PVC SportivAnca IlinaNessuna valutazione finora

- Easy Duct PDFDocumento8 pagineEasy Duct PDFSameera Sri VidurangaNessuna valutazione finora

- Aliplast TF VG500 ENGDocumento2 pagineAliplast TF VG500 ENGjasenkosNessuna valutazione finora

- DEXCOM 3 - BoQ Metal Works (CER1-2, 3&CUB)Documento41 pagineDEXCOM 3 - BoQ Metal Works (CER1-2, 3&CUB)MEAGAN CHNGNessuna valutazione finora

- OSB Technical InformationDocumento10 pagineOSB Technical InformationPrattyNessuna valutazione finora

- MediaDocumento9 pagineMediaxtdrifttxNessuna valutazione finora

- Cathodic Electrocoating of Body Skin Parts Made From Aluminum Semi-Finished ProductsDocumento5 pagineCathodic Electrocoating of Body Skin Parts Made From Aluminum Semi-Finished ProductsMaryana c100% (1)

- Fibrangeo BP 40-L: Stonewool Insulation Board With Knit Fibers & 4-Sides L-Cut EdgesDocumento6 pagineFibrangeo BP 40-L: Stonewool Insulation Board With Knit Fibers & 4-Sides L-Cut EdgesAlin StancuNessuna valutazione finora

- Sounder Checklist EN 2023-09Documento5 pagineSounder Checklist EN 2023-09Будимир ЗебићNessuna valutazione finora

- QPS-C5 Industrial & Costal Painting Procedure-OP - PP - WI - 006 - C5 PDFDocumento4 pagineQPS-C5 Industrial & Costal Painting Procedure-OP - PP - WI - 006 - C5 PDFDeepak UpadhyayNessuna valutazione finora

- Futural: Thermal Break 3-Chamber SystemDocumento2 pagineFutural: Thermal Break 3-Chamber SystemEren BoyaciNessuna valutazione finora

- Concept of CENA1Documento6 pagineConcept of CENA1taknevNessuna valutazione finora

- All Quantities Are Provisional and Subject For RemeasurementDocumento13 pagineAll Quantities Are Provisional and Subject For RemeasurementMatt CerosNessuna valutazione finora

- 1LE1503-1EB43-4JA4-Z B02+N06 Datasheet enDocumento1 pagina1LE1503-1EB43-4JA4-Z B02+N06 Datasheet enavinash mathurNessuna valutazione finora

- 1904-FG-ME-SPC-0016 BAC Coating SpecificationDocumento6 pagine1904-FG-ME-SPC-0016 BAC Coating Specificationmahan moradiNessuna valutazione finora

- Ampco Vs SteelDocumento9 pagineAmpco Vs SteelCopper AmpcometalNessuna valutazione finora

- Exhibit C - Work DescriptionDocumento127 pagineExhibit C - Work DescriptionVeera PandiNessuna valutazione finora

- TL 212 en 2021 06Documento9 pagineTL 212 en 2021 06David DomokosNessuna valutazione finora

- NORD-Painting CodeDocumento3 pagineNORD-Painting CodeubabNessuna valutazione finora

- Vendor Document Cover SheetDocumento75 pagineVendor Document Cover Sheetmujahed_muhammedNessuna valutazione finora

- Data Sheet 1996-06-01: Applications DesignationDocumento2 pagineData Sheet 1996-06-01: Applications DesignationEnoc AndradeNessuna valutazione finora

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1503-2DB09-0AJ4-ZDocumento1 paginaData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1503-2DB09-0AJ4-ZopplusNessuna valutazione finora

- 078-087 VINYL Comp PremiumDocumento5 pagine078-087 VINYL Comp PremiumPortal EmerNessuna valutazione finora

- Data Sheet For Three-Phase Squirrel-Cage-MotorsDocumento2 pagineData Sheet For Three-Phase Squirrel-Cage-MotorsKadehar4Nessuna valutazione finora

- 1LE1503-2DB09-0AJ4-Z E52+M1Y Datasheet enDocumento1 pagina1LE1503-2DB09-0AJ4-Z E52+M1Y Datasheet enopplusNessuna valutazione finora

- Exico Paint SpecificationDocumento5 pagineExico Paint SpecificationFredy Xavier DomínguezNessuna valutazione finora

- Empty BOQ SampleDocumento9 pagineEmpty BOQ SampleCyprian Metobo100% (1)

- Falcon Zinc Metal Industries L.L.CDocumento7 pagineFalcon Zinc Metal Industries L.L.Ccyril nbhhNessuna valutazione finora

- Non Returns Dampers Single PageDocumento12 pagineNon Returns Dampers Single PageALINessuna valutazione finora

- BILL OF QUANTITIES - KIHONDA FINAL TANePSDocumento27 pagineBILL OF QUANTITIES - KIHONDA FINAL TANePSD A R K S K YNessuna valutazione finora

- 1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enDocumento2 pagine1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enmohamed gomaaNessuna valutazione finora

- AGEPAN OSB 4 PUR Technical Data SheetDocumento2 pagineAGEPAN OSB 4 PUR Technical Data SheetDore EmilNessuna valutazione finora

- 1LE1603-1DC43-4AB4-Z H01+Q01 Datasheet enDocumento2 pagine1LE1603-1DC43-4AB4-Z H01+Q01 Datasheet ennarminaNessuna valutazione finora

- GH22148 0100D TD Man Ai 01 Rev0Documento51 pagineGH22148 0100D TD Man Ai 01 Rev0felix sowah-laryeaNessuna valutazione finora

- Paint Henelit Henedur SFCDocumento2 paginePaint Henelit Henedur SFCsljiva11Nessuna valutazione finora

- Metecno India CatalogueDocumento50 pagineMetecno India CatalogueBharat SinghNessuna valutazione finora

- Installation Manual: 17 PaintingDocumento10 pagineInstallation Manual: 17 PaintingMiguelNessuna valutazione finora

- PB p2 Technical Datasheet PDFDocumento2 paginePB p2 Technical Datasheet PDFbelal545Nessuna valutazione finora

- 03 - Paint Spec - Added - FDC 25KDocumento15 pagine03 - Paint Spec - Added - FDC 25KJIM CAMPBELLNessuna valutazione finora

- Technische Information - COSMOFIN-FG R - ENDocumento2 pagineTechnische Information - COSMOFIN-FG R - ENKat PNessuna valutazione finora

- TechnicalDataSheet EffisusBreatherFR BMembrane - ENGDocumento1 paginaTechnicalDataSheet EffisusBreatherFR BMembrane - ENGPaula MoçoNessuna valutazione finora

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZDocumento1 paginaData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZFredericks ACNessuna valutazione finora

- Paint Spec 2 Typical Coat SystemDocumento2 paginePaint Spec 2 Typical Coat SystembmacavanzaNessuna valutazione finora

- Boq Export f3Documento10 pagineBoq Export f3Daulat SainiNessuna valutazione finora

- Slab Master - : 3D Slab Inspection For Earliest Possible Quality DecisionsDocumento2 pagineSlab Master - : 3D Slab Inspection For Earliest Possible Quality DecisionsjjermanNessuna valutazione finora

- HSE. Chloride Stress Corrosion Cracking in Austenitic Stainless SteelDocumento62 pagineHSE. Chloride Stress Corrosion Cracking in Austenitic Stainless Steelfallalovaldes100% (1)

- Data Sheet PTCDocumento8 pagineData Sheet PTCjjermanNessuna valutazione finora

- Uhm Cee 11 02 PDFDocumento67 pagineUhm Cee 11 02 PDFjjermanNessuna valutazione finora

- 3 Storage Manual PDFDocumento11 pagine3 Storage Manual PDFjjermanNessuna valutazione finora

- Contractor Quality Control Plan For Storage Tank Erection PDFDocumento2 pagineContractor Quality Control Plan For Storage Tank Erection PDFshafxNessuna valutazione finora

- Eur 23510 enDocumento262 pagineEur 23510 enferrumdooNessuna valutazione finora

- Aluminium Alloysafsa - Corrosion - Pocket - Guide PDFDocumento36 pagineAluminium Alloysafsa - Corrosion - Pocket - Guide PDFYuvaraj NithyanandamNessuna valutazione finora

- En 1993 1 10 2005 PDFDocumento19 pagineEn 1993 1 10 2005 PDFSuleyman HaliciogluNessuna valutazione finora

- Innovative Rules in Eurocode 3, Part 1-10 For The Choice of Material PDFDocumento8 pagineInnovative Rules in Eurocode 3, Part 1-10 For The Choice of Material PDFjjermanNessuna valutazione finora

- FEM 1.001 Rules For The Design of Hoisting AppliancesDocumento312 pagineFEM 1.001 Rules For The Design of Hoisting AppliancesAlexander Gotte88% (43)

- Uhm Cee 11 02Documento67 pagineUhm Cee 11 02jjermanNessuna valutazione finora

- Ansys Coupled Analysis GuideDocumento0 pagineAnsys Coupled Analysis GuidejjermanNessuna valutazione finora

- Porous Media PDFDocumento9 paginePorous Media PDFcezar_iasiNessuna valutazione finora

- DonaldsonDocumento60 pagineDonaldsonraulguardaNessuna valutazione finora

- Delmia Robotics at Volvo PDFDocumento53 pagineDelmia Robotics at Volvo PDFVinodh VijayakumarNessuna valutazione finora

- IEC Motor ControlDocumento192 pagineIEC Motor ControlFlo MircaNessuna valutazione finora

- Specialists in Site Specific AssessmentDocumento4 pagineSpecialists in Site Specific AssessmentAhmed ElkhoulyNessuna valutazione finora

- RMMDocumento12 pagineRMMRameshNessuna valutazione finora

- Surface Roughness: Static Surface Finishes DefinitionsDocumento1 paginaSurface Roughness: Static Surface Finishes DefinitionsmetroroadNessuna valutazione finora

- MC ASN-GW Ver.3.5 System Manual 111207Documento378 pagineMC ASN-GW Ver.3.5 System Manual 111207ابرهيم منصورNessuna valutazione finora

- QW-QAL-626 - (Rev-00) - Prod. and QC Process Flow Chart - Ventura Motor No. 13 (35804)Documento6 pagineQW-QAL-626 - (Rev-00) - Prod. and QC Process Flow Chart - Ventura Motor No. 13 (35804)Toso BatamNessuna valutazione finora

- Sample PDFDocumento4 pagineSample PDFmohsin alamNessuna valutazione finora

- Manufacturing Services in IndiaDocumento21 pagineManufacturing Services in IndiaTahiya TahNessuna valutazione finora

- Monocoque Racecar Frame - MacleishDocumento17 pagineMonocoque Racecar Frame - MacleishRoberto PulinaNessuna valutazione finora

- CV AdamDocumento2 pagineCV AdamAdam DwipratamaNessuna valutazione finora

- Tata Indica v2 Xeta CarDocumento89 pagineTata Indica v2 Xeta Carsantoshk165Nessuna valutazione finora

- Understanding SQL Server Execution PlansDocumento39 pagineUnderstanding SQL Server Execution PlansAgam KrishnaniNessuna valutazione finora

- Project Engineering of Process Plants PDFDocumento364 pagineProject Engineering of Process Plants PDFJoão Carlos Protz Protz58% (12)

- Cement PDFDocumento16 pagineCement PDFhisemNessuna valutazione finora

- Man B W L32 40Documento321 pagineMan B W L32 40Aleksanrd Mihailov100% (1)

- Online Railway Reservation System Project Report PDFDocumento2 pagineOnline Railway Reservation System Project Report PDFLeela Krishna IndiaNessuna valutazione finora

- B2BDocumento788 pagineB2BrajinishNessuna valutazione finora

- 2013 State of Devops ReportDocumento12 pagine2013 State of Devops ReportJMassapinaNessuna valutazione finora

- Big Ben KingDocumento23 pagineBig Ben KingMY CLUBNessuna valutazione finora

- PT WikaDocumento6 paginePT WikaFrizky Triputra CahyahanaNessuna valutazione finora

- Muhammad Babar Muhammad Shahbaz Muhammad IshaqDocumento2 pagineMuhammad Babar Muhammad Shahbaz Muhammad IshaqAdv Imran RehmanNessuna valutazione finora

- CV - Sakthi.pDocumento3 pagineCV - Sakthi.pVenkatesh KumarNessuna valutazione finora

- Turbo Failure ChartDocumento2 pagineTurbo Failure ChartPoshan SahuNessuna valutazione finora

- Cavusgil CH01 RevisedDocumento27 pagineCavusgil CH01 RevisedUmar SulemanNessuna valutazione finora

- ISO9001 and IATF 16949 Combined - ReferenceDocumento62 pagineISO9001 and IATF 16949 Combined - ReferencezaulzaulNessuna valutazione finora

- Process Change NotificationDocumento3 pagineProcess Change NotificationchinnathambijNessuna valutazione finora

- Daily Programme: DC QC Form No. QI-04 (Version-2, 20/10/10)Documento1 paginaDaily Programme: DC QC Form No. QI-04 (Version-2, 20/10/10)burereyNessuna valutazione finora

- PHARMA Guia Corporativa 3-P11Documento11 paginePHARMA Guia Corporativa 3-P11karenrosseNessuna valutazione finora