Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pressure Vessel ITP Rev 0

Caricato da

Ahmad HasnanDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pressure Vessel ITP Rev 0

Caricato da

Ahmad HasnanCopyright:

Formati disponibili

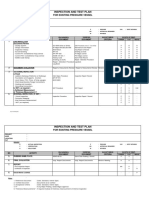

Client

Project

Test Plan PRESSURE VESSEL

Fabrication Site

Stages of Inspection / Characteristics/ Properties

ITEM

Inspection Activity to check.

1.0 DOCUMENTS

1.1 Quality Assurance Plan QAP As per Doc No: QAP Rev0

a. Welding Procedures, W.R.T.

1.2 WPS & PQR

Approved Drawing.

2.0 DOCUMENT CONTROL

2.1 Receive Documents from Client

3.0 MATERIAL CONTROL

3.1 Plates -Material Receiving Inspection

a) Check Packing Condition for damage

b) Check Material Physical condition a. Visual & Dimensional.

b. Verification of Mill Test Report &

c) Check Quantity correlation with Heat Marks &

stamping, if available OR Check Test

d) Attach Material Traceability Identification for Physical & Chem. Prop

e) Unpacking Inspection

3.2 Flanges -Material Receiving Inspection

FM-QAS-62 (Rev.0, 05/17/2010)

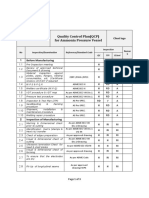

Client

Project

Test Plan PRESSURE VESSEL

Fabrication Site

Stages of Inspection / Characteristics/ Properties

ITEM

Inspection Activity to check.

a) Check Packing Condition for damage

b) Check Material Physical condition

a. Visual & Dimensional.

b. Verification of Manufacturer Test

c) Check Quantity

certificate & correlation with Heat

Marks & stamping

d) Attach Material Traceability Identification

e) Unpacking Inspection

3.3 Nozzle Pipes -Material Receiving Inspection

a) Check Packing Condition for damage

b) Check Material Physical condition a. Visual & Dimensional.

b. Verification of Manufacturers T.C.

c) Check Quantity Correlation with Heat Marks &

Stamping / Check Test for Physical &

d) Attach Material Traceability Identification Chem. Prop

e) Unpacking Inspection

3.4 Fasteners -Material Receiving Inspection

a) Check Packing Condition for damage

a. Visual & Dimensional.

b. Verification of Manufacturer Test FM-QAS-62 (Rev.0, 05/17/2010)

Client

Project

Test Plan PRESSURE VESSEL

Fabrication Site

Stages of Inspection / Characteristics/ Properties

ITEM

Inspection Activity to check.

b) Check Material Physical condition

a. Visual & Dimensional.

b. Verification of Manufacturer Test

c) Check Quantity

Certificate & correlation with Heat

Marks & stamping

d) Attach Material Traceability Identification

e) Unpacking Inspection

3.5 Gaskets -Material Receiving Inspection

a) Check Packing Condition for damage

b) Check Material Physical condition

a. Visual & Dimensional.

c) Check Quantity b. Verification of Manufacturers TC

Approved

d) Attach Material Traceability Identification

e) Unpacking Inspection

FM-QAS-62 (Rev.0, 05/17/2010)

Client

Project

Test Plan PRESSURE VESSEL

Fabrication Site a. Visual & Dimensional.

b. Verification of Manufacturers TC

Approved

Stages of Inspection / Characteristics/ Properties

ITEM

Inspection Activity to check.

3.6 Supports -Material Receiving Inspection

a) Check Packing Condition for damage

b) Check Material Physical condition

a. Visual & Dimensional.

c) Check Quantity

b. Chemical Analysis.

d) Attach Material Traceability Identification

e) Unpacking Inspection

4.0 FABRICATION STAGES

4.1 Dishend forming a. Visual & Dimensional Insp.

b. D.P. Tets on Knuckle & S.F.

c. Minimum Thickness.

4.2 Shell long seam setup a. V-groove Dimensional & Joint alignment

b. Curvature / Ovality

c. Circumference & other Dimensions.

4.3 Long seam back chip

a. D.P. Test

FM-QAS-62 (Rev.0, 05/17/2010)

Client

Project

Test Plan PRESSURE VESSEL

Fabrication Site

Stages of Inspection / Characteristics/ Properties

ITEM

Inspection Activity to check.

Circumseam setup of

4.4 main shell a. V-groove Dimensional, Joint

alignment & shell alignment

b. Straightness

4.5 Circumseam backchip of main shell

a. D.P.Test.

4.6 Nozzle to Shell/. Dishend Setup a. Nozzle Size & Flange dimensions

b. V-groove Dimensions

c. Orientation, Projection & Elevation

4.7 Backchip of Nozzle to Shell /Dishend

a. D.P.Test.

4.8 Circumference Setup of Shell to Dishend a. V-groove Dimensional & Joint

alignment

b. Straightness

4.9 Circumference Back chip of Shell to Dishend

a. D.P.Test.

4.10 Radiography (Spot = .T joints)

a. Weld Defects

4.11 Shell to Skirt Setup

a. V-groove Dimensional & Joint alignment

b. Straightness

FM-QAS-62 (Rev.0, 05/17/2010)

Client

Project

Test Plan PRESSURE VESSEL

Fabrication Site

Stages of Inspection / Characteristics/ Properties

ITEM

Inspection Activity to check.

a. V-groove Dimensional & Joint alignment

b. Straightness

5.0 FINAL INSPECTION

5.1 Visual & Dimensional before Hydro Test

a. Visual & Dimension Check

5.2 Hydraulic test - shell side a. Leakage

b.Pressure Guage Test Certificate

c. Hold Time 1 Hr. Min

FM-QAS-62 (Rev.0, 05/17/2010)

Client

Project

Test Plan PRESSURE VESSEL

Fabrication Site

Stages of Inspection / Characteristics/ Properties

ITEM

Inspection Activity to check.

6.0 SURFACE TREATMENT & FINAL PAINTING

Sand Blasting /Mechanical cleaning

6.1 a. Inspection of Surface cleaning before painting

finish & Painting

b. Check humidity condition

c. Check curing time

a. DFT Check 25 Micros DFT

7.0 FINAL STAMPING ON EQUIPMENT

a. Name Plate Data

b. Rub Off Marking

c. Spares & loose items bolted on job

FM-QAS-62 (Rev.0, 05/17/2010)

Purchase Order No: Documen

TAG No: Rev

Drawing No: Date

INSPECTION AND TEST PLAN

Surveillance

Project Specification Acceptance Verifying

Record/Form Manufacturer

Procedure/ Document Reference Criteria Document)

As per ASME, Sec- VIII DIV-1,

Approved DrAWINg Control Sheet P

Edition 2013

As per ASME, Sec- IX, Edition 2013 As per ASME, Sec- IX, Edition 2013 WPS & PQR Checklist WPS & PQR P

Distribution Matrix H

Material Receiving Inspection

Approved Drawing ASME Sec-II PO Pack H

Reports

Check Test

Material Control Procedure Part A and

Certificate

Material Receive List

Equipment Drawing

FM-QAS-62 (Rev.0, 05/17/2010)

Purchase Order No: Documen

TAG No: Rev

Drawing No: Date

INSPECTION AND TEST PLAN

Surveillance

Project Specification Acceptance Verifying

Record/Form Manufacturer

Procedure/ Document Reference Criteria Document)

Material Receiving Inspection

Approved Drawing ASME Sec-II PO Pack W

Reports

Material Control Procedure Part A and

Material Receive List

Equipment Drawing

Material Receiving Inspection

Approved Drawing ASME Sec-II PO Pack H

Reports

Material Control Procedure Part A and

Material Receive List

Equipment Drawing

FM-QAS-62 (Rev.0, 05/17/2010)

Purchase Order No: Documen

TAG No: Rev

Drawing No: Date

INSPECTION AND TEST PLAN

Surveillance

Project Specification Acceptance Verifying

Record/Form Manufacturer

Procedure/ Document Reference Criteria Document)

Material Receiving Inspection

Approved Drawing ASME Sec-II PO Pack R

Reports

Material Control Procedure Part A and

Material Receive List

Equipment Drawing

Material Receiving Inspection

Approved Drawing MOC : As per Approved Drawing PO Pack R

Reports

Material Control Procedure and

Material Receive List

Equipment Drawing

FM-QAS-62 (Rev.0, 05/17/2010)

Purchase Order No: Documen

TAG No: Rev

Drawing No: Date

INSPECTION AND TEST PLAN

Surveillance

Project Specification Acceptance Verifying

Record/Form Manufacturer

Procedure/ Document Reference Criteria Document)

Material Receiving Inspection

Approved Drawing MOC: PO Pack H

Reports

Material Control Procedure and

Material Receive List

Equipment Drawing

Approved Drawing Inspection Report

As per ASME, Sec- VIII DIV-1, Edition 2013 H

Approved Drawing Inspection Report

As per ASME, Sec- VIII DIV-1, Edition 2013 H

ASME, Sec- V, Edition 2013 Inspection Report

As per ASME, Sec- V, Edition 2013 H

FM-QAS-62 (Rev.0, 05/17/2010)

Purchase Order No: Documen

TAG No: Rev

Drawing No: Date

INSPECTION AND TEST PLAN

Surveillance

Project Specification Acceptance Verifying

Record/Form Manufacturer

Procedure/ Document Reference Criteria Document)

Approved Drawing Inspection Report

As per ASME, Sec- VIII DIV-1, Edition 2013 H

ASME, Sec- V, Edition 2013 Inspection Report

As per ASME, Sec- VIII DIV-1, Edition 2013 H

Approved Drawing Inspection Report

As per ASME, Sec- VIII DIV-1, Edition 2013 H

Approved Drawing Inspection Report

As per ASME, Sec- V, Edition 2013 H

Approved Drawing Inspection Report

As per ASME, Sec- VIII DIV-1, Edition 2013 H

ASME, Sec- V, Edition 2013 Inspection Report

As per ASME, Sec- VIII DIV-1, Edition 2013 H

Approved Drawing & Inspection Report

As per ASME, Sec- VIII DIV-1, Edition 2013 H

ASME, Sec- V, Edition 2013

Approved Drawing Inspection Report

As per ASME, Sec- VIII DIV-1, Edition 2013 H

FM-QAS-62 (Rev.0, 05/17/2010)

Purchase Order No: Documen

TAG No: Rev

Drawing No: Date

INSPECTION AND TEST PLAN

Surveillance

Project Specification Acceptance Verifying

Record/Form Manufacturer

Procedure/ Document Reference Criteria Document)

As per ASME, Sec- VIII DIV-1, Edition 2013 H

Approved Drawing Inspection Report

As per ASME, Sec- VIII DIV-1, Edition 2013 H

Approved Drawing Inspection Report

As per ASME, Sec- VIII DIV-1, Edition 2013.

H

(No leakage)

FM-QAS-62 (Rev.0, 05/17/2010)

Purchase Order No: Documen

TAG No: Rev

Drawing No: Date

INSPECTION AND TEST PLAN

Surveillance

Project Specification Acceptance Verifying

Record/Form Manufacturer

Procedure/ Document Reference Criteria Document)

Manufacturer Specification Equipment Drawing Painting Inspection Report

W

As per Drawing (Painting

Approved Drawing Specification) / ASME, Sec- VIII DIV- and Manual

1, Edition 2013.

Approved Drawing As per Drawing Rub off

H

FM-QAS-62 (Rev.0, 05/17/2010)

Document No.

Rev:

Date:

Surveillance Inspection

QA

Remarks

(Consultant)

A Existing relevant WPS/PQR, will be reviewed In case

any new WPS/PQR

R/W required, it will be done under QA (Consultant)

FM-QAS-62 (Rev.0, 05/17/2010)

Document No.

Rev:

Date:

Surveillance Inspection

QA

Remarks

(Consultant)

FM-QAS-62 (Rev.0, 05/17/2010)

Document No.

Rev:

Date:

Surveillance Inspection

QA

Remarks

(Consultant)

FM-QAS-62 (Rev.0, 05/17/2010)

Document No.

Rev:

Date:

Surveillance Inspection

QA

Remarks

(Consultant)

RN

RN

FM-QAS-62 (Rev.0, 05/17/2010)

Document No.

Rev:

Date:

Surveillance Inspection

QA

Remarks

(Consultant)

RN

RN

RN

RN

RN

RN

RN

FM-QAS-62 (Rev.0, 05/17/2010)

Document No.

Rev:

Date:

Surveillance Inspection

QA

Remarks

(Consultant)

W

FM-QAS-62 (Rev.0, 05/17/2010)

Document No.

Rev:

Date:

Surveillance Inspection

QA

Remarks

(Consultant)

FM-QAS-62 (Rev.0, 05/17/2010)

Potrebbero piacerti anche

- Pressure Vessel ITP Rev 0Documento10 paginePressure Vessel ITP Rev 0SLC HosurNessuna valutazione finora

- ITP Pressure VesselDocumento21 pagineITP Pressure VesselSds Mani SNessuna valutazione finora

- APV STD Insp & Test Plan API6D ValvesDocumento4 pagineAPV STD Insp & Test Plan API6D ValvesdbmingoNessuna valutazione finora

- Itp VesselDocumento4 pagineItp VesselHakim BaihaqiNessuna valutazione finora

- Inspection and Test Plan (Itp) For Fabrication Pressure VesselDocumento1 paginaInspection and Test Plan (Itp) For Fabrication Pressure VesselNikki RobertsNessuna valutazione finora

- ITP For Pressure Vessel - Static EquipmentDocumento8 pagineITP For Pressure Vessel - Static EquipmentReduddboyNessuna valutazione finora

- Qap HPCLDocumento13 pagineQap HPCLdarshan100% (1)

- ITP FOR SKID COMPRESSOR (Rev.0)Documento14 pagineITP FOR SKID COMPRESSOR (Rev.0)Richard AdolfNessuna valutazione finora

- F.sq-p.002 Rev. 0 Procedure For Existing Pressure VesselDocumento6 pagineF.sq-p.002 Rev. 0 Procedure For Existing Pressure VesselIksan Adityo MulyoNessuna valutazione finora

- Manufacturing Quality Plan For Tank: FGD Sysyem, 2X550 MW TpsDocumento4 pagineManufacturing Quality Plan For Tank: FGD Sysyem, 2X550 MW TpsBhanu Pratap ChoudhuryNessuna valutazione finora

- Diaphragm Pumps SOWDocumento30 pagineDiaphragm Pumps SOWalliancemarine2011Nessuna valutazione finora

- Inspection and Test Plan For New Pressure VesselDocumento2 pagineInspection and Test Plan For New Pressure VesselCak Nhass0% (1)

- ES.5.06.0001 RA - PressureVesselsDocumento28 pagineES.5.06.0001 RA - PressureVesselsJagadeesh PuppalaNessuna valutazione finora

- Itp - Tanks - 01Documento10 pagineItp - Tanks - 01ravigurajapuNessuna valutazione finora

- Chemical Resistance (LLDPE) PDFDocumento24 pagineChemical Resistance (LLDPE) PDFrubyshreeNessuna valutazione finora

- Procedure Qualification ReportDocumento5 pagineProcedure Qualification ReportDieu TranNessuna valutazione finora

- Burckhardt Compression (India) PVT - LTD.: 1.0 MaterialsDocumento2 pagineBurckhardt Compression (India) PVT - LTD.: 1.0 MaterialsYOGESHNessuna valutazione finora

- ITP For Field Erected Tank Rev ADocumento9 pagineITP For Field Erected Tank Rev AHoang Tuan Kiet100% (1)

- PQR Asme Ix - CompletedDocumento3 paginePQR Asme Ix - CompletedCarlos Nombela Palacios100% (1)

- Sample WPS 1Documento13 pagineSample WPS 1waqas pirachaNessuna valutazione finora

- Qap 8000ce Reactor - Repat - 1Documento2 pagineQap 8000ce Reactor - Repat - 1AliasgarNessuna valutazione finora

- Tips Wps FormatDocumento5 pagineTips Wps FormatWaqas WaqasNessuna valutazione finora

- Jacobs: Equipment Inspection Code: ADocumento2 pagineJacobs: Equipment Inspection Code: ASigit BintanNessuna valutazione finora

- Std-Insp-0002 (Incoming Material Inspection Procedure)Documento3 pagineStd-Insp-0002 (Incoming Material Inspection Procedure)airbroomNessuna valutazione finora

- Material Traceability Inspection ReportDocumento32 pagineMaterial Traceability Inspection ReportBalmiki SinghNessuna valutazione finora

- ITP-PRESSURE VESSEL ExistingDocumento2 pagineITP-PRESSURE VESSEL ExistingArisNessuna valutazione finora

- Quality Control Plan (QCP) For Ammonia Pressure Vessel: Before ManufacturingDocumento3 pagineQuality Control Plan (QCP) For Ammonia Pressure Vessel: Before ManufacturingFaisal Awad100% (1)

- Itp PipingDocumento4 pagineItp PipingkennethNessuna valutazione finora

- 2G & 5GDocumento2 pagine2G & 5GRahul MoottolikandyNessuna valutazione finora

- QIR 101 Welder Qualification CertificateDocumento1 paginaQIR 101 Welder Qualification CertificateSamer BayatiNessuna valutazione finora

- 2018-01-15 Kasuari WTP Erection & Installation ProcedureDocumento6 pagine2018-01-15 Kasuari WTP Erection & Installation ProcedureavriamandaNessuna valutazione finora

- ITP New Pressure VesselDocumento2 pagineITP New Pressure Vesselyosafateden60% (5)

- Flow Chart Test PackageDocumento1 paginaFlow Chart Test PackagejajakaNessuna valutazione finora

- Client Approval Remarks: Rev Date Descriptions Prepared by Reviewed by Approved byDocumento7 pagineClient Approval Remarks: Rev Date Descriptions Prepared by Reviewed by Approved bySARSAN NDTNessuna valutazione finora

- Al-Uqlah Central Processing Facility Water Level & Settlement TableDocumento12 pagineAl-Uqlah Central Processing Facility Water Level & Settlement TableSantosh Kumar BogelaNessuna valutazione finora

- Welding Procedure Specification For Storage Tank & Piping SystemDocumento3 pagineWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNessuna valutazione finora

- Inspection and Test Plan For Storage TankDocumento6 pagineInspection and Test Plan For Storage Tankpluton1954Nessuna valutazione finora

- Heat Exchanger QAPDocumento3 pagineHeat Exchanger QAPRajnikant PatelNessuna valutazione finora

- Check List-Heat ExchangerDocumento2 pagineCheck List-Heat Exchangersarmad009Nessuna valutazione finora

- ITP For Process PipingDocumento4 pagineITP For Process PipingSebastian RajeshNessuna valutazione finora

- Rapid p0030 CPP U0030 Qac Mom 0024 Quality MeetingDocumento13 pagineRapid p0030 CPP U0030 Qac Mom 0024 Quality MeetingAtuk Safiz100% (1)

- Inspection Test Plan (Itp)Documento1 paginaInspection Test Plan (Itp)widhisaputrawijayaNessuna valutazione finora

- Itp Safety ValveDocumento3 pagineItp Safety ValveLim Dongseop100% (1)

- Circularity Inspection Report: Shell Course (LW) CW CWDocumento14 pagineCircularity Inspection Report: Shell Course (LW) CW CWaszlizaNessuna valutazione finora

- Roundness Before Weld TK012-strike 1Documento2 pagineRoundness Before Weld TK012-strike 1yuwantoniNessuna valutazione finora

- Sample ItpDocumento4 pagineSample ItpWijayanto BekasiNessuna valutazione finora

- Ug PipingDocumento1 paginaUg PipingVinoth KumarNessuna valutazione finora

- Pressure Form Test RecordDocumento1 paginaPressure Form Test Recordphyo7799Nessuna valutazione finora

- Reverse Engineering Pressure Vessel ChecklistDocumento5 pagineReverse Engineering Pressure Vessel ChecklistES RouzaNessuna valutazione finora

- Job Procedure For Hot Insulation Work of Piping & Equipment1Documento13 pagineJob Procedure For Hot Insulation Work of Piping & Equipment1ravi00098100% (1)

- Piping Inspect & Testing ProcedureDocumento11 paginePiping Inspect & Testing ProcedureErlanggaBonaparteNessuna valutazione finora

- TANK 06 Test PackDocumento12 pagineTANK 06 Test PackGomathyselvi100% (2)

- Safety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingDocumento5 pagineSafety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingvietnampetrochemicalNessuna valutazione finora

- Asa-146 NSH Apco Ir 040Documento10 pagineAsa-146 NSH Apco Ir 040Fahad AhmadNessuna valutazione finora

- 4-QAP Heat EXDocumento8 pagine4-QAP Heat EXAjit Patil100% (1)

- Visual Inspection of Tanks & Pressure VesselsDocumento29 pagineVisual Inspection of Tanks & Pressure VesselsShahul Hameed Razik100% (5)

- WPS Asme Ix PDFDocumento4 pagineWPS Asme Ix PDFSergiu LungNessuna valutazione finora

- Hydrotest Form 1Documento2 pagineHydrotest Form 1jrod915Nessuna valutazione finora

- Form ITP Pressure Vessel - RevDocumento8 pagineForm ITP Pressure Vessel - Revsuratno 25Nessuna valutazione finora

- Quality Control Procedure SampleDocumento12 pagineQuality Control Procedure Samplepocharquitecturaromania92% (50)

- 3phase Single Line DiagramDocumento1 pagina3phase Single Line DiagramAhmad Hasnan100% (1)

- Infrastruktur: Jurnal Teknik SipilDocumento8 pagineInfrastruktur: Jurnal Teknik SipilAhmad HasnanNessuna valutazione finora

- Aplikasi CFD MultiphaseDocumento7 pagineAplikasi CFD MultiphaseAhmad HasnanNessuna valutazione finora

- 2 - Electrical Energy Audit PDFDocumento10 pagine2 - Electrical Energy Audit PDFPrachi BhaveNessuna valutazione finora

- Max Torque, Gammax (N-MM) Max Speed, Wmax (RPM, Rad/sec) Torque Speed Slope Constant, K WincDocumento9 pagineMax Torque, Gammax (N-MM) Max Speed, Wmax (RPM, Rad/sec) Torque Speed Slope Constant, K WincAhmad HasnanNessuna valutazione finora

- Steel Work Inspection ReportDocumento3 pagineSteel Work Inspection ReportAhmad Hasnan100% (1)

- Site Inspection ReportDocumento45 pagineSite Inspection ReportAhmad HasnanNessuna valutazione finora

- Chapter 2 Magnetic Effects of Current XDocumento25 pagineChapter 2 Magnetic Effects of Current XPawan Kumar GoyalNessuna valutazione finora

- Build A 10 Ton Hydraulic PressDocumento10 pagineBuild A 10 Ton Hydraulic PressManuel SterlingNessuna valutazione finora

- MS3XV30 Hardware 1.3Documento229 pagineMS3XV30 Hardware 1.3Colton CarmichaelNessuna valutazione finora

- Unit 16 AssignmentDocumento15 pagineUnit 16 AssignmentRavi Gajenthran100% (1)

- FINAL ITP 2024 CompressedDocumento388 pagineFINAL ITP 2024 Compressedhamidjumat77Nessuna valutazione finora

- A Simplified Two-Stage Method To Estimate The Settlement and Bending Moment of Upper Tunnel Considering The Interaction of Undercrossing Twin TunnelsDocumento32 pagineA Simplified Two-Stage Method To Estimate The Settlement and Bending Moment of Upper Tunnel Considering The Interaction of Undercrossing Twin TunnelsJianfeng XueNessuna valutazione finora

- Standard Costing ExercisesDocumento3 pagineStandard Costing ExercisesNikki Garcia0% (2)

- Seismic Design & Installation Guide: Suspended Ceiling SystemDocumento28 pagineSeismic Design & Installation Guide: Suspended Ceiling SystemhersonNessuna valutazione finora

- Common Inspection Training Report Kosovo (UNHCR1244)Documento51 pagineCommon Inspection Training Report Kosovo (UNHCR1244)awfahNessuna valutazione finora

- An Analysis of The Ejector-Ram-Rocket EngineDocumento9 pagineAn Analysis of The Ejector-Ram-Rocket Enginefundamental_aeroNessuna valutazione finora

- Session PlanDocumento11 pagineSession PlanMat Domdom Sansano100% (1)

- Wireshark Protocol Help Product PreviewDocumento6 pagineWireshark Protocol Help Product Previewsunil1978Nessuna valutazione finora

- Heat ExchangersDocumento25 pagineHeat ExchangersMohammed Kabiruddin100% (7)

- Rev2 Service Manual Apollo PDFDocumento370 pagineRev2 Service Manual Apollo PDFJordi Vaquero RamirezNessuna valutazione finora

- Limak 2017 Annual ReportDocumento122 pagineLimak 2017 Annual Reportorcun_ertNessuna valutazione finora

- MC9S12XD128 ProcessadorDocumento1.350 pagineMC9S12XD128 ProcessadorMarcelo OemNessuna valutazione finora

- Molinos VerticalesDocumento172 pagineMolinos VerticalesLeonardo RodriguezNessuna valutazione finora

- 3 3 1 Material Sorter Design ChallengeDocumento3 pagine3 3 1 Material Sorter Design Challengeapi-343534512Nessuna valutazione finora

- Construction of Rajive Gandhi Urja Bhawan, Ongc Energy Center & Corporate OfficeDocumento23 pagineConstruction of Rajive Gandhi Urja Bhawan, Ongc Energy Center & Corporate OfficeDevendra SharmaNessuna valutazione finora

- Oil and Wildlife Conservation in UgandaDocumento40 pagineOil and Wildlife Conservation in UgandaAfrican Centre for Media ExcellenceNessuna valutazione finora

- Splunk 7 Essentials Third EditionDocumento388 pagineSplunk 7 Essentials Third EditionHaripriya100% (1)

- Connection DiagramsDocumento3 pagineConnection Diagramsfahad pirzadaNessuna valutazione finora

- 17.4 Boiler and Feed-Water TreatmentDocumento28 pagine17.4 Boiler and Feed-Water Treatmentnomeacuerdo1Nessuna valutazione finora

- Drying AgentDocumento36 pagineDrying AgentSo MayeNessuna valutazione finora

- Us06-106 850 01 01 02 PDFDocumento6 pagineUs06-106 850 01 01 02 PDFF2CANALESNessuna valutazione finora

- Computer Laboratory Maintenance Plan and ScheduleDocumento5 pagineComputer Laboratory Maintenance Plan and ScheduleJm Valiente100% (3)

- Acids and Bases Part 3 (Weak Acids) EdexcelDocumento2 pagineAcids and Bases Part 3 (Weak Acids) EdexcelKevin The Chemistry TutorNessuna valutazione finora

- YcivDocumento68 pagineYcivBelhassen Saddadi100% (2)

- Surveying Civil Engineering Pictorial Booklet 15 English MediumDocumento125 pagineSurveying Civil Engineering Pictorial Booklet 15 English MediumtnstcnpalanisamyNessuna valutazione finora

- Ruckus Wired Accreditation ExamDocumento15 pagineRuckus Wired Accreditation ExamDennis Dube25% (8)