Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

M & e MST - 031 Rev. 0

Caricato da

Anonymous 3eHGEDbxDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

M & e MST - 031 Rev. 0

Caricato da

Anonymous 3eHGEDbxCopyright:

Formati disponibili

Xyz COMPANY

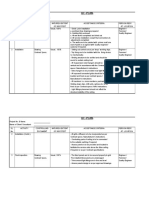

METHOD STATEMENT M & E NO.: M & E MST- 031/ REV 0 Page 1 of 3

G. I. DUCT FABRICATION.

TITLE:

G. I. DUCT FABRICATION.

1.0 PURPOSE

The purpose of this procedure is to describe the method for G.I duct fabrication.

2.0 SCOPE

This procedure shall be applicable for the duct system used to transmit air from

the air handling apparatus to the space to be conditioned.

3.0 REFERENCE

3.1 QAP ~ 050 Document & Data Control

3.2 QAP ~ 100 Inspection & Testing

3.3 QAP ~ 040 Design Control.

4.0 DEFINITION

4.1 Company XYZ.

4.2 Quality Engineer Nominated Quality Engineer at Site.

4.3 Discipline Engineer Company designated HVAC Engineer as

decided by the Management and assigned with the

responsibility of managing electrical part of the

Project.

4.4 DW 142 Duct Work Standard

4.5 ASHRAE American Society of Heating, Refrigeration and air-

conditioning Engineering.

M & E MST- 031/ REV 0 Date: January 26, 2001

Xyz COMPANY

METHOD STATEMENT M & E NO.: M & E MST- 031/ REV 0 Page 2 of 3

G. I. DUCT FABRICATION.

TITLE:

5.0 PROCEDURE

5.1 Responsibility

5.1.1 The responsibility for carrying out this Method Statement shall be that of the

Discipline Engineer/ Foremen, unless otherwise specifically mentioned in this

procedure. The Quality Engineer/ Discipline Engineer/ Foremen shall be

responsible for inspection & testing.

5.2 Preparation

5.2.1 Particular project specification and DW standard should be verified from the

approved shop drawing and Mechanical specification book.

5.2.2 Thickness of acoustic liner and minimum required distance of acoustic liner rom

unit outlet should be verified and accordingly duct sketches shall be made.

5.2.3 In every sketch, thickness (gauge) of the sheet, volume control damper and fire

dampers position in the duct shall be shown in order to fabricate the duct

accordingly.

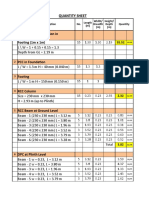

5.3 Fabrication

5.3.1 All fabrication shall be done according to the DW standard, which is shown in

the approved drawings or in the specification.

5.3.2 During fabrication fabricator should make sure that the wastage should not

exceeds more than 10% of the total fabricated duct area.

5.3.3 According to DW / ASHRAE standard, all duct joining, stiffener shall be

provided in the duct workshop itself.

5.3.4 All G.I. sheets shall be handled in a proper way so that it should not get

damaged during transportation and handling at duct workshop. Supervisor

must make sure that hand gloves are supplied to all workers and all workers

must use during the time of working.

5.3.5 During cutting of G.I. sheet, supervisor must make sure that cut edges are

sharp without any burr, if it is not satisfactory then blade must be sharpened.

5.3.6 Lock former overlap shall be checked and to be verified for the size of standard.

M & E MST- 031/ REV 0 Date: January 26, 2001

Xyz COMPANY

METHOD STATEMENT M & E NO.: M & E MST- 031/ REV 0 Page 3 of 3

G. I. DUCT FABRICATION.

TITLE:

5.3.7 Duct work shop supervisor should check and verify for any manufacturing

defects and dimensional discrepancy before dispatching all fabricated ducts

to site

5.3.8 Sheet consumption for each project and daily wise shall be recorded in the

workshop material register.

5.3.9 Monthly / Quarterly invoice shall be raised to each project / party

5.3.10 All required check- list shall be checked and verified accordingly before

despatching any fabricated duct to respective sites.

6.0 DOCUMENTATION/ RECORDS

6.1 G. I. Duct works- Inspection report M & E QC~Form- 031-01/ REV. 0.

M & E MST- 031/ REV 0 Date: January 26, 2001

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- GlazingDocumento81 pagineGlazingAnjalySinhaNessuna valutazione finora

- Endura MRL: Low-Rise ElevatorDocumento24 pagineEndura MRL: Low-Rise ElevatorMohd Abu AjajNessuna valutazione finora

- NQA ISO 45001 Implementation GuideDocumento36 pagineNQA ISO 45001 Implementation GuideAnonymous 3eHGEDbx100% (11)

- MS For Ductwork SystemDocumento19 pagineMS For Ductwork SystemTruong Quoc Bao100% (1)

- Utilization Factor PDFDocumento4 pagineUtilization Factor PDFMuraryspotty33% (3)

- M & e MST - 038 Rev. 0Documento3 pagineM & e MST - 038 Rev. 0Anonymous 3eHGEDbxNessuna valutazione finora

- Elec Wiring Regs 2007 Rev 01Documento240 pagineElec Wiring Regs 2007 Rev 01Anonymous 3eHGEDbxNessuna valutazione finora

- MOUNT - Fixing PlatesDocumento8 pagineMOUNT - Fixing PlatesAnonymous 3eHGEDbxNessuna valutazione finora

- Historical Record Dimensions and PropertiesDocumento145 pagineHistorical Record Dimensions and PropertiesAnonymous 3eHGEDbxNessuna valutazione finora

- National Gypsum Steel StudPartitionsDocumento9 pagineNational Gypsum Steel StudPartitionsAnonymous 3eHGEDbxNessuna valutazione finora

- Pub 100427Documento5 paginePub 100427Engr Nabeel AhmadNessuna valutazione finora

- Acoustic Brochure PDFDocumento6 pagineAcoustic Brochure PDFAnonymous 3eHGEDbxNessuna valutazione finora

- Steel Window Service: Scale Drawn CheckedDocumento1 paginaSteel Window Service: Scale Drawn CheckedAnonymous 3eHGEDbxNessuna valutazione finora

- Xyz Company: PurposeDocumento5 pagineXyz Company: PurposeAnonymous 3eHGEDbxNessuna valutazione finora

- M & e MST - 036 Rev. 0Documento3 pagineM & e MST - 036 Rev. 0Anonymous 3eHGEDbxNessuna valutazione finora

- Purpose: Method Statement M & E No.: M & E Mst-004/ Rev 0 Page 1 of 4 Title: LV Switchgear Installation and TestingDocumento4 paginePurpose: Method Statement M & E No.: M & E Mst-004/ Rev 0 Page 1 of 4 Title: LV Switchgear Installation and TestingAnonymous 3eHGEDbxNessuna valutazione finora

- Xyz Company: PurposeDocumento3 pagineXyz Company: PurposeAnonymous 3eHGEDbxNessuna valutazione finora

- Xyz Company: PurposeDocumento3 pagineXyz Company: PurposeAnonymous 3eHGEDbxNessuna valutazione finora

- 051 GlazingDocumento2 pagine051 GlazingAnonymous 3eHGEDbxNessuna valutazione finora

- 021-Suspended CeilingDocumento4 pagine021-Suspended CeilingAnonymous 3eHGEDbxNessuna valutazione finora

- 018 Insitu FlooringDocumento4 pagine018 Insitu FlooringAnonymous 3eHGEDbxNessuna valutazione finora

- M & E QC Plan - 0063b REV. 0Documento4 pagineM & E QC Plan - 0063b REV. 0Anonymous 3eHGEDbxNessuna valutazione finora

- 015-Roofing, Insulation &water ProofingDocumento4 pagine015-Roofing, Insulation &water ProofingAnonymous 3eHGEDbxNessuna valutazione finora

- 019-Carpentary, Joinery & General FixingDocumento2 pagine019-Carpentary, Joinery & General FixingAnonymous 3eHGEDbxNessuna valutazione finora

- Building Estimation Excel SheetDocumento15 pagineBuilding Estimation Excel SheetDheeraj Kumar Pandey100% (3)

- CRCM Manual 2 9 16Documento33 pagineCRCM Manual 2 9 16سجى وليدNessuna valutazione finora

- Quotation For Rapicon WallDocumento2 pagineQuotation For Rapicon WallDebkumar ChowdhuryNessuna valutazione finora

- Composite Deck Technical Manual: 3WH-36 Hi FormDocumento33 pagineComposite Deck Technical Manual: 3WH-36 Hi FormVinod Kumar ReddyNessuna valutazione finora

- NAIMA - Facts About Metal Building Acoustic InsulationDocumento4 pagineNAIMA - Facts About Metal Building Acoustic InsulationbatteekhNessuna valutazione finora

- Summary of Rain Water Leakage Report - 07.11.2023Documento3 pagineSummary of Rain Water Leakage Report - 07.11.2023Siva SankarNessuna valutazione finora

- Product Data Sheet For CFS-S SIL SL Firestop Silicone Sealant Technical Information ASSET DOC LOC 2617979 PDFDocumento1 paginaProduct Data Sheet For CFS-S SIL SL Firestop Silicone Sealant Technical Information ASSET DOC LOC 2617979 PDFrekcahzNessuna valutazione finora

- Kelvinator G6 Series Furnace ManualDocumento44 pagineKelvinator G6 Series Furnace ManualAlec Leo BurghardtNessuna valutazione finora

- Footing Inspection ChecklistDocumento2 pagineFooting Inspection ChecklistHamidullah TotakhailNessuna valutazione finora

- Bending Machine Sustarin Rollers Nargesa - 4Documento1 paginaBending Machine Sustarin Rollers Nargesa - 4yossef albanaNessuna valutazione finora

- Point 1 Point 2 Point 3 Point 4 Point 5Documento15 paginePoint 1 Point 2 Point 3 Point 4 Point 5Annisa Prita MelindaNessuna valutazione finora

- Final Bank DesignDocumento90 pagineFinal Bank DesigneshNessuna valutazione finora

- Annex IX - Bill of QuantityDocumento6 pagineAnnex IX - Bill of QuantityIshteyak AlamNessuna valutazione finora

- Assignment 2 Pre Stressed Concrete FrameDocumento21 pagineAssignment 2 Pre Stressed Concrete Frameillya amyraNessuna valutazione finora

- Sanitary Ni CristDocumento1 paginaSanitary Ni CristJun MichaelNessuna valutazione finora

- Mar305-0 Tech Data CXVDocumento8 pagineMar305-0 Tech Data CXVgoodspeed_phNessuna valutazione finora

- Fan Coil Asia York FICHADocumento4 pagineFan Coil Asia York FICHAAnderson Márquez PaniaguaNessuna valutazione finora

- Construction Method and Project Management ReportDocumento5 pagineConstruction Method and Project Management Reportleselle quitanegNessuna valutazione finora

- Concrete Floor SystemsDocumento40 pagineConcrete Floor SystemsDinuNessuna valutazione finora

- EDGE User Guide For All Building Types Version 3.0.A BetaDocumento289 pagineEDGE User Guide For All Building Types Version 3.0.A Betawar. zonNessuna valutazione finora

- Commercial - Building - Electrical - Design (Inc)Documento17 pagineCommercial - Building - Electrical - Design (Inc)Stephany PolinarNessuna valutazione finora

- Materials Case StudyDocumento14 pagineMaterials Case StudyAkanksha BhakareNessuna valutazione finora

- Behavior of Cantilever SlabsDocumento1 paginaBehavior of Cantilever Slabsatoz2033Nessuna valutazione finora

- Act3 (Doors and Winddows) - Rola&Quemi BSCE-2D-Layout1Documento1 paginaAct3 (Doors and Winddows) - Rola&Quemi BSCE-2D-Layout1Rola, Crystel Joy B.Nessuna valutazione finora

- PHC Pile Model2Documento1 paginaPHC Pile Model2Chan ThornNessuna valutazione finora

- Flexible Pavement vs. Rigid PavementDocumento10 pagineFlexible Pavement vs. Rigid PavementJeneveive Mae BalbinNessuna valutazione finora