Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

QIP-Digitalization of RHEO Data - A3

Caricato da

sharmasanjivCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

QIP-Digitalization of RHEO Data - A3

Caricato da

sharmasanjivCopyright:

Formati disponibili

QC STORY

QC STORY

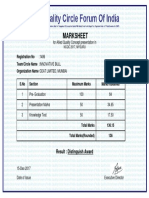

Team Leader: Shrikant bansode Phone No: 8554992995 Email: shrikant.bansode@ceat.in Team Members Sampayan Kar, Parag Mote, Bobin Sasi, Bhushan Dhanawade, Rajendra Jadhav

Organization: CEAT Limited, Nashik

Mentor: ML patel Phone No: Email: ML.Patel@ceat.in Start Date Planned 15.09.2016 Completion Date Planned: 15.09.2016

1A)Brief Problem Description 1. Reason for Improvement 3.2 Confirm the probable cause(s) Start Date Actual: 30.12.2016 Completion Date Actual: 30.12.2016

Sl.N Probable Cause Testing and Observations Conclusion

a) What : Digitalization Of Rapid Control Laboratory.

b) Where : Rapid Control Lab

c) When : FY17 (Q3)

e) Present level: 0% f) Target 100% digitalization and paperless

1 B - Justification

* CEAT Vision towards Digitization and Innovation

* Muri of QA inspectors to check and write each parameter in log-

book.

* Eco-friendly by eliminating paper usage through online

management system

* Easy analysis of data, storage and retrievable.

1 C - Emergency response and interim action (if required): 2. Current Situation 3.3 Identify the root cause(s) 4. Why Why analysis

2a) Observation of process:

1.1 Theme/Pain Area(Q1):

Tech. Disposition decisions on held-up batches(non conforming batches) after 24 hrs. resulting on unnecessary delay

& increase of floor inventory due to material blockage.

Extensive paper intensive, manual duplication work such as entries in log book by testers.

Adverse Impact on 5S ratings.

1.2 Measures:

Elimination of paper usage with green initiative. From 216 kgs. per Annum to 0 kgs.

Zero breakdown hours.

b) Reduction in tech. deposition time from 24 hrs. to 8 hrs. thus work away of held up batches in the subsequent 4. Counter Measures

shifts.

c) Standardization of SOP from 3 nos. to 1 no.

2b) Understand the current situation

Different make machines for Testing.

Different vendors for AMC.

Motherboard for 2 nos. ODR m/c is Imported and having replacement frequency of 1 year worth Rs.2.25 Lacs.

Paper consuming, as results needs to be in print out only.

As data is in hard copy, analysis and interpretation of results is very difficult job. So lack of results analysis.

Print outs and record management requires place to keep and a workmen once in week for one shift. i.e. non-value adding activity.

As m/c are different make, SOP for each m/c is different and due to MURA increased. 5.1 Verify Results 5. Result Check

One Dot matrix printer require for two machines.

If Printer is breakdown, then testing and releasing of compound batches delays which directly affects further delaying of process.

3.1 Identify all possible causes 3. Analysis

6. Standardization

6.1 Updating of documents:

Microsoft Office

Excel Worksheet

7. Future Plan

1. Integration of Rheo Test Results with SAP.

2. Auto disposition and mail triggered to Concern people.

Potrebbero piacerti anche

- How To Set KPI: (Key Performance Indicator)Documento16 pagineHow To Set KPI: (Key Performance Indicator)herjantoNessuna valutazione finora

- MSAENV272B - ASI - Assessment 3 - Project 2 - Part NestingDocumento10 pagineMSAENV272B - ASI - Assessment 3 - Project 2 - Part NestingJames DanielNessuna valutazione finora

- Six Sigma Green Belt.8169983.powerpointDocumento18 pagineSix Sigma Green Belt.8169983.powerpointsumit singhNessuna valutazione finora

- DMAIC - CSAT ImprovementDocumento135 pagineDMAIC - CSAT Improvementbiswazoom100% (1)

- P 006 EspDocumento7 pagineP 006 EspRamneet Singh ChadhaNessuna valutazione finora

- Quality Management MetricsDocumento3 pagineQuality Management MetricsalegabipachecoNessuna valutazione finora

- DMAIC Cycle Time ReductionDocumento50 pagineDMAIC Cycle Time Reductionblitzkrig100% (1)

- Comparative Software Size and Efforts EstimationDocumento10 pagineComparative Software Size and Efforts Estimationj16a1984Nessuna valutazione finora

- Quality Prediction Modeling For Multistage ManufacDocumento6 pagineQuality Prediction Modeling For Multistage Manufacronald christenkksonNessuna valutazione finora

- Sampling Plan Implementation On Machining Components Using Statistical Process ControlDocumento1 paginaSampling Plan Implementation On Machining Components Using Statistical Process ControlHemendra WaswaniNessuna valutazione finora

- Acca107 Strat Cost MGT PrelimsDocumento2 pagineAcca107 Strat Cost MGT PrelimsShaneen AdorableNessuna valutazione finora

- Jurnal Pengendalian MutuDocumento12 pagineJurnal Pengendalian MutuJohny Iskandar Arsyad NstNessuna valutazione finora

- Structural Lab 1Documento21 pagineStructural Lab 1Stefhany RapioNessuna valutazione finora

- Ritiik 1Documento10 pagineRitiik 1Deepak BeheraNessuna valutazione finora

- Matt PalmerQA And Dosimetry in Nuclear Medicine 1Documento53 pagineMatt PalmerQA And Dosimetry in Nuclear Medicine 1klearoseni31Nessuna valutazione finora

- Quiz4: Production Cell Design Concepts: Instructions: You Have 25 Minutes To Complete This QuizDocumento3 pagineQuiz4: Production Cell Design Concepts: Instructions: You Have 25 Minutes To Complete This QuizMatthew GoodmanNessuna valutazione finora

- Onilne RestaurantDocumento108 pagineOnilne RestaurantIndar GuptaNessuna valutazione finora

- Program 3 PSP Regression and Correlation AnalysisDocumento18 pagineProgram 3 PSP Regression and Correlation AnalysisElizabeth PerezNessuna valutazione finora

- t6 Mbap Day 3 v3.14Documento14 paginet6 Mbap Day 3 v3.14Keng Whye LeongNessuna valutazione finora

- Optimization of Connected Component LabellingDocumento8 pagineOptimization of Connected Component LabellingTim LeeNessuna valutazione finora

- MS ProjectDocumento3 pagineMS ProjectShoaib TaqiNessuna valutazione finora

- 1892 - TST Document DV 4876 003Documento5 pagine1892 - TST Document DV 4876 003Jesús Eduardo Mora PérezNessuna valutazione finora

- Appendix 2 Sample Operations For Pilot Study Sample Pilot Study Schedule OutlineDocumento12 pagineAppendix 2 Sample Operations For Pilot Study Sample Pilot Study Schedule OutlineCarissa CkNessuna valutazione finora

- Cse Btech IV Yr Vii Sem Scheme Syllabus July 2022Documento25 pagineCse Btech IV Yr Vii Sem Scheme Syllabus July 2022Ved Kumar GuptaNessuna valutazione finora

- 2.5.3 Examination ManualDocumento55 pagine2.5.3 Examination Manuala NaniNessuna valutazione finora

- Pom Imp QuestionsDocumento7 paginePom Imp QuestionsramsastryNessuna valutazione finora

- Accelerating quality control with image processingDocumento6 pagineAccelerating quality control with image processingAnurdha shammikaNessuna valutazione finora

- TIE 6230 Quality Systems - 2016-2017Documento5 pagineTIE 6230 Quality Systems - 2016-2017tafara mundereNessuna valutazione finora

- QCC Velg MobilDocumento7 pagineQCC Velg MobilariniNessuna valutazione finora

- Operations Management CourseDocumento8 pagineOperations Management Courseelsonpaul100% (1)

- GSM KPI Optimization Process and GuideDocumento22 pagineGSM KPI Optimization Process and GuideZouhir El AllaouiNessuna valutazione finora

- Timelredline Offlineine: A. B. C. DDocumento4 pagineTimelredline Offlineine: A. B. C. DJesús Eduardo Mora PérezNessuna valutazione finora

- Process Improvement by Using Value Stream Mapping A Case Study in Small Scale Industry IJERTV1IS5333Documento10 pagineProcess Improvement by Using Value Stream Mapping A Case Study in Small Scale Industry IJERTV1IS5333Praveen KumarNessuna valutazione finora

- Design and Development of Kistler 8840 Rotational Accelerometer MountingDocumento32 pagineDesign and Development of Kistler 8840 Rotational Accelerometer Mountingirfanrosli90Nessuna valutazione finora

- Lab 10 SQL JOINS INNER SELF OUTERDocumento13 pagineLab 10 SQL JOINS INNER SELF OUTERMisbah UllahNessuna valutazione finora

- Performane Improvement by Scheduling Techniques Article by Abduletif HabibDocumento16 paginePerformane Improvement by Scheduling Techniques Article by Abduletif HabibAbduletif HeboNessuna valutazione finora

- Lab Manual 01 CSE 324 Project ProposalDocumento6 pagineLab Manual 01 CSE 324 Project ProposalShimul Chandra DasNessuna valutazione finora

- .Printed Circuit Board Assembly Defects Detection Using Image Processing TechniquesDocumento6 pagine.Printed Circuit Board Assembly Defects Detection Using Image Processing TechniquesKM PRIYA SINGHNessuna valutazione finora

- Synopsis BCA-5Documento13 pagineSynopsis BCA-5lomir76956Nessuna valutazione finora

- Industrial Engineering: B.E. (Mechanical Engineering) Seventh Semester (C.B.S.)Documento4 pagineIndustrial Engineering: B.E. (Mechanical Engineering) Seventh Semester (C.B.S.)Shashwat JainNessuna valutazione finora

- Industrial Project Thesis TAL - Navratan, HemendraDocumento94 pagineIndustrial Project Thesis TAL - Navratan, HemendraHemendra WaswaniNessuna valutazione finora

- Thesis - Proposal (Cloud Networked Robotics in The Field of Manufacturing)Documento11 pagineThesis - Proposal (Cloud Networked Robotics in The Field of Manufacturing)Nafees SiddiqueNessuna valutazione finora

- Learning OutcomesDocumento13 pagineLearning OutcomesWan2wantNessuna valutazione finora

- Resort Event Management SystemDocumento5 pagineResort Event Management Systemfihava5658Nessuna valutazione finora

- Problem SolvingDocumento75 pagineProblem SolvingndesigngmailNessuna valutazione finora

- System Analysis & Design: Waiters On Wheels - Group AssignmentDocumento48 pagineSystem Analysis & Design: Waiters On Wheels - Group Assignmentজান্নাতুন খান নাঈমNessuna valutazione finora

- AIC Case AssignmentDocumento2 pagineAIC Case AssignmentSinem Düden0% (2)

- B.Tech. in Mechanical Engineering: "Value Stream Mapping For Wiring Harness"Documento7 pagineB.Tech. in Mechanical Engineering: "Value Stream Mapping For Wiring Harness"Vijay ParteNessuna valutazione finora

- lgt5158Documento4 paginelgt5158StanleyNessuna valutazione finora

- Lab No. 01 Title: Project Assignment, Proposal Preparation and PlanningDocumento6 pagineLab No. 01 Title: Project Assignment, Proposal Preparation and PlanningMufizul islam NirobNessuna valutazione finora

- Machine Learning (16CIC73) Project Report TemplateDocumento12 pagineMachine Learning (16CIC73) Project Report TemplateKarishma Kurickal50% (2)

- 14ME720Documento6 pagine14ME720tprakashtceNessuna valutazione finora

- MP1 Template For Project ProposalDocumento11 pagineMP1 Template For Project ProposalSujan NeupaneNessuna valutazione finora

- Project ReportDocumento9 pagineProject Reportsmm azadNessuna valutazione finora

- Project ManagementDocumento59 pagineProject ManagementAsad JavedNessuna valutazione finora

- Preparation of Calibration Curves A Guide To Best PracticeDocumento31 paginePreparation of Calibration Curves A Guide To Best PracticeSohail AzharNessuna valutazione finora

- Vijay KumarDocumento4 pagineVijay Kumarkaran bainsNessuna valutazione finora

- Aster Qa Plan v2.0Documento41 pagineAster Qa Plan v2.0Italo MelgarNessuna valutazione finora

- Computer Aided Process Planning (CAPP): 2nd EditionDa EverandComputer Aided Process Planning (CAPP): 2nd EditionNessuna valutazione finora

- Test Driven: Practical TDD and Acceptance TDD for Java DevelopersDa EverandTest Driven: Practical TDD and Acceptance TDD for Java DevelopersNessuna valutazione finora

- Chapter08-The New SevenTools For Management and PlanningDocumento24 pagineChapter08-The New SevenTools For Management and Planningjade chavezNessuna valutazione finora

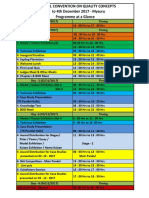

- Quality Concepts Cultural BreakthroughDocumento9 pagineQuality Concepts Cultural BreakthroughsharmasanjivNessuna valutazione finora

- D1N3oS2crrS PDFDocumento38 pagineD1N3oS2crrS PDFsharmasanjivNessuna valutazione finora

- Cii Recognised Kaizen Practices at KeplDocumento1 paginaCii Recognised Kaizen Practices at KeplsharmasanjivNessuna valutazione finora

- Guidelines for 14th KAIZEN CompetitionDocumento1 paginaGuidelines for 14th KAIZEN CompetitionsharmasanjivNessuna valutazione finora

- 5S ImplementationDocumento35 pagine5S ImplementationPrateek Gupta100% (1)

- NCQCDocumento1 paginaNCQCsharmasanjivNessuna valutazione finora

- AbdullahDocumento245 pagineAbdullahKhaled ToffahaNessuna valutazione finora

- Maths Grade 8studentDocumento371 pagineMaths Grade 8studentsharmasanjivNessuna valutazione finora

- 7311 - Innovative Bull (Allied)Documento64 pagine7311 - Innovative Bull (Allied)sharmasanjivNessuna valutazione finora

- 2 Day Workshop On Skill Development March 2016Documento1 pagina2 Day Workshop On Skill Development March 2016sharmasanjivNessuna valutazione finora

- Private Pilot Knowledge Test GuideDocumento125 paginePrivate Pilot Knowledge Test Guidesharmasanjiv100% (2)

- Knowledge Test SampleDocumento1 paginaKnowledge Test SamplesharmasanjivNessuna valutazione finora

- Industry 4 - Future of Manufacturing PDFDocumento20 pagineIndustry 4 - Future of Manufacturing PDFStephanie ÁngelNessuna valutazione finora

- Tools For Quality ImprovementDocumento64 pagineTools For Quality Improvementmuzammil21_adNessuna valutazione finora

- Quality Circles Convention Organized by PSITDocumento7 pagineQuality Circles Convention Organized by PSITsharmasanjivNessuna valutazione finora

- 7308 Screaming Eagles MarksDocumento1 pagina7308 Screaming Eagles MarkssharmasanjivNessuna valutazione finora

- The Impact of Wind Turbine Generators On The Lanscape - : Løgstør - DenmarkDocumento4 pagineThe Impact of Wind Turbine Generators On The Lanscape - : Løgstør - DenmarksharmasanjivNessuna valutazione finora

- 025 Edelman Basic Ultrasound PhysicsDocumento44 pagine025 Edelman Basic Ultrasound Physicssharmasanjiv100% (9)

- Interactive Earth Science Textbook PDFDocumento463 pagineInteractive Earth Science Textbook PDFSoona JaffNessuna valutazione finora

- 4.12app of Non ConventionalDocumento15 pagine4.12app of Non Conventionalpetro121Nessuna valutazione finora

- Effective Root Cause Analysis with 3 Legged 5 WhyDocumento42 pagineEffective Root Cause Analysis with 3 Legged 5 WhySerchecko JaureguiNessuna valutazione finora

- 7430 SKILLED CertificateDocumento6 pagine7430 SKILLED CertificatesharmasanjivNessuna valutazione finora

- CEAT Deming Team Members at NCQC 2017 ConferenceDocumento3 pagineCEAT Deming Team Members at NCQC 2017 ConferencesharmasanjivNessuna valutazione finora

- 11 - Chapter 3 PDFDocumento33 pagine11 - Chapter 3 PDFozkanyilmazNessuna valutazione finora

- 7312 Exel Warriors CertificateDocumento3 pagine7312 Exel Warriors CertificatesharmasanjivNessuna valutazione finora

- New England Wind Takes A Wild Ride: A Wind Powering America Project Volume 1, Issue 4 - May 2008Documento13 pagineNew England Wind Takes A Wild Ride: A Wind Powering America Project Volume 1, Issue 4 - May 2008sharmasanjivNessuna valutazione finora

- Comparison of Wind Energy Power Industry in India, China, and SpainDocumento25 pagineComparison of Wind Energy Power Industry in India, China, and SpainAmitNessuna valutazione finora

- 7429 EAGLE CertificateDocumento6 pagine7429 EAGLE CertificatesharmasanjivNessuna valutazione finora

- 7311 Innovative Bull MarksDocumento1 pagina7311 Innovative Bull MarkssharmasanjivNessuna valutazione finora

- Data Sheet ECU-TESTDocumento2 pagineData Sheet ECU-TESTmeetbalakumarNessuna valutazione finora

- MAST20026 Real Analysis With Applications, August 10, 2011. This Document Was Produced by Steve Carnie and Adapted by Alex GhitzaDocumento2 pagineMAST20026 Real Analysis With Applications, August 10, 2011. This Document Was Produced by Steve Carnie and Adapted by Alex Ghitzavanessa8pangestuNessuna valutazione finora

- Defining Yourself As A LeaderDocumento1 paginaDefining Yourself As A Leaderrosli2503Nessuna valutazione finora

- Abm Trial Balance ActivityDocumento3 pagineAbm Trial Balance ActivityRoxanne RoldanNessuna valutazione finora

- Vissim 11 - ManualDocumento1.219 pagineVissim 11 - Manualmauricionsantos60% (5)

- IBPS PO Preliminary Practice Set 5Documento41 pagineIBPS PO Preliminary Practice Set 5Nive AdmiresNessuna valutazione finora

- A. RSQM (DQ-029)Documento350 pagineA. RSQM (DQ-029)deso tblNessuna valutazione finora

- Central Bank Digital Currencies For Beginners A Quick Guide Into CbdcsDocumento33 pagineCentral Bank Digital Currencies For Beginners A Quick Guide Into CbdcsCarlos Bueno HorcajoNessuna valutazione finora

- Pulau Besar Island Off Malacca CoastDocumento5 paginePulau Besar Island Off Malacca CoastLucy TyasNessuna valutazione finora

- 3 IT18 Information Assurance and Security 2 Prelim ExamDocumento2 pagine3 IT18 Information Assurance and Security 2 Prelim Examsarah miinggNessuna valutazione finora

- 2021-2022 Reopening Plan 2.0Documento22 pagine2021-2022 Reopening Plan 2.0Dan LehrNessuna valutazione finora

- VRIL-Compendium-Vol-7-Dendritic Ground Systems-1992 PDFDocumento204 pagineVRIL-Compendium-Vol-7-Dendritic Ground Systems-1992 PDFAnton Dremlyuga100% (3)

- Certificate of IncorporationDocumento1 paginaCertificate of IncorporationVaseem ChauhanNessuna valutazione finora

- Marie Bjerede and Tzaddi Bondi 2012 - Learning Is Personal, Stories of Android Tablet Use in The 5th GradeDocumento50 pagineMarie Bjerede and Tzaddi Bondi 2012 - Learning Is Personal, Stories of Android Tablet Use in The 5th Gradeluiz carvalhoNessuna valutazione finora

- 71cryptocurrencies Have Become One of The Hottest Topics in The Financial WorldDocumento2 pagine71cryptocurrencies Have Become One of The Hottest Topics in The Financial WorldicantakeyouupNessuna valutazione finora

- PHB 55n03lta Logic Level FetDocumento15 paginePHB 55n03lta Logic Level FetyusufwpNessuna valutazione finora

- Aartv Industrial Training ReportDocumento48 pagineAartv Industrial Training ReportRupal NaharNessuna valutazione finora

- (OBIEE11g) Integrating Oracle Business Intelligence Applications With Oracle E-Business Suite - Oracle Bi SolutionsDocumento11 pagine(OBIEE11g) Integrating Oracle Business Intelligence Applications With Oracle E-Business Suite - Oracle Bi SolutionsVenkatesh Ramiya Krishna MoorthyNessuna valutazione finora

- (Lecture 10 & 11) - Gearing & Capital StructureDocumento18 pagine(Lecture 10 & 11) - Gearing & Capital StructureAjay Kumar TakiarNessuna valutazione finora

- Tool Selection For Rough and Finish CNC Milling OpDocumento4 pagineTool Selection For Rough and Finish CNC Milling Opmatic91Nessuna valutazione finora

- Lala Lajpat Rai College: Public Relations Project Rough Draft Topic: Nike V/S AdidasDocumento34 pagineLala Lajpat Rai College: Public Relations Project Rough Draft Topic: Nike V/S AdidasNikitha Dsouza75% (4)

- Income from Business and Profession Section 28,29&30Documento14 pagineIncome from Business and Profession Section 28,29&30imdadul haqueNessuna valutazione finora

- Section E Self Assessment Checklist For Metal Control StandardsDocumento2 pagineSection E Self Assessment Checklist For Metal Control StandardsMohammed Ishak100% (1)

- Condrada v. PeopleDocumento2 pagineCondrada v. PeopleGennard Michael Angelo AngelesNessuna valutazione finora

- Ds Gigavue FM Fabric ManagerDocumento9 pagineDs Gigavue FM Fabric ManagerMARCELOTRIVELATTONessuna valutazione finora

- Προσχέδιο Έκθεσης Γ.Γ. ΟΗΕ για Καλές ΥπηρεσίεςDocumento20 pagineΠροσχέδιο Έκθεσης Γ.Γ. ΟΗΕ για Καλές ΥπηρεσίεςARISTEIDIS VIKETOSNessuna valutazione finora

- Jabiru Inc S Senior Management Recently Obtained A New Decision Support DatabaseDocumento1 paginaJabiru Inc S Senior Management Recently Obtained A New Decision Support DatabaseDoreenNessuna valutazione finora

- Netflix AccountsDocumento2 pagineNetflix AccountsjzefjbjeNessuna valutazione finora

- Astm STP 855-Eb.1044238-1Documento352 pagineAstm STP 855-Eb.1044238-1Jayanta Mondal100% (1)

- PT-E - Fundamentals of Process Plant Layout and Piping DesignDocumento14 paginePT-E - Fundamentals of Process Plant Layout and Piping DesignNofrizal HasanNessuna valutazione finora