Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Spliced Axially-Loaded Single-Angle Members in Compression

Caricato da

Jennifer TurnerCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Spliced Axially-Loaded Single-Angle Members in Compression

Caricato da

Jennifer TurnerCopyright:

Formati disponibili

Spliced Axially-Loaded Single-Angle Members

in Compression

SHERIEF S. S. SAKLA, YOHANNA M. F. WAHBA, and MURTY K. S. MADUGULA

SUMMARY different tower sections. These tower legs are usually de-

Due to construction and transportation considerations, an- signed as concentrically-loaded members since the angle

gles used as leg members in latticed towers are often is connected by both legs. In the panel where the legs of

joined together in the field using bolted splice plates. In the tower are spliced, questions arise as to the effect of

many instances, the centroid of the angle cross section splicing on the compressive ultimate load carrying capac-

does not coincide with centroid of the splice plates used ity and on the behavior of the angle legs. These leg mem-

to connect the angles. It is not known what effect such a bers are usually of slenderness ratio that can be classified

splice has on the compressive ultimate load carrying ca- as stocky. A survey revealed that no research results are

pacity of the single-angle member. Research results on available in the published literature on the effect of splic-

spliced axially-loaded single-angle struts are not avail- ing on the compressive resistance of axially-loaded single-

able in the literature. Results of compression tests on five angle struts.

spliced angle specimens of low slenderness ratio (fab-

ricated according to the communication tower industry

practice) and one reference specimen of the same size

4x4x3/8 in. angle

and length are reported herein and compared with AISC-

LRFD Specification. It is shown that the ultimate load car- r11 r h

rying capacity of spliced specimens was, on the average,

8% less than that of the reference specimen.

&1 ft 3 / 8 in. splice plate

1

l ^i JJT |j-

INTRODUCTION JJ-

Single angles are widely used in many structural appli-

cations. One important use of these structural members

fl (12) 5 / 8 " A325 bolts

is as leg members or diagonals in transmission and com-

munication towers. These towers can be self-supporting

[H

L_j_j

J-L

or guyed depending on the tower height and loading.

To speed the construction procedure and minimize trans-

portation cost and obstacles, a tower is divided into sev-

eral sections suitable for transportation that are fabricated

in the shop and then transported to the construction site

where they are assembled together to erect the complete

tower structure. It is a common practice in the commu- I f

nication tower industry to use bolted-splice plates in-

stead of bolted splice angles for the leg splice to connect

Sherief S.S. Sakla is Senior Design Engineer, Gala & Asso-

ciates, Inc., Beverly Hills, Michigan.

Yohanna M.F. Wahba is Manager, Engineering, LeBlanc &

Royle Telcom Inc., Oakville, Ontario, Canada. 2.5"

Murty K.S. Madugula is Professor of Civil Engineering, Fac-

ulty of Engineering, College of Engineering and Science,

University of Windsor, Windsor, Ontario, Canada.

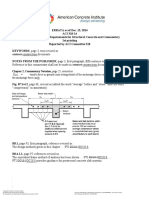

Fig. 1(a). Details of a typical test specimen

4 ENGINEERING JOURNAL / FIRST QUARTER / 1999

To illustrate the problem, consider the spliced single- Referring to Figure 2, it can be seen that the minor prin-

angle tower leg shown in Figure 1(a) and 1(b). Four cipal axis of the angle, the z axis, does not coincide with

2 V2 X 12^4 in. splice plates of % in. thickness are used for the minor principal axis of the four splice plates, the z'

splicing a 4 X 4 X % in. angle. Thus the gross area of the axis. As the angle is loaded concentrically, this load is

splicing plates is 30% higher than that of the connecting transferred eccentrically to the splice plates. The value of

angles. The % in. bolts are spaced at two inches on each this eccentricity is 0.291 in. for the connection shown in

side of the connection. The gage distance is 2.5 in. while Figures 1(a) and 1(b). The eccentricity of the load with

the edge distance is 1.5 in. This results in the minor princi- respect to the splice plates results in the stress distribu-

pal axis of the spliced angle not coincident with the minor tion shown in Figure 2. Thus for a compression load of P

principal axis of the four splice plates. A question arises kips, the maximum compression stress of 0.562P ksi oc-

here regarding how to evaluate the load carrying capacity curs in the outer splice plate near the angle heel. If the

of the spliced axially-loaded angle. splice plates have a yield stress of 36 ksi, a load of 64.1

Two different design practices are adopted by engineers kips (i.e., 36/0.562) will initiate yielding of the splice plate

when evaluating the ultimate load carrying capacity of assuming that the angle strut remains straight during load-

such a member. In one practice, the cross sectional area ing. This will be the compressive capacity of the splice

of the splice plates is sized to be 1.25 times that of the an- as per the European practice. If the angle member has a

gle gross area, hence the effect of the splice is neglected yield stress of 50 ksi, and the buckling length is 34 in.,

and the capacity is evaluated based on that of the axially- which was the length of the specimens used in this inves-

loaded single-angle strut. The simple-column equation of tigation, the ultimate load carrying capacity of the axially-

the AISC-LRFD,1 AISC-ASD,2 or any other design stan- loaded column according to AISC-LRFD1 is 124.8 kips

dard is used to find the ultimate load carrying capacity of using a resistance factor, qb, of 1.0. This would be the ca-

the axially-loaded member for which the slenderness ratio, pacity of the splice as per the North American practice.

yield stress, and cross-sectional area are known. This is the Thus, a great difference exists between the two practices

practice that is generally followed by the communication for calculating the maximum compressive strength. The

tower industry in North America. The second practice is to difference increases as the slenderness ratio of the angle

evaluate the load that initiates yielding in the splice plates member decreases and/or the eccentricity between the z-

assuming that the single-angle column remains straight axis and z'-axis increases.

during the application of the load, thus ignoring any sec-

ondary stresses developed due to the deflected shape of

the angle under the applied load. This practice is gener-

ally followed in Europe.

2.5"

1- 1

2" .&

<f>

2"

<t>

2.5" 12.71

i 2"

*

z

r\

i \

_ 3/8 i

splice plate

Fig. 2. Stress distribution in the splice plates according to the beam

Fig. 1(b). Details of a typical splice plate theory

ENGINEERING JOURNAL / FIRST QUARTER / 1999 5

EXPERIMENTAL PROGRAM global axes at the ends of the specimen. At the base of

the specimen, the load was applied using a 200-kip capac-

Test Specimens ity hydraulic jack and a hand-operated pump. A Strainsert

calibrated flat load cell with a digital readout gage was

An experimental program was carried out to study the ef-

used to obtain direct load measurements. Two dial gages

fect of splicing on the behavior and ultimate load carrying

at mid-height of the specimen, as illustrated in Figure 4,

capacity of axially-loaded single-angle members. The ex-

were used to measure lateral deflections.

perimental program consisted of six ultimate strength tests

Each specimen was loaded up to about 10 kips and the

of axially-loaded single angles. A typical test specimen is

strain gage readings were taken. The load was then re-

shown in Figure 1(a) and 1(b). In order to reduce the num-

leased to almost zero and the specimen was then adjusted

ber of variables in this study, the same size angle was used

to eliminate any eccentricity. The same procedure was re-

for all tests. The angle length was kept at 32 in. This re-

peated several times until the load was concentric. In all

sulted in a buckling length of 34 in. and a slenderness ra-

cases the test proceeded when the applied load was con-

tio of 43. A typical spliced test specimen consisted of two

centrically applied to the specimen causing the four strain

pieces of 4 X 4 X % in. single angle made of ASTM Grade

gage readings to be within 5% of each other. Figure 4

50 steel. The two angle pieces were connected together

shows specimen S-6 in place ready to be tested. The white-

using four Grade A36 splice plates. Twelve % in. A325

washed specimen, the hydraulic jack, the lower and up-

bolts pretensioned to a 150 lb-in. torque (which represents

per plates, and the test frame can be seen in that figure.

a snug-tight condition) were used in the connection. As

A visual inspection of the cracks developed in the white-

shown in Figure 1(a), there was a clearance of V4 in. be-

wash was made throughout the tests. The mode of fail-

tween the two angles comprising the specimen. Four spec-

ure was determined, recorded, and photographed. In all

imens of this configuration, designated S-l, S-2, S-3, and

S-5, were fabricated and tested. A fifth specimen, desig-

nated S-4, of the same configuration as SI, S2, S3, and S5

was tested after the clearance between the connected an-

gles was filled with two steel packing bars of V4 X V4 X 4 in. V

I -K L

A 4 X 4 X \ in. angle of 32 in. length, designated S-6, was

tested to be used as a reference specimen for comparison

purposes. top plate

Each of the test specimens was then machined at both

ends to ensure that the ends were perfectly square and par-

allel to each other. For all the specimens, four strain gages

were attached at a distance of 7 in. from bottom as shown

in Figure 5. These were attached to help ensure concen-

tric axial loading of the angle. To study the behavior of the

splice plates at the gap between the two angles, six strain

gages were attached to the splice plates of specimen S2,

as shown in Figure 5. In order to detect the yielding pat-

test specimen

tern during loading, all the specimens were coated with a

thin layer of white wash before testing and allowed to dry.

bottom plate

This brittle coating that flaked off at the points of yielding

exposing the steel surface below, provided a very econom-

ical solution for detecting high-yielding zones.

load cell

Test Procedure

All the tests were carried out using a 200 kip capacity

test frame in the Structures Laboratory at the University hydraulic jack

of Windsor. Details of the test setup are shown in Figure

3 and 4. Hinged end conditions were created at the ends

of the specimens. Ball and socket joints at the ends of the

base and top plates were used to facilitate transfer of con-

centric axial load to the angles being tested. These end

fixtures were designed to permit rotations about the three Fig. 3. Test setup

6 ENGINEERING JOURNAL / FIRST QUARTER / 1999

cases, before reading the strain gages at a given load level, These values were used in all theoretical computations of

the system was allowed to reach equilibrium, which was the failure loads of test specimens.

assumed to be the point at which the load cell and strain

gage readings had stopped changing. In all tests, the fail- Failure Mode

ure load was determined to be the maximum recorded load The maximum load carrying capacities of the angle test

with no further possible increase in load. A typical test specimens are shown in Table 1. All the specimens

took an average of two hours to complete both the setup showed the typical mode of failure observed in testing

and testing. very short columns. Lateral deflections were very small at

the beginning of loading and did not have a certain direc-

Mechanical Properties tion. Increasing the applied load caused the bolts to slip.

In order to determine the yield stress, four tension tests The first sound of slipping was heard at a load level be-

were conducted on coupons taken from the same stock as tween 30 and 37 kips for Specimens S-l, S-2, S-3, and

that of the test specimens. Two were taken from the an- S-5 and at a load level of 43 kips for Specimen S-4. For

gle and the other two from the splice plates. The speci- Specimens S-l, S-2, S-3, and S-5, the white-wash started

mens were prepared according to the ASTM E8-89,3 but flaking at the outer splice plates near the heel of the angle,

their dimensions were adapted to suit the dimensions of as predicted, at a load level of 83 to 89 kips. The cracks

the angles and the grips of the testing machine. The thick- in the white-wash started propagating toward the center

nesses of the specimens were the same as those of the an- of the splice plates and toward the splice ends and cracks

gles and plates. The tension tests were carried out in a

300 kN Tinius Olsen Universal Testing Machine. The av-

erage yield stress of the angles was found to be 52.8 ksi.

For the splice plates, the average yield stress was 43.5 ksi.

-4-

i

t i

t

t

L L

I

1

1

i

!

1

i

1

D -r

I CM

I

I J

Sec. I- Sec. I l - I

Fig. 4. Test setup for Specimen S-6 Fig. 5. Location of strain gages

ENGINEERING JOURNAL / FIRST QUARTER / 1999 7

started also showing around the bolts (i.e. cracks started reference specimen, S-6, failed at a load of 125.2 kips as

propagating in all directions). At about 90% of the failure given in Table 1. Horizontal cracks at the ends of the angle

load, horizontal cracks in the white-wash were visible at were noticed at a load of 110 kips indicating squashing of

the toes of the angle, especially at the ends. This was due

to the excessive deformation of the splice plate which

caused the gap between the angles to close at the heel

and open at the toes, causing more compression toflowto-

wards the heel of the angle at the splice location but more

uniform towards the ends. At failure, the ends of the angle

were completely squashed as was indicated by the flaking

of the white-wash at the ends of the specimens. A typi-

cal crack pattern is shown in Figure 6 for specimen S-l.

As can be seen from that figure, the angle was bent due

to closure of the gap near the heel and the opening of the

gap near the toes. Figure 7 is a close-up view of the outer

splice plates for specimen S-l. Theflakedwhite-wash can

be seen at the mid-length of the splice plate. As expected,

the yield zone was much longer on the side of the splice

plate towards the heel of the angle. The squashing of the

angle legs at the ends can also be seen.

For Specimen S-4 with packing bars, the maximum load

carrying capacity was 121.0 kips as given in Table 1. The

failure mode was basically the same as specimens S-l, S-

2, S-3, and S-5 except that there was no excessive flak-

ing of the white-wash in the splice plates. The white-wash

started flaking at the outer splice plates near the heel at a

load of about 74 kips. No furtherflakingof the white-wash

was noticed after the initial flaking. At about 90% of the

failure load, horizontal cracks in the white wash were vis-

ible at the toes of the angle along the entire-length. More

white-wash cracks were visible at the ends of the spec-

imen indicating a squashing pattern although no propa-

gation of cracks in the splice plates was observed. The Fig. 6. Typical crack pattern (Specimen S-l)

Table 1.

Maximum Compressive Load Carrying Capacity of Angle Test

Specimens

Maximum Compressive

Load Carrying Capacity Average Ratio with Respect to a

Test Specimen I.D. (kips) (kips) Non-Spliced Angle

(1) (2) (3) (4)

S-1 117.7

S-2 105.0 115.0 0.92

S-3 122.3

S-5 115.0

S-4 a 121 0.97

b

S-6 125.2 1

a

Packing bars were used between the spliced angles.

b

Reference specimenone piece of angle without any splice plates.

8 ENGINEERING JOURNAL / FIRST QUARTER / 1999

the angle ends as shown in Figure 8. Horizontal cracks the column compression joints at splice or at base plates

were visible at the toes of the angle along the entire length. should keep the gap to Vi6 in. or less. If the gap exceeds Vi6

Cracks continued propagating towards the heel all over the in. but is less than \ in., and if an engineering investiga-

entire length of the specimen. tion shows that sufficient contact area does not exist, the gap

Figures 9 to 11 show, for load levels of 10, 20, and 60 should be packed out with non-tapered steel shims. Gaps

kips respectively, a comparison between the stresses ob- V4 in. and over are not covered by AISC specifications. In

tained from the experimental strains (Ee) and the stresses the present investigation, four of the five specimens had

calculated using the beam theory assuming that the load is a uniform gap of \ in., which is the practice in the com-

applied through the centroid of the angle. At a load level munication tower industry. Thus a lower capacity of the

of 10 kips, a reasonable agreement existed between the spliced specimens (average 115 kips) is expected as com-

experimentally measured stresses and the beam theory. pared to the spliced specimen with shims provided (121

At that level the lateral deflections were very minimal. kips). At 90% of the failure load, excessive deformations

As the load increased, the angle struts started to buckle of the splice plates caused the gap between the angles to

and the eccentricity of the load with respect to the splice close at the heel and open at the toe, causing more secondary

plates increased as the angle cross-section shifted. It can be bending effects.

seen from Figures 9 to 11 that as the load increased there In transmission tower leg design, the compression splice

was less agreement between the experimental stresses and for the leg angle is sized to have a cross-sectional area 1.25

stresses according to the beam theory. After the splice plates times that of the angle leg. In the present investigation,

yielded, the gap at the heel of the angles closed and the the ratio of the gross area of the splice plates to the angle

load eccentricity with respect to the splice plates increased. gross area is 1.31 (i.e., 3.75/2.86) and the ratio of the yield

stress of the splice plates to the yield stress of the angle

DISCUSSION is 0.82 (i.e., 43.5/52.8). Thus the capacity of the splice

Section M3 of the AISC-LRFD Specification - 1993, as plates in compression yielding is 1.08 times that of the

well as the 1989 AISC-ASD specification, requires that

Fig. 7. Close-up view of outer splice plates (Specimen S-l) Fig. 8. Crack pattern at the top of Specimen S-6

ENGINEERING JOURNAL / FIRST QUARTER / 1999 9

angle (i.e., 3.75 x 43.5 versus 2.86 x 52.8). This is less

than 1.25 required as per the transmission tower design

practice. However, the specimens were fabricated in con-

formity with the communication tower industry practice.

It is desirable to eliminate the eccentricity in the splice by

changing the gage distance of the bolts or changing the

width of the outer splice plates. The use of angles, instead

of plates, to form the splices may also reduce the eccen-

tricity.

CONCLUSIONS AND RECOMMENDATIONS

For the conditions of the experimental investigation re-

ported herein, the following conclusions can be drawn:

(1) There is no significant decrease in the ultimate load

carrying capacity of axially-loaded spliced single-

angles when compared with axially-loaded one-

piece angles.

(2) The initiation of yielding was always in the mid-

length of the splice plate.

(3) Using packing bars between the two pieces of the

spliced angles did not have a significant effect on the

Fig. 9. Stress distribution at mid-length of splice plates at a load maximum compressive load carrying capacity.

level of 10 kips.

IU.U

0.0

o.o

-10 0

V)

-20.0

iff

-30.0 A

-10.0 \

-40.0

-15.0 \

beam theory A f beam theory

-50.0

O Stresses in Face 1 Stresses in Face 1

A Stresses in Face 2 H A Stresses in Face 2

_j ^v ) I

- l | 1 1 I | I | I 1 1

I ' I ' I 1 1 '

0.0 0.5 1.0 1.5 2.0 2.5 0.0 0.5 1.0 1.5 2.0 2.5

Distance (in.) Distance (in.)

Fig. 10. Stress distribution at mid-length of splice plates at a load Fig. 11. Stress distribution at mid-length of splice plates at a load

level of 20 kips. level of 60 kips.

10 ENGINEERING JOURNAL / FIRST QUARTER / 1999

REFERENCES Test Methods and Analytical Procedures, Section

1. American Institute of Steel Construction, Inc., Load Vol. 03.01, pp. 131-161, Philadelphia, 1989.

and Resistance Factor Design Manual of Steel Con-

struction, 2nd Edition, Chicago, IL, 1994. NOTATION

2. American Institute of Steel Construction, Inc., Allow-

z - z = minor principal axis of angle cross section

able Stress Design Manual of Steel Construction, 9th

z' - z' = minor principal axis of the splice plates

Edition, Chicago, IL, 1989.

(f> = resistance factor

3. American Society for Testing and Materials, Metals

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Advanced Mechanics of Materials and Applied ElasticityDocumento108 pagineAdvanced Mechanics of Materials and Applied Elasticityasas86% (7)

- Mechanical Springs WahlDocumento463 pagineMechanical Springs WahlVicente Scott67% (3)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Corus - Design of Shs Welded JointsDocumento48 pagineCorus - Design of Shs Welded JointsDylan RamasamyNessuna valutazione finora

- Sci P399Documento196 pagineSci P399vincent02hk_57881301100% (2)

- Angle Bar Bracings in LatticeDocumento116 pagineAngle Bar Bracings in LatticeJennifer TurnerNessuna valutazione finora

- Compression Members - Local Buckling and Section Classification PDFDocumento15 pagineCompression Members - Local Buckling and Section Classification PDFAnonymous lswzqloNessuna valutazione finora

- StairsDocumento21 pagineStairstomnubiNessuna valutazione finora

- ACI 318-14 ErrataDocumento4 pagineACI 318-14 ErrataJennifer TurnerNessuna valutazione finora

- Mechanical Properties For Steel FastenersDocumento7 pagineMechanical Properties For Steel FastenersepriyonoNessuna valutazione finora

- ACI-Strut and Tie ModelDocumento128 pagineACI-Strut and Tie ModelJennifer TurnerNessuna valutazione finora

- StairsDocumento21 pagineStairstomnubiNessuna valutazione finora

- Concrete Anchor Design GuideDocumento21 pagineConcrete Anchor Design GuideAri PranantaNessuna valutazione finora

- Irc 58 2011Documento122 pagineIrc 58 2011Anonymous YHcvra8Xw60% (1)

- StairsDocumento21 pagineStairstomnubiNessuna valutazione finora

- BOF OST Strange-SunDocumento12 pagineBOF OST Strange-SunJennifer TurnerNessuna valutazione finora

- Excel Eng French CommandsDocumento15 pagineExcel Eng French CommandsJennifer TurnerNessuna valutazione finora

- 7.4 Tower Design: Bracing SystemsDocumento49 pagine7.4 Tower Design: Bracing SystemsBoisterous_Girl100% (1)

- 7.4 Tower Design: Bracing SystemsDocumento49 pagine7.4 Tower Design: Bracing SystemsBoisterous_Girl100% (1)

- 7.4 Tower Design: Bracing SystemsDocumento49 pagine7.4 Tower Design: Bracing SystemsBoisterous_Girl100% (1)

- 7.4 Tower Design: Bracing SystemsDocumento49 pagine7.4 Tower Design: Bracing SystemsBoisterous_Girl100% (1)

- Quick Reference R2005 PDFDocumento0 pagineQuick Reference R2005 PDFelcivilengNessuna valutazione finora

- 7.4 Tower Design: Bracing SystemsDocumento49 pagine7.4 Tower Design: Bracing SystemsBoisterous_Girl100% (1)

- Quick Reference R2005 PDFDocumento0 pagineQuick Reference R2005 PDFelcivilengNessuna valutazione finora

- Quick Reference R2005 PDFDocumento0 pagineQuick Reference R2005 PDFelcivilengNessuna valutazione finora

- Beam Design Formulas With Shear and MomentDocumento20 pagineBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- Quick Reference R2005 PDFDocumento0 pagineQuick Reference R2005 PDFelcivilengNessuna valutazione finora

- Bamboo Reinforced Concrete PDFDocumento24 pagineBamboo Reinforced Concrete PDFshahbaghi100% (1)

- Quick Reference R2005 PDFDocumento0 pagineQuick Reference R2005 PDFelcivilengNessuna valutazione finora

- Beam Design Formulas With Shear and MomentDocumento20 pagineBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- Steel Interchange (May 2014)Documento2 pagineSteel Interchange (May 2014)Jennifer TurnerNessuna valutazione finora

- CAD Forum - How To Add Classic Workspace (Toolbars) To AutoCAD 2015Documento2 pagineCAD Forum - How To Add Classic Workspace (Toolbars) To AutoCAD 2015Jennifer TurnerNessuna valutazione finora

- Energy-Related Web Sites: Alternative ApproachesDocumento7 pagineEnergy-Related Web Sites: Alternative ApproachesJennifer TurnerNessuna valutazione finora

- Beam Design Formulas With Shear and MomentDocumento20 pagineBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- EigenvaluesDocumento29 pagineEigenvaluesarmjafariNessuna valutazione finora

- Architectural StructuresDocumento462 pagineArchitectural Structuresmatteo_1234100% (1)

- Column Buckling TestDocumento8 pagineColumn Buckling TestWiy GuomNessuna valutazione finora

- Bs5950 RevisionsDocumento18 pagineBs5950 RevisionsRo-bert MagoNessuna valutazione finora

- Lpile 2019 Technical ManualDocumento271 pagineLpile 2019 Technical Manualee SsNessuna valutazione finora

- AerialCat Manual - Aerial - PhysicsDocumento46 pagineAerialCat Manual - Aerial - PhysicsmarkNessuna valutazione finora

- Beechwood Primary School Structural CalculationsDocumento28 pagineBeechwood Primary School Structural CalculationsRonnie SmithNessuna valutazione finora

- New FDP BrochureDocumento2 pagineNew FDP BrochuressrNessuna valutazione finora

- Buckling AnalysisDocumento26 pagineBuckling AnalysisbachNessuna valutazione finora

- Buckling of Columns ME 272 Experiment #6: ObjectiveDocumento4 pagineBuckling of Columns ME 272 Experiment #6: ObjectiveBahah TytyNessuna valutazione finora

- FR - 567 Development of Guidelines For Transportation of Long Prestressed Concrete GirdersDocumento294 pagineFR - 567 Development of Guidelines For Transportation of Long Prestressed Concrete GirderswalaywanNessuna valutazione finora

- 12 Lowry Close, Sandhurst - Steelwork DesignDocumento8 pagine12 Lowry Close, Sandhurst - Steelwork DesignInoshan Madushika JayawickramaNessuna valutazione finora

- Steel GirderDocumento26 pagineSteel GirderChan Nov100% (1)

- Design of Unstiffened Extended Single Plate Shear ConnectionsDocumento14 pagineDesign of Unstiffened Extended Single Plate Shear ConnectionsGonzalo ContrerasNessuna valutazione finora

- Design of Steel Structures Compression MembersDocumento42 pagineDesign of Steel Structures Compression MembersDeviprasad PradhanNessuna valutazione finora

- Southwell Method To Study Flexural Instability of Column: Experiment-5Documento7 pagineSouthwell Method To Study Flexural Instability of Column: Experiment-5Sharan Teja ElagandulaNessuna valutazione finora

- Requirements Concerning Gas Tankers: International Association of Classification SocietiesDocumento31 pagineRequirements Concerning Gas Tankers: International Association of Classification Societiesharikrishnanpd3327Nessuna valutazione finora

- Water Tank DesignDocumento23 pagineWater Tank DesignAnish Neupane100% (1)

- The Composite Steel Reinforced Concrete Column Under Axial and Seismic Loads: A ReviewDocumento19 pagineThe Composite Steel Reinforced Concrete Column Under Axial and Seismic Loads: A ReviewPatel TosifNessuna valutazione finora

- SECED 2015: Using Ductility in Nuclear FacilitiesDocumento10 pagineSECED 2015: Using Ductility in Nuclear FacilitieslsaishankarNessuna valutazione finora

- "Stiffner" - Steel Beam Web Stiffener Analysis: Program DescriptionDocumento6 pagine"Stiffner" - Steel Beam Web Stiffener Analysis: Program DescriptionGustavo PaganiniNessuna valutazione finora

- FEAC FinalDocumento313 pagineFEAC FinalmgilbelNessuna valutazione finora

- Ec9 Ex56 Compression OrthotropicDocumento6 pagineEc9 Ex56 Compression OrthotropicimotalpNessuna valutazione finora

- Moment-Curvature Relationship of Flexure-Dominated Walls With PartiallyDocumento13 pagineMoment-Curvature Relationship of Flexure-Dominated Walls With Partiallyabraham_cea9076Nessuna valutazione finora

- Detailed Design of Multi Block Producing Machine With Mixer and ConveyorDocumento35 pagineDetailed Design of Multi Block Producing Machine With Mixer and ConveyorHAIMANOTNessuna valutazione finora

- Analysis of Buckling Strength of Inner WindingsDocumento5 pagineAnalysis of Buckling Strength of Inner Windingsalex696Nessuna valutazione finora