Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Air Leak Test

Caricato da

Waqas WaqasCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Air Leak Test

Caricato da

Waqas WaqasCopyright:

Formati disponibili

Air Leak Test

General

This document presents minimum requirements of air leak test that will be applied of reinforcement pad

of storage tank.

Particular attention of this test is leakage detection that shall be applied to circumference finish fillet weld

reinforcement plate to shell on each opening using tell-tale hole before the tank is filled with test water.

Testing Apparatus

Compressor 1 unit

Pressure gauge 1 unit

Flexible hose

Soup solution

Testing Method

Applying pneumatic pressure and soup film as media of finish fillet welds between reinforcement plate

and shell for Leakage detection.

Preparation

i) Pneumatic pressure test shall be performed after visual examination.

ii) The joint should be thoroughly cleaned from debris and foreign materials using suitable cleaning

process.

iii) Keep dry of surface area that will be tested.

iv) The temperature limits of metal surface shall be between 4o C (40 o F) and 52 o C (125oF), unless the

film solution is proven to work at temperatures outside these limits, either by testing or manufacturers

recommendations.

v) Prepare soup solution suitable for detection of leak.

vi) A minimum light intensity of 1000 lux (100Fc) at the point of examination is required during the

application of the examination and evaluation for leaks.

vii)The examiner shall has vision (with correction, if necessary) to be able to read a Jagger Type 2

standard chart at distance of not less than 300 mm (12 in).

viii) The examiner shall competent in the technique of the pneumatic pressure testing, including

performing the examination and interpreting and evaluating the results.

Test Execution

i) Applying pneumatic pressure to the each opening of 100 kpa (15 lbf/in2) and hold pressure.

ii) Verifying and Examine the weld of outside tank for evidence of leakage.

In case the leakage happens of welding seam, it will be indicated with formation of bubbles and pressure

drop indicated at pressure gauge. If leakage found, Identify using marker at leakage area for repair work

and retested.

iii) Result of test shall be documented and maintain.

iv) When rainfall during a test makes the checking for leaks, required agreement between COMPANY

and CONTRACTOR that the test shall be postponed until weather permits possible to inspect.

v) The tested surface shall be cleaned and dry, after pneumatic pressure test complete.

Acceptance Criteria

There is no bursting bubble at welding seam tested.

Repair of Defective Welds

i) Defect in welds shall be repaired by grinding or chipping or melting out the defects and re-welding in

accordance with previous WPS.

ii) The repair weld shall be retested as paragraph 5.

PURPOSE

The purpose of this document is to reinforcing the activities that will be carried out for

the performance of the pneumatic tests that are required on reinforcement pads of

nozzles, saddles, attachments etc.

DEFINITIONS

The following definitions are applicable to this document:

LEAK: Is the evidence that a fluid is passing from on side to another in a closed vessel,

independent the amount of fluid.

PROCEDURE

The inspection area shall be clean and free of dirt, oxidation, scale, slag, splatters, oil or

other foreigner materials that can hide weld defects.

The reinforcement pad shall have one threaded hole of NPT in that which shall

be applied the air at least to 0.5 bar for a sufficient time to permit inspection of the

welds.

The examination shall be made using soaps suds looking for any leakage inside and

outside of the nozzle and on the pipe neck to reinforcement pad weld, and the

reinforcement pad to vessel weld.

ACCEPTANCE CRITERIAL

No leaks are permitted. In the case that is detected any leak, this one has to be

repaired using approved welding procedure, and retested using the procedure described

above.

FORMS

The Pneumatic Test results shall be recorder in the Pneumatic Test Report; acceptance

of the test is obtained by signature and dated in the document

Potrebbero piacerti anche

- 6) Pneumatic Pressure TestDocumento3 pagine6) Pneumatic Pressure Testbacabacabaca100% (1)

- Pneumatic Test ProcedureDocumento2 paginePneumatic Test Proceduredyke_engg67% (3)

- Vaccum Test MethodDocumento4 pagineVaccum Test MethodMahmud AlamNessuna valutazione finora

- Vacuum Box Test Procedure GudielinesDocumento3 pagineVacuum Box Test Procedure Gudielinessbmmla100% (3)

- Hydrostatic Test ProcedureDocumento3 pagineHydrostatic Test Proceduredep_vin100% (4)

- Pneumatic TestDocumento3 paginePneumatic Testpuneethkumarr100% (1)

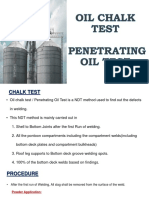

- Oil Chalk Test/Penetrating Oil TestDocumento6 pagineOil Chalk Test/Penetrating Oil TestWeld ManiacNessuna valutazione finora

- Hydrostatic Shell TestDocumento5 pagineHydrostatic Shell TestsojeckNessuna valutazione finora

- Pneumatic Test ProcedureDocumento12 paginePneumatic Test ProcedurePower Power100% (4)

- Pneumatic Test (Air Test) ProcedureDocumento4 paginePneumatic Test (Air Test) ProcedureHansel Francis100% (5)

- Air Testing TanksDocumento2 pagineAir Testing TanksTatiana CruzNessuna valutazione finora

- To Commissioning Manual: Appendix No. 1Documento7 pagineTo Commissioning Manual: Appendix No. 1Bassem BalghouthiNessuna valutazione finora

- Weld Repair Procedure Rev0Documento2 pagineWeld Repair Procedure Rev0aszliza100% (1)

- Dye Penetrant Testing ProcedureDocumento5 pagineDye Penetrant Testing ProcedureTabish Shaikh50% (2)

- Vaccum Box Test Procedure For All TanksDocumento6 pagineVaccum Box Test Procedure For All Tanksויליאם סן מרמיגיוסNessuna valutazione finora

- Duties of Tank InspectorDocumento1 paginaDuties of Tank InspectorJawed AlamNessuna valutazione finora

- Job Procedure For PWHT of Storage Tanks: 10 of Ramadan City, Industrial Area A1, EgyptDocumento5 pagineJob Procedure For PWHT of Storage Tanks: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNessuna valutazione finora

- Zzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsDocumento1 paginaZzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsSARSAN NDTNessuna valutazione finora

- SA04C2-T-MET-AAG-00037 Hydrotest Method StatementDocumento25 pagineSA04C2-T-MET-AAG-00037 Hydrotest Method StatementABAID ULLAH100% (2)

- Index: Method Statement For Post Weld Heat TreatmentDocumento8 pagineIndex: Method Statement For Post Weld Heat TreatmentsomiqatarNessuna valutazione finora

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocumento2 pagineASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNessuna valutazione finora

- Procedure For Vacuum Box TestingDocumento3 pagineProcedure For Vacuum Box TestingZakirUllahNessuna valutazione finora

- Pressure Testing of API TanksDocumento7 paginePressure Testing of API TanksRakesh Ranjan50% (2)

- Inspection Test Plan For Pipeline JobsDocumento6 pagineInspection Test Plan For Pipeline Jobsمحمد أزها نو الدينNessuna valutazione finora

- Hydrostatic Test Procedure - PipingDocumento4 pagineHydrostatic Test Procedure - Pipingmahi1437Nessuna valutazione finora

- Method Statement For Titanium PipeworkDocumento3 pagineMethod Statement For Titanium Pipeworkprem nautiyalNessuna valutazione finora

- Pneumatic Test ProcedureDocumento3 paginePneumatic Test Procedurevijay padale50% (2)

- PWHT PROCEDURE (11) Rev 0Documento14 paginePWHT PROCEDURE (11) Rev 0AbdulNeyasNessuna valutazione finora

- Kerosene Leak TestDocumento4 pagineKerosene Leak Testskc50% (2)

- Butt JointsDocumento21 pagineButt JointsRaj1-23Nessuna valutazione finora

- Pneumatic Testing Procedure For PipelinesDocumento3 paginePneumatic Testing Procedure For PipelinesKu Masayu Ku HusinNessuna valutazione finora

- Mock UP Procedure Rev ADocumento6 pagineMock UP Procedure Rev AFauzan Rusmayadi Reharder100% (1)

- Job Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptDocumento13 pagineJob Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNessuna valutazione finora

- SCTPL Q SP 002 A1 Vaccum Box Testing ProcedureDocumento6 pagineSCTPL Q SP 002 A1 Vaccum Box Testing ProcedureKandula Raju100% (1)

- BPV IX-16-3 QW-283 - ButteringDocumento1 paginaBPV IX-16-3 QW-283 - ButteringyutweldingNessuna valutazione finora

- Welding Procedure Specification: Technip KT India LimitedDocumento5 pagineWelding Procedure Specification: Technip KT India LimitedDeepak100% (1)

- 3-Piping Repair Weld Procedure - PR003Documento5 pagine3-Piping Repair Weld Procedure - PR003mohd as shahiddin jafriNessuna valutazione finora

- Asme Sec 9 - ADocumento144 pagineAsme Sec 9 - Aروشان فاطمة روشانNessuna valutazione finora

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocumento1 paginaStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFJaco CalitzNessuna valutazione finora

- API Repair ProcedureDocumento1 paginaAPI Repair ProcedurejacquesmayolNessuna valutazione finora

- Pneumatic TestDocumento10 paginePneumatic Testchitobarba19726762100% (3)

- 3.painting InspectionDocumento2 pagine3.painting InspectionSRINIVASAN S M100% (1)

- Hydrotest & Pneumatic TestDocumento3 pagineHydrotest & Pneumatic TestjokishNessuna valutazione finora

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Documento17 pagineWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNessuna valutazione finora

- Iot-Q-Bbb-Pr-005 Vacuum Box Test Procedure Rev - ADocumento7 pagineIot-Q-Bbb-Pr-005 Vacuum Box Test Procedure Rev - AMikiRoniWijaya100% (4)

- Hydrostatic and Settlement Tests ProcedureDocumento12 pagineHydrostatic and Settlement Tests Procedureツ ツ100% (1)

- Asme Ix Welder Qualification Interpretation PDFDocumento95 pagineAsme Ix Welder Qualification Interpretation PDFnizam1372Nessuna valutazione finora

- Api 653 Report-Hydrolic Test PDFDocumento12 pagineApi 653 Report-Hydrolic Test PDFnaoufel1706Nessuna valutazione finora

- Gap Control For Socket Weld Back Welded Threaded FittingsDocumento12 pagineGap Control For Socket Weld Back Welded Threaded Fittingslaz_k100% (1)

- Final Inspection Release NoteDocumento2 pagineFinal Inspection Release NoteMark ThrelfallNessuna valutazione finora

- Air Leak Test Report: Instrumentation and Gauge Calibration RecordDocumento2 pagineAir Leak Test Report: Instrumentation and Gauge Calibration Recordvinoth100% (1)

- Hydro Test ProcedureDocumento9 pagineHydro Test ProcedureAdeel QaiserNessuna valutazione finora

- 1645400A05 - QAP For Compressor ZR450 - R01 - 20170109Documento4 pagine1645400A05 - QAP For Compressor ZR450 - R01 - 20170109shahkunal11Nessuna valutazione finora

- Vaccum Box Test ProcedureDocumento3 pagineVaccum Box Test ProcedureAJOJOY009Nessuna valutazione finora

- Method of Statement VBDocumento9 pagineMethod of Statement VBAhmed IrakyNessuna valutazione finora

- Rreinforcement Pad Leak Test ProcedureDocumento5 pagineRreinforcement Pad Leak Test ProcedureAmin Thabet100% (2)

- Portfolio Vacuum ProcedureDocumento2 paginePortfolio Vacuum ProcedureAli SalmanNessuna valutazione finora

- Reinforcement Pad Leak Test Procedure - Method StatementDocumento6 pagineReinforcement Pad Leak Test Procedure - Method StatementJaveed A. KhanNessuna valutazione finora

- Vacume Box Test ProcedureDocumento5 pagineVacume Box Test ProcedureFarhan Sheikh100% (3)

- VBT Procedure Rkl-Pro-06-ThocDocumento7 pagineVBT Procedure Rkl-Pro-06-ThocEmmad JriNessuna valutazione finora

- Tensile TestDocumento1 paginaTensile TestWaqas WaqasNessuna valutazione finora

- Tap & DrillDocumento1 paginaTap & DrillWaqas WaqasNessuna valutazione finora

- As Per ASTM A l79Documento1 paginaAs Per ASTM A l79Waqas WaqasNessuna valutazione finora

- Auditing Welds Under ASME IX PDFDocumento21 pagineAuditing Welds Under ASME IX PDFkbldamNessuna valutazione finora

- Face & Root BendDocumento1 paginaFace & Root BendWaqas WaqasNessuna valutazione finora

- W1 Material and Welding For Gas Tankers W1Documento13 pagineW1 Material and Welding For Gas Tankers W1AlbertNessuna valutazione finora

- Weld Overlay Obtained by FCAW ProcessDocumento2 pagineWeld Overlay Obtained by FCAW ProcessWaqas WaqasNessuna valutazione finora

- QW 453Documento1 paginaQW 453Waqas WaqasNessuna valutazione finora

- ASTM E6-09b Standard Terminology Relating To Methods of Mechanical TestingDocumento27 pagineASTM E6-09b Standard Terminology Relating To Methods of Mechanical TestingPacifier Nothingface0% (1)

- Bolt TighteningDocumento1 paginaBolt TighteningWaqas WaqasNessuna valutazione finora

- QW 381Documento1 paginaQW 381Waqas WaqasNessuna valutazione finora

- 2010 Edition of The ASME Boiler and Pressure Vessel Code (BPVC)Documento6 pagine2010 Edition of The ASME Boiler and Pressure Vessel Code (BPVC)kangsungjinNessuna valutazione finora

- Astm A350 LF2 PDFDocumento1 paginaAstm A350 LF2 PDFTanah Tak BertuanNessuna valutazione finora

- Request For InspDocumento1 paginaRequest For InspWaqas WaqasNessuna valutazione finora

- Auditing Welds Under ASME IX PDFDocumento21 pagineAuditing Welds Under ASME IX PDFkbldamNessuna valutazione finora

- ISO IQA For DDFC by AJMAL29-04-14Documento52 pagineISO IQA For DDFC by AJMAL29-04-14Waqas WaqasNessuna valutazione finora

- ISO IQA For DDFC by AJMAL29-04-14Documento52 pagineISO IQA For DDFC by AJMAL29-04-14Waqas WaqasNessuna valutazione finora

- Welding Procedure SummaryDocumento1 paginaWelding Procedure SummaryWaqas WaqasNessuna valutazione finora

- Reduced Sec. Tensile TestDocumento1 paginaReduced Sec. Tensile TestWaqas WaqasNessuna valutazione finora

- Procedure For Tank Shell To AnnularDocumento1 paginaProcedure For Tank Shell To AnnularWaqas WaqasNessuna valutazione finora

- Dimensional Inspection Report: 175mm 150mm 55 29Documento3 pagineDimensional Inspection Report: 175mm 150mm 55 29Waqas WaqasNessuna valutazione finora

- Changing AIADocumento1 paginaChanging AIAWaqas WaqasNessuna valutazione finora

- Procedure For Tank Shell To AnnularDocumento1 paginaProcedure For Tank Shell To AnnularWaqas WaqasNessuna valutazione finora

- ISO 14001 Environmental Management Systems: Training, Audit & Certification ServicesDocumento2 pagineISO 14001 Environmental Management Systems: Training, Audit & Certification ServicesWaqas WaqasNessuna valutazione finora

- 9.3 Qualification of WeldersDocumento1 pagina9.3 Qualification of WeldersWaqas WaqasNessuna valutazione finora

- Welding API TankDocumento1 paginaWelding API TankWaqas WaqasNessuna valutazione finora

- Codes & Standards For Natural GasDocumento13 pagineCodes & Standards For Natural Gasharikrishnanpd3327Nessuna valutazione finora

- WPSDocumento25 pagineWPSWaqas WaqasNessuna valutazione finora

- Asmesecii Partamtrverificationfinalcopy 180402033626Documento47 pagineAsmesecii Partamtrverificationfinalcopy 180402033626SULTAN100% (1)

- Helicopter Logging Operations - ThesisDocumento7 pagineHelicopter Logging Operations - ThesisAleš ŠtimecNessuna valutazione finora

- Optimization Process of Biodiesel Production With Ultrasound Assisted by Using Central Composite Design MethodsDocumento47 pagineOptimization Process of Biodiesel Production With Ultrasound Assisted by Using Central Composite Design MethodsMiftahFakhriansyahNessuna valutazione finora

- UNIT 3 Polymer and Fuel ChemistryDocumento10 pagineUNIT 3 Polymer and Fuel Chemistryld6225166Nessuna valutazione finora

- Tropical Fruit CHAPTER-3Documento32 pagineTropical Fruit CHAPTER-3Jeylan FekiNessuna valutazione finora

- Toolbox Talks - Near Miss ReportingDocumento1 paginaToolbox Talks - Near Miss ReportinganaNessuna valutazione finora

- List Acreditated JournalDocumento2.124 pagineList Acreditated JournalSetiyo PrajokoNessuna valutazione finora

- JOHARI Window WorksheetDocumento2 pagineJOHARI Window WorksheetAnonymous j9lsM2RBaINessuna valutazione finora

- MPSI OverviewDocumento15 pagineMPSI OverviewZaqee AlvaNessuna valutazione finora

- Physical Activity and Weight ControlDocumento6 paginePhysical Activity and Weight Controlapi-288926491Nessuna valutazione finora

- Week 4 (Theories)Documento15 pagineWeek 4 (Theories)Erica Velasco100% (1)

- Mental Health & TravelDocumento18 pagineMental Health & TravelReyza HasnyNessuna valutazione finora

- Installation and Operation Manual: Proact™ Ii Electric Powered Actuator and DriverDocumento32 pagineInstallation and Operation Manual: Proact™ Ii Electric Powered Actuator and DriverDjebali MouradNessuna valutazione finora

- Epilepsy 2 AAN 2018Documento12 pagineEpilepsy 2 AAN 2018Eashaa KumarNessuna valutazione finora

- MoRTH 1000 Materials For StructureDocumento18 pagineMoRTH 1000 Materials For StructureApurv PatelNessuna valutazione finora

- Keandalan Bangunan Rumah SusunDocumento9 pagineKeandalan Bangunan Rumah SusunDewi ARimbiNessuna valutazione finora

- Big Elephants Are Useful Mnemonics & IdiomsDocumento144 pagineBig Elephants Are Useful Mnemonics & IdiomsNachoAndrésLlorente100% (1)

- Untitled Form - Google Forms00Documento3 pagineUntitled Form - Google Forms00Ericka Rivera SantosNessuna valutazione finora

- Non-Binary or Genderqueer GendersDocumento9 pagineNon-Binary or Genderqueer GendersJuan SerranoNessuna valutazione finora

- HandbookDocumento6 pagineHandbookAryan SinghNessuna valutazione finora

- Drug Abuse - A Threat To Society, Essay SampleDocumento3 pagineDrug Abuse - A Threat To Society, Essay SampleAnonymous o9FXBtQ6H50% (2)

- Lpalmer ResumeDocumento4 pagineLpalmer Resumeapi-216019096Nessuna valutazione finora

- Tarot Cards: Cheat SheetDocumento1 paginaTarot Cards: Cheat SheetDipti100% (7)

- Dysfunctional Uterine Bleeding (DUB)Documento1 paginaDysfunctional Uterine Bleeding (DUB)Bheru LalNessuna valutazione finora

- Safety at Hand PDFDocumento48 pagineSafety at Hand PDFAdesijiBlessingNessuna valutazione finora

- Dig Inn Early Summer MenuDocumento2 pagineDig Inn Early Summer MenuJacqueline CainNessuna valutazione finora

- MCQ Cell InjuryDocumento19 pagineMCQ Cell InjuryMoaz EbrahimNessuna valutazione finora

- Amino AcidsDocumento17 pagineAmino AcidsSiddharth Rohilla100% (2)

- Emergency War Surgery Nato HandbookDocumento384 pagineEmergency War Surgery Nato Handbookboubiyou100% (1)

- De Thi Chon HSGDocumento10 pagineDe Thi Chon HSGKiều TrangNessuna valutazione finora

- The Cyanide Canary: A True Story of InjusticeDa EverandThe Cyanide Canary: A True Story of InjusticeValutazione: 4 su 5 stelle4/5 (52)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDa EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterNessuna valutazione finora

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionDa EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionValutazione: 3 su 5 stelle3/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretDa EverandWaste: One Woman’s Fight Against America’s Dirty SecretValutazione: 5 su 5 stelle5/5 (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridDa EverandShorting the Grid: The Hidden Fragility of Our Electric GridValutazione: 4.5 su 5 stelle4.5/5 (2)

- Carbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersDa EverandCarbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersValutazione: 4.5 su 5 stelle4.5/5 (2)

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!Da EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!Nessuna valutazione finora

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDa EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesValutazione: 4.5 su 5 stelle4.5/5 (21)

- A Pathway to Decarbonise the Shipping Sector by 2050Da EverandA Pathway to Decarbonise the Shipping Sector by 2050Nessuna valutazione finora

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceDa EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceNessuna valutazione finora

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionNessuna valutazione finora

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionValutazione: 5 su 5 stelle5/5 (1)

- Electrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977Da EverandElectrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977Nessuna valutazione finora

- Nuclear Energy in the 21st Century: World Nuclear University PressDa EverandNuclear Energy in the 21st Century: World Nuclear University PressValutazione: 4.5 su 5 stelle4.5/5 (3)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsDa EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsValutazione: 4.5 su 5 stelle4.5/5 (2)

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerDa EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerNessuna valutazione finora

- Global Landscape of Renewable Energy FinanceDa EverandGlobal Landscape of Renewable Energy FinanceNessuna valutazione finora

- Practical Reservoir Engineering and CharacterizationDa EverandPractical Reservoir Engineering and CharacterizationValutazione: 4.5 su 5 stelle4.5/5 (3)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsDa EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNessuna valutazione finora

- Formulas and Calculations for Drilling OperationsDa EverandFormulas and Calculations for Drilling OperationsNessuna valutazione finora

- Renewable Energy: A Very Short IntroductionDa EverandRenewable Energy: A Very Short IntroductionValutazione: 4.5 su 5 stelle4.5/5 (12)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsDa EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNessuna valutazione finora

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsDa EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsNessuna valutazione finora

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successDa EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successValutazione: 4.5 su 5 stelle4.5/5 (3)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetDa EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetValutazione: 2 su 5 stelle2/5 (1)

- The Way Home: Tales from a life without technologyDa EverandThe Way Home: Tales from a life without technologyValutazione: 4 su 5 stelle4/5 (45)

- Practical Methods for Analysis and Design of HV Installation Grounding SystemsDa EverandPractical Methods for Analysis and Design of HV Installation Grounding SystemsValutazione: 4.5 su 5 stelle4.5/5 (2)