Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Aniline PFD

Caricato da

keyur1109Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Aniline PFD

Caricato da

keyur1109Copyright:

Formati disponibili

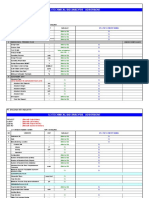

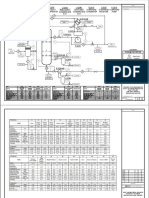

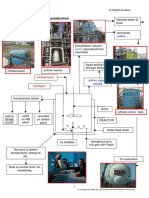

AN I LI N E P LA N T P R O C E S S FLOW D IAG RAM

Catalyst

Spent catalyst

filter

H2 VENT TO FLARE Recovered Aniline Aniline product

for distillation Hydrogenation Water

Trim Water Aniline catalyst From

Coarse Water slurry cake Product

NB Decantar

To PURGE Crude

NB SLURRY Schiff's base Rectification

THICKINING

RECOVERY Aniline

HYDROGENATION COLUMN Crude Aniline reactor column

H2 Aniline Dehydration CRUDE CRUDE

Waste water Tar Aniline Aniline

To WWT

Fresh Catalyst

25 Kg/hr Slurry Tar +Aniline for Aniline & tar

Sealing incineration 12 Bar g MP steam 3 Bar g LP steam C.W I/L to Purge recovery

water

filters Crude To Reactor & To extractor

FRESH Hot Aniline Crude Aniline Crude Aniline Series of coolers

CATALYST CATALYST FEED TANK

BATCH for cooling Aniline

vapour from Waste Heat Waste Heat Aniline Decantation

Reactor top Boiler (WHB) Boiler (WHB) Crude

BFW BFW C.W O/L Aniline

from DM from DM To

CATALYST INGREDIENTS D.M water Plant plant Dehyd column

Pd 4.50%

Pt 0.50%

Fe 5.00% waste water

carbon 90% Make-up DM water from DM plant to WWT Counter current

Extractor

NB from T/F NB to Reactor

NOTE :

Material of construction of section is Carbon Steel (CS)

Material of construction of section is Carbon Steel (CS) & Stainless Steel

Material of construction of section is SS-304

Potrebbero piacerti anche

- MPI Architectural Painting Manual: Guide Specification Revision - September 2012 Section 09900 Painting Page 1 of 28Documento28 pagineMPI Architectural Painting Manual: Guide Specification Revision - September 2012 Section 09900 Painting Page 1 of 28Alsayed DiabNessuna valutazione finora

- Pts 0800 - A (Process Description)Documento6 paginePts 0800 - A (Process Description)ingegnere1234Nessuna valutazione finora

- Boiler ParameterDocumento2 pagineBoiler ParameterFieNessuna valutazione finora

- PropertiesandapplicationsoffoamedconcreteareviewDocumento17 paginePropertiesandapplicationsoffoamedconcreteareviewEJ KooNessuna valutazione finora

- Calculation of Heat and Mass BalanceDocumento16 pagineCalculation of Heat and Mass BalanceHEMANTNessuna valutazione finora

- Properties and Characteristics of Liquid FuelsDocumento18 pagineProperties and Characteristics of Liquid FuelsTin Aung Kyi100% (2)

- Repair and Maintenance of Historic Marble and Limestone StructuresDocumento9 pagineRepair and Maintenance of Historic Marble and Limestone StructuresIdaHodzicNessuna valutazione finora

- Ta 0 °C Pa 0.98 Bar Xa 9260 % Ha 2435 KJ/KG: EvaporatorDocumento8 pagineTa 0 °C Pa 0.98 Bar Xa 9260 % Ha 2435 KJ/KG: EvaporatorShella Theresya PandianganNessuna valutazione finora

- Calculation Sheet for Stairs Reinforcement DesignDocumento18 pagineCalculation Sheet for Stairs Reinforcement Designsarafan leewan0% (1)

- LPG Amine Cooler-SummaryDocumento15 pagineLPG Amine Cooler-SummaryJEEVITHANessuna valutazione finora

- Rubber Additives - Compounding Ingredients: R. N. Datta and F. A. A. InghamDocumento42 pagineRubber Additives - Compounding Ingredients: R. N. Datta and F. A. A. InghamRubber TeamNessuna valutazione finora

- Revised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedDocumento10 pagineRevised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedAnonymous bHh1L1Nessuna valutazione finora

- 9572 TBA Progressive Cavity Pump - Rev.0Documento4 pagine9572 TBA Progressive Cavity Pump - Rev.0budy wening setyo wibowoNessuna valutazione finora

- V-710 CPRP-7Documento22 pagineV-710 CPRP-7balajikrishnanNessuna valutazione finora

- TBA - AdsorbentDocumento4 pagineTBA - AdsorbentTifano KhristiyantoNessuna valutazione finora

- Plano de SaturadorDocumento6 paginePlano de SaturadorRodrigo Andres CeledonNessuna valutazione finora

- Liquid Pipe Sizing: Group Technology SolutionsDocumento1 paginaLiquid Pipe Sizing: Group Technology SolutionsAhmad SiddiqNessuna valutazione finora

- Section 7Documento64 pagineSection 7WlopezaNessuna valutazione finora

- GET - Safety Presentation 2009Documento27 pagineGET - Safety Presentation 2009keyur1109Nessuna valutazione finora

- Project No. P12513 Feed For New Flow Suction Tank On Bu Hasa CdsDocumento6 pagineProject No. P12513 Feed For New Flow Suction Tank On Bu Hasa CdssarathNessuna valutazione finora

- Aniline Process DescriptionDocumento13 pagineAniline Process Descriptionkeyur1109100% (3)

- Manual IrDocumento292 pagineManual IrSISOYDANNYNessuna valutazione finora

- Dish End Weight CalculationDocumento5 pagineDish End Weight CalculationAniket royNessuna valutazione finora

- ETHANOL (6.0D X 8.825 H), Rev. 0Documento26 pagineETHANOL (6.0D X 8.825 H), Rev. 0Sangramkeshari BejaNessuna valutazione finora

- SEL-TBD-O-CA-001 R0 Process Simulation Report SignedDocumento12 pagineSEL-TBD-O-CA-001 R0 Process Simulation Report Signedahmad santosoNessuna valutazione finora

- Jacket Denting Calculation Rev.0Documento87 pagineJacket Denting Calculation Rev.0Arif RusyanaNessuna valutazione finora

- Stack Gas Specification: Project Name Client Location GeneralDocumento6 pagineStack Gas Specification: Project Name Client Location Generalbudi utomoNessuna valutazione finora

- DH PEP PPS PR 001 Process DescriptionDocumento6 pagineDH PEP PPS PR 001 Process Descriptionfadli arsyadaNessuna valutazione finora

- Surge Vessel Testing: (Update As of 30th April 2015)Documento2 pagineSurge Vessel Testing: (Update As of 30th April 2015)Syed AliNessuna valutazione finora

- U Cal For ReactorDocumento5 pagineU Cal For ReactorwestewrNessuna valutazione finora

- Data Sheet For T-8101.RevCDocumento5 pagineData Sheet For T-8101.RevCSuresh SjNessuna valutazione finora

- Heat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtriDocumento1 paginaHeat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtrivikzefgNessuna valutazione finora

- Design and optimization of a tubular reactor for methanol synthesisDocumento47 pagineDesign and optimization of a tubular reactor for methanol synthesisPrable SekhriNessuna valutazione finora

- Random Packing: From Competitive Products To Advanced SolutionsDocumento16 pagineRandom Packing: From Competitive Products To Advanced SolutionsiazcuzcNessuna valutazione finora

- MP Condensate Flash VesselDocumento4 pagineMP Condensate Flash VesselGanesh BhardwajNessuna valutazione finora

- National Oil Corporation: Rev Date Description Checked ApprovedDocumento18 pagineNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNessuna valutazione finora

- Data Sheet Rectangular - BG22383Documento12 pagineData Sheet Rectangular - BG22383Fitroh MalikNessuna valutazione finora

- Data Sheet For Flare Package (PK-720)Documento3 pagineData Sheet For Flare Package (PK-720)samynatha PrasathNessuna valutazione finora

- Engineering Units ConverterDocumento19 pagineEngineering Units Convertertitou_d8638Nessuna valutazione finora

- Gas Chiller Datasheet PDFDocumento2 pagineGas Chiller Datasheet PDFidilfitriNessuna valutazione finora

- Flare Stack Calculation Sheet by Erwin ADocumento8 pagineFlare Stack Calculation Sheet by Erwin AaltruismNessuna valutazione finora

- Boil Up RateDocumento1 paginaBoil Up RateNitin KurupNessuna valutazione finora

- SVDN CPP I 0023 D01 0002 Rev.04 General Arrangement Drawing in Signaler ReplaceDocumento8 pagineSVDN CPP I 0023 D01 0002 Rev.04 General Arrangement Drawing in Signaler ReplacejfdlksaNessuna valutazione finora

- S.no Description Data For ApprovalDocumento2 pagineS.no Description Data For ApprovalVenkatNessuna valutazione finora

- Calculation of a Gas-Liquid Separator Flash Drum DesignDocumento2 pagineCalculation of a Gas-Liquid Separator Flash Drum DesignCan YıldırımNessuna valutazione finora

- CO2 Condenser 02-03-2023-15 PMDocumento37 pagineCO2 Condenser 02-03-2023-15 PMahmad santosoNessuna valutazione finora

- Specification For Air Compressors and Air Dryer PackagesDocumento21 pagineSpecification For Air Compressors and Air Dryer PackagesSudjono BroNessuna valutazione finora

- Superheated Steam SeparatorDocumento4 pagineSuperheated Steam SeparatorGanesh BhardwajNessuna valutazione finora

- Ras Markaz Crude Oil Park Project (Phase1) Material Take-Offs For Piping Bulks-InitialDocumento24 pagineRas Markaz Crude Oil Park Project (Phase1) Material Take-Offs For Piping Bulks-Initialanil pkNessuna valutazione finora

- Hoja de Datos Sistema Aire Comprimido ReferencialDocumento18 pagineHoja de Datos Sistema Aire Comprimido ReferencialchepeluchounNessuna valutazione finora

- RASPRODocumento36 pagineRASPROVera Yulianti100% (2)

- 202366-VP10-DWG-002 - Rev.1 Detail Drawing For Inlet Compressor Filter Separator F-1011Documento6 pagine202366-VP10-DWG-002 - Rev.1 Detail Drawing For Inlet Compressor Filter Separator F-1011Pham LanphuongNessuna valutazione finora

- Specification Sheet For Separator: Operating Conditions SketchDocumento12 pagineSpecification Sheet For Separator: Operating Conditions SketchAngelikaOdimer100% (1)

- IPA HeaterDocumento14 pagineIPA HeaterNitin KurupNessuna valutazione finora

- Two-Phase Ethyl Chloride Process NotesDocumento2 pagineTwo-Phase Ethyl Chloride Process NotesAgravante JakeNessuna valutazione finora

- BFW Cooler Datasheet Rev-2Documento3 pagineBFW Cooler Datasheet Rev-2Anonymous iCFJ73OMpDNessuna valutazione finora

- Equipment DatasheetDocumento9 pagineEquipment DatasheetBimal DeyNessuna valutazione finora

- For Information: GE OfficialDocumento6 pagineFor Information: GE OfficialMaulik Dave50% (2)

- Syn CompressorDocumento23 pagineSyn CompressorManish GautamNessuna valutazione finora

- API Tank Data SheetDocumento1 paginaAPI Tank Data SheetAtomic JNessuna valutazione finora

- 16 B 06 HDocumento20 pagine16 B 06 HVaibhav Bhoir0% (1)

- Pipi G Material Specificatio: Ref. Proce. O. Issue Umber Revision O. Revision Date ODS/SOP/008 To 015 2 1 1/8/2006Documento78 paginePipi G Material Specificatio: Ref. Proce. O. Issue Umber Revision O. Revision Date ODS/SOP/008 To 015 2 1 1/8/2006Aravind VickyNessuna valutazione finora

- Tank Agitator Data Sheet Engineering Procurement Project ManagementDocumento10 pagineTank Agitator Data Sheet Engineering Procurement Project ManagementAliZenatiNessuna valutazione finora

- Valve Sizing Calculation8Documento2 pagineValve Sizing Calculation8PIDNessuna valutazione finora

- SCH-00-J-7000 Inst. Cable Schedule Rev - 3Documento28 pagineSCH-00-J-7000 Inst. Cable Schedule Rev - 3Kishore KrishnaNessuna valutazione finora

- Total Types of Wastes:: Bostik IndiaDocumento23 pagineTotal Types of Wastes:: Bostik IndiaAnonymous pVoSWn8yh0Nessuna valutazione finora

- Pressure KG/CM G Temperature °C MOC: Sr. No. Type Material of Construction Item DescriptionDocumento3 paginePressure KG/CM G Temperature °C MOC: Sr. No. Type Material of Construction Item DescriptionDarshan PanchalNessuna valutazione finora

- Dykewall CalculationDocumento4 pagineDykewall CalculationVipul GandhiNessuna valutazione finora

- Microsoft Word - 2007 - 07 - 25 Huntsman Ver 03 of 03 Flowcharts With Pics PDFDocumento2 pagineMicrosoft Word - 2007 - 07 - 25 Huntsman Ver 03 of 03 Flowcharts With Pics PDFShyamal TalukdarNessuna valutazione finora

- POLY-OLEFINS by LOW PRESSURE Ziegler Process: Aluminum Alkyl Drier Light Ends DiluentDocumento3 paginePOLY-OLEFINS by LOW PRESSURE Ziegler Process: Aluminum Alkyl Drier Light Ends Diluentessakkiraj.mNessuna valutazione finora

- C P P Total SeriesDocumento1 paginaC P P Total Serieskeyur1109Nessuna valutazione finora

- Detailed Advertisement of OM Manpower RecruitmentDocumento15 pagineDetailed Advertisement of OM Manpower Recruitmentkeyur1109Nessuna valutazione finora

- C P P Total SeriesDocumento18 pagineC P P Total Serieskeyur1109Nessuna valutazione finora

- CPP History BoardDocumento3 pagineCPP History Boardkeyur1109Nessuna valutazione finora

- 1c225 General Merit List BiotechnologyDocumento10 pagine1c225 General Merit List Biotechnologykeyur1109Nessuna valutazione finora

- NB ReactionDocumento1 paginaNB Reactionkeyur1109Nessuna valutazione finora

- Influence of Tilting Pad Bearing Clearance On Rotor Response of Steam Turbine PDFDocumento20 pagineInfluence of Tilting Pad Bearing Clearance On Rotor Response of Steam Turbine PDFAhtsham AhmadNessuna valutazione finora

- 2005 Seal and Its FunctionDocumento1 pagina2005 Seal and Its FunctionHaseeb BokhariNessuna valutazione finora

- 4417 Self Aligning Bearing SystemDocumento22 pagine4417 Self Aligning Bearing SystemSayed KassarNessuna valutazione finora

- Bearing Tolerances PDFDocumento13 pagineBearing Tolerances PDFkeyur1109Nessuna valutazione finora

- Course M-3041Documento44 pagineCourse M-3041Satya NarayananNessuna valutazione finora

- Bearing Electro PittingDocumento19 pagineBearing Electro PittinglyanagustNessuna valutazione finora

- Ball BearingDocumento70 pagineBall Bearingpatrik710Nessuna valutazione finora

- 2015-3 CE ArticleDocumento1 pagina2015-3 CE Articlekeyur1109Nessuna valutazione finora

- Ball Bearing Prefixes and SuffixesDocumento6 pagineBall Bearing Prefixes and Suffixeskeyur1109Nessuna valutazione finora

- Angular Contact Ball Bearing Universal Matching - Back To BackDocumento2 pagineAngular Contact Ball Bearing Universal Matching - Back To Backkeyur1109Nessuna valutazione finora

- EagleBurgmann - Statotherm R Profile Rings R901 - B.. - ENDocumento1 paginaEagleBurgmann - Statotherm R Profile Rings R901 - B.. - ENkeyur1109Nessuna valutazione finora

- State Bank of IndiaDocumento1 paginaState Bank of Indiakeyur1109Nessuna valutazione finora

- Finned TubeDocumento6 pagineFinned Tubekeyur1109Nessuna valutazione finora

- EagleBurgmann Buratherm N 9544 N enDocumento1 paginaEagleBurgmann Buratherm N 9544 N enkeyur1109Nessuna valutazione finora

- EagleBurgmann Burachem Brown 9655 R enDocumento1 paginaEagleBurgmann Burachem Brown 9655 R enkeyur1109Nessuna valutazione finora

- EagleBurgmann TS4000 enDocumento3 pagineEagleBurgmann TS4000 enkeyur1109Nessuna valutazione finora

- Thermosiphon seal supply system overviewDocumento4 pagineThermosiphon seal supply system overviewkeyur1109Nessuna valutazione finora

- B-7901cd Seal Flushing SystemDocumento2 pagineB-7901cd Seal Flushing Systemkeyur1109Nessuna valutazione finora

- EagleBurgmann - Statotherm V Cover Seal V881 - ENDocumento1 paginaEagleBurgmann - Statotherm V Cover Seal V881 - ENkeyur1109Nessuna valutazione finora

- EagleBurgmann Statotherm P Foil 9591 P enDocumento1 paginaEagleBurgmann Statotherm P Foil 9591 P enkeyur1109Nessuna valutazione finora

- EagleBurgmann - Statotherm V Cover Seal V901 - ENDocumento1 paginaEagleBurgmann - Statotherm V Cover Seal V901 - ENkeyur1109Nessuna valutazione finora

- Folien SFPS 0Documento6 pagineFolien SFPS 0BUDAPESNessuna valutazione finora

- BPMN 3123 MANAGEMENT ETHICS IndividualDocumento13 pagineBPMN 3123 MANAGEMENT ETHICS IndividualZulhilmi ZainiNessuna valutazione finora

- Eczema and Nummular Dermatitis GuideDocumento91 pagineEczema and Nummular Dermatitis GuideJhost Clinton PurbaNessuna valutazione finora

- Ocean Pollution ThesisDocumento7 pagineOcean Pollution Thesisjenniferslatteryranchocucamonga100% (2)

- The Present Situation of The Old Shoes Recycling ADocumento7 pagineThe Present Situation of The Old Shoes Recycling AEvan GohNessuna valutazione finora

- Magnesium Chloride PowderDocumento2 pagineMagnesium Chloride PowderNatalia NeliNessuna valutazione finora

- Comparing Fermentation Rates of Wheat, Gram, Rice and PotatoDocumento10 pagineComparing Fermentation Rates of Wheat, Gram, Rice and PotatovipulNessuna valutazione finora

- Chap 10 Fluid Machenics Theory PDFDocumento41 pagineChap 10 Fluid Machenics Theory PDFTECHNICAL orbisNessuna valutazione finora

- Micropreparation of RuH2 (P (C6H5) 3) 4: A Transition Metal Hydride CompoundDocumento17 pagineMicropreparation of RuH2 (P (C6H5) 3) 4: A Transition Metal Hydride CompoundramlihitamNessuna valutazione finora

- Biofar 3Documento11 pagineBiofar 3dediNessuna valutazione finora

- Whole soybean probiotic carrierDocumento6 pagineWhole soybean probiotic carrieryamunaa91Nessuna valutazione finora

- Astm D178Documento9 pagineAstm D178Rodrigo Escárate BernalNessuna valutazione finora

- Science of SlimeDocumento3 pagineScience of SlimeMax Is hereNessuna valutazione finora

- Effect of Temperature on Chemical and Physical WeatheringDocumento4 pagineEffect of Temperature on Chemical and Physical WeatheringAshlynNessuna valutazione finora

- Csec Chemistry - A5Documento17 pagineCsec Chemistry - A5Mencarty DocentNessuna valutazione finora

- Green ? Chemistry ?Documento8 pagineGreen ? Chemistry ?bhongalsuvarnaNessuna valutazione finora

- Fibrolit® - Fett-Ld: Safety Data SheetDocumento5 pagineFibrolit® - Fett-Ld: Safety Data Sheetks2000n1Nessuna valutazione finora

- EffiKlean SI PDS R1Documento1 paginaEffiKlean SI PDS R1soumitrabanNessuna valutazione finora

- Code All Item RohanDocumento127 pagineCode All Item RohanKapooNessuna valutazione finora

- Moscow Refining, Gas & Petrochemical WeekDocumento11 pagineMoscow Refining, Gas & Petrochemical Weekdheeraj sehgalNessuna valutazione finora

- Beam On Elastic FoundationDocumento15 pagineBeam On Elastic FoundationKshitiz ShresthaNessuna valutazione finora

- E-Waste Management: A Case Study of Bangalore, IndiaDocumento5 pagineE-Waste Management: A Case Study of Bangalore, IndiaJatindra Kumar PradhanNessuna valutazione finora