Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Microorganisms in Diesel and in Biodiesel Fuel

Caricato da

adrimelisCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Microorganisms in Diesel and in Biodiesel Fuel

Caricato da

adrimelisCopyright:

Formati disponibili

744 Acta Chim. Slov.

2007, 54, 744748

Technical paper

Microorganisms in Diesel and in Biodiesel Fuels

Bo{tjan Klofutara and Janvit Golobb

a Agency of the Republic of Slovenia for compulsory oil stocks, Gospodinjska ulica 8,

1000 Ljubljana, Slovenia

b Faculty of Chemistry and Chemical Technology, University of Ljubljana, A{ker~eva cesta 5,

1000 Ljubljana, Slovenia

* Corresponding author: E-mail: b.klofutar@zord.org

Received: 07-09-2007

Dedicated to the memory of professor Vojko Ozim

Abstract

The presence of microorganisms in tanks used for petroleum products is caused by contamination, i.e. fouling of petro-

leum products when replenishing stocks by adding new fuel. The presence and growth of microorganisms results in the

creation of sediments, sludge and slime, and consequently leads to deterioration of the quality of fuel and damage to the

tank farm fuel-handling facilities such as the storage tanks, pipelines, pumps, filters and valves, and indirectly also cau-

ses difficulties when using contaminated fuel.

Of the basic categories of fuels comprising automotive gasoline, middle distillates (diesel and domestic heating oil) and

aviation fuel JET-A1, the group containing middle distillates is the most sensitive to the growth of microorganisms. Spe-

cifically with the introduction of biodiesel blended fuel, the exposure of this group to microorganisms has increased.

In this study analytical results are presented for cases where there is a possibility for growth of microorganisms in unb-

lended diesel fuels and in the combination with biodiesel, both in the medium free of water and in the medium contai-

ning water, as well as in the presence and absence of biocides in the samples.

The results obtained indicate that the most significant criterion for the prevention of microorganisms in fuels is the ab-

sence of water. In the case when microorganisms have started to grow, adding a biocide can inhibit their growth.

Keywords: Microorganisms in oil; hydrocarbon fuels; biodiesel; biocides; microbial corrosion.

centages of biofuels that can be blended in mineral oil fu-

1. Introduction els, as well as the quality parameters for biodiesel need to

Environmental protection is becoming the overri- be specified. The maximum allowed content of biodiesel

ding challenge faced by the oil industry, which remains in diesel fuel is restricted to 5% in line with the technical

one of the worlds biggest industries. Driven by rising cru- specifications set forth in the relevant standard.1

de oil prices and insatiable thirst for fuels on one hand and The introduction of biofuels is associated with diffi-

legislation focused on protection of the environment along culties in transport and storage, as well as in their use. Ex-

the lines of the Kyoto Protocol addressing climate change perience with storage of biodiesel has revealed problems,

on the other, the demand for alternative sources of energy mostly in connection with the content of water and the

has been integrated into the energy policy of many coun- presence and growth of microorganisms: the experience

tries. The newly prescribed environmental protection po- of the German stock-holding state agency (EBV) con-

licy has spurred the European Union to give a boost to firms the above statement.2

biofuels primarily to bioethanol and biodiesel. The Eu- The presence of microorganisms and sediments in

ropean Directive 2003/30/EC promotes the use of bio- drainage water is most characteristic of middle distillates

fuels or other renewable fuels for transport purpose. such as diesel fuel, biodiesel and domestic heating oil.3

The biofuels blended in mineral oil fuels are prima- In diesel fuel the maximum allowed water content1 is

rily bioethanol blended in gasoline and biodiesel blended 200 mg/kg, and in biodiesel the content must be below4

in diesel fuel. For blending biodiesel in diesel fuel the per- 500 mg/kg.

Klofutar and Golob: Microorganisms in Diesel and in Biodiesel Fuels

Acta Chim. Slov. 2007, 54, 744748 745

As long as oil terminals operate normally, fuel is equipment and accessory defects is elaborated below6:

kept stored in oil tanks for relatively short periods of time The majority of microorganisms that are found in fuel

of up to 30 days. However, during that period, microorga- cause an increase in the content of water, the creation of

nisms can appear in the stocked fuel. Microorganism fuel sediments and solid particles in the fuel.

contamination occurs through the water, air and walls of Certain types of microorganisms (moulds and bacteria,

the tank or the pipeline. The majority of microorganisms which generate polymers) have been identified as a cau-

remain at the bottom of the tank, and together with sedi- se of a number of failures: clogged pipelines, vents, fil-

ments and drained water, forms the tank sludge. ters and irregular functioning of the automatic measure-

ment equipment.

Moulds and aerobic bacteria cause decomposition of

hydrocarbons,

Moulds and anaerobic bacteria cause corrosion on the

inner walls of tanks.

Endotoxic bacteria (opportunistic pathogens, SRB) cau-

se health problems.

Irrespective of the way in which microorganisms en-

ter fuel stocks, the outcome is similar. As a result of the

aforementioned conditions necessary for the presence and

growth of microorganisms, the result is a failure of stora-

ge or transport facilities and/or impaired fuel quality.

Under ideal conditions the number of microorga-

nisms can double every 20 minutes. As microorganisms

Figure 1. Extensive microbial contamination, i.e. a microbial po- grow and develop, they create by products and dead mi-

pulation, in a tank

croorganisms that fall to the bottom of the tank as sedi-

ments. The products created as a result of the growth of

The most common microorganisms that grow in fu- microorganisms cause pitting of steel and copper.

els are Cladosporium and Pseudomonas aeruginosa5. Since the issue of microorganisms is of crucial im-

The issue of microbial attack is a cause for concern portance for the stability of oil tank performance, a syste-

also for long-term fuel stocks maintained as mandatory matic analysis of the behaviour of microorganisms in

reserves of petroleum products. Fuel stocks lie undistur- middle distillates is even more important for preventive

bed at tank farms for several years (up to 8 years). The and curative purposes.

longer storage time calls for continuous monitoring of the The purpose of the present study was to determine

condition of stocks. the impact caused by temperature, water content, and bio-

Water is drained from all stocked petroleum pro- cide content on the growth of microorganisms in diesel

ducts and represents a more serious technical problem and biodiesel fuel, in particular examining three aspects:

than that the content of insoluble impurities. The content iii. The impact of diesel fuel, biodiesel and blends of both

of water in fuel is the cause of enhanced chemical and mi- fuels on the growth of bacteria, fungi and yeasts as the

crobiological reactions and of microbial growth. The fac- essential species of microorganisms.

tors that influence water separation are difficult to define iii. The impact of added water in fuel on the growth of mi-

precisely since they are a consequence of surface tension, croorganisms in various blends of diesel and biodiesel

viscosity, density and temperature changes. In the presen- fuel.

ce of water, microorganisms also need oxygen, a suffi- iii. n analysis of the conditions for protection against mi-

cient temperature of the fuel, phosphorus and sulphur croorganisms and the level of success achieved when

contents and the right pH to grow. trying to prevent the effects of an already developed

Microorganisms start to grow in the water phase, but microbial system in the fuel by using biocides for vari-

they feed on fuel at the phase boundary (Figure 1). Conse- ous blends of diesel and biodiesel fuel, and water.

quently microbial contamination damages fuel at the bot-

tom of the tank. For microorganisms to be present and for

their growth, the content of water in the fuel must be at 2. Experimental Work

least 1%(V/V).6

The content of microorganisms does not affect only Fuel: For the investigation of diesel fuel, 5% (V/V)

the quality of fuel but also the storage facilities. The failu- biodiesel and diesel fuel blend and 100% (V/V) biodiesel

res, i.e. breakdowns, that can be expected as a result of the were supplied by Petrol d.d. Slovenia, and a biocide (PBK

presence of microorganisms in fuel are described below. 2.5 BD) by Pinus d.d. Slovenia.

The relation between the type of microorganism and the Microorganisms: The microorganisms Pseudomo-

potential deterioration affecting stored fuel or causing nas aeruginosa, Escherichia coli, Staphylococcus, Bacil-

Klofutar and Golob: Microorganisms in Diesel and in Biodiesel Fuels

746 Acta Chim. Slov. 2007, 54, 744748

a) b) c)

7 8 9

Figure 2. a) Pseudomonas aeruginosa , b) Cladosporium c) Candida tropicalis

lus cereus), moulds (Cladosporium, Aspergillus tereus, The nutrient solution for microorganisms prepared

Aureobasidium pullulans, Fusarium solani, Geotrichum in the microbiological laboratory had the following initial

candidum, Penecillium funiculosum, Aspergillus ustus) content characteristics:11

and yeasts (Candida tropicalis, Trichosporon asahii) were

supplied by the Faculty of Chemical Engineering and Table 2. The initial content of microorganisms in the solution/cul-

ture medium at constant temperature:

Technology, Zagreb, Croatia. All added microorganisms

originated from the prepared suspension supplied. An Microorganisms Content levels after 4 X inoculation

amount of 0.1 ml suspension on individual colony of mi- Bacteria (T = 37 C) 4.6 109

croorganisms was used. Typical samples of each microor- Fungi (T = 28 C) 1.3 107

ganism are presented in Figure 2: Yeasts (T = 37 C) 6.2 107

Equipment/apparatus: Standard equipment and

apparatus were used. An autoclave from Selecta, an incu-

bator and sterilizer from MMM Medcenter Einrichtungen The number of microorganisms was determined by

Gmbh, Agar medium from Merck 1.05450, Millipore applying a method based on counting the microorganisms

0,45m HA filter paper, distilled water from PETROL d.d. in the medium10.

Laboratory and sterile laboratory glassware, were emplo-

yed.

Test method: The experiment was conducted in 3. Results and Discussion

conformity with the standard IP 385/99,10 a procedure that

includes determination of the viable aerobic microbial 1 cm3 of the culture media suspensions of microor-

content of fuel components boiling below 390 C and the ganisms (bacteria, fungi and yeasts) were added four ti-

filtration and culture method. For monitoring the quality mes at 7 day intervals to sterile samples of fuel. The re-

of diesel fuel and 5% (V/V) biodiesel in diesel fuel blend sults for the same mixture are listed in Table 3 and Table 4

the standard SIST EN 5901 was applied. For monitoring for blended fuels at temperatures of 37 and 28 C, respec-

of the quality of 100%(V/V) biodiesel the standard EN tively.

142144 method was used. The results in the above tables show that the mi-

Sample preparation: Samples of pure diesel fuel croorganisms in the tested samples were not growing opti-

(1000 ml) and of biodiesel blend 5% (V/V) (1000 ml), as mally, except in the case of sporogen bacteria, where a

well as the samples of pure biodiesel 100% (V/V) (1000 high resistance to biocides was observed. The reverse si-

ml) were taken. To certain fuel samples we also added tuation was revealed regarding the growth of fungi, where

biocide at a concentration of 1 mg/kg. The description of the impact of the biocide on the number of fungi was noti-

investigated samples are given in Table 1. ceable.

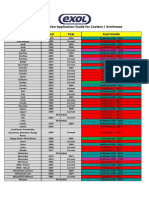

Table 3. The number of bacteria and yeasts in 1 ml of sample over

Table 1. Legend for sample codes a period of 4 weeks at a constant temperature of 37 C:

Sample code Fuel Sample The number of bacteria in 1 cm3

DG Diesel fuel 1st week 2nd week 3rd week 4th week

DG+B Diesel fuel + biocide (1mg/kg) DG 6.6 103 2.3 103 7.4 103 1.0 104

3 3 3

B5 Blend of diesel fuel and 5%(V/V) biodiesel DG+B 4.2 10 4.5 10 1.8 10 4.9 103

B5+B Blend of diesel fuel and 5%(V/V) B5 3.0 103 4.2 103 6.0 103 7.0 103

3 3 3

biodiesel+ biocide (1mg/kg) B5+B 3.0 10 4.2 10 4.0 10 3.3 104

2 2 3

B100 100%(V/V) Biodiesel B100 4.0 10 5.0 10 1.4 10 1.9 103

B100+B 100%(V/V) Biodiesel + biocide (1mg/kg) B100+B 4.0 102 1.9 103 7.0 103 1.0 103

Klofutar and Golob: Microorganisms in Diesel and in Biodiesel Fuels

Acta Chim. Slov. 2007, 54, 744748 747

Table 4. The number of fungi in 1 cm3 of the sample over the Table 5: Content of microorganisms, i.e. the number of colonies, in

4-week-periods at a constant temperature of 28 C samples containing 10% water at a constant temperature of 25 C

Sample The number of bacteria in 1 cm3 Sample Number Number of colonies /

st

1 week 2nd week 3rd week 4th week of colonies 1000 cm3**

DG 2.5 103

2.5 10 3

7.0 10 3

3.8 104 DG >300 *

DG+B 1.0 102 DG+B 100 1000

B5 1.0 103 7.0 102 B5 >300 *

B5+B 9.0 103 1.0 101 B5+B 15 150

B100 B100 >300 *

B100+B 9.0 101 B100+B 0 0

* after completing the test, the filter was completely covered

with the microorganism culture calculation was not possible,

** Calculation ''A'' under the standard procedure IP 385/99

In samples B100 and B100+B only the presence of

the bacterium Bacillus cereus was found in the 4-week

test. added biocide was also effective in sample B5 with and

In sample DG, bacteria were present after the first without water added and in the diesel fuel. In cases where

inoculation was made, comprising Bacillus cereus and no biocide was added, the growth of microorganisms was

Staphylococcus. Following the third addition, also the very fast and they completely covered (overgrew) the fil-

bacteria Pseudomonas aerginosa, the yeasts Candida tro- ter paper.

picalis and Trichosporon and the mould Geotrichum can- The next experimental series was performed to es-

didum started to grow. tablish the impact of the addition of a second portion of

In sample DG+B the bacteria Bacillus cereus was biocide to the samples. After 7 days none of the samples

present throughout the test period. At the end of the test (4th showed even traces of the presence of microorganisms.

week) the bacteria Staphylococcus aureus was growing. The addition of the extra quantity of biocide thus proved

In sample B5 the bacteria Bacillus cereus prevailed to be a successful (effective) solution to the problem of

throughout the test period. At the end the test (3rd week) microorganism growth. Nevertheless trends in the direc-

the yeasts Candida tropicalis and Trichosporon sp. and tion of avoiding or reducing the use of additives as harm-

the mould Geotrichum candidum appeared. In sample ful to the environment should also be taken into account.

B5+B throughout the testing period only the bacteria Ba- The impact on the materials of the storage facilities

cillus cereus was present. Only after performing the first was as follows: Several types of mechanisms that lead to

inoculation with microorganisms was the presence of the corrosion caused by various strains of microorganisms

moulds Geotrichum candidum found, but it could not be present16 are known today. Extensive studies have been

detected in the sample afterwards. conducted regarding corrosion caused predominately by

In samples B5 and B5+B the bacteria Bacillus ce- bacteria, which reduce the sulphate ion to H2S gas, a me-

reus prevailed throughout the test period. Following the tabolic product of the aforementioned bacteria, which is

last inoculation, the yeasts Candida tropicalis started to highly corrosive even in extremely small quantities. Iron

grow in both samples. corrosion occurs as graphitization, while on steel and cop-

During the test, visual inspection12 of fuel was also per it is evidenced as pitting corrosion. Even aluminium is

performed. At the end of the test it was established that the not immune to corrosion effects. In parallel corrosion also

colour of the tested samples became darker, from yellow occurs (at neutral pH medium and in anaerobic condi-

to brown, where the change of colour13 was between 1.0 tions) based on accelerated depolarisation of cathodic and

and 4.0, and sediment formation appeared at the botton of anodic surfaces, being the metallic part and the fuel with

the vessel. water, respectively. The products of corrosion are iron

Sample B100 remained clear and bright after testing salts (sulphides), hydroxides and carbonates.

was completed, whereas other samples were hazy. The Figure 3 illustrates pitting corrosion of a copper

In addition, the content of sediment14 and corrosion strip12, occurring after tests with contaminated diesel fuel

to copper15 also appeared. and also fuel B5. Copper plates not affected by corrosion

In continuation the impact of water and the added

biocide on microorganism growth was studied. 10% of

water was added to fuel samples and the growth of mi-

croorganisms (incubation time 7 days) was followed and

their content determined. The results obtained are shown

in Table 5.

The results given in Table 5 show that the impact of

microorganisms was the least pronounced in a 100%

FAME (Fatty acid methyl ester) with added biocide. The Figure 3. Pitting corrosion on a copper strip

Klofutar and Golob: Microorganisms in Diesel and in Biodiesel Fuels

748 Acta Chim. Slov. 2007, 54, 744748

are shiny, smooth and with no pits. Corrosion of testing 2. C. F. Barth, Market Experience with Bio Fuel Blends, in

did not appear when a second portion of biocide was added. ACOMES Limassol, ACOMES, Limassol, 2005, 7/126.

3. Hill, E. C. Fuels and Microbial Problems in the Offshore Oil

Industry, E. C. Hill, J. Shennan and R. Watkinson, Wiley,

4. Conclusion New York, 1987, pp. 219230.

4. SIST EN 14214 Automotive fuels fatty acid methyl esters

It has been confirmed that in the fuels under consi- (FAME) for diesel engines Requirements and test methods

deration microorganisms are present both in diesel fuel, 2003, European Committee for Standardisation/Tehnical

as well as in biodiesel. The necessary conditions for the Committee CEN/TC 19, Bruxelles.

growth of microorganisms in fuels are the content of wa- 5. Biodiesel handling and use guidelines 2004, U.S. Depart-

ter and an adequate temperature. The microorganisms pre- ment of Energy/Energy Efficiency and Renewable Energy,

sent play an important role in the fuel-ageing process. Washington, 2525.

They also have a strong impact on the storage facilities, 6. C. C.Gaylarde, F. M.Bento, J. Kelly, Revista de Microbiolo-

e.g. tanks, pipelines, pumps, filters. gia 1999, 30, 110.

In order to prevent the occurrence and growth of mi- 7. www.cellsalive.com

croorganisms, various methods can be used: 8. www.mycology.adelaide.edu.au

a. The most successful method is cleanliness and frequent 9. www.mycology.adelaide.edu.au

drainage of water. 10. IP 385/99 Determination of the viable aerobic microbial

b. Lower temperature of oil stocks (underground tanks content of fuel components boiling below 390 C Filtration

fuel temperature <10 C), and culture method 1999, IP INSTITUTE OF PETROLE-

c. In the case of a higher degree of fuel contamination, UM TEST METHODS, London.

biocides have to be used. 11. F. Bri{ki, Microbiological testing of protect and non-protect

When the content of biocide was elevated (>2 samples of fuel, Faculty of Chemical Engineering and Tech-

mg/kg) in samples, microorganisms were no longer pre- nology, Zagreb, 2005, pp 112.

sent after a 48 hour test. 12. M. Svolj{ak, Laboratoy report, Petrol d. d Laboratory, Ljub-

In the storage of petroleum products, the stocking ljana, 2005, pp 16.

procedure plays an important role: regular water drainage, 13. SIST ISO 2049 Petroleum products Determination of co-

regular monitoring of the quality of stocked fuel, and in lour (ASTM scale) 1996, International organisation for

extreme cases also the use of biocides are required. standardisation/Tehnical Committee ISO/TC 28/ Switzer-

It has also been observed that in addition to sedi- land.

ment formation the presence of microcroorganisms also 14. SIST EN 12662 Liquid petroleum products Determination

has a huge impact on fuel quality. of contamination in middle distillates 1998, European Com-

mittee for Standardisation/Tehnical Committee CEN/TC 19,

Bruxelles.

5. References 15. SIST EN ISO 2160 Petroleum products Corrosiveness to

copper Copper strip test 1998, European Committee for

1. SIST EN 590 Automotive fuels diesel requirements and Standardisation/Tehnical Committee CEN/TC 19, Bruxelles.

test methods 2004, European Committee for Standardisa- 16. E. C. Hill , G. C. Hill, Trans. Inst. Marine Eng., 1993, 104,

tion/Tehnical Committee CEN/TC 19, Bruxelles. 119130.

Povzetek

Potrjeno je, da se v gorivih lahko nahajajo mikroorganizmi tako v dizelskem gorivu kot tudi v biodizlu. Pogoj za rast

mikroorganizmov v gorivih je voda in ustrezna temperatura. Nastali mikroorganizmi vplivajo na staranje in kakovost

goriva. Velik vpliv mikroorganizmov pa je tudi na skladi{~ne naprave: rezervoarje, cevovode, ~rpalke in filtre.

Rezultati raziskave so podani za primere mo`nosti nastanka mikroorganizmov v dizelskih gorivih samih in v kombina-

ciji z biodizlom, tako ob prisotnosti oziroma odsotnosti vode, ter ob prisotnosti biocidov kot tudi brez njih.

Klofutar and Golob: Microorganisms in Diesel and in Biodiesel Fuels

Potrebbero piacerti anche

- Common Position Paper 2012 Signed B7 PDFDocumento5 pagineCommon Position Paper 2012 Signed B7 PDFcarbasemyNessuna valutazione finora

- Common-Cause Failures of Centrifugal PumpsDocumento30 pagineCommon-Cause Failures of Centrifugal PumpsingrbarrosNessuna valutazione finora

- A Matlab Model of A 1.6 Liter Engine With Experimental Verificati PDFDocumento79 pagineA Matlab Model of A 1.6 Liter Engine With Experimental Verificati PDFManicharanNessuna valutazione finora

- Sample Pages Research Report Aircraft Fuelling HAC 19.07.17Documento9 pagineSample Pages Research Report Aircraft Fuelling HAC 19.07.17pocetak1Nessuna valutazione finora

- Design of Dieselmax UnitDocumento168 pagineDesign of Dieselmax Unitengr_aqeel0% (1)

- Frederick Passman Microbial Contamination Control Fuel SystemsDocumento17 pagineFrederick Passman Microbial Contamination Control Fuel SystemsAnaniasRodriguesChavesFilhoNessuna valutazione finora

- Wormald Portable Fire Catalogue PDFDocumento16 pagineWormald Portable Fire Catalogue PDFZain ShariffNessuna valutazione finora

- LPG Diesel Dual Fuel Engine - A Critical Review: Alexandria Engineering JournalDocumento22 pagineLPG Diesel Dual Fuel Engine - A Critical Review: Alexandria Engineering JournalSai HS BodduNessuna valutazione finora

- Stationary Natural Gas Engine LubricationDocumento9 pagineStationary Natural Gas Engine Lubricationiyan22suryana_827197Nessuna valutazione finora

- Study of Air Inlet Preheating and EGR Impacts For Improving The Operation of Compression Ignition Engine Running UnderDocumento14 pagineStudy of Air Inlet Preheating and EGR Impacts For Improving The Operation of Compression Ignition Engine Running UnderEsa Nur ShohihNessuna valutazione finora

- Tribology Brochure PrintDocumento20 pagineTribology Brochure PrintVito Digeo100% (1)

- Proposed Diesel Fuel Consumption Test PRDocumento95 pagineProposed Diesel Fuel Consumption Test PRSanjay Sanjay100% (1)

- Safety Lockwire TechniquesDocumento8 pagineSafety Lockwire TechniquesJames HollettNessuna valutazione finora

- Antifreeze Application Guide EXOLDocumento3 pagineAntifreeze Application Guide EXOLRobNessuna valutazione finora

- MORE THAN JUST DRY AIR: SOLUTIONS FOR LONG-TERM STORAGEDocumento3 pagineMORE THAN JUST DRY AIR: SOLUTIONS FOR LONG-TERM STORAGEJoão Pedro AlmeidaNessuna valutazione finora

- Ansul Bulk Low Pressure CO2 System PDFDocumento4 pagineAnsul Bulk Low Pressure CO2 System PDFMohammed ZabiNessuna valutazione finora

- Fuel InjectionDocumento262 pagineFuel InjectionZaid Tariq AlabiryNessuna valutazione finora

- (BS EN 12981 - 2005+A1 - 2009) - Coating Plants. Spray Booths For Application of Organic Powder Coating Material. Safety Requirements.Documento54 pagine(BS EN 12981 - 2005+A1 - 2009) - Coating Plants. Spray Booths For Application of Organic Powder Coating Material. Safety Requirements.Simon ThaonNessuna valutazione finora

- 4 Diesel Combustion and EmissionDocumento80 pagine4 Diesel Combustion and EmissionCharlie TejNessuna valutazione finora

- GMGN2497 (Iss 1) Guidance On Railway Wheelset Tread, Gauging and Damage IdentificationDocumento43 pagineGMGN2497 (Iss 1) Guidance On Railway Wheelset Tread, Gauging and Damage IdentificationSofia D'AlessandroNessuna valutazione finora

- Norma Britanica y Europea-13306-Maintenance-Terminology PDFDocumento58 pagineNorma Britanica y Europea-13306-Maintenance-Terminology PDFarielchazangNessuna valutazione finora

- Caterpillar RC1000 Containerized Diesel Generator SetDocumento4 pagineCaterpillar RC1000 Containerized Diesel Generator SetMacAllister MachineryNessuna valutazione finora

- Potential Uses of Dairy Biogas and BiomethaneDocumento26 paginePotential Uses of Dairy Biogas and BiomethaneHari650Nessuna valutazione finora

- Damage Brochure MAHLE Original TurbochargersDocumento16 pagineDamage Brochure MAHLE Original Turbochargerszhengdong618Nessuna valutazione finora

- SP 1800Documento1 paginaSP 1800Anass ChtaybiNessuna valutazione finora

- Cleaner Combustion Chem201602676Documento12 pagineCleaner Combustion Chem201602676jcpa1000Nessuna valutazione finora

- Rotax Operators Manual 912Documento84 pagineRotax Operators Manual 912DelNessuna valutazione finora

- Air Conditioning System With Refrigerant R134aDocumento102 pagineAir Conditioning System With Refrigerant R134aMarko VeselinNessuna valutazione finora

- Wirelock ManualDocumento27 pagineWirelock Manualmujeebtalib100% (1)

- 2019 Formica Asia Residential Collection - en PDFDocumento52 pagine2019 Formica Asia Residential Collection - en PDFKornumaNessuna valutazione finora

- Fuels & Combustion - Emission & Control Technology TYBE COEP DR Vora 040422Documento93 pagineFuels & Combustion - Emission & Control Technology TYBE COEP DR Vora 040422Amey gaikwadNessuna valutazione finora

- Michelin Tire RefDocumento12 pagineMichelin Tire RefSanket_DhanaveNessuna valutazione finora

- Automotive Engine Components DesignDocumento15 pagineAutomotive Engine Components DesignSathistrnpcNessuna valutazione finora

- Estimating Power from Diesel Engine Converted to LPG OperationDocumento6 pagineEstimating Power from Diesel Engine Converted to LPG OperationAmol TembhareNessuna valutazione finora

- Machinery Lubrication I y II - BrochureDocumento12 pagineMachinery Lubrication I y II - BrochureFrancisca VeraNessuna valutazione finora

- Effect of Performance and Emissions On DI Diesel Engine Using Ethanol Diesel BlendsDocumento9 pagineEffect of Performance and Emissions On DI Diesel Engine Using Ethanol Diesel BlendsNgocTinhPhamNessuna valutazione finora

- Air Pollution Lect.1Documento277 pagineAir Pollution Lect.1Nah Sr AdNessuna valutazione finora

- Exh Gas Emission CTRL Man B&WDocumento36 pagineExh Gas Emission CTRL Man B&WAnonymous 4ylE57C6Nessuna valutazione finora

- CompAir Turboscrew BrochureDocumento8 pagineCompAir Turboscrew BrochureBoban StanojlovićNessuna valutazione finora

- F Me A of Journal BearingDocumento6 pagineF Me A of Journal BearingkulilistrikNessuna valutazione finora

- Spark Plug Selection TableDocumento3 pagineSpark Plug Selection Tablemahdi zamani100% (1)

- Delphi Heavy Duty Emissions Brochure 2011 2012Documento100 pagineDelphi Heavy Duty Emissions Brochure 2011 2012Younwoo NamNessuna valutazione finora

- En779 2012 enDocumento4 pagineEn779 2012 enweikai_ngNessuna valutazione finora

- Power System PDFDocumento24 paginePower System PDFlethanhtu0105Nessuna valutazione finora

- Hydraulics and Pneumatics NotesDocumento79 pagineHydraulics and Pneumatics NotesSolomon DurairajNessuna valutazione finora

- DFDE 4 Stroke Wartsila PDFDocumento60 pagineDFDE 4 Stroke Wartsila PDFpadangiringNessuna valutazione finora

- Applied Energy: Antonio Mariani, Fabrice FoucherDocumento11 pagineApplied Energy: Antonio Mariani, Fabrice Fouchermanu binodNessuna valutazione finora

- CIMAC Fuel RecommendationsDocumento3 pagineCIMAC Fuel Recommendationschemicalchouhan9303100% (1)

- ILC Lube Lubrication Construction MachineryDocumento9 pagineILC Lube Lubrication Construction MachineryScarduelliNessuna valutazione finora

- 2004-01-0403 - Design and Analysis of Fuel Tank Baffles To Reduce The Noise Generated From Fuel SloshingDocumento14 pagine2004-01-0403 - Design and Analysis of Fuel Tank Baffles To Reduce The Noise Generated From Fuel SloshingCaio PaimNessuna valutazione finora

- ATV630 650 Installation Manual en EAV64301 04Documento118 pagineATV630 650 Installation Manual en EAV64301 04Luis Guillermo Rodríguez A.100% (1)

- Life Cycle Cost CalculationDocumento8 pagineLife Cycle Cost CalculationJames Bryle VillarealNessuna valutazione finora

- Guidelines For Operation On Fuels With Less Than 0 1 SulphurDocumento24 pagineGuidelines For Operation On Fuels With Less Than 0 1 SulphurFuchsbauNessuna valutazione finora

- Project Fatigue PDFDocumento219 pagineProject Fatigue PDFdudescapeNessuna valutazione finora

- Gas Turbine Book DownloadsDocumento12 pagineGas Turbine Book Downloadsaddisud0% (1)

- AVL Emission Testing Handbook V1.0 PA3088E PDFDocumento80 pagineAVL Emission Testing Handbook V1.0 PA3088E PDFmrginj67% (3)

- Burner, Series 300-700Documento32 pagineBurner, Series 300-700Luthfi Adri Angkasa PutraNessuna valutazione finora

- Structural Health MonitoringDa EverandStructural Health MonitoringDaniel BalageasNessuna valutazione finora

- Effect of Biodiesel Concentration On Corrosion of Carbon Steel by Serratia MarcescensDocumento7 pagineEffect of Biodiesel Concentration On Corrosion of Carbon Steel by Serratia MarcescensVivi AisahNessuna valutazione finora

- Filipino scientist wins praise from Obama for salt lamp inventionDocumento6 pagineFilipino scientist wins praise from Obama for salt lamp inventionSamuel SeriñaNessuna valutazione finora

- Risk Focus Engine Room FiresDocumento20 pagineRisk Focus Engine Room FiresA.K.M. MohiuddinNessuna valutazione finora

- Homework Chapter 6-1Documento7 pagineHomework Chapter 6-1FionaRoyNessuna valutazione finora

- Defining Power Barge ComponentsDocumento17 pagineDefining Power Barge ComponentsHumphrey DrepiteNessuna valutazione finora

- TRF OilDocumento47 pagineTRF Oilಶ್ರೀಕಾಂತ್ ತಿಪ್ಪೇರುದ್ರಪ್ಪNessuna valutazione finora

- Feedstocks and Raw Materials: Ammonia PlantDocumento40 pagineFeedstocks and Raw Materials: Ammonia PlantSaad Khan100% (3)

- Alarms in Nokia Flexi BTS: 1.) 7401 AlarmDocumento8 pagineAlarms in Nokia Flexi BTS: 1.) 7401 AlarmManu ThakralNessuna valutazione finora

- Gate 2001 PDFDocumento14 pagineGate 2001 PDFVammsy Manikanta SaiNessuna valutazione finora

- F350aet'08 Fl350aet'08: (6aw1) (6ax1)Documento82 pagineF350aet'08 Fl350aet'08: (6aw1) (6ax1)Jose Gregorio Aponte PerezNessuna valutazione finora

- Abe 414Documento4 pagineAbe 414JohnNessuna valutazione finora

- HF Treatment Through DSTDocumento8 pagineHF Treatment Through DSTmoorpvrNessuna valutazione finora

- Emulsion Explosives: The Wave of FutureDocumento5 pagineEmulsion Explosives: The Wave of Futureopql1234Nessuna valutazione finora

- FP350 Foam ConcentrateDocumento2 pagineFP350 Foam ConcentrateoscarninanNessuna valutazione finora

- Piston SeizuresDocumento7 paginePiston SeizuresMoaed KanbarNessuna valutazione finora

- Debates rage over fixed- vs. fluid-bed MA production and aqueous vs. solvent recoveryDocumento4 pagineDebates rage over fixed- vs. fluid-bed MA production and aqueous vs. solvent recoveryTCBerkcanErbilgeNessuna valutazione finora

- Energy Technology Class NotesDocumento139 pagineEnergy Technology Class NotesAngothu ThirupathiNessuna valutazione finora

- Srinivas Institute of Technology: Ranganatha Y H Asst. Professor Department of Mechanical Engineering Sub. Code:15ME662Documento36 pagineSrinivas Institute of Technology: Ranganatha Y H Asst. Professor Department of Mechanical Engineering Sub. Code:15ME662raghurockramNessuna valutazione finora

- En Us t1 2003Documento482 pagineEn Us t1 2003mazacotes100% (1)

- Truobleshooting Refinery Vacuum TowerDocumento33 pagineTruobleshooting Refinery Vacuum TowerGUZMAN0% (1)

- Pipeline and BlendingDocumento37 paginePipeline and Blendingsohail1985Nessuna valutazione finora

- Maintenance & RepairDocumento26 pagineMaintenance & RepairGrid Lock100% (1)

- EUROPEAN COMMISSION APPROVES MACQUARIE/OILTANKING JOINT CONTROL OF OILTANKING ODFJELL TERMINAL SINGAPOREDocumento3 pagineEUROPEAN COMMISSION APPROVES MACQUARIE/OILTANKING JOINT CONTROL OF OILTANKING ODFJELL TERMINAL SINGAPOREPaijo TenarNessuna valutazione finora

- Bobcat 3 Phase: Quick SpecsDocumento4 pagineBobcat 3 Phase: Quick SpecsAnonymous SDeSP1Nessuna valutazione finora

- The Drilling RisersDocumento26 pagineThe Drilling RisersNeel KSNessuna valutazione finora

- Char Point and Bloom - Physicochemical and AnalyticalDocumento2 pagineChar Point and Bloom - Physicochemical and AnalyticalKhanh NguyenNessuna valutazione finora

- PDFDocumento32 paginePDFJuan Carlos Cahuasquí IntriagoNessuna valutazione finora

- Ec (2jz-Gte) PDFDocumento12 pagineEc (2jz-Gte) PDFAshokNessuna valutazione finora

- Module-18-Design Safety Practices (Petrofac)Documento55 pagineModule-18-Design Safety Practices (Petrofac)Riyadh Saleh100% (1)

- Krishna Sie FPT 2000Documento33 pagineKrishna Sie FPT 2000Chia Sheng WuNessuna valutazione finora