Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cutting Perfect Tapers

Caricato da

Antônio CastroCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cutting Perfect Tapers

Caricato da

Antônio CastroCopyright:

Formati disponibili

Plans N O W

w w w. p l a n s n o w. c o m

cutting perfect

Tapers

Most of us spend a lot of time tuning up workers think of is a jig like the ones you have to hold it against a stop at the

our table saws to get dead-on straight shown in the box below. This type of jig back of the jig while pushing the entire

cuts that are perfectly parallel with the has two arms that are hinged at one end. assembly forward. So youre pushing

rip fence. So the idea of using a table saw You simply adjust the spread of the arms and pulling at the same time, which can

to make a tapered cut might seem a little to suit the taper your project calls for. The feel awkward.

strange. But in reality, tapered cuts are rip fence is used to guide the jig past the But the main reason I dont care for this

just straight cuts at an angle. The trick is saw blade. style of jig is that if youre tapering a leg

to hold the workpiece at the correct angle The advantage of this style of jig is that or narrow workpiece, its hard to hold

for the taper you want. And all you need its adjustable, so you can use it over and onto the workpiece and keep your fingers

to do this is a taper jig. over to cut tapers of different angles. But a safe distance away from the blade (see

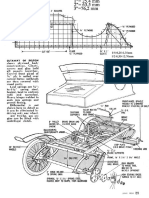

Adjustable Jigs. When it comes to there are a few drawbacks as well. Since photo in box on the bottom of the oppo-

taper jigs, the first thing many wood- the workpiece isnt fastened to the jig, site page).

Whats Available:

Adjustable Taper Jigs

Commercial Jig. Constructed

out of aluminum, this taper jig

features an angle scale and an

adjustable stop (see inset).

{ Shop-Made Jig. You can

build your own taper jig out of

a few scraps, a hinge, and a

handful of other hardware.

From ShopNotes Magazine page 1 of 2 2004 August Home Publishing

All rights reserved One copy for personal use. Other copies prohibited.

Fixed Angle Jigs. Most of the edge of the jig. Then place the fence

time I prefer to just make a simple, and stop against the workpiece and

one-time-use taper jig that is suited screw them to the base of the jig.

to the task at hand. (Take a look Control. Regardless of the kind

at the jig in the main photo on the of jig youre using, the key to cut-

opposite page for an example.) ting tapers is to always maintain

The design of the jig you use control of the workpiece. Toggle

will depend on the size and shape clamps or double-sided tape can be

of your workpieces. But it doesnt used to hold the workpiece to the

have to be complicated. All it has to jig, which allows you to keep

do is hold the workpiece at the cor- your hands a safe dis-

rect angle while you cut the taper. tance from the

Usually, I just make a simple blade. This

sled with a fence and a stop (see way, all you END VIEW POSITION

CLAMPS

drawing at right). The fence holds have to con- AWAY FROM

BLADE

the workpiece at the correct angle, centrate on

and the stop prevents it from is keeping the FENCE WORK-

PIECE

moving. Since the workpiece rides jig against the rip

on top of the jig, all you have to do fence as you push it SLED WASTE

is push the jig forward. past the blade.

Construction. There are a couple Sometimes, theres no conve-

of tips to follow when making taper nient way to secure the workpiece

jigs. First, I like to make the base of to the jig. You simply have to hold

the jig wide enough so that I have it against the stop. In these cases, I

a safe place to put my hands while usually prefer to locate the stop at

using the jig. the leading end of the jig. That way, < Hold-Down.

Second, when making the jig, I you are pushing the workpiece Toggle clamps

position the fence so the taper on against the stop as you slide for- hold the work-

the workpiece lines up with the ward past the saw blade. This feels piece securely,

edge of the jig. This way, the bottom safer to me than trying to hold the allowing you to

of the workpiece is supported as workpiece against a stop. keep your fingers

the blade exits the cut. Finally, if youre tapering a work- clear of the blade.

To do this, simply lay out the piece on all four faces, youll need

taper on your workpiece and then to take some extra steps, as shown

place it on the base of the jig so the in the box below.

waste portion overhangs the left

Technique:

4-Sided Tapers < Four-Sided

Tapers. After

Cutting a taper on one or two faces of a workpiece cutting tapers on

is pretty straightforward. But if youre cutting tapers the first two faces,

on all four faces (like on a table leg, for example), you tape the waste

have a bit of a challenge. After cutting away the waste pieces back in

on the first two faces, you no longer have a straight place to create

edge to place against the fence of the jig to cut the a square face

remaining two tapers. for cutting the

Depending on the type of jig youre using, there remaining tapers.

are a couple of ways to deal with this problem. One

of the simplest is to first tape the wedge-shaped waste

pieces back on to the two tapered faces of the work-

piece. Then cut the remaining two tapers. (Because of

the kerf, you will have to move the wedges down a bit

on the workpiece as shown in the drawings.) This way,

you maintain the original square shape of the blank.

From ShopNotes Magazine page 2 of 2 2004 August Home Publishing

All rights reserved One copy for personal use. Other copies prohibited.

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Wood Carving PDFDocumento157 pagineWood Carving PDFAntônio CastroNessuna valutazione finora

- Diy - Popular Woodworking PlansDocumento108 pagineDiy - Popular Woodworking Plansrlfd14183% (6)

- Micro-Lathe Plans (Popular Mechanics)Documento4 pagineMicro-Lathe Plans (Popular Mechanics)sjdarkman1930100% (13)

- Size of Tackle: The First Thing To Know Is What: OR LeatherDocumento5 pagineSize of Tackle: The First Thing To Know Is What: OR Leatherelectricnusi100% (7)

- All About Routing PDFDocumento24 pagineAll About Routing PDFAntônio CastroNessuna valutazione finora

- SEP1950 Popular MechanicsDocumento316 pagineSEP1950 Popular MechanicsAntônio Castro100% (1)

- 10 Best Table Saw AccessoriesDocumento6 pagine10 Best Table Saw AccessoriesAntônio Castro100% (2)

- Hold Down TracksDocumento3 pagineHold Down TracksAntônio CastroNessuna valutazione finora

- 1901 Olds PlansDocumento15 pagine1901 Olds PlansFrenchwolf420100% (2)

- 03 mIXDocumento3 pagine03 mIXAntônio CastroNessuna valutazione finora

- Popular Mechanics Plans-Homemade Sandblasting Cabinet BlueprintsDocumento6 paginePopular Mechanics Plans-Homemade Sandblasting Cabinet Blueprintsjlw2135554961% (28)

- Quadricycle Manual PDFDocumento118 pagineQuadricycle Manual PDFserban_elNessuna valutazione finora

- Part One - Basic DimentionsDocumento5 paginePart One - Basic Dimentionseu1mister6002Nessuna valutazione finora

- Vintage - Service.station Model PaperDocumento5 pagineVintage - Service.station Model PaperAntônio CastroNessuna valutazione finora

- Mini BikeDocumento6 pagineMini BikeraadianNessuna valutazione finora

- MidgetDocumento1 paginaMidgetAntônio CastroNessuna valutazione finora

- 1901 PackardDocumento8 pagine1901 PackardAntônio CastroNessuna valutazione finora

- Toys at Home-OldsDocumento104 pagineToys at Home-OldsAntônio Castro100% (6)

- Early Chevrolet PartsDocumento26 pagineEarly Chevrolet PartsAntônio Castro50% (2)

- Aviao de MontarDocumento2 pagineAviao de MontarAntônio CastroNessuna valutazione finora

- The Santos-Dumont DemoiselleDocumento7 pagineThe Santos-Dumont DemoiselleAntônio CastroNessuna valutazione finora

- Maquete SteamDocumento33 pagineMaquete SteamAntônio CastroNessuna valutazione finora

- Intelligent WiringDocumento12 pagineIntelligent Wiringg_junk5213Nessuna valutazione finora

- Esq Eletr LambrettaDocumento1 paginaEsq Eletr LambrettaAntônio CastroNessuna valutazione finora

- Kart 10Documento1 paginaKart 10Antônio CastroNessuna valutazione finora

- Sanata Clara Model TDocumento16 pagineSanata Clara Model TAntônio CastroNessuna valutazione finora

- Dog Kennel PlansDocumento1 paginaDog Kennel PlansR_gabrielczykNessuna valutazione finora

- Hobbies Special Design Sheet 206 Model of Old English Stage Coach PDFDocumento1 paginaHobbies Special Design Sheet 206 Model of Old English Stage Coach PDFpassagerx007Nessuna valutazione finora

- Kart 09Documento1 paginaKart 09Antônio CastroNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Microfinance Ass 1Documento15 pagineMicrofinance Ass 1Willard MusengeyiNessuna valutazione finora

- Community Architecture Concept PDFDocumento11 pagineCommunity Architecture Concept PDFdeanNessuna valutazione finora

- Embedded Systems Online TestingDocumento6 pagineEmbedded Systems Online TestingPuspala ManojkumarNessuna valutazione finora

- Rights of Parents in IslamDocumento11 pagineRights of Parents in Islamstoneage989100% (2)

- STS Module 11Documento64 pagineSTS Module 11Desiree GalletoNessuna valutazione finora

- Fake News Infographics by SlidesgoDocumento33 pagineFake News Infographics by SlidesgoluanavicunhaNessuna valutazione finora

- Lenovo NotebooksDocumento6 pagineLenovo NotebooksKamlendran BaradidathanNessuna valutazione finora

- 2022 Tony Elumelu EntrepreneursDocumento10 pagine2022 Tony Elumelu EntrepreneursOladosu EmmanuelNessuna valutazione finora

- Reaserch On Effect of Social Media On Academic Performance: Study On The Students of University of DhakaDocumento27 pagineReaserch On Effect of Social Media On Academic Performance: Study On The Students of University of DhakaFatema Tuz Johoora88% (114)

- Digital Electronics Chapter 5Documento30 pagineDigital Electronics Chapter 5Pious TraderNessuna valutazione finora

- Sap New GL: Document Splitting - Configuration: ChooseDocumento3 pagineSap New GL: Document Splitting - Configuration: ChooseChandra Sekhar PNessuna valutazione finora

- Current Trends and Issues in Nursing ManagementDocumento8 pagineCurrent Trends and Issues in Nursing ManagementMadhu Bala81% (21)

- Benefits and Limitations of BEPDocumento2 pagineBenefits and Limitations of BEPAnishaAppuNessuna valutazione finora

- Transparency and Digitalization in The Public Administration of RomaniaDocumento8 pagineTransparency and Digitalization in The Public Administration of RomaniaMădălina MarincaşNessuna valutazione finora

- LFF MGDocumento260 pagineLFF MGRivo RoberalimananaNessuna valutazione finora

- Calculus For The Life Sciences 2nd Edition Greenwell Solutions ManualDocumento26 pagineCalculus For The Life Sciences 2nd Edition Greenwell Solutions ManualSharonPerezozqy100% (56)

- Adaptive Leadership: Leadership: Theory and PracticeDocumento14 pagineAdaptive Leadership: Leadership: Theory and PracticeJose Daniel Quintero100% (1)

- UFO Yukon Spring 2010Documento8 pagineUFO Yukon Spring 2010Joy SimsNessuna valutazione finora

- Akilas Mebrahtom ResumeDocumento1 paginaAkilas Mebrahtom ResumeAnonymous lLpBfQNessuna valutazione finora

- L5V 00004Documento2 pagineL5V 00004Jhon LinkNessuna valutazione finora

- What You Need To Know About Your Drive TestDocumento12 pagineWhat You Need To Know About Your Drive TestMorley MuseNessuna valutazione finora

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Documento1 paginaS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaNessuna valutazione finora

- UAV Design TrainingDocumento17 pagineUAV Design TrainingPritam AshutoshNessuna valutazione finora

- Bubble Test Direct Pressure InserviceDocumento3 pagineBubble Test Direct Pressure InserviceEdAlmNessuna valutazione finora

- Advertisement: National Institute of Technology, Tiruchirappalli - 620 015 TEL: 0431 - 2503365, FAX: 0431 - 2500133Documento4 pagineAdvertisement: National Institute of Technology, Tiruchirappalli - 620 015 TEL: 0431 - 2503365, FAX: 0431 - 2500133dineshNessuna valutazione finora

- Paper 1 AnalysisDocumento2 paginePaper 1 AnalysisNamanNessuna valutazione finora

- Cipet Bhubaneswar Skill Development CoursesDocumento1 paginaCipet Bhubaneswar Skill Development CoursesDivakar PanigrahiNessuna valutazione finora

- Persuasive Speech 2016 - Whole Person ParadigmDocumento4 paginePersuasive Speech 2016 - Whole Person Paradigmapi-311375616Nessuna valutazione finora

- Web-Based Attendance Management System Using Bimodal Authentication TechniquesDocumento61 pagineWeb-Based Attendance Management System Using Bimodal Authentication TechniquesajextopeNessuna valutazione finora

- Data Network Unit 6 - UCDocumento15 pagineData Network Unit 6 - UCANISHA DONDENessuna valutazione finora