Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

C2 CRoadmap NE3

Caricato da

TheDeathFromHellTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

C2 CRoadmap NE3

Caricato da

TheDeathFromHellCopyright:

Formati disponibili

E-mail info@c2c-solutions.

com for a printable electronic copy of the latest version of this Flowchart

(B) Understanding your (A) Business Case

"Concept Customer"

Customers better than and Project Plan

they do ! (VOC + MOC)

Video ->www.kanomodel.com

to

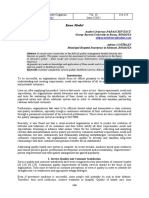

PROJECT PLAN (Integrating DFSS "best-practices" into a Product Development Flowchart)

Issues / Mission

ID Customers In the late 20th century leading companies realized that the Product Development Process was as

Excitement Market Segment important as the product itself. This process must involve Strategic Thinking, Customer Input, Technical

D. Verduyn - 6/23/00 - Revision Date: 10/23/2007 - This roadmap gets "enhanced & updated" regularly. What you are reading is "probably" an "out-of-date" version - E-mail us at info@c2c-solutions.com for a printable electronic copy of the latest version of this Roadmap

Needs Performance

Project Scope

Discipline, Advanced Knowledge, Creativity, Speed, and Innovation to ensure a successful output for

Project Goals

Needs Project Constraints your Customers. This uniquely structured "C2C Flowchart" integrates leading Design for Six Sigma

Project Strategy (DFSS) "tools" which accelerate product introduction and ensures profitable life cycles. Along the right

Team Membership

Basic

side is a very brief explanation of the Integration steps. Each step represents a DFSS "tried and

Needs proven" technique which additional detailed explanation is available. Detailed explananation of each

step is available upon request. c

1999 - 2010 C2C Solutions, Inc. (All rights reserved) - www.c2c-solutions.com

(D) Develop Metrics A. Business Case / Project Plan - Here the team explains why it is important to

work on this "Project" and develops a plan which includes the Issues, identification of

(C) Document & Prioritize and set Product Goals Customers, Market, Scope, Goals, Constraints, Strategy, Team Membership, etc.

the Customers' "Needs" (HOQ Optional)

B. Understanding your Customer's Needs - The cornerstone for every

sucessful project. The "Enhanced" Kano Model illustrates three critical types of

All Customer Wants

Company Measures

Priority Index

needs that must be delivered to the customer: 1) Basic Needs - Are expected

needs, yet unspoken by the customers. 2) Performance Needs - Are the

Customer

Score-

Priority

Wants

spoken and consciously evaluated needs that customers will talk about.

cards 3) Excitement Needs - Are the Innovations, "WOWs", & neat surprises.

Target Values Over 35 strategies exist to "uncover" the Voice of the Customer (VOC)

and truly understand the "Mind" of the Customer (MOC).

Technical Competitive

A useful and optional e-QFD "Shortcut/Filter") Assessment

Result: A Prioritized Hierarchy of Customer Needs C. Document & Prioritize the Customers' "Needs" -

A well documented and prioritized list of requirements helps

keep them current and visible. This (eQFD "shortcut") uses

"Standard" specific criteria to help decide how each requirement will

Low be "deployed". This also keeps a "House of Quality"

Product Difficulty Medium

Engineering of Product from turning into a "Mansion of Quality"!!

Procedures

Goals?

D. Developing Metrics & Goals - It's very

High hard to improve things that can't be measured.

The QFD "House of Quality" is an excellent

"tool" to help develop metrics and specific

(F) Design FMEA (E) Product Function Analysis goals for the customer's "fuzzy" requirements.

(If Design Concept is known)

E. Product Function Analysis - "A

problem well described is a problem 80%

solved." Functions are the most important

aspect of any engineering system. Here, we

describe in terms of functions, our engineering

(G) The "Trimming system, it's problems, and perform a

comprehensive "Value" Analysis.

Technique" **

Are

F. Design & Process FMEA's - An

High RPN's

Cost,

Complexity, Yes $$ $ FMEA (Failure Modes & Effects Analysis) is a

or Breakthrough proactive systematic approach used by

major

Product & Process Engineers to help assure

drivers?

your product and processes perform their

intended functions over their entire life span.

"**" - TRIZ Techniques No A tabular method is applied to analyze

potential failure modes, their effects, and

(H) 25+ Tools for Innovation, develop an action plan to ensure your

Problem Solving, and Concept Generation Design "Challenges" customers never see these failures.

Watch Video --> www.c2c-solutions.com/sys-inn01.html

G. The "Trimming Technique" - When

cost reduction, complexity reduction, or a true

"Left Brained" Techniques . . . . . . ."Right Brained Techniques" breakthrough is needed in the design, this

1) Knowledge base of 9,000 Scientific Effects ** 8) Product & Society Trends 15) Brainwriting 6-3-5 technique uses cost and complexity reduction

2) Separation Principles for Physical Conflicts ** 9) Lateral Benchmarking Ideas, 16) Have the "Right" People strategies and algorithms for simplified

3) Inventive Principles for Engineering Conflicts ** 10) The Holistic Cube Concepts, product or process scenarios. (VA/VE "Tool")

Solutions 17) "Painstorming"

4) Patterns of System Evolution ** 11) Customer Modifications 18) Unintended Uses/Applications

5) The "Ideal" System and the Use of Resources ** 12) The Trimming Technique **

H H. 25+ Strategies for Innovation -

19) The MSE Effect Difficult problems need breakthrough thinking.

6) Strategic Patent Analysis 13) Morphological Tables

20) Super Lateral Benchmarking Most people think only "special" people have

7) Semantic "Knowledge" Mining 14) Blue Ocean Strategy the ability to Innovate. NOT TRUE!! Several

21) Biomimicry

Design Psychological and Technological strategies for

22) DeBono's 6 Hats

Concepts "Systematic Innovation" are being leveraged

23) Simplified Synectics

(J) Detailed by "normal" people to accelerate innovation.

24) Time Savers

Product Design Manufacturing

I. Concept Selection - Several methods

"Challenges" 25) Can't Fix it?, Feature it!

Product Design for Concept Selection exist ranging from

(I) Design Concept Parameters

(Control Factors)

Noise

Factors

26) The "Pagoda" Effect

simple multivoting techniques to sophisticated

Evaluation and Selection 27) Future-Mapping mathematical methods that take into

Performance

28) And several more . . . .

Functions &

Concepts

consideration multiple opinions, confidence

Metrics,

Targets

DFM & Robust levels and risk. Deciding which method to use

Alternatives Process

D + s + + Engineering Concepts depends on the importance of the decision.

Evaluation

a s + s

Criteria

-

t s- + - -

u

m +

+

-

-

-

+

s

+ Targets & Ranges/ J. Detailed Product Design - This step

Tolerances Conditions integrates DFM principles & Taguchi's

Totals

Methods for "Robust Designs" with QFD to

detail critical Design Characteristics with

(I) Process Concept "optimized" target values to achieve a "Robust

Evaluation and Selection Design" that is easy to manufacture.

"Standard" Low Medium

Difficulty

Manufacturing Concepts

of Process Alternatives

K. Process Function Analysis - "A

Engineering

Goals? problem well described is a problem 80%

Procedures D + s + +

Evaluation

a s + s solved." Process functions are the most

Criteria

-

t s- + - -

u

m + - - s important aspect of manufacturing design.

+ - + +

High Here we describe, in terms of functions, our

Totals

manufacturing process, its problems, and

perform an operational "Value" Analysis.

(F) Process FMEA (K) Process

(If Process Concept is known) Function Analysis ** L. Detailed Process Design - This step

(L) Detailed integrates Dr. Taguchi's philosophy of

Process Design "Robustness" with QFD to detail the critical

Process Parameters and "optimized" target

Process Design

Parameters

Noise values to achieve a "Robust Process".

Factors

(Control Factors)

M. Production Control - These are the

Functions &

"shop floor" activities that are needed in order

Targets

Robust

Design

Targets

to maintain capable processes and approach

Manufacturing a Six Sigma operation. These activities help

Are

Cost, to prevent reverting back to the "old way".

High RPN's Targets & Ranges/

Complexity, No Tolerances Conditions

or Breakthrough N. Kaizen - Methods to encourage gradual,

major

drivers?

structured, and continuous improvement for

internal and external "customers" through the

C 2C

C C

elimination of waste. People work together

Yes (M) Production Control on making small continuous improvements

without large capital investments.

SolutionS

ON-LINE QUALITY ENG.

MISTAKE PROOFING

Concept Customer (G) The "Trimming GAGE R&R STUDIES

PREVENTIVE MAINTENANCE

Technique" OPERATOR TRAINING

Delivery to Customer (N) Kaizen!

( With Quality, Cost, and Time

Product Development QUALITY CONTROL CHARTS

Services $$ $ UCL

Objectives Achieved )

Technical Workshops, Target

Training, Consulting, LCL

Project based Coaching

c 1999 - 2010 C2C Solutions, Inc. (All rights reserved) - e-mail: info@c2c-solutions.com - Phone # 248-879-8040 - Visit our web-site and request a "printable" electronic copy of this roadmap ( www.c2c-solutions.com ) (Acrobat Reader required)

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Stevenson 14e Chap004 PPT AccessibleDocumento48 pagineStevenson 14e Chap004 PPT AccessibleLady PilaNessuna valutazione finora

- 100+ Business Analyst Interview Questions & Answers in 2022Documento17 pagine100+ Business Analyst Interview Questions & Answers in 2022Sendil Kumar100% (1)

- Lean Six Sigma Green BeltDocumento109 pagineLean Six Sigma Green BeltTathagata GopeNessuna valutazione finora

- Caterpillar PPT 2Documento75 pagineCaterpillar PPT 2Vvb SatyanarayanaNessuna valutazione finora

- Thesis GrabDocumento56 pagineThesis GrabMarites R. Cabuquin100% (4)

- Banana Beach Resort Services and The Level of Customer SatisfactionDocumento11 pagineBanana Beach Resort Services and The Level of Customer SatisfactionJheiAr Corpuz Mojeca100% (1)

- MODULE 3 - Product and DesignDocumento15 pagineMODULE 3 - Product and DesignRhodora SantosNessuna valutazione finora

- Kano ModelDocumento9 pagineKano ModelNikola SvorcanNessuna valutazione finora

- The Importance of Service Quality and The Evaluation of Meeting Customer ExpectationsDocumento7 pagineThe Importance of Service Quality and The Evaluation of Meeting Customer ExpectationsUpasana Abhishek GuptaNessuna valutazione finora

- Kosice Schulze Bramey PDFDocumento13 pagineKosice Schulze Bramey PDFandrel_fariasNessuna valutazione finora

- According To Hasemark and AlbinssonDocumento6 pagineAccording To Hasemark and AlbinssonAshwinKumarNessuna valutazione finora

- Service Quality Excellence in Healthcare Quiz 1Documento5 pagineService Quality Excellence in Healthcare Quiz 1Dharm Veer RathoreNessuna valutazione finora

- Quality and Performance Excellence 8E CHAPTER 1 RECORDEDDocumento26 pagineQuality and Performance Excellence 8E CHAPTER 1 RECORDEDAE BARCELONANessuna valutazione finora

- KANO Model Managing Innovation Through Classification of NeedsDocumento13 pagineKANO Model Managing Innovation Through Classification of NeedsShrutiBindalNessuna valutazione finora

- Kano Model: Presented By: Prachi ChauhanDocumento21 pagineKano Model: Presented By: Prachi ChauhanAjay DewanganNessuna valutazione finora

- Mba Mascarenhas J 2019Documento111 pagineMba Mascarenhas J 2019Rami RohanNessuna valutazione finora

- KANO Best PracticesDocumento25 pagineKANO Best PracticesDasaManNessuna valutazione finora

- Project Management - Assignment 07Documento4 pagineProject Management - Assignment 07abhipankajNessuna valutazione finora

- Applied Sciences: Smart Product Design Process Through The Implementation of A Fuzzy Kano-AHP-DEMATEL-QFD ApproachDocumento28 pagineApplied Sciences: Smart Product Design Process Through The Implementation of A Fuzzy Kano-AHP-DEMATEL-QFD ApproachKimberly ZavaletaNessuna valutazione finora

- Group 9Documento46 pagineGroup 9Kimberly Solomon JavierNessuna valutazione finora

- New Product Development and Managing Innovation - Sem 4Documento10 pagineNew Product Development and Managing Innovation - Sem 4Yash GuptaNessuna valutazione finora

- Kano Model: From Wikipedia, The Free EncyclopediaDocumento4 pagineKano Model: From Wikipedia, The Free EncyclopediasoorajNessuna valutazione finora

- The Process To Define and Improve The Competitive Advantage Value by Using Dmadv Approach at PT Telkom Indonesia, TBKDocumento137 pagineThe Process To Define and Improve The Competitive Advantage Value by Using Dmadv Approach at PT Telkom Indonesia, TBKmuhtia luchfiNessuna valutazione finora

- Analisis Model KanoDocumento4 pagineAnalisis Model KanoAnonymous lK9r9XNessuna valutazione finora

- UntitledDocumento263 pagineUntitledpavan kammaraNessuna valutazione finora

- BA / BA (Hons) Marketing Management (133-19310) : AssignmentDocumento17 pagineBA / BA (Hons) Marketing Management (133-19310) : AssignmentMaria MohammedNessuna valutazione finora

- Activity Based Costing (ABC) : 7 QC ToolsDocumento16 pagineActivity Based Costing (ABC) : 7 QC ToolsManas DasguptaNessuna valutazione finora

- AssignmentDocumento8 pagineAssignmentJunaid AfridiNessuna valutazione finora

- Neha's Strategic ManagementDocumento6 pagineNeha's Strategic Managementneha bakshiNessuna valutazione finora

- Kano Model Mobile ExampleDocumento4 pagineKano Model Mobile ExampleEbrahim AbdelrahmanNessuna valutazione finora