Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fundicion de Metales Preciosos

Caricato da

4gen_20 valutazioniIl 0% ha trovato utile questo documento (0 voti)

90 visualizzazioni3 pagineTitolo originale

fundicion de metales preciosos

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

TXT, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato TXT, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

90 visualizzazioni3 pagineFundicion de Metales Preciosos

Caricato da

4gen_2Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato TXT, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

SESSION 4

Precious Metals Processing

Fund is a transaction that achieves the fusion of metals. It is performed most c

ommonly in the preparation of precious alloys in soldering and recoveries, which

can carry out a handmade or special tools and equipment depending on the pad an

d the volume of production. It is the first step in developing a piece of jewelr

y and metalwork and depending on its form, the melting and casting will be in wi

re or sheet over a mold or lost wax casting. EJECUACIÓN PROCESS STEP 1: Weigh th

e metal necessary for the alloy. OBSERVATIONS: • Cut metal pieces for easier mel

ting and then put in a crucible weighed. • First place the metal of higher melti

ng point. Determine the shape and length of the ingot to be obtained.

STEP 2:

STEP 3: STEP 4: STEP 5:

Spread the rails of the mold evenly with oil to facilitate an ingot with a smoot

h surface. Position the mold next to the crucible of cast iron cabin. Light the

torch and heat the crucible with the metal cut, add borax powder. NOTE: • If the

furnace is the first time, heat and sprinkle borax around inside the head of th

e torch to 6 cm. the bottom of the pot until the borax is dissolved. • Place the

pieces of metal in the crucible, first the higher melting point by heating them

to reach their point and then add the pieces of metal of lower melting point to

achieve its pre-cast adding borax. CAUTION: • Use a leather apron and safety gl

asses if possible.

STEP 6:

Case material and reduce the flame of the torch until it has a yellow tip slowly

stirring the pot. NOTE: • If the sand was not completely melted, continue apply

ing the reduced flame until a homogeneous mixture and bright. • Add salt and bor

ax to clean it to clarify the liquid metal by applying heat and continue until t

he run as a mercury metal.

STEP 7:

Vacee material to the mold. Secure the crucible with the tongs in his left hand

and keep the flame of the torch with his right hand on the edge of the crucible.

CAUTION: • The mold must be heated at the same time because heat is applied to

the crucible to melt.

STEP 8:

Vacee molten metal from the crucible to the mold gently carried by the song of t

he same and get a molten metal takes the form of wire or sheet metal. NOTE: • Do

not forget to continue to apply fire on the edge of the pot to ensure complete

emptying. • This operation should be immediate and continuous flow.

STEP 9:

Remove the ingot mold and then cool under running water, wash and dry. NOTE: • O

nly in this case that the bar has an oxidized surface or borax joined the ingot

is immersed in an acidic solution. • In case of dumping the acid rinse and dry t

he slug in sawdust. CAUTION: • Use apron, filter mask and safety glasses.

DEPURANTES and fluxes

DEPURANTES: These are substances that are added to refine (clear) the melt, in t

he first instance. Depurantes Examples of this type: the salt, baking soda, cand

y coal, sawdust, potassium cyanide, zinc, etc.. Flux: These are substances that

are added to melted mass that reacts with oxygen in the air, available as a laye

r on the surface of molten metal, thereby avoiding contact with air, and in turn

allows the flow of merger. Among the major fluxes have to: borax, boric acid, c

alcium fluoride. The Boric acid dissolved in alcohol is an excellent flux, also

because it has a certain power degreaser. But their use is not very common. Bori

c acid begins to protect the metal from oxidation at about 577 º C approximately

borax to higher temperature, precisely to 741 º C 164 º C or more. One liter of

alcohol dissolves 55 g of boric acid: a liter of water at 21 º C, dissolved 51.

5 g.

Boric acid dissolved in denatured alcohol

Borax: Borax is a white, crystalline, soluble in cold water, with a slight alkal

ine taste. From a chemical point of view is a salt formed by the union of boric

acid and sodium, forming the sodium tetraborate, whose formula is: Na2B4O7 - 10H

2O. It is the oldest flow and used in the gold in the process of welding and mel

ting of metals, to dissolve metal oxides that form on the surface thereof and to

facilitate the process of casting. Main features of Metal

• Brightness:

Metals have their own shine, especially after polishing. It conducts heat well a

nd electricity.

• Conductivity:

• Density: The ratio between the mass of a solid or liquid and the mass of water

or

room temperature. Ability to transform into thin slices by rolling or hammering.

For example the gold leaf can be rolled up to 0.0001 mm. thick. • Ductility: Th

e metal can be stretched into fine threads. So the gold for example, can be redu

ced to fine enough to thread embroidery. • Elasticity: The ability to resist def

ormation and return to the original shape when the opposition stops the effort.

This is the same property of the elastic. • Resistance: Ability to withstand a c

ertain weight without breaking.

• Malleability:

PREVENTIVE MAINTENANCE IN THE CAST • • • • • For continuous operation and perfec

t the torch, we recommend cleaning around the gas injection needle can clean the

nozzle. It is used in a small brush, round, hard bristles soaked in gasoline or

kerosene. The safety glasses must be clean before use, for better viewing. Must

be protected with the protective glasses to avoid collisions. Avoid direct cont

act with hot parts. COMMENTS: In casting, the green lens wearers, size No. 6.

• • •

For heat treatment, are shown blue lenses. PREVENTION OF GAS HAZARDS TO: Check t

he record enrollment and characteristics of propane gas equipment and oxygen and

controlled before use. When using gas, never leave the drain cock open if the f

lame is off. If for any reason the room is full of gas, necessary, open all door

s and windows and shut down your computer. It is very dangerous to light a match

, connect a switch or push a buzzer until the air is not renewed. Any of these c

auses can cause an explosion. To check whether a compressed gas cylinder is leak

ing is found using a mixture of soap and solution.

•

EXERCISES: CALCULATION OF PRECIOUS METAL ALLOYS Solve the following problems 1.

Calculate the number of links to be added to a bar of 56 grams of fine gold to d

ownload it to 18K. 2. Find the amount of silver to be added to a pure gold bar f

or 10 grams of 18 carat yellow gold. Apply the percentage formula. 3. We want to

reduce the law to bar 32 grams of 18k to 12k. How much should I add links. 4. I

f we have 120 grams of 21 carat and we turn to the law of carats. How many grams

of league add? 5. Find it much fine gold, which should add to a sheet of 25 gra

ms of gold of 14 carat gold to give us 18K. 6. If we have 250 grams of fine silv

er and we want him down a law to 0.970 How much copper should add? 7. Calculate

the number of links that we add to 65 grams of silver to lower 0.970 0.925 8 law

. If we have 250 grams in the currencies of five tenths and we want to upload yo

ur law 950 How much fine silver should add?

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- RPG - The Vaccine RevoltDocumento4 pagineRPG - The Vaccine Revolt4gen_2Nessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- BTT Mecanica Basica v22Documento1 paginaBTT Mecanica Basica v224gen_2Nessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Secret Code of The Bible and KabbalahDocumento8 pagineThe Secret Code of The Bible and Kabbalah4gen_2100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Catalog CeedDocumento9 pagineCatalog Ceed4gen_2Nessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Help FeedburnerDocumento13 pagineHelp Feedburner4gen_2Nessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- SUCCESSIONDocumento4 pagineSUCCESSION4gen_2Nessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- 3x3 Rubik's Cube SolveDocumento2 pagine3x3 Rubik's Cube Solve4gen_2Nessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Layout of A Typical Garage, Service StationDocumento2 pagineLayout of A Typical Garage, Service StationSunil NepalNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Wirtgen Surface Mining Manual: Edition 2002Documento52 pagineWirtgen Surface Mining Manual: Edition 2002rtegac15100% (4)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Brochure Carbon Additives For PolymersDocumento24 pagineBrochure Carbon Additives For PolymersTUNGNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Crude Oil A Commodity That Moves The MarketDocumento4 pagineCrude Oil A Commodity That Moves The MarketChetan PanchamiaNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Sizing of Steam Coil of Insulated Tank Rev 3Documento2 pagineSizing of Steam Coil of Insulated Tank Rev 3ypatels50% (2)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- P-8931 LaserStar 1530 09-17-04Documento2 pagineP-8931 LaserStar 1530 09-17-04takenoveraccountNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Astm TestingDocumento7 pagineAstm TestingFallo SusiloNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Diaphragm Elimination Using Taper-Lok - NPRADocumento11 pagineDiaphragm Elimination Using Taper-Lok - NPRAAntonio PerezNessuna valutazione finora

- Space Shuttle Main Engine Turbopump DesignDocumento10 pagineSpace Shuttle Main Engine Turbopump DesignsmhosNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Yanmar-Datasheet 4JH57Documento2 pagineYanmar-Datasheet 4JH57Sandro MiqueletiNessuna valutazione finora

- 06-14 GMP UpdatedDocumento260 pagine06-14 GMP UpdatedGyimah SamuelNessuna valutazione finora

- Cessna 402C Limitations/Systems Review GuideDocumento33 pagineCessna 402C Limitations/Systems Review GuideNorge Maninski100% (3)

- Eric Botnick Cessna 150 ChecklistsDocumento4 pagineEric Botnick Cessna 150 ChecklistsVictor Alfonso Castañeda CeballosNessuna valutazione finora

- INDUTEC Manual Sd4 UkDocumento12 pagineINDUTEC Manual Sd4 UkluisNessuna valutazione finora

- ECU ResetDocumento3 pagineECU ResetzulhazwanNessuna valutazione finora

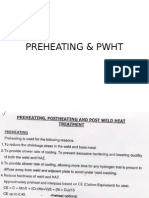

- 08 Preheating, PWHT & Sand Blasting - PaintingDocumento23 pagine08 Preheating, PWHT & Sand Blasting - PaintingFasil ParuvanathNessuna valutazione finora

- 380K Portable TriGas Analyzer 2014Documento2 pagine380K Portable TriGas Analyzer 2014Arzu Akar100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Changes Contained in Addendum 4 of API 570: Piping Inspection CodeDocumento7 pagineChanges Contained in Addendum 4 of API 570: Piping Inspection CodeabuyiboNessuna valutazione finora

- Corrosion Failure of 4" Pipeline of A Gas Production Well in Egypt Western DesertDocumento7 pagineCorrosion Failure of 4" Pipeline of A Gas Production Well in Egypt Western DesertSEP-PublisherNessuna valutazione finora

- Opel Corsa C Oil Filter ReplacementDocumento12 pagineOpel Corsa C Oil Filter ReplacementAndrásBakosNessuna valutazione finora

- CY100 Engineering Chemistry Syllabus 2016Documento2 pagineCY100 Engineering Chemistry Syllabus 2016Siju N. AntonyNessuna valutazione finora

- MechDocumento6 pagineMechapi-236544093Nessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- MG ROEWE 350 2010 Service ManualDocumento749 pagineMG ROEWE 350 2010 Service ManualÁlvaro Araúz100% (1)

- Service and Maintenance Manual: ModelDocumento116 pagineService and Maintenance Manual: ModelAdriano Alves SilvaNessuna valutazione finora

- Nef 250 N40 Ent M25-N60-Nef400Documento222 pagineNef 250 N40 Ent M25-N60-Nef400jvega_534120100% (3)

- Air Standard Power CycleDocumento24 pagineAir Standard Power Cycle24sandeep24Nessuna valutazione finora

- Tm2500 Mobile Gas TurbineDocumento2 pagineTm2500 Mobile Gas TurbinegustiramadaniNessuna valutazione finora

- r05312401 Design of Machine ElementsDocumento8 paginer05312401 Design of Machine ElementsSrinivasa Rao GNessuna valutazione finora

- Cbe 202 HW 3Documento2 pagineCbe 202 HW 3김민성Nessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)