Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Table 5.02 - Marshall Mix Design Criteria

Caricato da

Mahesh Kumar sukhadiyaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Table 5.02 - Marshall Mix Design Criteria

Caricato da

Mahesh Kumar sukhadiyaCopyright:

Formati disponibili

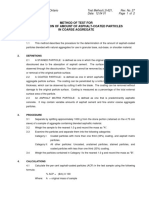

Table 5.

02 - Marshall Mix Design Criteria

(After: "Mix Design Methods", MS-2, 6th Ed. Asphalt Institute, 1993)

Light Traffic2 Medium Traffic2 Heavy Traffic2

Marshall Method Mix

Surface & Base Surface & Base Surface & Base

Criteria1

Min Max Min Max Min Max

Compaction, number of blows

35 50 75

each end of specimen3

N 3336 - 5338 - 8006 -

Stability

(lb.) (750) - (1200) - (1800) -

Flow4, 0.25 mm (0.01 inch) 8 18 8 16 8 14

Percent Air Voids5 3 5 3 5 3 5

Percent Voids in the Mineral

See Table 5.03

Aggregate6 (VMA)

Percent Voids Filled with

Asphalt (VFA)

70 80 65 78 65 75

Notes:

1. All criteria, not just stability value alone, must be considered in designing an asphalt paving mix. Hot mix asphalt bases that do

not meet these criteria when tested at 60C (140F) are satisfactory if they meet the criteria when tested at 38C (100F) and

are placed 100 mm (4 inches) or more below the surface. This recommendation applies only to regions having a range of climatic

conditions similar to those prevailing throughout most of the United States. A different lower test temperature may be

considered in regions having more extreme climatic conditions.

2. Traffic Classifications:

4

Light: Traffic conditions resulting in a Design EAL < 10

4 6

Medium: Traffic conditions resulting in a Design EAL between 10 and 10

6

Heavy: Traffic conditions resulting in a Design EAL > 10

3. Laboratory compaction efforts should closely approach the maximum density obtained in the pavement under traffic.

4. The flow value refers to the point where the load begins to decrease.

5. The portion of asphalt cement lost by absorption into the aggregate particles must be allowed for when calculating percent air

voids.

6. Percent voids in the mineral aggregate is to be calculated on the basis of the ASTM bulk specific gravity for the aggregate.

Potrebbero piacerti anche

- As 3727-1993 Guide To Residential PavementsDocumento6 pagineAs 3727-1993 Guide To Residential PavementsSAI Global - APAC0% (2)

- F1136F1136M 11Documento3 pagineF1136F1136M 11Manuel Antonio Santos Vargas0% (1)

- SDBC Design CalculationsDocumento30 pagineSDBC Design Calculationsakst1976200095% (19)

- Fundamentals of Structural DynamicsDocumento217 pagineFundamentals of Structural DynamicsAndy Garcia100% (8)

- ASTM D6926 Standard Practice For Preparation of Asphalt Mixture Specimens Using Marshall ApparatusDocumento8 pagineASTM D6926 Standard Practice For Preparation of Asphalt Mixture Specimens Using Marshall ApparatusRafael EstradaNessuna valutazione finora

- D6926 - Preparation of Test Specimens Using Marshall HammerDocumento7 pagineD6926 - Preparation of Test Specimens Using Marshall HammerKev Santiago0% (1)

- What Is The Marshall TestDocumento13 pagineWhat Is The Marshall TestQuality ControlNessuna valutazione finora

- Marshall Mix Design MethodDocumento11 pagineMarshall Mix Design MethodAndrea TapingNessuna valutazione finora

- Marshall Method of Mix DesignDocumento6 pagineMarshall Method of Mix DesignfawazNessuna valutazione finora

- FPMTAGChapter10-ThinOverlaysDocumento41 pagineFPMTAGChapter10-ThinOverlayswilliam alachanNessuna valutazione finora

- Recommended Performance Guideline For Chip Seal: NoticeDocumento9 pagineRecommended Performance Guideline For Chip Seal: NoticeAnna KLNessuna valutazione finora

- Aashto M325-2012Documento6 pagineAashto M325-2012Hải LongNessuna valutazione finora

- Preparation of Asphalt Mixture Specimens Using Marshall ApparatusDocumento8 paginePreparation of Asphalt Mixture Specimens Using Marshall ApparatusAnbuchelvan CNessuna valutazione finora

- Superpave Mix Design: Objective of A Mix Design: The Objective Mix Design Is To Select and ProportionDocumento19 pagineSuperpave Mix Design: Objective of A Mix Design: The Objective Mix Design Is To Select and ProportionMohammedAlkhozaiNessuna valutazione finora

- Preparation of Asphalt Mixture Specimens Using Marshall ApparatusDocumento8 paginePreparation of Asphalt Mixture Specimens Using Marshall Apparatussumukh swaroopNessuna valutazione finora

- Chapter 3 - Mix DesignDocumento16 pagineChapter 3 - Mix DesignAbel MulugetaNessuna valutazione finora

- 28 - SuperpaveDocumento10 pagine28 - SuperpaveNagaraj PatilNessuna valutazione finora

- Appendix I. Marshall Stability CriteriaDocumento1 paginaAppendix I. Marshall Stability CriteriaMarl John PinedaNessuna valutazione finora

- Asphalt SpecifictionDocumento11 pagineAsphalt SpecifictionvjtaanmNessuna valutazione finora

- Lec - 8 Mix Design Applications PDFDocumento68 pagineLec - 8 Mix Design Applications PDFAZIMERAWNessuna valutazione finora

- Superpave Mix DesignDocumento7 pagineSuperpave Mix DesignkbgainsanNessuna valutazione finora

- Marshall Mix Design MethodDocumento8 pagineMarshall Mix Design MethodJeffrey James AvenidoNessuna valutazione finora

- Preparation of Asphalt Mixture Specimens Using Marshall ApparatusDocumento7 paginePreparation of Asphalt Mixture Specimens Using Marshall ApparatusAgung Ariefat LubisNessuna valutazione finora

- Long-Term Performance of Cadmium AlternativesDocumento8 pagineLong-Term Performance of Cadmium Alternatives同道文档中心100% (2)

- ASTM D6926 - 2016 - Preparation of Asphalt Mixture Specimens Using Marshall ApparatusDocumento7 pagineASTM D6926 - 2016 - Preparation of Asphalt Mixture Specimens Using Marshall ApparatusTamanna JerinNessuna valutazione finora

- Sma 2005finalDocumento10 pagineSma 2005finalibrahim tanko abeNessuna valutazione finora

- ASTM D2940 Agregates For Base CourseDocumento1 paginaASTM D2940 Agregates For Base Courseتوفيق عبداللهNessuna valutazione finora

- Standard Specifications For Transportation Materials and Methods of Sampling and Testing - Print WindowDocumento13 pagineStandard Specifications For Transportation Materials and Methods of Sampling and Testing - Print WindowrajibchattarajNessuna valutazione finora

- Infineum - API Engine Oil Classifications PDFDocumento12 pagineInfineum - API Engine Oil Classifications PDFAnca DanNessuna valutazione finora

- Section 4 - Chip SealsDocumento18 pagineSection 4 - Chip SealsFranklinNessuna valutazione finora

- Marshall Mix Design GuideDocumento7 pagineMarshall Mix Design GuideMuhsin KhanNessuna valutazione finora

- Recommended Performance Guideline Micro Surfacing: NoticeDocumento17 pagineRecommended Performance Guideline Micro Surfacing: NoticeRaAl GaRuNessuna valutazione finora

- RubberDocumento36 pagineRubbermohanad ghanimNessuna valutazione finora

- Asphalt Lab ReportDocumento12 pagineAsphalt Lab ReportMansueta StefanusNessuna valutazione finora

- FLEX bestDocumento7 pagineFLEX bestBarnababas BeyeneNessuna valutazione finora

- Marshall (Class Handouts)Documento25 pagineMarshall (Class Handouts)usman amirNessuna valutazione finora

- Third Geotech Conf Cairo - Marchetti Keynote on DMT Design AppsDocumento27 pagineThird Geotech Conf Cairo - Marchetti Keynote on DMT Design AppsKaren LealNessuna valutazione finora

- Use of Pavement Wastes (Reclaimed Asphalt Pavement) in Base and Sub-Base Layers of Road ConstructionDocumento11 pagineUse of Pavement Wastes (Reclaimed Asphalt Pavement) in Base and Sub-Base Layers of Road ConstructionSamdhani StrikesNessuna valutazione finora

- Mastic Asphalt Wearing Course SurfacingDocumento18 pagineMastic Asphalt Wearing Course SurfacingSoumitra SengarNessuna valutazione finora

- A105 - Slurry SealDocumento16 pagineA105 - Slurry SealRaAl GaRuNessuna valutazione finora

- Super PaveDocumento20 pagineSuper PaveHashem EL-MaRimeyNessuna valutazione finora

- Awlfair LWDocumento3 pagineAwlfair LWBosunPopaNessuna valutazione finora

- Mix Design SuperpaveDocumento37 pagineMix Design SuperpaveYasruddin MtNessuna valutazione finora

- Minimum Quality Assurance Testing Requirements Hot In-Place Recycled Asphalt Concrete Pavement (Hir)Documento2 pagineMinimum Quality Assurance Testing Requirements Hot In-Place Recycled Asphalt Concrete Pavement (Hir)Sami AjNessuna valutazione finora

- D 2940 - 98 - Rdi5ndatukveDocumento3 pagineD 2940 - 98 - Rdi5ndatukvevinoth kumar SanthanamNessuna valutazione finora

- 2 20071125 Material Test Framework For WMA Trials Dec2006Documento6 pagine2 20071125 Material Test Framework For WMA Trials Dec2006jorge alberto sanchezNessuna valutazione finora

- A143 Revision For PublicatioDocumento17 pagineA143 Revision For PublicatioBlNessuna valutazione finora

- Slurry Seal Issa A105Documento16 pagineSlurry Seal Issa A105Luis Miguel PachecoNessuna valutazione finora

- Norma Slurry SealsDocumento16 pagineNorma Slurry SealsFidelMtzNessuna valutazione finora

- Asphalt Mix DesignDocumento20 pagineAsphalt Mix DesignEmile TabetNessuna valutazione finora

- Cement: A) Brand 2. Aggregates: A) Fine Aggregate B) Coarse Aggregate The Characteristics of Materials Are Given in Table 1 To 3Documento7 pagineCement: A) Brand 2. Aggregates: A) Fine Aggregate B) Coarse Aggregate The Characteristics of Materials Are Given in Table 1 To 3Praneeth KumarNessuna valutazione finora

- Asphalt Concrete Wearing Course Mixture SpecificationDocumento4 pagineAsphalt Concrete Wearing Course Mixture Specificationqadiradnan71770% (1)

- Asphalt Rubber Open Graded Friction Course (AR-OGFCDocumento15 pagineAsphalt Rubber Open Graded Friction Course (AR-OGFCYousef AlipourNessuna valutazione finora

- Remove Preload SubmitDocumento11 pagineRemove Preload SubmitdyaharsyaNessuna valutazione finora

- Effect of Superpave Defined Restricted Zone On Hot Mix Asphalt PerformanceDocumento31 pagineEffect of Superpave Defined Restricted Zone On Hot Mix Asphalt PerformanceZarshad KhanNessuna valutazione finora

- Cold Microsurfacing, A Solution in The Maintenance of Roads With High Level of TrafficDocumento52 pagineCold Microsurfacing, A Solution in The Maintenance of Roads With High Level of Trafficjoe briffaNessuna valutazione finora

- Asphalt Compaction GuideDocumento14 pagineAsphalt Compaction GuideAmir BakhtiarNessuna valutazione finora

- Aashto Pp-14 (2018) Diseño OgfcDocumento9 pagineAashto Pp-14 (2018) Diseño OgfcMario Esteban Solano RodriguezNessuna valutazione finora

- CV301 Mod 3 Asphalt Hot Mix DesignDocumento17 pagineCV301 Mod 3 Asphalt Hot Mix Designvarunsingh214761Nessuna valutazione finora

- ISSA Microsurfacing A143-2010Documento16 pagineISSA Microsurfacing A143-2010Roger Molero PachecoNessuna valutazione finora

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDa EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNessuna valutazione finora

- Shortcut Methods for Alphabet and Number TestsDocumento8 pagineShortcut Methods for Alphabet and Number TestsMahesh Kumar sukhadiyaNessuna valutazione finora

- 5 Months Study Plan For Prelims 2017 - UnacademyDocumento8 pagine5 Months Study Plan For Prelims 2017 - UnacademyMahesh Kumar sukhadiyaNessuna valutazione finora

- Job MixDocumento38 pagineJob MixRakesh DaveNessuna valutazione finora

- Inverse Power MethodDocumento16 pagineInverse Power MethodDarsHan MoHanNessuna valutazione finora

- Structural Dynamics Prof. P. Banerji Department of Civil Engineering Indian Institute of Technology, Bombay Lecture - 3 Dynamics of SDOF StructureDocumento19 pagineStructural Dynamics Prof. P. Banerji Department of Civil Engineering Indian Institute of Technology, Bombay Lecture - 3 Dynamics of SDOF StructureMahesh Kumar sukhadiyaNessuna valutazione finora

- Applications of Bituminous Emulsions in Road ConstructionDocumento27 pagineApplications of Bituminous Emulsions in Road Constructionravi1625Nessuna valutazione finora

- Evolution of Highway Failures and Their Maintenance: I R J E T (Irjet)Documento11 pagineEvolution of Highway Failures and Their Maintenance: I R J E T (Irjet)Faraz hasan KhanNessuna valutazione finora

- Roads 1Documento42 pagineRoads 1Musiime AlvinNessuna valutazione finora

- Selection and Use of Emulsified Asphalts: Standard Practice ForDocumento4 pagineSelection and Use of Emulsified Asphalts: Standard Practice ForBarkah WidiNessuna valutazione finora

- Guidelines For National Greenhouse Gas Inventories. Volume 2 - EnergyDocumento319 pagineGuidelines For National Greenhouse Gas Inventories. Volume 2 - EnergyEduardo VillacrésNessuna valutazione finora

- List of SA CodesDocumento23 pagineList of SA CodesHenry Jamie Bwerinofa100% (1)

- Use of Waste Plastic in Bituminous RoadsDocumento27 pagineUse of Waste Plastic in Bituminous Roadssachin palNessuna valutazione finora

- 6 Methods For Curing of ConcreteDocumento3 pagine6 Methods For Curing of ConcreteNeetesh KumarNessuna valutazione finora

- Block 06 Bhatwari - SoR - MORTHDocumento70 pagineBlock 06 Bhatwari - SoR - MORTHdaisyNessuna valutazione finora

- Department of Public Works and Highways (DPWH)Documento30 pagineDepartment of Public Works and Highways (DPWH)Dave FederisoNessuna valutazione finora

- IS 1200 Method of Measurement Standard for Construction MaterialsDocumento11 pagineIS 1200 Method of Measurement Standard for Construction MaterialsShantanu DuttaNessuna valutazione finora

- Comparison of Mix Design Methods For Porous Asphalt MixturesDocumento2 pagineComparison of Mix Design Methods For Porous Asphalt MixturesMaureen GalinganNessuna valutazione finora

- FlexiblePavements QCTablesDocumento22 pagineFlexiblePavements QCTablesV Venkata Narayana100% (2)

- IRC specifications and design codesDocumento13 pagineIRC specifications and design codesjndlsmtNessuna valutazione finora

- CRMB DistadvantageDocumento2 pagineCRMB Distadvantageabhishek pathakNessuna valutazione finora

- Understanding Compaction ProblemsDocumento100 pagineUnderstanding Compaction Problemssomesh2727Nessuna valutazione finora

- Astm D 6380-2018Documento4 pagineAstm D 6380-2018Mohammed AliNessuna valutazione finora

- The Delta TC ParameterDocumento5 pagineThe Delta TC ParameterAlfonsoYanaMNessuna valutazione finora

- DPWH Davao Public Projects Costs ListDocumento26 pagineDPWH Davao Public Projects Costs ListDenver KarlNessuna valutazione finora

- Pavements DesignDocumento21 paginePavements DesignRamil S. ArtatesNessuna valutazione finora

- Test Method for Asphalt Coated ParticlesDocumento2 pagineTest Method for Asphalt Coated Particles李思源Nessuna valutazione finora

- World Distribution of BitumenDocumento6 pagineWorld Distribution of BitumenMuhammad Ibrahim SugunNessuna valutazione finora

- Scaqmd Rule 1168Documento18 pagineScaqmd Rule 1168Guillermo Hernández EspinozaNessuna valutazione finora

- Improving Waterproofing WorkmanshipDocumento16 pagineImproving Waterproofing Workmanshipniran_udayangaNessuna valutazione finora

- 2014 - MSC - WMA Vs HMA PDFDocumento159 pagine2014 - MSC - WMA Vs HMA PDFYongliang LiuNessuna valutazione finora

- Chapter 1 - Loading, Unloading, Carriage & Setting Out: Item No. Unit Rate (RS.) DescriptionDocumento38 pagineChapter 1 - Loading, Unloading, Carriage & Setting Out: Item No. Unit Rate (RS.) DescriptionAbhijeet SahuNessuna valutazione finora

- Utilization of Waste Plastic in Manufacturing of Plastic Soil Bricks PDFDocumento6 pagineUtilization of Waste Plastic in Manufacturing of Plastic Soil Bricks PDFcristina100% (1)

- Unit 3 MCQS FinalDocumento49 pagineUnit 3 MCQS FinalAshik M Ali100% (2)

- PR 10037 Canvass SheetDocumento4 paginePR 10037 Canvass SheetjaymarNessuna valutazione finora