Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Design and Implementation of Metallic Waste Collection Robot

Caricato da

Mohd Tanveer AshrafDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Design and Implementation of Metallic Waste Collection Robot

Caricato da

Mohd Tanveer AshrafCopyright:

Formati disponibili

See

discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/265601586

Design and Implementation of Metallic Waste Collection Robot

Conference Paper March 2014

DOI: 10.13140/2.1.3924.4168

CITATIONS READS

0 249

3 authors, including:

Tarek Sobh

University of Bridgeport

332 PUBLICATIONS 721 CITATIONS

SEE PROFILE

All content following this page was uploaded by Tarek Sobh on 14 September 2014.

The user has requested enhancement of the downloaded file.

Design and Implementation of Metallic Waste

Collection Robot

Hesham Alsahafi, Majed Almaleky. Advisor: Prof. Tarek Sobh

Robotics, Intelligent Sensing & Control (RISC) Laboratory,

School of Engineering, University of Bridgeport.

Abstract Software Architecture

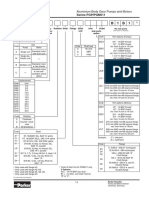

The accumulation of waste has become a problem in urban city dumps. There are The general algorithm has the following

different kinds of waste that affect our environment, for example metallic and plastic steps to accomplish the task, they are

waste. Developing metallic waste collection robotic system is a big challenge. There is start, travel, stop, drop, pickup, and end.

limited research available about robotic systems that specialize in the collection and The program will begin with start step;

processing of waste. In this paper we propose robotic system that can be used for through this step the Arduino Mega will

metallic waste collection and processing. This robot is equipped with a metal detector, run and check for pins and then go to the

ultrasonic sensor, control and power unit, and actuators. This autonomous robot can next step, which is travel. During this

perform tasks such as obstacle avoidance and metal detection. step, the robot moves and utilizes both

the metal detector and IR sensor to

Introduction check for any object. In case the

detector or IR sensor finds an object, the

As a result of the accumulation of metallic waste in recent times, researchers are

robot will stop and then go to the pickup

working to find possible solutions to reduce environmental pollution caused by these

step to pick the object up. After that, the

waste dumps. Some of those solutions are related with robotics, such as Zen Robotic

robot will check if the object is metallic

Recycling, which has multiple sensors for accurate analysis. Based on the analysis, the

object or not by passing it over the metal

robot can make independent decisions to pick up objects from the waste stream. Zen

detector. In case the object is metallic

Robotic Recycling can be used only in recycling factories and some commercial

the robot will go to drop step and drop it

establishments, but it has high-cost and it is non-usable in different environments. We

in box 2 and increment the metallic

decided to design and implement our own metallic waste collection robot. Some of the

counter then check for the limit of

factors considered in this work are cost, size, flexibility, weight, and autonomy. The

metallic object counter. If metallic

purpose of this work is to detect metallic objects in a specific area and pick them up by

counter equal to the limit of metallic

using a robotic arm.

object counter, the robot will go to end

There are different kinds of microcontrollers that can be used as a platform for this

step. Otherwise, the robot will return to

system. These include Arduino, LilyPad, SparkFun and Seeed Studio. Arduino

the travel step till it finds another object.

microcontroller can be programmed using the Arduino programming language. To meet

On the other hand, if object was not

the objective of this work, several sensors such as Ultrasonic sensor, and IR sensor are

metallic, the robot will go to drop step

used. In order for a metallic object to be picked up, the metal detector plays a significant

and drop it in box 1 and increment the

role. There is an IR distance sensor mounted on top of contraption is used in this work

non-metallic object counter then check

for object detection and servomotors that control the movement of robotic arm.

for the limit of non-metallic counter. In

DC motors are also used in this work. The Arduino Motor Shield allows the

case if non-metallic counter equal to the

microcontroller to drive the two-channel DC motor. Speed control is accomplished

limit of non-metallic object counter, the

through conventional PWM, which can be obtained from Arduino PWM output pins. This

robot will go to end step. Otherwise, the

paper has two main sections, which are methodology and experimental results. Section

robot will return to the travel step. Figure

2, methodology, describes hardware and software used on this work. Section 3, shows

3 shows an overview of general

a experimental results this robot.

Figure 3: Operating Algorithm . algorithm.

Experimental Results

Hardware Software

Locomotion Algorithm

Obstcacles

Arm

Avoidance

Metal

Detection

detector

Arm

sensory

movement

control unit

Figure 1: Hardware and Software

Figure 2: Hardware Architecture Design. Figure 4: Drop Metallic Object on Box 2 . Figure 5: Metallic Waste Collection Robot.

Modules.

We have performed different experiments to explain systems ability and its accuracy in

doing the task. Figure 4, 5, 6 show different views of Metallic Waste Collection Robot

Methodology performing the task. We noticed the robot moved forward and then stopped and started

moving the arm smoothly to pick it up, and then passed it over metal detector to check if

This work consists of four modules locomotion, detection, pickup, and control. The the object is metallic or not. After that, the robot dropped the object in metallic object box.

locomotion module is equipped with a transport device for transporting the robotic The result of these experiments showed that the robot succeeded in performing object

vehicle from a start location to a target location. Locomotion module depends on detection, obstacle avoidance, and arm movement. According to the results, the robot

detection module for moving and stopping. In addition, this work is divided into two preformed the required task efficiently.

important sections, hardware and software. Hardware section contains four main

subsections, which are arm, locomotion, metal detector, and control module. While the

software section contains three subsections, which are obstacle avoidance, detection,

and arm movement. Figure 1 shows working sections that are implemented in this

work

Hardware Design

Figure 6: Side view of the Robot. Figure 7: Robots Arm. Figure 8: Control Unit.

The hardware architecture design is shown in Figure 2. Robot consist of five

components Lynx5 Robotic Arm shown in Figure 7, IR Distance Sensor, Arduino

Mega 2500 Microcontroller with Arduino Motor Shield, metal detector, and 4WD1

Conclusion

Robot Rover kit. In this work, we utilized above components and built a re- Our goal was to build a robot that can identify and collect metallic or non-metallic objects

configurable robot. In addition, we designed a contraption and installed it on front of in a specific area. We demonstrated the working of this robotic system using a set of

rover to give the robot enough support for the object collection task. Furthermore, we experiments. Finally, this modular system can be extended to handle different types of

added two boxes on the robot. Box 1 was placed on right side of robot to contain waste.

non-metallic objects. Box 2 was placed on left side of the robot to contain metallic

objects. In this section, we describe hardware components with more details. Figure For more information about this work including working videos, pictures, and code, please

8 shows Arduino mega microcontroller with motor shield that we used to control this visit: www.robobcomes.com

robot .

View publication stats

Potrebbero piacerti anche

- FR-8x Editor Eng01 WDocumento8 pagineFR-8x Editor Eng01 WRadulian Daniel100% (1)

- Gordon NovelDocumento50 pagineGordon NovelNic Hotep100% (2)

- NanorobotsDocumento5 pagineNanorobotsMạc Đăng QuangNessuna valutazione finora

- Design For Manufacturing Course - by DFRDocumento257 pagineDesign For Manufacturing Course - by DFRhlgc63100% (2)

- Pick and Place Robot Report New Edited2Documento19 paginePick and Place Robot Report New Edited2Kshitij BandarNessuna valutazione finora

- Introduction To RoboticsDocumento54 pagineIntroduction To RoboticsEjidokun TemitayoNessuna valutazione finora

- Interface LCD (16X2) To Arduino: Step 1: Hardware ConnectionsDocumento2 pagineInterface LCD (16X2) To Arduino: Step 1: Hardware ConnectionsMohd Tanveer AshrafNessuna valutazione finora

- Human Emotions in Robots Human Emotions in Robots: Presentation by Yash Presentation by YashDocumento26 pagineHuman Emotions in Robots Human Emotions in Robots: Presentation by Yash Presentation by YashYash Sharad MandhareNessuna valutazione finora

- Apqp - DR SHFTDocumento60 pagineApqp - DR SHFTrajesh5000100% (2)

- Autonomous Robot 5Documento5 pagineAutonomous Robot 5Keith KnightNessuna valutazione finora

- Grundfos S Pump 5 - 29 KW Super VortexDocumento20 pagineGrundfos S Pump 5 - 29 KW Super Vortexdalveerchoudhary100% (1)

- Pick and Place Robotic Arm Using Arduino: December 2017Documento7 paginePick and Place Robotic Arm Using Arduino: December 2017visionNessuna valutazione finora

- Ijsetr Vol 6 Issue 12 1568 1573Documento7 pagineIjsetr Vol 6 Issue 12 1568 1573Siddhartha PvpNessuna valutazione finora

- Arduino Project1Documento3 pagineArduino Project1Kristine Barredo0% (1)

- Path Planning Algorithm Development For Autonomous PDFDocumento7 paginePath Planning Algorithm Development For Autonomous PDFIchwan KurniawanNessuna valutazione finora

- Land Mine Detection Robot Using BLE-3.0 Voice Controlled, Using Joystick and Gyroscopic SensorDocumento6 pagineLand Mine Detection Robot Using BLE-3.0 Voice Controlled, Using Joystick and Gyroscopic SensorInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- An Introduction To RoboticsDocumento4 pagineAn Introduction To RoboticsAkash SoniNessuna valutazione finora

- Can Robots Are Changing The World: A Review: International Research Journal of Engineering and Technology (IRJET)Documento7 pagineCan Robots Are Changing The World: A Review: International Research Journal of Engineering and Technology (IRJET)Pavan KumarNessuna valutazione finora

- Project Report FinalDocumento69 pagineProject Report Finalrohitsaini2383% (6)

- Kalb Report - CseDocumento20 pagineKalb Report - CseabrarmuzzammilNessuna valutazione finora

- An Introduction To RoboticsDocumento5 pagineAn Introduction To RoboticsRana PrathapNessuna valutazione finora

- SR211122201836Documento6 pagineSR211122201836Shailesh RanawareNessuna valutazione finora

- LandmineDocumento12 pagineLandmineGech ManNessuna valutazione finora

- Performance Specifications of Industrial RobotDocumento42 paginePerformance Specifications of Industrial RobotKeshav GargNessuna valutazione finora

- Obstacle Detection Robot PDFDocumento2 pagineObstacle Detection Robot PDFJenniferNessuna valutazione finora

- ROADPGCDocumento4 pagineROADPGCE KarunamoorthyNessuna valutazione finora

- Robotics - 2Documento65 pagineRobotics - 2chandansonics06Nessuna valutazione finora

- Tracking A Moving Object With Real-Time Obstacle Avoidance: Research ArticleDocumento9 pagineTracking A Moving Object With Real-Time Obstacle Avoidance: Research ArticleRafael LucasNessuna valutazione finora

- Bluetooth Control Pick and Place Robot Using Arduino IJERTCONV10IS11043Documento3 pagineBluetooth Control Pick and Place Robot Using Arduino IJERTCONV10IS11043Ernest ChiwaleNessuna valutazione finora

- Unit I INTRODUCTION AND ROBOT KINEMATICSDocumento11 pagineUnit I INTRODUCTION AND ROBOT KINEMATICShicet mechhodNessuna valutazione finora

- 9 DR - Mujiarto PaperID SST NOV 2020 1074 FinalRevision1Documento12 pagine9 DR - Mujiarto PaperID SST NOV 2020 1074 FinalRevision1benmesano026Nessuna valutazione finora

- A Review Comparative Analysis of Arduino Micro Controllers in Robotic CarDocumento10 pagineA Review Comparative Analysis of Arduino Micro Controllers in Robotic CarTariq AngelNessuna valutazione finora

- Seminar ReportDocumento18 pagineSeminar ReportCS084Rishav SinghNessuna valutazione finora

- Robotics: EverythingDocumento11 pagineRobotics: Everythingabu saidNessuna valutazione finora

- Sorting of Objects Based On Colour by PiDocumento10 pagineSorting of Objects Based On Colour by PiFarhab Khan FFNessuna valutazione finora

- 2 Obstacle Avoiding Robot PDFDocumento7 pagine2 Obstacle Avoiding Robot PDFRaj AryanNessuna valutazione finora

- Literature Survey 2Documento9 pagineLiterature Survey 2AnshNessuna valutazione finora

- Tree ClimbingDocumento37 pagineTree ClimbingJeevan Landge PatilNessuna valutazione finora

- Path Planning of Mobile Agents Using Ai TechniqueDocumento64 paginePath Planning of Mobile Agents Using Ai TechniqueGautam RaminiNessuna valutazione finora

- Automated Waste Segregator Bin202020Documento10 pagineAutomated Waste Segregator Bin202020MANOJ KNessuna valutazione finora

- Moradi Arian Synthesis Paper-1Documento21 pagineMoradi Arian Synthesis Paper-1api-611744595100% (1)

- Seminar ReportDocumento31 pagineSeminar ReportPriyaranjan BeheraNessuna valutazione finora

- RoboticsDocumento120 pagineRoboticsmivanoNessuna valutazione finora

- Robotic Arm With Base Rotation, Elbow and Wrist Motion With Functional Gripper For Pick and Place ApplicationsDocumento3 pagineRobotic Arm With Base Rotation, Elbow and Wrist Motion With Functional Gripper For Pick and Place Applicationsrock starNessuna valutazione finora

- Library Management Robot: Bomble Pranit R. G. Dipika Dr. ShaikhmeeravaliDocumento4 pagineLibrary Management Robot: Bomble Pranit R. G. Dipika Dr. ShaikhmeeravaliAnandu KBNessuna valutazione finora

- Moveit! (ROS Topics) : IEEE Robotics & Automation Magazine March 2012Documento3 pagineMoveit! (ROS Topics) : IEEE Robotics & Automation Magazine March 2012Gaby HayekNessuna valutazione finora

- Glass Cleaner Smart Robot: International Journal of Scientific Research in Science, Engineering and TechnologyDocumento8 pagineGlass Cleaner Smart Robot: International Journal of Scientific Research in Science, Engineering and Technologymsingh231974Nessuna valutazione finora

- Mobile Robotics: (Self Study Report)Documento25 pagineMobile Robotics: (Self Study Report)deepak_vk13Nessuna valutazione finora

- Bio Inspired RoboticsDocumento8 pagineBio Inspired RoboticsmycatalystsNessuna valutazione finora

- Scope of The ProjectDocumento2 pagineScope of The ProjectMuhammad HamzaNessuna valutazione finora

- Pro Yec To Robotic ADocumento4 paginePro Yec To Robotic AAnthony MadezcoNessuna valutazione finora

- Automatic Pick and Place Robotic Arm Vehicle: IjarcceDocumento3 pagineAutomatic Pick and Place Robotic Arm Vehicle: Ijarccebendali nadirNessuna valutazione finora

- Parameter Based Auto-SegregationDocumento2 pagineParameter Based Auto-SegregationInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Wireless Surveillance Robot With Motion Detection and Live Video TransmissionDocumento9 pagineWireless Surveillance Robot With Motion Detection and Live Video TransmissionrajatpreetNessuna valutazione finora

- Swarm Intelligence Based Fire Fighting RobotDocumento6 pagineSwarm Intelligence Based Fire Fighting RobotIJAERS JOURNALNessuna valutazione finora

- DEVELOPMENT OF ROBOTIC ARM USing (1) - 1Documento27 pagineDEVELOPMENT OF ROBOTIC ARM USing (1) - 1Keshav Salgotra CEC208020Nessuna valutazione finora

- Metal and Gas Detecting RobotDocumento8 pagineMetal and Gas Detecting Robotraji hammedNessuna valutazione finora

- Robotics Notes 1Documento19 pagineRobotics Notes 1Dammalapati HarshavardhanNessuna valutazione finora

- Implementation of Ros Navigation Stack On Lego Mindstorms NXT 2.0 RobotDocumento6 pagineImplementation of Ros Navigation Stack On Lego Mindstorms NXT 2.0 RobotwendersoncsdepNessuna valutazione finora

- 504 - Swachh Abhiyan - Door-to-Door Pickup of Household Hazardous WasteDocumento11 pagine504 - Swachh Abhiyan - Door-to-Door Pickup of Household Hazardous WasteSrideviNessuna valutazione finora

- SETR 07: RoboticsDocumento13 pagineSETR 07: RoboticsHoover InstitutionNessuna valutazione finora

- DocumentationDocumento40 pagineDocumentationPurna Suresh PedamalluNessuna valutazione finora

- Zubayer Al Billal Khan Research Engineer, IICT BUET 01913469663Documento43 pagineZubayer Al Billal Khan Research Engineer, IICT BUET 01913469663SELVAKUMAR RNessuna valutazione finora

- AMP Microproject CoDocumento23 pagineAMP Microproject CovvppolycoNessuna valutazione finora

- Ijmerr v3n1 9Documento8 pagineIjmerr v3n1 9KwameOpareNessuna valutazione finora

- Floor Cleaning RobotDocumento2 pagineFloor Cleaning RobotMohd Tanveer AshrafNessuna valutazione finora

- Digest::SHA - Perl Extension For SHA-1/224/256/384/512Documento8 pagineDigest::SHA - Perl Extension For SHA-1/224/256/384/512Mohd Tanveer AshrafNessuna valutazione finora

- ARM Seven Development BoardDocumento3 pagineARM Seven Development BoardMohd Tanveer AshrafNessuna valutazione finora

- Micro ControllerDocumento9 pagineMicro ControllerMohd Tanveer AshrafNessuna valutazione finora

- PCB CNC MachineDocumento2 paginePCB CNC MachineMohd Tanveer AshrafNessuna valutazione finora

- Networking - Interview Questions and Answers Page 3 PDFDocumento3 pagineNetworking - Interview Questions and Answers Page 3 PDFMohd Tanveer AshrafNessuna valutazione finora

- Java TCP Chat - Multiple Client - Java Developers ZoneDocumento5 pagineJava TCP Chat - Multiple Client - Java Developers ZoneMohd Tanveer Ashraf100% (1)

- Cdma Mobile Communication Trainer: Microtek EnterprisesDocumento1 paginaCdma Mobile Communication Trainer: Microtek EnterprisesMohd Tanveer AshrafNessuna valutazione finora

- Build-A-Bard ABB - RFQ-807683Reaprovechamiento Relaves - SR For Cotejado 010A - HVACDocumento18 pagineBuild-A-Bard ABB - RFQ-807683Reaprovechamiento Relaves - SR For Cotejado 010A - HVACchristianNessuna valutazione finora

- SR No Co Name Salutation Person Designation Contact NoDocumento4 pagineSR No Co Name Salutation Person Designation Contact NoAnindya SharmaNessuna valutazione finora

- Advance Logic Activity On CountersDocumento31 pagineAdvance Logic Activity On CountersKrinx BuliganNessuna valutazione finora

- How To Measure MTFDocumento64 pagineHow To Measure MTFamtcorporationNessuna valutazione finora

- Magneto Hydro Dynamics PresentationDocumento19 pagineMagneto Hydro Dynamics PresentationVipul GuptaNessuna valutazione finora

- 03-1 Synchronous Machines 1 DNDocumento25 pagine03-1 Synchronous Machines 1 DNsaif thuraonNessuna valutazione finora

- Solar Pond - Awesome PDFDocumento26 pagineSolar Pond - Awesome PDFKartik MahajanNessuna valutazione finora

- VB Script ReferenceDocumento27 pagineVB Script ReferenceRajkumarNessuna valutazione finora

- Simatic EKB Install 2012-03-08Documento2 pagineSimatic EKB Install 2012-03-08Oton SilvaNessuna valutazione finora

- Eje Delantero BMW F10Documento94 pagineEje Delantero BMW F10Daniel Muñoz SotomayorNessuna valutazione finora

- AI in RobotsDocumento75 pagineAI in RobotsIslam SehsahNessuna valutazione finora

- Acceleration GrpahDocumento14 pagineAcceleration GrpahRAFAEL TORRESNessuna valutazione finora

- PG 511 B 1 B 1: Ordering Code Series PGP/PGM511Documento7 paginePG 511 B 1 B 1: Ordering Code Series PGP/PGM511Four SticksNessuna valutazione finora

- Asme Wec Chapter Annual ReportDocumento12 pagineAsme Wec Chapter Annual ReportManazar HussainNessuna valutazione finora

- Ude My For Business Course ListDocumento51 pagineUde My For Business Course ListShehroz BhuttaNessuna valutazione finora

- The Difference Between The Internet and World Wide WebDocumento3 pagineThe Difference Between The Internet and World Wide WebSonal Jain100% (1)

- Pds 55930Documento2 paginePds 55930ekosuryonoNessuna valutazione finora

- Geotechnical Engineering 1 (RMIT) Course RevisionDocumento53 pagineGeotechnical Engineering 1 (RMIT) Course RevisionSaint123Nessuna valutazione finora

- Solar Module CellDocumento4 pagineSolar Module CellVinod BabhaleNessuna valutazione finora

- HighpuritysealsDocumento6 pagineHighpuritysealstuannhocutNessuna valutazione finora

- Turbin 1Documento27 pagineTurbin 1Durjoy Chakraborty100% (1)

- RT L2 General Examination PaperDocumento4 pagineRT L2 General Examination PaperdaddadNessuna valutazione finora

- IEM PI A401 - ANNEXE - Design & Site ExperienceDocumento5 pagineIEM PI A401 - ANNEXE - Design & Site ExperienceapiplajengilaNessuna valutazione finora

- Module002 LaboratoryExercise002Documento2 pagineModule002 LaboratoryExercise002Joaquin SmithNessuna valutazione finora

- Optimasi Blending Pertalite Dengan Komponen Reformate Di PT. XYZ BalikpapanDocumento7 pagineOptimasi Blending Pertalite Dengan Komponen Reformate Di PT. XYZ BalikpapanFrizki AkbarNessuna valutazione finora