Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Jacketed Reactor Vessel PDF

Caricato da

SH1961Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Jacketed Reactor Vessel PDF

Caricato da

SH1961Copyright:

Formati disponibili

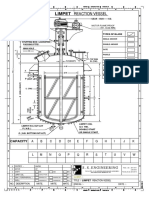

Process Heating Solutions Worldwide

Chemical &

Heat/Cool System

Pharmaceutical

for Jacketed Industry Case History

Reactor Vessel

Application:

Features and Benefits: A company producing photographic

chemicals for the printing industry wanted

Improved Product Quality better temperature control for heating and

cooling a gelatin-based emulsion in 480

Easy Heat/Cool Transition gallon jacketed vessels. A hot water system

Uniform Jacket Temperatures was considered to replace their steam jacket

method. The steam jacket method exposed

Accurate Temperature Control sensitive chemicals to hot spots and made

Total System Design Capability transition to cooling difficult. Batches were

very expensive, making product quality of

and Responsibility utmost importance.

Operating Conditions:

3-23F temperature rise per pass

CUSTOMERS

CASCADE PI PI

RTD 180F jacket temperature

CONTROLLER PUMP

120F product temperature in 1.1 hour

18 PSIG steam supply pressure

CUSTOMERS

JACKETED

Solution:

KETTLE

COOLING

VALVE

ARV

TI

RTD

I

P The Pick 6X7-3HCS Pre-Packaged

TO DRAIN, Heat/Cool System included the basic

COOLING TOWER

OR CHILLED WATER

RESERVOIR

Constant Flow Heater along with a cooling

STEAM

valve for "metered out" control during

PICK

PI VALVE HEATER cooling mode. Steam and cooling valves are

BPRV

I

P

controlled with separate I/P transducers

STEAM taking signal from customer supplied

INLET

cascade temperature controller. Complete

PI

WPCV

PI scope of supply including water circulation

COOLING

WATER

pump, check valves, shut off valves, relief

INLET

valve, piping and fittings assembled on

heavy duty angle iron frame.

AP-C1

730 South Indiana Avenue | West Bend, WI 53095

ph: 262-338-1191 | fax: 262-338-8489 | www.pickheaters.com | info1@pickheaters.com

Potrebbero piacerti anche

- Design Calculations of Pitch Blade TurbineDocumento6 pagineDesign Calculations of Pitch Blade TurbineAyaz_HasanjiNessuna valutazione finora

- Jacketed VesselsDocumento2 pagineJacketed VesselsImamRNNessuna valutazione finora

- Final Energy Balance-Vizag DT 9-6-18Documento6 pagineFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYNessuna valutazione finora

- Calculate Outside Heat Transfr Coeff. For JacketDocumento6 pagineCalculate Outside Heat Transfr Coeff. For JacketSuryakant RanderiNessuna valutazione finora

- Heat Exchanger CalculatorDocumento6 pagineHeat Exchanger CalculatorJM Flores De SilvaNessuna valutazione finora

- Agitated VesselDocumento8 pagineAgitated VesselBharatShethNessuna valutazione finora

- Heat Loss From An Insulated Pipe: ParametersDocumento4 pagineHeat Loss From An Insulated Pipe: ParametersMohan BabuNessuna valutazione finora

- Heat Exchanger Specification Sheet SI UnitsDocumento2 pagineHeat Exchanger Specification Sheet SI UnitssalamrefighNessuna valutazione finora

- He SelectionDocumento7 pagineHe SelectionKaizerNessuna valutazione finora

- TUBESHEETDocumento5 pagineTUBESHEETMehta MehulNessuna valutazione finora

- Condenser Design: Calculation of LMTD: Hot Fluid (Cold Fluid (Difference (Documento5 pagineCondenser Design: Calculation of LMTD: Hot Fluid (Cold Fluid (Difference (Lokesh EmandiNessuna valutazione finora

- DheerajDocumento7 pagineDheerajSaksham KakarNessuna valutazione finora

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocumento8 pagineHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNessuna valutazione finora

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Documento4 pagineSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRINessuna valutazione finora

- Shell Data:: Input Echo, Tubesheet Number 1, Description: Main ShellDocumento8 pagineShell Data:: Input Echo, Tubesheet Number 1, Description: Main ShellAbhishek LadNessuna valutazione finora

- Questionaire For Drum Flaker - NEWDocumento2 pagineQuestionaire For Drum Flaker - NEWBhavin TalatiNessuna valutazione finora

- Determination and Correlation of Heat Transfer Coefficients in A Falling Film Evaporator PDFDocumento7 pagineDetermination and Correlation of Heat Transfer Coefficients in A Falling Film Evaporator PDFGonzaloNessuna valutazione finora

- Grand Prix Engg.: Tag No. 90-EH-02Documento6 pagineGrand Prix Engg.: Tag No. 90-EH-02Abhay UpadhyayNessuna valutazione finora

- Stirred Tank Heat ExchangerDocumento4 pagineStirred Tank Heat ExchangerMiguel OjedaNessuna valutazione finora

- Biomass Storage Capacity - Rev.01Documento5 pagineBiomass Storage Capacity - Rev.01vidyaNessuna valutazione finora

- Limpet Reaction Vessel PDFDocumento1 paginaLimpet Reaction Vessel PDFarajamani78Nessuna valutazione finora

- Multilayer Pressure VesselDocumento9 pagineMultilayer Pressure VesselRaj SharmaNessuna valutazione finora

- Finned Tube Heat ExchangerDocumento3 pagineFinned Tube Heat ExchangerShreya Sahajpal KaushalNessuna valutazione finora

- Einstein - Unified Field Theory of Gravitation & ElectricityDocumento3 pagineEinstein - Unified Field Theory of Gravitation & ElectricityBryan Graczyk50% (2)

- Dimpled Jacket 2Documento4 pagineDimpled Jacket 2grincheu7050% (2)

- Shell and Tube Heat Exchanger Design Using CFD ToolsDocumento4 pagineShell and Tube Heat Exchanger Design Using CFD ToolsChockalingam AthilingamNessuna valutazione finora

- Thermia BDocumento4 pagineThermia Bsofian juniardiNessuna valutazione finora

- Shell and Tube Heat Exchanger Design: Fluid AllocationDocumento6 pagineShell and Tube Heat Exchanger Design: Fluid AllocationLungeloNessuna valutazione finora

- Burner DatasheetDocumento6 pagineBurner DatasheetHafiz Muhammad AbubakarNessuna valutazione finora

- Pressure KG/CM G Temperature °C MOC: Sr. No. Type Material of Construction Item DescriptionDocumento3 paginePressure KG/CM G Temperature °C MOC: Sr. No. Type Material of Construction Item DescriptionDarshan PanchalNessuna valutazione finora

- Boiler Specification 2Documento3 pagineBoiler Specification 2AbdulBasitNessuna valutazione finora

- WI06-0260 Calculations For Obround Nozzle ConnectionsDocumento4 pagineWI06-0260 Calculations For Obround Nozzle ConnectionskumarNessuna valutazione finora

- BoilersDocumento6 pagineBoilersdnageshm4n244Nessuna valutazione finora

- 50T Tank External Heating Coil (Limpet) Calculation: Puma Energy (Australia) Holdings ClientDocumento7 pagine50T Tank External Heating Coil (Limpet) Calculation: Puma Energy (Australia) Holdings ClientArjunNessuna valutazione finora

- 12 PDO Heat TransferDocumento55 pagine12 PDO Heat Transferaxel2100Nessuna valutazione finora

- Propane Storage TankDocumento1 paginaPropane Storage TankMarakanaMaheshNessuna valutazione finora

- Agitator Design 5 PDF FreeDocumento36 pagineAgitator Design 5 PDF FreeMeisam MomeniNessuna valutazione finora

- Standard Design Details KapitolineDocumento359 pagineStandard Design Details KapitolineMohamed100% (2)

- Mean Metal TempsDocumento1 paginaMean Metal TempsThiruppathi RajanNessuna valutazione finora

- Ecway Technologies: Design and Fabrication of Cyclone Seperator Using Vane PumpDocumento9 pagineEcway Technologies: Design and Fabrication of Cyclone Seperator Using Vane Pumpieee4mybusinessonly100% (1)

- KIRK KWM Mist EliminatorsDocumento3 pagineKIRK KWM Mist EliminatorsperrychemNessuna valutazione finora

- PV Elite 2014 Licensee Filename: Rectangular Vessel Rectves Analysis: New Rectangular Item: 1 8:09P Aug 25,2015Documento7 paginePV Elite 2014 Licensee Filename: Rectangular Vessel Rectves Analysis: New Rectangular Item: 1 8:09P Aug 25,2015Pressure VesselNessuna valutazione finora

- Agitated Vessel Heat Transfer PDFDocumento6 pagineAgitated Vessel Heat Transfer PDFMuthuKumar ArunachalamNessuna valutazione finora

- Crossflow Heat Exchanger Ex PDFDocumento5 pagineCrossflow Heat Exchanger Ex PDFprinesst0% (1)

- Hitachi S-4700 InstructionsDocumento19 pagineHitachi S-4700 InstructionssuperheoNessuna valutazione finora

- Bulk Air Eliminator R1Documento1 paginaBulk Air Eliminator R1hydrothermsNessuna valutazione finora

- D 129 Ui 4 ß109 U 51 P 4 Ji 1591243 Uj 1 oDocumento20 pagineD 129 Ui 4 ß109 U 51 P 4 Ji 1591243 Uj 1 orobert2pe10unuNessuna valutazione finora

- 00000-JDS-015 (ERV Manhole) Rev 0Documento10 pagine00000-JDS-015 (ERV Manhole) Rev 0sithulibraNessuna valutazione finora

- Shell and Tube Heat ExchangerDocumento19 pagineShell and Tube Heat ExchangerMangesh MandgeNessuna valutazione finora

- Manual On Chilled Water Pump CalculationsDocumento18 pagineManual On Chilled Water Pump CalculationsImas Mnu AbdNessuna valutazione finora

- Heat Exchanger Specification Sheet US Units: 47,5 InchDocumento1 paginaHeat Exchanger Specification Sheet US Units: 47,5 InchGreisly MarrugoNessuna valutazione finora

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 1.86Da EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 1.86Nessuna valutazione finora

- TS 1-3 en 2014Documento2 pagineTS 1-3 en 2014aljadNessuna valutazione finora

- Case Study & Gains ReportDocumento15 pagineCase Study & Gains ReportManoj SinghNessuna valutazione finora

- Igh Flow: HistoryDocumento2 pagineIgh Flow: HistoryAntonio Carlos ArredondoNessuna valutazione finora

- Ammonia Refrigeration PDFDocumento8 pagineAmmonia Refrigeration PDFducky 99100% (1)

- Aquatherm Hot Water GeneratorDocumento2 pagineAquatherm Hot Water GeneratorNakul AhirraoNessuna valutazione finora

- Heat 029143 1Documento4 pagineHeat 029143 1khairnarsayali257Nessuna valutazione finora

- 1 Air To Water Heating - Cooling Pump - Data SheetDocumento10 pagine1 Air To Water Heating - Cooling Pump - Data Sheetmostafa mNessuna valutazione finora

- InTech-Corrosive Effects of Chlorides On MetalsDocumento41 pagineInTech-Corrosive Effects of Chlorides On MetalsAndrey756Nessuna valutazione finora

- Industrial Shaft Seals - 10919 - 2 EN PDFDocumento488 pagineIndustrial Shaft Seals - 10919 - 2 EN PDFAwan AJaNessuna valutazione finora

- Industrial Shaft Seals - 10919 - 2 EN PDFDocumento488 pagineIndustrial Shaft Seals - 10919 - 2 EN PDFAwan AJaNessuna valutazione finora

- FSA Gasket Handbook - June 2017Documento138 pagineFSA Gasket Handbook - June 2017Dijin MaroliNessuna valutazione finora

- Data SF3300Documento2 pagineData SF3300Ingrid Johhana BalbinNessuna valutazione finora

- 444 StainlessDocumento4 pagine444 StainlessSH1961Nessuna valutazione finora

- Chloride SCC of 316 SSTDocumento5 pagineChloride SCC of 316 SSTSH1961100% (1)

- Velan High Pressure Steam Trapping Brochure PDFDocumento8 pagineVelan High Pressure Steam Trapping Brochure PDFSH1961Nessuna valutazione finora

- FSA Gasket Handbook - June 2017Documento138 pagineFSA Gasket Handbook - June 2017Dijin MaroliNessuna valutazione finora

- 444 StainlessDocumento4 pagine444 StainlessSH1961Nessuna valutazione finora

- Pipe Marking - Full Guide PDFDocumento27 paginePipe Marking - Full Guide PDFSH1961Nessuna valutazione finora

- Non Ferrous MaterialsDocumento8 pagineNon Ferrous MaterialsSH1961Nessuna valutazione finora

- Klinger Gasket FactorsDocumento3 pagineKlinger Gasket FactorsGeorge TanasescuNessuna valutazione finora

- Vba Edelmann Clamp FastenersDocumento2 pagineVba Edelmann Clamp FastenersSH1961Nessuna valutazione finora

- Pickling HandbookDocumento20 paginePickling HandbookRhona100% (1)

- Complete CatalogDocumento52 pagineComplete CatalogrbsaylorsNessuna valutazione finora

- Non Returne ValvesDocumento22 pagineNon Returne ValvesSH1961Nessuna valutazione finora

- Pipe Symbols For Isometric DrawingsDocumento3 paginePipe Symbols For Isometric DrawingsSH1961Nessuna valutazione finora

- Bolt Tightening TorquesDocumento3 pagineBolt Tightening Torquesatanughosh125Nessuna valutazione finora

- Passivating & Pickling Stainless SteelDocumento16 paginePassivating & Pickling Stainless Steelfeki2607Nessuna valutazione finora

- Dynalene HC Engineering GuideDocumento38 pagineDynalene HC Engineering GuideSH1961Nessuna valutazione finora

- Tightening TorquesDocumento4 pagineTightening Torquesflanker76Nessuna valutazione finora

- Lumi GlassDocumento1 paginaLumi GlassSH1961Nessuna valutazione finora

- Corrosion Resistance ofDocumento44 pagineCorrosion Resistance ofalkem7Nessuna valutazione finora

- Carbon Steel Swage Nipples and Bull Plugs: Price Sheet SN-908Documento18 pagineCarbon Steel Swage Nipples and Bull Plugs: Price Sheet SN-908rocknyvNessuna valutazione finora

- Aalco Datasheet ST ST BS enDocumento12 pagineAalco Datasheet ST ST BS enSH1961Nessuna valutazione finora

- Gaskets - Graphite PDFDocumento4 pagineGaskets - Graphite PDFSH1961Nessuna valutazione finora

- Algoma Steel Sheet PDFDocumento10 pagineAlgoma Steel Sheet PDFSH1961Nessuna valutazione finora

- Aalco Datasheet ST ST BS enDocumento2 pagineAalco Datasheet ST ST BS enSalai LokeshNessuna valutazione finora

- Stainless Steel Pressure RatingsDocumento7 pagineStainless Steel Pressure RatingsNauman KhanNessuna valutazione finora

- 2, 3, and 4 Wire RTDs - What Is The Difference - PDFDocumento2 pagine2, 3, and 4 Wire RTDs - What Is The Difference - PDFKelly chatingNessuna valutazione finora

- DCW - Zoomlion Technical Specs of 6m3 Truck Mixer PDFDocumento8 pagineDCW - Zoomlion Technical Specs of 6m3 Truck Mixer PDFjacques Perron0% (1)

- Black Body Radiation-Online NotesDocumento3 pagineBlack Body Radiation-Online NotesNeeraj Mosawa50% (4)

- Heating Coil in The Main Air Handling UnitDocumento15 pagineHeating Coil in The Main Air Handling UnitMohsinShaikh100% (2)

- Chapter 5: The Second Law of Thermodynamics: in A Cyclic ProcessDocumento42 pagineChapter 5: The Second Law of Thermodynamics: in A Cyclic Processأحمد صلاح الدينNessuna valutazione finora

- E.M.C. QuestionsDocumento38 pagineE.M.C. QuestionsJoshnewfound67% (3)

- Work Energy Power G8Documento13 pagineWork Energy Power G8Rodney Lemuel FortunaNessuna valutazione finora

- Maquina de Anestesia Pelon Prima - sp2 - Service - ManualDocumento110 pagineMaquina de Anestesia Pelon Prima - sp2 - Service - Manualperla_canto_1Nessuna valutazione finora

- Siemens Loher Flameproof & Special Designed MotorsDocumento21 pagineSiemens Loher Flameproof & Special Designed Motorspokiri100% (1)

- Rotating Equipment Start Up Operation Maintenance TroubleshootingDocumento4 pagineRotating Equipment Start Up Operation Maintenance TroubleshootingGhulam MurtazaNessuna valutazione finora

- Chemical Kinetics: The Iodine Clock Reaction: J. CortezDocumento6 pagineChemical Kinetics: The Iodine Clock Reaction: J. CortezKyle CortezNessuna valutazione finora

- Hengxin RF Leaky Cable PDFDocumento16 pagineHengxin RF Leaky Cable PDFculeros1Nessuna valutazione finora

- Ptfe HandbookDocumento38 paginePtfe Handbookparthihce100% (1)

- Catalogo BalkampDocumento998 pagineCatalogo BalkampSeal House Sac50% (2)

- Cuna Ge PandaDocumento62 pagineCuna Ge PandaEmilio A Secas100% (1)

- Mitigation of Internal Corrosion in Sour Gas Gathering SystemsDocumento34 pagineMitigation of Internal Corrosion in Sour Gas Gathering SystemsMohamed Wael Zakhama100% (1)

- 3M Ultra 600 Scotchshield - Micro Layered Composite Construction 150 Microns Bomb Resistant Antishatter Film - 60" X 100' Roll SizeDocumento2 pagine3M Ultra 600 Scotchshield - Micro Layered Composite Construction 150 Microns Bomb Resistant Antishatter Film - 60" X 100' Roll Sizeharoon abidNessuna valutazione finora

- .Fabrication of Solar Air Cooler For Remote AreaDocumento4 pagine.Fabrication of Solar Air Cooler For Remote AreaAnonymous Clyy9NNessuna valutazione finora

- Propulsive PowerDocumento13 paginePropulsive PowerWaleedNessuna valutazione finora

- Us8801359 PDFDocumento49 pagineUs8801359 PDFfermeskopNessuna valutazione finora

- Bee PPT-1Documento309 pagineBee PPT-1wondimagegn debebeNessuna valutazione finora

- Gen2 Otis PDFDocumento6 pagineGen2 Otis PDFEng M ElseaidyNessuna valutazione finora

- Literature Review Green MarketingDocumento4 pagineLiterature Review Green Marketingadi2343sh75% (4)

- Mechanics of Pole Vaulting: A Review: Sports Biomechanics June 2010Documento18 pagineMechanics of Pole Vaulting: A Review: Sports Biomechanics June 2010BorypdNessuna valutazione finora

- Spring Summer 2023 Technical Exams ListDocumento10 pagineSpring Summer 2023 Technical Exams ListAshraf BadrNessuna valutazione finora

- IMEC - 07 - 60 - IMEC Members Contact Details List - Updated Version October 2007Documento25 pagineIMEC - 07 - 60 - IMEC Members Contact Details List - Updated Version October 2007elinpetNessuna valutazione finora

- Water Distribution SystemDocumento6 pagineWater Distribution SystemGDELA CRUZ, PRINCEZKHA ANN D.Nessuna valutazione finora

- Elementary Cascade TheoryDocumento3 pagineElementary Cascade Theoryapoorvs75100% (1)

- IEC 61727 1 KW To 3 KWDocumento3 pagineIEC 61727 1 KW To 3 KWChandresh GambhirNessuna valutazione finora

- Centrifugal Compressor Surge and Speed ControlDocumento13 pagineCentrifugal Compressor Surge and Speed ControlDaniel Puello RodeloNessuna valutazione finora