Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

503406-TK4842-A29-0004 - Sub01 - 1KHK015445-AA - Risk Assessment PDF

Caricato da

nsadnanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

503406-TK4842-A29-0004 - Sub01 - 1KHK015445-AA - Risk Assessment PDF

Caricato da

nsadnanCopyright:

Formati disponibili

503406

EMIRATES ALUMINIUM

SMELTER COMPLEX

VENDOR OR SUBVENDORS NAME REVISION DATE VENDORS APPROVAL NAME

ABB Switzerland Ltd. 23.08.2011 Charles Sprli

SUBMITTED FOR : RA (Review) INF (Information) VF (Final)

Equipment Title 220 kV GIS Substation

Tag Nos. N.A.

Purchase Order No. & Title TK 4842 - Phase 1 Extension 220kV GIS

VDR Codes

1 WORK MAY PROCEED

2 REVISE AND RESUBMIT. WORK MAY PROCEED.

SUBJECT TO RESOLUTION OF INDICATED

COMMENTS

3 REVISE AND RESUBMIT. WORK MAY NOT

Vendor's drawing review for conformity with PROCEED

specifications and design drawing.

4 REVIEW NOT REQUIRED OR FOR INFORMATION

This review does not relieve the vendor of his 5 AS BUILT CERTIFIED

responsibility for errors in design and detailing as

detailed in his contract. 6 CANCELLED

Vendor No: 1KHK015445 Rev.: AA Date

received:

Doc. Title: Risk Assessment

Reviewed by: Project: 503406 Emirates Aluminium Smelter Complex

SLII Document No. Submittal

Date: 503406-TK4842-A29-0004 01

Total Number of Pages Including Front Sheet:_8_

Template: 503406-AD0000-37AF-00001_R00 (2011-03-15) 503406-TK4842-A29-0004_Sub01_1KHK015445-AA_Risk Assessment.doc

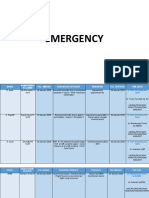

RISK ASSESSMENT FOR INSTALLATION AND COMMISSIONING OF HV PRODUCTS

Project Site: EMAL EXTENSION 2010 Date of Assessment: 23.08.2011

Client: ABB PSS BADEN Assessed by: Charles Sprli

Approved by:

Date of Approval:

Objective is to identify and mitigate risk level to five or below.

1. Hazard Identification 2. Risk Evaluation 3. Risk Control

1a 1b 1c 1d 2a 2b 2c 2d 3a 3b 3c 3d

Revised

Consequence Existing Likely Risk Revised

No. Work Activity Hazard Severity

hood Level

Further Risk Control Action By

Likely hood

Risk

(Possible Accident) Controls / Mitigations Level

1 Journey preparation

1.1 Planning of the journey Travel restrictions, medical No travel approval, illness due to missing Inform yourself about the ABB Travel restriction and 4 2 8 Check list Journey preparation Installation Project 1 4

precautions, special entry regulation vaccinations Travel Security Procedures. 1HC0017384 and Check list Manager

of the host country Clarify with the Institute for Occupational Medicine Construction site preparation

whether medical precations have to be taken 1HC0019577

(vaccination, etc)

2 Travel activities

2.1 Driving with company/ rental car Hazards resulting from unsafe Personal injury Ensure technical and safety of vehicle. Beware of 5 2 10 Making clear that the Supervisor, 1 5

vehicles; traffic rules consumption of alcohol is Commissioning,

Inadequate operational reliability and prohibited. local ABB

roadworthiness of vehicles; Urging drivers to adapt their

Improper behavior on roads. driving to the given situation.

2.2 General travel Failure to have Passport during Potential arrest by Border Patrol at Ensure that documentation is on person daily for 4 2 8 all 1 4

travel to and from site Checkpoint presentation to Border Patrol.

2.3 Traffic accidents Inadequate operational reliability and The danger in these activities are not Ensure technical and safety of vehicle. Beware of 5 2 10 Making clear that the Supervisor, 1 5

roadworthiness of vehicles; assessable, the measures are regarded as traffic rules consumption of alcohol is Commissioning,

Improper behavior on roads. a fundamental precaution. prohibited. local ABB

Urging drivers to adapt their

driving to the given situation.

2.4 Road traffic, ignorance of local Inadequate operational reliability and The danger in these activities are not Check the vehicle's roadworthiness 5 2 10 Supervisor, 1 5

regulations and conditions roadworthiness of vehicles; assessable, the measures are regarded as Ensure the driver's suitability. Commissioning,

Improper behavior on roads. a fundamental precaution. Pay attention to keeping to a light diet on long local ABB

journeys.

3 Local site conditions

3.1 Working outdoors during high Climatic conditions Heat Stress Ensure that acclimatization for working in hot 4 2 8 Eat electrolyte replacing food Individual 1 4

temperatures. environment is allowed. such as fresh fruit and abstain

from the use of caffeine and

alcohol during acclimatization

period.

3.2 Work environment Unawareness of the characteristics Injuries of human body parts Attend training class on hazards specific to the local 4 2 8 Onsite first aid available as are Supervisor, 1 4

at the work place work environment. first aid/CPR trained staff. Commissioning,

local ABB

3.3 Working with electrical equipment Electrical shock, fire and arc flash. Electrocution. death, or tissue damage as Only qualified employees will work near or on electrical 5 4 20 Supervisor, 1 5

and appliances. well as damage of equipment and machine equipment. Use only proper tools that have a current Commissioning,

parts. inspection local ABB

Ensure the ABB Seven Steps are followed.

3.4 Working with other personal Failure to interact with each other Injuries, damage of equipment and Depending on the type of activity, the employer shall 3 4 12 Ensure that adjacent work Supervisor, 1 3

and absence of a Job Hazard machinery. ascertain that the employees of other employers activates and associated risks Commissioning,

Assessment. working nearby have been adequately instructed with are understood. Stay out of non- local ABB

regard to the hazards of each other tasks and ABB work areas.

processes to reduce risk.

3.5 Work with hazardous substances. Exposure that could result in acute or Injuries of human body parts Complete and document hazard communications 4 2 8 Avoid skin contact and inhalation local ABB SM 1 4

chronic effects. training for employees. potential.

Follow operation instruction.

Ensure relevant PPE is used.

3.6 Use of tools Crush, knock, strike, shear, etc. Injuries, damage to equipment an/or parts. Use proper tools that have been inspected Only 5 2 10 All tools must be inspected on a Supervisor, 1 5

qualified and trained employees are allowed to work. quarterly basis and prior to use Commissioning,

by the employee. local ABB, local

Personnel

Template 1HC0054187 E01 AB 1/6 Worksheet: Risk assessment

RISK ASSESSMENT FOR INSTALLATION AND COMMISSIONING OF HV PRODUCTS

Project Site: EMAL EXTENSION 2010 Date of Assessment: 23.08.2011

Client: ABB PSS BADEN Assessed by: Charles Sprli

Approved by:

Date of Approval:

Objective is to identify and mitigate risk level to five or below.

1. Hazard Identification 2. Risk Evaluation 3. Risk Control

1a 1b 1c 1d 2a 2b 2c 2d 3a 3b 3c 3d

Revised

Consequence Existing Likely Risk Revised

No. Work Activity Hazard Severity

hood Level

Further Risk Control Action By

Likely hood

Risk

(Possible Accident) Controls / Mitigations Level

3.7 Work with energized equipment. Electrical shock. Death, burn, deep tissue destruction, bone Ensure the ABB Seven Steps are followed. 5 2 10 Deenergized and ground when Supervisor, 1 5

damage. Damage to equipment Energized parts within working area are insulated. possible. Commissioning,

Ensure relevant PPE is used. Utilise only qualified and trained local ABB

Prohibit unauthorized entry. employees.

Follow operation instruction.

3.8 Overtime working Tiredness Injuries, damage of equipment and Apply and keep proposed time schedule. 4 4 16 Provide of the required day-off Supervisor, 1 4

machinery. time as per labour regulations Commissioning,

local ABB

4 Installation

4.1 Are the employees qualified to do Electrocution Severe injury or death Check qualifications prior to allowing employee to work 5 1 5 None required 1 5

the work? on electrical systems.

4.2 Was proper management Unauthorized and untrained staff Electrocution, death, severe electrical burn. Ensure that approval is obtained from site 4 1 4 None required 1 4

approval secured? working in an unsafe manner Damage to equipment and injury of worker management prio to starting work.

4.3 Is there a description of the circuit Unknown aspects of circuits can lead Electrocution, death, severe electrical burn. Single line must be available for review and use, 5 3 15 Continuous interface with site local ABB SM 1 5

or equipment at the job location? to electrocution Damage to equipment and injury of worker updates required must be reviewed and approved. management and client.

4.4 Is there a detailed job description Encountering energized equipment Electrocution, death, severe electrical burn. All work planned for the day must be reviewed and 4 3 12 Ensure that site management local ABB SM 1 4

of planned work? thought to be dead. Damage to equipment and injury of worker risks assessed, detailed job plan must be updated and installation crew interface

daily. daily.

4.5 Can you justify why equipment Electrocution, death Violation of ABB Electrocution, death, severe electrical burn. Work on energized circuits must be prevented and 5 4 20 Only those employees qualified Supervisor, 1 5

cannot be de-energized or the job policy Damage to equipment and injury of worker when necessary a comprehensive review of the scope to work on energized circuits will Commissioning,

deferred until the next scheduled of the job and safety precautions must be employeed. do so and a job hazard local ABB

outage? Use ABB 7-Steps. assessment will be completed

for each task.

4.6 Were required electrical safety Failure to recognize or understand Electrocution, death, severe electrical burn. An assessment of electrical hazards relative to 3 3 9 A job hazard assessment is 1 3

analyses performed? risks. Damage to equipment and injury of worker ongoing work and adjacent work must be included in required for each task and must

the job hazard assessment. be signed by each employee.

4.7 Were proper tools and equipment Untested tools used conducting Electrocution, death, severe electrical burn. Only tools with a current certificate of testing will be 4 2 8 Only use tools that are Supervisor, 1 4

used? current. Damage to equipment and injury of worker used for high voltage work. appropriate for the task and Commissioning,

have a current certificate of local ABB

testing.

4.8 Staging and installing equipment Crush, knock, strike, shear, etc. Injuries, damage of equipment and machine No transport and lift above persons. 5 2 10 Inform personal about working Supervisor, local 1 5

parts. Crane be qualified and a lift plan current. activity. Follow operation Personnel

All llifting equipment must have a current annual instruction.

inspection and inspected daily. Defect lifting equipment to be

Equipment to be secured against turn over. marked and secured against

Ensure relevant PPE is used. reuse.

Discuss communication between

cranedriver and rigger before

lifting activity.

4.9 Installation of GIS parts Crush, knock, strike, shear, etc. Injuries of human bodyparts, damage of Only qualified and trained employees are allowed to 4 2 8 Inform personal about working Supervisor, local 1 4

equipment and machine parts. work. activity. Follow operation Personnel

Relevant PPE to be used. instruction.

Use the insulated tools when working on or near Only use approved tools and

energized equipment. equipment.

Template 1HC0054187 E01 AB 2/6 Worksheet: Risk assessment

RISK ASSESSMENT FOR INSTALLATION AND COMMISSIONING OF HV PRODUCTS

Project Site: EMAL EXTENSION 2010 Date of Assessment: 23.08.2011

Client: ABB PSS BADEN Assessed by: Charles Sprli

Approved by:

Date of Approval:

Objective is to identify and mitigate risk level to five or below.

1. Hazard Identification 2. Risk Evaluation 3. Risk Control

1a 1b 1c 1d 2a 2b 2c 2d 3a 3b 3c 3d

Revised

Consequence Existing Likely Risk Revised

No. Work Activity Hazard Severity

hood Level

Further Risk Control Action By

Likely hood

Risk

(Possible Accident) Controls / Mitigations Level

4.10 Filling equipment with SF6 gas Release of SF6 gas to the Adverse effect upon the environment Only qualified and trained employees are allowed to 4 1 4 Use recycling equipment to supervisor, local 1 4

environment work. capture the SF6 gas and make Personne,

Relevant PPE to be used. sure that all connections are customer

Use the correct tools. secure and leaks do not occur.

Use only closed cycle system with work SF6 gas.

4.11 Filling equipment with SF6 gas Displacement of air by SF6 gas Risk of asphyxiation Only qualified and trained employees are allowed to 5 1 5 Warn employee by using Supervisor, local 1 5

work. warning signs. Personnel ,

Relevant PPE to be used. Follow operation instruction. customer

Use the correct tools. Prohibit unauthorized entry.

Use only closed cycle system with work SF6 gas.

Generally provide a good air supply of the work space.

Ventilate all basement areas to ensure that a buildup

fo SF6 in lower areas is prevented.

Eating, drinking and smoking in the work area are

prohibited.

4.12 Filling equipment with SF6 gas Exposure to high pressure release Injuries of human bodyparts, damage of Only qualified and trained employees are allowed to 4 2 8 Warn workplace by caution Supervisor, local 1 4

equipment and machine parts. work. label. Personnel

Relevant PPE to be used. Inform personal about working

Use the correct tools. activity.

For filling of equipment follow operation instruction and Check the quality of the

gas layout. pressure hoses.

4.13 Evacuate SF6 gas. Release to the environment Adverse impact to the environment. Only qualified and trained employees are allowed to 4 2 8 Follow operation instruction. Supervisor, local 1 4

work. Inform personal about working Personnel

Relevant PPE to be used. activity.

Use the correct tools.

Use recycling equipment to recycle SF6 and ensure

that charging operations stop when any leak of SF6 is

observed.

4.14 Evacuate SF6 gas. Eliminate air by SF6 gas Risk of suffocation Only qualified and trained employees are allowed to 3 1 3 Warning Workplace by caution Supervisor, local 2 6

work. label. Contaminated objects with Personnel

Relevant PPE to be used. SF6 gas to be separately

Use the correct tools. disposed. Consider operating

Use only closed cycle system with work SF6 gas. instruction.

Ensure that supply ventilation is used in the work area. Follow operation instruction.

Ventilate cavities and more deeply lying areas. Prohibit unauthorized entry.

Eating, drinking and smoking in the work area are

prohibited.

4.15 Evacuate SF6 gas. High pressure Injuries of human bodyparts, damage of Only qualified and trained employees are allowed to 3 2 6 Warn workplace by caution Supervisor, local 1 3

equipment and machine parts. work. label. Personnel

Relevant PPE to be used. Inform personal about working

Use the correct tools. activity.

Check the quality of the

pressure hoses.

Template 1HC0054187 E01 AB 3/6 Worksheet: Risk assessment

RISK ASSESSMENT FOR INSTALLATION AND COMMISSIONING OF HV PRODUCTS

Project Site: EMAL EXTENSION 2010 Date of Assessment: 23.08.2011

Client: ABB PSS BADEN Assessed by: Charles Sprli

Approved by:

Date of Approval:

Objective is to identify and mitigate risk level to five or below.

1. Hazard Identification 2. Risk Evaluation 3. Risk Control

1a 1b 1c 1d 2a 2b 2c 2d 3a 3b 3c 3d

Revised

Consequence Existing Likely Risk Revised

No. Work Activity Hazard Severity

hood Level

Further Risk Control Action By

Likely hood

Risk

(Possible Accident) Controls / Mitigations Level

4.16 Installation of secondary Crush, knock, strike, shear, etc. Injuries, damage of equipment and machine Only qualified and trained employees are allowed to 5 2 10 Relevant PPE to be used. Supervisor, local 1 5

equipment parts. work. Inform personal about working Personnel

Relevant PPE to be used. activity. Follow operation

Use the correct tools. instruction.

Only use approved tools and

equipment.

4.17 Installation of secondary Electrical shock. Injuries, damage of equipment and machine Only qualified and trained employees are allowed to 5 2 10 Follow operation instruction. Supervisor, local 1 5

equipment parts. work. Personnel

Relevant PPE to be used.

Use the correct tools.

4.18 Cabling of equipment. Crush, knock, strike, shear, etc. Injuries, damage of equipment and machine Only qualified and trained employees are allowed to 3 2 6 Relevant PPE to be used. Supervisor, local 2 6

parts. work. Inform personal about working Personnel

Relevant PPE to be used. activity. Follow operation

Use the correct tools. instruction.

Work according cable schedule. Only use approved tools and

equipment.

4.19 Cabling of equipment. Stumble and fall Injuries Cover or barricade all trip/slip fall hazards. 4 2 8 Warn workplace by caution supervisor, local 1 4

When working at heights above six feet, use fall label. Personnel ,

protection. customer

4.20 Earthing of equipment. Crush, knock, strike, shear, etc. Injuries Only qualified and trained employees are allowed to 3 3 9 Follow operation instruction. Supervisor, local 1 3

Exposure to induced voltage work. Working according earthing Personnel

Relevant PPE to be used. schedule.

Use the correct tools.

4.21 Wiring of equipment. Electrical shock. Injuries, damage of equipment and machine Only qualified and trained employees are allowed to 5 2 10 Check drawings, contact Supervisor, local 1 5

parts. work. engineering if problems arise. Personnel

Relevant PPE to be used. Inform personal about working

Use the correct tools. activity.

Work according termination drawing.

4.22 Wiring of equipment. Crush, knock, strike, shear, etc. Injuries Only qualified and trained employees are allowed to 3 3 9 Follow operation instruction. Supervisor, local 1 3

work. Personnel

Relevant PPE to be used.

Use the correct tools.

4.23 Installation of parts Crush, knock, strike, shear, etc. Injuries Only qualified and trained employees are allowed to 4 2 8 Follow operation instruction. Supervisor, local 1 4

work. Inform personal about working Personnel

Relevant PPE to be used. activity.

Use the correct tools.

4.24 Installation of parts Electrical shock. Injuries, damage of equipment and machine Only qualified and trained employees are allowed to 5 2 10 Follow operation instruction. Supervisor, local 1 5

parts. work. Inform personal about working Personnel

Relevant PPE to be used. activity.

Use the correct tools.

4.25 Installation of steel supports. Crush, knock, strike, shear through Injuries, damage of equipment and machine Only qualified and trained employees are allowed to 5 3 15 Working at height use relevant Supervisor, local 1 5

tools and materials. parts. work. safety equipment. Personnel

Relevant PPE to be used.

Use the correct tools.

Use assembly drawing for Installation.

4.26 Insertion of HV cable into GIS Crush, knock, strike, shear, etc. Injuries, damage of equipment and machine Only qualified and trained employees are allowed to 3 3 9 Follow operation instruction. Supervisor, local 1 3

parts. work. Inform personal about working Personnel

Relevant PPE to be used. activity.

Use the correct tools.

5 Commissioning and

HV Test

Template 1HC0054187 E01 AB 4/6 Worksheet: Risk assessment

RISK ASSESSMENT FOR INSTALLATION AND COMMISSIONING OF HV PRODUCTS

Project Site: EMAL EXTENSION 2010 Date of Assessment: 23.08.2011

Client: ABB PSS BADEN Assessed by: Charles Sprli

Approved by:

Date of Approval:

Objective is to identify and mitigate risk level to five or below.

1. Hazard Identification 2. Risk Evaluation 3. Risk Control

1a 1b 1c 1d 2a 2b 2c 2d 3a 3b 3c 3d

Revised

Consequence Existing Likely Risk Revised

No. Work Activity Hazard Severity

hood Level

Further Risk Control Action By

Likely hood

Risk

(Possible Accident) Controls / Mitigations Level

5.1 Are the employees qualified to do Electrocution Severe injury or death Check qualifications prior to allowing employee to work 5 1 5 Check qualifications prior to local ABB 1 5

the work? on electrical systems. allowing employee to work on

electrical systems.

5.2 Is there a description of the circuit Unknown aspects of circuits can lead Damage to equipment and injury of worker Single line must be available for review and use, 5 3 15 Continuous interface with site Commissioning 1 5

or equipment at the job location? to electrocution updates required must be reviewed and approved. management and client.

5.3 Can you justify why equipment Violation of ABB policy and high Severe injury or death Work on energized circuits must be prevented and 5 4 20 Only those employees qualified Commissioning, 1 5

cannot be de-energized or the job potential for contacting energized when necessary a comprehensive review of the scope to work on energized circuits will local ABB SM

deferred until the next scheduled circuits. of the job and safety precautions must be employeed. do so and a job hazard

outage? Use ABB 7-Steps. assessment will be completed

for each task.

5.4 Were required electrical safety Failure to recognize or understand Damage to equipment and injury of worker An assessment of electrical hazards relative to 3 3 9 A job hazard assessment is 1 3

analyses performed? risks. ongoing work and adjacent work must be included in required for each task and must

the job hazard assessment. be signed by each employee.

5.5 Were proper tools and equipment Untested tools used cinducting Damage to equipment and injury of worker Only tools with a current certificate of testing will be 4 2 8 Only use tools that are 1 4

used? current. used for high voltage work. appropriate for the task and

have a current certificate of

testing.

5.6 Was the necessary PPE FR Clothing required to prevent burn Injuries, damage of equipment and machine Arc flash analysis must be completed to determine 4 2 8 Wear FR rated clothing 1 4

determined? from arc flash. parts. appropriate PPE. appropriate for the potential

energy present.

5.7 Visual check of equipment. Crush, knock, strike, shear, etc. Injuries Only use tested and relevant accessories (e.g. ladder 3 3 9 Working at height use relevant Commissioning, 1 3

and steps). safety equipment. local Personnel

Follow commissioning instruction.

5.8 Manual check of equipment. Crush, knock, strike, shear, etc. Injuries, damage of equipment and machine Only qualified and trained employees are allowed to 3 3 9 Inform personal about working Commissioning, 1 4

parts. work. activity. local Personnel

Relevant PPE to be used. Secure and label danger area.

Use the correct tools.

Follow commissioning instruction.

5.9 Installation HV Test equipment, Lifting of heavy test equipment, Injuries, damage of equipment and machine Only qualified and trained employees are allowed to 5 1 5 Working only with work permits HV Test engineer 1 4

site preparation and organisation working in hights . parts. work. for all personell as safety Client's Test

for HV Test. Follow the Safety Instruction for HV Test on site (ABB instruction 1HC0081057 says engineers

Document 1HC0081057)

5.10 HV testing Electrical shock. Injuries, damage of equipment and machine Only qualified and trained employees are allowed to 5 2 10 Follow operation manual and HV Test engineer 1 5

parts. work. testing instruction 1HC0081057 Client's Test

Relevant PPE to be used. Inform personal and site about engineers

Use the correct tools. testing activity.

Secure and label testing and danger area. During testing prohibit

unauthorized entry.

Ensure the five electrical safety

rules are followed.

5.11 Test of secondary equipment. Crush, knock, strike, shear, etc. Injuries, damage of equipment and machine Only qualified and trained employees are allowed to 3 3 9 Inform personal about testing Commissioning, 1 3

parts. work. activity. local Personnel

Relevant PPE to be used. During testing prohibit

Use the correct tools. unauthorized entry.

Follow commissioning instruction.

Secure and label danger area.

Template 1HC0054187 E01 AB 5/6 Worksheet: Risk assessment

RISK ASSESSMENT FOR INSTALLATION AND COMMISSIONING OF HV PRODUCTS

Project Site: EMAL EXTENSION 2010 Date of Assessment: 23.08.2011

Client: ABB PSS BADEN Assessed by: Charles Sprli

Approved by:

Date of Approval:

Objective is to identify and mitigate risk level to five or below.

1. Hazard Identification 2. Risk Evaluation 3. Risk Control

1a 1b 1c 1d 2a 2b 2c 2d 3a 3b 3c 3d

Revised

Consequence Existing Likely Risk Revised

No. Work Activity Hazard Severity

hood Level

Further Risk Control Action By

Likely hood

Risk

(Possible Accident) Controls / Mitigations Level

5.12 Test of secondary equipment. Electrical shock. Injuries, damage of equipment and machine Only qualified and trained employees are allowed to 5 2 10 Inform personal about testing Commissioning, 1 5

parts. work. activity. local Personnel

Relevant PPE to be used. During testing prohibit

Use the correct tools. unauthorized entry.

Follow commissioning instruction. Ensure the five electrical safety

Secure and label danger area. rules are followed.

5.13 Test of secondary equipment. Electrical shock through tools. Injuries, damage of equipment and machine Only qualified and trained employees are allowed to 5 2 10 Follow operation manual and Commissioning, 1 5

parts. work. testing instruction. local Personnel

Relevant PPE to be used.

Use the correct tools.

5.14 CT Testing Electrical shock. Injuries, damage of equipment and machine Only qualified and trained employees are allowed to 2 1 2 during testing keep hands clear Commissioning, 1 2

parts. work. of test leads and voltage source. local Personnel

Relevant PPE to be used.

Use the correct tools.

Follow commissioning instruction.

Secure and label danger area.

5.15 PT Testing Electrical shock. Injuries, damage of equipment and machine Only qualified and trained employees are allowed to 5 2 10 during testing keep hands clear Commissioning, 1 5

parts. work. of test leads and voltage source. local Personnel

Relevant PPE to be used.

Use the correct tools.

Follow commissioning instruction.

Secure and label danger area.

5.17 Test of secondary equipment. Carelessness Injuries, damage of equipment and machine Ensure break and rest time 3 2 6 Follow work schedule. Commissioning, 1 3

parts. Remove source of interference. local Personnel

Template 1HC0054187 E01 AB 6/6 Worksheet: Risk assessment

RISK ASSESSMENT FOR INSTALLATION AND COMMISSIONING OF HV PRODUCTS

Likelyhood

5 1 2 3 3 3

Severity 4 1 2 3 3 3

Severity

3 1 2 2 3 3

2 1 1 2 2 3

1 1 1 1 2 2

1 2 3 4 5

Likelyhood

Risk level 3 1 Risk minimal

Risk level 2 2 Risk akzeptabel

Risk level 1 3 Risk non akzeptabel

Kategorie SEVERITY Definition LIKELYHOOD Definition of likelyhood

5 extremly high death frequently >1 a month

4 high heavy lasting illness occasionally 1 time a month

3 middle light lasting illness rarely 1 time a year

2 small light injury and loss of work improbably 1 time every 5 years

1 low light injury and no loss of work not possibly 1 time every 20 years

SEVERITY

Description Score Definition

Fatal Injury 5 Multiple or single fatality per event

A major fracture of any bone

Loss of limb or eye

Severe Injury 4 Lost of sight or hearing (permanent)

Acute illness requiring medical treatment

Any injury requiring > 30 days off work

Fracture of the hand, wrist, or ankle

Unconsciousness

Major Injury 3 Major burn

Amputation of fingers or toes

Loss of sight or hearing (temporary)

Any injury leading to 3-30 days off work

Fracture of digits

Strains, scratches, cuts and abrasions

Minor burn

Minor Injury 2 General discomfort

Minor occupational related illness

Occupationally induced allergic reaction

Any injury resulting in < 3 days off work

Superficial Injury 1 Very minor or superficial injury where First Aid may be required but no lost

LIKELYHOOD

Description Score Definition

Event is likely to occur if controls are not adequate

Highly likely 5

Possible weekly frequency of occurrence

Likely 4 Event is likely to occur at least once a month

Possible 3 Event could occur at least once every year

Unlikely 2 Expected to occur every few years

Remote 1 Very rare event likely only every 10 years

Table 1: Risk Assessment Matrix

Severity Superficial

Likelihood Fatal Injury Severe Injury Major Injury Minor Injury Injury

High likely 25 20 15 10 5

Likely 20 16 12 8 4

Possible 15 12 9 6 3

Unlikely 10 8 6 4 2

Remote 5 4 3 2 1

Risk factor Interpretation

Risk factor Action and Timescale

Risk Factor = 15, 16,

20 or 25 Work should not be started until the risk has been reduced;

HIGH Considerable resources may have to be allocated to review and investigate the case for removing / reducing the risk or

Where the risk involves work in progress, urgent action should be taken.

Risk Factor = 12, 10,

9 or 8 Efforts should be made to reduce the risk, but the costs of prevention should be carefully measured and limited;

MEDIUM Risk Reduction measures should be implemented within a defined time period.

Risk Factor = 6, 5, 4,

3, 2 or 1 No additional controls are required;

LOW Consideration may be given to a more cost effective solution or improvement that imposes no additional cost burden;

Monitoring is required to ensure that the controls are maintained.

Template 1HC0054187 E01 AB Worksheet: Legende

Potrebbero piacerti anche

- ONVIF Profile Feature Overview v2-2Documento6 pagineONVIF Profile Feature Overview v2-2nsadnanNessuna valutazione finora

- BSIA Cyber Secure It January 2019Documento16 pagineBSIA Cyber Secure It January 2019nsadnanNessuna valutazione finora

- ONVIF Profile T Specification v1-0Documento77 pagineONVIF Profile T Specification v1-0nsadnanNessuna valutazione finora

- Checklist For Access Control System InstallationDocumento6 pagineChecklist For Access Control System Installationnsadnan71% (7)

- Peer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GageDocumento5 paginePeer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GagensadnanNessuna valutazione finora

- ONVIF Profile - S Specification v1-2Documento42 pagineONVIF Profile - S Specification v1-2nsadnan0% (1)

- DDC Systems2Documento28 pagineDDC Systems2nsadnan100% (1)

- Checklist For Pre Commissioning of CCTV SystemDocumento1 paginaChecklist For Pre Commissioning of CCTV Systemnsadnan67% (6)

- 1 45Documento3 pagine1 45nsadnan0% (1)

- Checklist For Commissioning of CCTV SystemDocumento2 pagineChecklist For Commissioning of CCTV Systemnsadnan70% (10)

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocumento6 pagineRISK ASSESSMENT - TK-4742-Operation Training For Overhead CranensadnanNessuna valutazione finora

- CCTV Testing and Commissioning Pre-Check List (ID 1506)Documento1 paginaCCTV Testing and Commissioning Pre-Check List (ID 1506)nsadnan67% (3)

- Testing and Commissioning Pre-Check List (ID 1506)Documento1 paginaTesting and Commissioning Pre-Check List (ID 1506)nsadnan0% (2)

- Excel Intelligent Pdu User InstructionsDocumento2 pagineExcel Intelligent Pdu User InstructionsnsadnanNessuna valutazione finora

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDocumento6 pagineRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- Risk Assessment - Installation of Ventilation FanDocumento6 pagineRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocumento3 pagineRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Documento4 pagineRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNessuna valutazione finora

- Risk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control BuildingDocumento14 pagineRisk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control Buildingnsadnan91% (82)

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Documento3 pagineRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (2)

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Documento3 pagineRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocumento3 pagineRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDocumento9 pagineRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- Risk Assessment For GIS Preparation For HV Cable TestDocumento11 pagineRisk Assessment For GIS Preparation For HV Cable Testnsadnan100% (3)

- Risk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and TestingDocumento12 pagineRisk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and Testingnsadnan100% (1)

- RISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The MaterialsDocumento6 pagineRISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The Materialsnsadnan100% (5)

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDocumento10 pagineRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- Risk Assessment - Distribution Board (DB) & Junction Box (JB) InstallationDocumento6 pagineRisk Assessment - Distribution Board (DB) & Junction Box (JB) Installationnsadnan91% (11)

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Documento4 pagineRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNessuna valutazione finora

- Risk Assessment - Cg-4750-Installation of Lighting Protection Pole, Street Lighting Pole and Light FittingsDocumento6 pagineRisk Assessment - Cg-4750-Installation of Lighting Protection Pole, Street Lighting Pole and Light Fittingsnsadnan86% (21)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- ABC's of Fall Protection: Murray State University Susan MillerDocumento24 pagineABC's of Fall Protection: Murray State University Susan MillerSam SalesNessuna valutazione finora

- Dwitiya SopanDocumento23 pagineDwitiya SopanMallikarjunPatil86% (14)

- Ersonal Rotective Quipment: Sequent Scientific LimitedDocumento49 pagineErsonal Rotective Quipment: Sequent Scientific LimitedshyamNessuna valutazione finora

- MensHealth UK TrainLikeaBeastDocumento2 pagineMensHealth UK TrainLikeaBeastGreg Cross BuissonNessuna valutazione finora

- Clippard THNTD Instruction Sheet.Documento2 pagineClippard THNTD Instruction Sheet.John Melanathy IINessuna valutazione finora

- Question Preparation Exam2023-1Documento350 pagineQuestion Preparation Exam2023-1alicNessuna valutazione finora

- Rheumatology 2012 MrcppassDocumento131 pagineRheumatology 2012 MrcppassRaouf Ra'fat Soliman100% (5)

- CHAyDocumento69 pagineCHAyAtfi Mohd RazaliNessuna valutazione finora

- Arthroscopic Debridement and Drilling of Osteochondral Lesions of The TalusDocumento15 pagineArthroscopic Debridement and Drilling of Osteochondral Lesions of The TalusAnonymous kdBDppigENessuna valutazione finora

- 160413162134Documento45 pagine160413162134Vivek SharmaNessuna valutazione finora

- Dermatome Myotome SclerotomeDocumento4 pagineDermatome Myotome SclerotomeAdhya TiaraNessuna valutazione finora

- Whiplash InjuryDocumento25 pagineWhiplash InjuryMarco PeroliNessuna valutazione finora

- Laporan Emergency 2 FebDocumento8 pagineLaporan Emergency 2 FebbisturisevenNessuna valutazione finora

- Manual Muscle Testing of Infants, Toddlers Hal 4-9Documento7 pagineManual Muscle Testing of Infants, Toddlers Hal 4-9deasy100% (1)

- Nama Otot Yang Terlibat Dalam Aktiviti Teh TarikDocumento2 pagineNama Otot Yang Terlibat Dalam Aktiviti Teh TarikKhanz WongNessuna valutazione finora

- Adult Emergency Nurse Protocol HEAD INJURY (Closed)Documento3 pagineAdult Emergency Nurse Protocol HEAD INJURY (Closed)widyadariNessuna valutazione finora

- Dont Be Intimidated by Incident ReportsDocumento2 pagineDont Be Intimidated by Incident ReportsCherie Boulware AkinNessuna valutazione finora

- ICF Codes:: Related To The Reported Activity Limitation or Participation RestrictionsDocumento19 pagineICF Codes:: Related To The Reported Activity Limitation or Participation RestrictionsHONGJYNessuna valutazione finora

- Part CDocumento383 paginePart CTom ReedNessuna valutazione finora

- Electrical Risk Assessment FormDocumento1 paginaElectrical Risk Assessment FormGyogi MitsutaNessuna valutazione finora

- Warmup VolleyballDocumento2 pagineWarmup Volleyballapi-345720435Nessuna valutazione finora

- Grizzly Shaper ManualDocumento64 pagineGrizzly Shaper ManualjoetylorNessuna valutazione finora

- Inguinal HerniaDocumento33 pagineInguinal Herniatianally100% (2)

- Types of Insurance in Construction ContractsDocumento13 pagineTypes of Insurance in Construction ContractsGagana Sandaruwan100% (1)

- Dehisced Surgical Wounds - Medihoney Power Webinar Episode 9Documento42 pagineDehisced Surgical Wounds - Medihoney Power Webinar Episode 9Lynn Paredes MargullisNessuna valutazione finora

- Price Needs Updating, Should We Call The Police?: C M Bleakley, P Glasgow, D C MacauleyDocumento2 paginePrice Needs Updating, Should We Call The Police?: C M Bleakley, P Glasgow, D C MacauleyAna BelchiorNessuna valutazione finora

- Club FootDocumento47 pagineClub FootSujanaNessuna valutazione finora

- O319912v21 - LV 177777 21 LV 319912 21 160992A57N - 201907Documento56 pagineO319912v21 - LV 177777 21 LV 319912 21 160992A57N - 201907thomassolomon111Nessuna valutazione finora

- Skill Jig Saw ManualDocumento40 pagineSkill Jig Saw ManualelchamacoNessuna valutazione finora

- PolytraumaDocumento19 paginePolytraumaSri MahadhanaNessuna valutazione finora