Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

3 - Development of Energy Consumption Norms Fert Ind-Rev1

Caricato da

rvnesari0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

170 visualizzazioni26 pagineThis is a presentation made in Fertilizer sector workshop of BEE/GTZ under 3L program.

Titolo originale

3_Development of Energy Consumption Norms Fert Ind-Rev1

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis is a presentation made in Fertilizer sector workshop of BEE/GTZ under 3L program.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

170 visualizzazioni26 pagine3 - Development of Energy Consumption Norms Fert Ind-Rev1

Caricato da

rvnesariThis is a presentation made in Fertilizer sector workshop of BEE/GTZ under 3L program.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 26

Development of Energy

Consumption Standards/ Norms

for

Ammonia/ Urea Plants for

Implementation of EA-2001

R V Nesari

1st Sept. 2008

Fertilizer Sector Workshop, 1

New Delhi

Energy Conservation Act-2001

Objectives

• Bridging the gap between energy

demand & supply.

• Reducing environmental emissions

through energy saving and

• Reduction in the energy import bill.

• The Act provides the much needed

legal framework and institutional

arrangement for embarking an energy

efficiency drive.

Fertilizer Sector Workshop, 2

New Delhi

Provisions of EA-2001 Act

• Identify Energy intensive sectors of

industries/ establishments and specify as

Designated Consumers of energy.

• Establish and prescribe energy consumption

standards/ norms for Designated

Consumers.

• This study is being conducted for setting up

Energy consumption standards & norms for

Fertilizer Industry specified as one of the

designated consumers.

Fertilizer Sector Workshop, 3

New Delhi

Fertilizer Industry as Designated

Consumer

• Any fertilizer unit having annual energy consumption

equal to or more than 30,000 metric tonnes of oil

equivalent (MTOE) per year.

• Evaluation of energy consumption levels and notification

of norms for specific energy consumption by BEE.

• The limit of annual energy consumption in terms of

MTOE shall be reviewed every three years.

• A high powered technical committee represented by

senior officials/executives from ministry, FAI and

fertilizer units shall be constituted for evaluation of

recommended energy consumption norms.

Fertilizer Sector Workshop, 4

New Delhi

Factors Affecting Energy Consumption in

Fertilizer Industry

• Diversified technologies,

• Variety of raw materials/ feedstock,

• Fuel characteristics,

• Age factor of plants,

• Location,

• Plant capacity & capacity utilization,

• Performance of critical equipment.

Fertilizer Sector Workshop, 5

New Delhi

Broad Activities of Study

1.Categorization/ Groups.

2.Design of the data collection format.

3.Design of the Annual reporting format.

4.Collection and compilation of data.

5.Data analysis for setting up specific energy

consumption standards/ norms.

6. Preparing draft report on Sp. Energy consumption

standards/ norms and discuss with all participating

units and FAI and Govt. representatives through

meetings/ workshops to finalise the norms.

7. Report presentation to High Power Technical

Committee.

Fertilizer Sector Workshop, 6

New Delhi

Fertilizer Industry in India

• Ammonia Plants: 32 No.

• Urea Plants: 31 No.

• DAP based NPK Plants: 12 No.

• ANP Plants: 3 No.

• Sulphuric Acid/ Phosphoric Acid

Plants: 10 No.

• SSP Plants: small scale not likely to fall

under Designated Consumer Category.

Fertilizer Sector Workshop, 7

New Delhi

Ammonia/ Urea Plants

• Controlled price of sale of urea to farmers.

• Fixation of preset energy consumption

norms of individual units for calculating NPS.

• 6 groups of plants based on feed-stock use

and starting year of commercial production

viz. Pre-1992 gas, Post-1992 gas, Pre-1992

Naphtha, Post-1992 Naphtha, FO/ LSHS and

Mixed Feedstock.

Fertilizer Sector Workshop, 8

New Delhi

Gokak Committee Report on Efficient

Energy Levels for Urea Plants

• Committee constituted by GoI in June 2001 to

suggest efficient energy levels based on

prevailing energy norms and norms expected

from modern plants.

• Committee recommended target energy levels

for six groups.

• Committee felt that targets suggested were

relevant as milestones to achieve national goal

of energy conservation.

• Committee View: Major decisions on efficient

energy levels to be taken by BEE to implement

EC Act-2001

Fertilizer Sector Workshop, 9

New Delhi

Energy Norms for NPS-III

• Actual norms fixed for NPS-III are different than

those suggested by Gokak Committee.

• Norms fixed based on historic data of operation

i.e. energy norm for NPS-II or actual specific

energy consumption of 2002-03, whichever is

lower.

• Norms does not take into account energy

conservation potential.

• Norms are more than 5 years old; need a fresh

look.

Fertilizer Sector Workshop, 10

New Delhi

NPS-III Policy Objectives

• Promote usage of most efficient and cheaper

feedstock NG/LNG for urea production.

• Conversion of all non-gas based units to gas (9

units running presently on naphtha/ LSHS)

within 3 years from 1.10.2006.

• Progress on conversion to NG/LNG still slow

due to various constraints including fertilizer

policy faced by units as well as uncertainty of

LNG supply.

Fertilizer Sector Workshop, 11

New Delhi

Comparison of NPS-III Energy Norms

with Actual Sp. Energy Consumption

S. Name of Unit NPS-III 2004-05 2005-06 2006-07

No. Norm,

Gcal/ MT

of urea

1 CFCL-I 5.621 5.709 5.611 5.613

2 CFCL-II 5.678 5.608 5.556 5.603

3 IFFCO-Aonla-I 5.69 5.738 5.618 5.673

4 IFFCO-Aonla-II 5.522 5.544 5.494 5.510

5 IFFCO-Kalol 6.607 6.347 6.179 5.981

6 IFFCO-Ph-I 7.584 7.630 7.433 7.091

Fertilizer Sector Workshop, 12

7 RCF-Thal 6.938 6.477

New Delhi 6.505 6.506

Comparison of NPS-III Energy Norms

with Actual Sp. Energy Consumption

(Contd.)

S. No. Name of Unit NPS-III 2004-05 2005-06 2006-07

Norm,

Gcal/MT

of urea

8 NFL- Vijaipur-I 5.952 5.807 5.795 5.756

9 NFL- Vijaipur-II 5.712 5.464 5.488 5.415

10 KRIBHCO 5.952 5.872 5.902 NA

11 IGFL 5.534 5.43 5.38 5.31

12 NFCL-I 5.712 5.711 5.62 NA

13 TCL 5.417 5.23 5.13 5.18

Fertilizer Sector Workshop, 13

14 GNFC 7.989 7.56

New Delhi 7.45 7.65

Benefits of Developing Energy Norms

• Encouraging efficiency improvement

through benchmarking.

• Adopting newer technologies to reduce

energy losses

• Improving bottom line of Balance Sheet

• Reduction in environmental emissions

(GHGs).

• Key to continual improvements.

Fertilizer Sector Workshop, 14

New Delhi

Questionnaire for Data collection

• A first step towards developing energy

norms

• A draft questionnaire developed for the

data collection was presented in Mumbai

Workshop in May 2008.

• Feedback of the questionnaire contents.

• Modifications required have been done.

• Units to fill in the questionnaire and send

to me/ BEE.

Fertilizer Sector Workshop, 15

New Delhi

Contents of Questionnaire

• General:

1. Name of Unit:

2. Name of Organization:

3. Unit’s Postal Address:

4. Name of CEO/ Contact Person, designation,

communication contact details.

5. Name of Energy Manager

6. Energy Management Policy of Unit

Fertilizer Sector Workshop, 16

New Delhi

Ammonia Plant

1. Daily rated capacity, MTPD:

2. Month and year of commissioning:

3. Month and year of starting commercial production:

4. Feedstock used:

5. Process technology:

a) Front End:

» Desulphurisation:

» Gasification Process

» Gas Purification Process

» CO2 Removal Process

Fertilizer Sector Workshop, 17

New Delhi

Ammonia Plant (contd.)

b) Synthesis:

Loop pressure:

Synthesis Convertor flow: Axial/ Radial/ Axial

radial

c) Purge Gas Hydrogen recovery:

Membrane/ Cryogenic

d) Other related facilities in Ammonia plant: Naphtha

handling/ Cooling Tower/ IA/ IG/ Ammonia storage

and handling

6. PFD with design/ actual material balance at key

points.

Fertilizer Sector Workshop, 18

New Delhi

Ammonia Plant (contd.)

7. Operating data of Energy consumption for last 3

years (earlier 5 years):

Production

Raw materials consumption:

a) Feed

b) Fuel

Steam consumption (import):

Steam Export:

Power Consumption (Captive/ Purchased):

Fertilizer Sector Workshop, 19

New Delhi

Ammonia Plant (contd.)

8. GCV and NCV of feedstock and fuel used.

9. Specific Energy Consumption data:

10. Stream days achieved:

11. Data on Best performance achieved so far:

12. Whether external energy audit carried out?

13. If yes, name of EA organization:

14. Main recommendations made and implemented:

15. Improvements through internal energy audit and suggestions:

16. Major revamps/ retrofitting carried out:

17. Energy saving schemes studied but not implemented with reasons:

18. Next three years’ planning of energy conservation:

Fertilizer Sector Workshop, 20

New Delhi

Urea Plant and Utilities

• Questionnaire contents similar to

Ammonia plant

• CDR unit data (added)

• Utilities:

1. Steam

2. Power

• Details of utilities supplied to other plants

not included in Ammonia and urea plant

operation.

Fertilizer Sector Workshop, 21

New Delhi

Energy Conservation Activities

• Energy Management Policy of Company/

Unit

• Appointment of Energy Manager

• Formation and Functioning of EC Cell

• Encouragement to employees to pass

Energy Auditor/ Energy Manager

Examination; List of EAs/ EMs

• Any other scheme like Suggestion scheme

Fertilizer Sector Workshop, 22

New Delhi

Questionnaire Feedback

• Group Norms instead of Single norm: Yes

• Factors related to Equipment/ machinery and

their operating parameters in Energy

Consumption

• Capacity related: Original or revamped- data for

the plant being operated now.

• Fuel for Boilers- coal/fuel oil/ naphtha etc.

• Use of RLNG or any other gas/ feedstock-

Questionnaire may be modified by EM of Unit

suitably.

Fertilizer Sector Workshop, 23

New Delhi

Questionnaire Feedback

• NCV and GCV values: per NM3 or per SM3

• Energy Consumption for Gas turbines and

WHRB

• Energy factors for utilities like steam,

purchased power

• PFD of Ammonia/ Urea plants with key

parameters- to identify difference in design

and operating parameters which affects

specific energy consumption.

Fertilizer Sector Workshop, 24

New Delhi

Conclusions

• Development of Energy Consumption standards/ norms

for Fertilizer Sector essential to implement Energy

Conservation Act-2001, in spite of various factors and

difficulties.

• Norms considering all factors- group based

• Development through consensus and not by force and

without clashing with existing Govt. policies.

• Cooperation of all Ammonia and Urea Manufacturing

units prerequisite for the success of this execise.

• Units to fill up the questionnaire and send to R V Nesari,

Coordinator for the Study.

• Self Evaluation through BEE software to be developed.

• Encouraging energy conservation and energy efficiency

improvement efforts.

• Benefits to stakeholders and Workshop,

Fertilizer Sector the country. 25

New Delhi

Fertilizer Sector Workshop, 26

New Delhi

Potrebbero piacerti anche

- Wereld Ongelijkheid Rapport 2018Documento300 pagineWereld Ongelijkheid Rapport 2018Chris de Vries100% (1)

- ENERGY 2020 A Strategy For Competitive, Sustainable and Secure Energy.Documento28 pagineENERGY 2020 A Strategy For Competitive, Sustainable and Secure Energy.EKAI CenterNessuna valutazione finora

- Wereld Ongelijkheid Rapport 2018Documento300 pagineWereld Ongelijkheid Rapport 2018Chris de Vries100% (1)

- Biomass Gasifiers For Sustainable EnergyDocumento7 pagineBiomass Gasifiers For Sustainable EnergyrvnesariNessuna valutazione finora

- Gas If Ication State of Art DescriptionDocumento91 pagineGas If Ication State of Art DescriptionrvnesariNessuna valutazione finora

- 1995 AICHE Thiels Failures in Urea Reactor VesselsDocumento22 pagine1995 AICHE Thiels Failures in Urea Reactor VesselsrvnesariNessuna valutazione finora

- Boiler Design and Operation PDFDocumento8 pagineBoiler Design and Operation PDFChungNguyenNessuna valutazione finora

- Role of Education in Energy ConservationDocumento4 pagineRole of Education in Energy ConservationrvnesariNessuna valutazione finora

- Rating The Environmental Impacts of Motor VehiclesDocumento53 pagineRating The Environmental Impacts of Motor VehiclesrvnesariNessuna valutazione finora

- Biomass Energy Data BookDocumento254 pagineBiomass Energy Data BookrvnesariNessuna valutazione finora

- CDM Methodology Booklet - Nov. 12Documento264 pagineCDM Methodology Booklet - Nov. 12rvnesariNessuna valutazione finora

- Design Guidelines For Safety in Piping NetworkDocumento15 pagineDesign Guidelines For Safety in Piping NetworkrvnesariNessuna valutazione finora

- Engineering Design Guideline - HX Rev2Documento24 pagineEngineering Design Guideline - HX Rev2Ashfaq AnwerNessuna valutazione finora

- India Energy Equivalence Matrix PaperDocumento12 pagineIndia Energy Equivalence Matrix Papersatish1992Nessuna valutazione finora

- Waste-heat recovery environmental factorsDocumento7 pagineWaste-heat recovery environmental factorsrvnesariNessuna valutazione finora

- PAT Scheme Drives Energy Efficiency in Cement SectorDocumento44 paginePAT Scheme Drives Energy Efficiency in Cement SectorrvnesariNessuna valutazione finora

- Design Guidelines For Safety in Piping NetworkDocumento15 pagineDesign Guidelines For Safety in Piping NetworkrvnesariNessuna valutazione finora

- The Energy Report-EcofysDocumento4 pagineThe Energy Report-EcofysrvnesariNessuna valutazione finora

- Introduction to India's Fertilizer IndustryDocumento11 pagineIntroduction to India's Fertilizer IndustryrvnesariNessuna valutazione finora

- Introduction to India's Fertilizer IndustryDocumento11 pagineIntroduction to India's Fertilizer IndustryrvnesariNessuna valutazione finora

- PAT Consultation Document - 10jan2011Documento82 paginePAT Consultation Document - 10jan2011suchi.b8611Nessuna valutazione finora

- Glass GuideDocumento121 pagineGlass Guidervnesari100% (1)

- Malaysian Sewerage Guidelines AppendicesDocumento30 pagineMalaysian Sewerage Guidelines AppendicesrvnesariNessuna valutazione finora

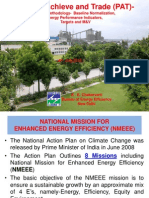

- National Mission For Enhancing Energy EfficiencyDocumento21 pagineNational Mission For Enhancing Energy EfficiencyrvnesariNessuna valutazione finora

- Developing A Safety Case OutlineDocumento22 pagineDeveloping A Safety Case OutlinervnesariNessuna valutazione finora

- 1 RCF Ammo V RevampDocumento7 pagine1 RCF Ammo V RevamprvnesariNessuna valutazione finora

- Afa Doha Qatar 1998 Large Capacity Increase in Ammonia and Urea Plants New TrendsDocumento16 pagineAfa Doha Qatar 1998 Large Capacity Increase in Ammonia and Urea Plants New TrendsrvnesariNessuna valutazione finora

- Ammonia Technology TodayDocumento22 pagineAmmonia Technology Todayrvnesari100% (3)

- 2002 Tech Orphan IdesDocumento15 pagine2002 Tech Orphan IdesrvnesariNessuna valutazione finora

- RE Study ReportDocumento207 pagineRE Study ReportrvnesariNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Dimetra Tetra System White PaperDocumento6 pagineDimetra Tetra System White PapermosaababbasNessuna valutazione finora

- 11 EngineDocumento556 pagine11 Enginerumen80100% (3)

- Time Series Forecasting - Project ReportDocumento68 pagineTime Series Forecasting - Project ReportKhursheedKhan50% (2)

- What is a Server ClusterDocumento2 pagineWhat is a Server Clusterfikru tesefayeNessuna valutazione finora

- How To Use Oracle Account Generator For Project Related TransactionsDocumento40 pagineHow To Use Oracle Account Generator For Project Related Transactionsapnambiar88Nessuna valutazione finora

- How to Get Nigeria Passport in 40 StepsDocumento42 pagineHow to Get Nigeria Passport in 40 Stepsgynn100% (1)

- TESA Doorclosers and Door Operators PDFDocumento46 pagineTESA Doorclosers and Door Operators PDFDawood Shaik Abdul CadarNessuna valutazione finora

- A320 21 Air Conditioning SystemDocumento41 pagineA320 21 Air Conditioning SystemBernard Xavier95% (22)

- Research Paper About Cebu PacificDocumento8 pagineResearch Paper About Cebu Pacificwqbdxbvkg100% (1)

- Lecture Notes in Airport Engineering PDFDocumento91 pagineLecture Notes in Airport Engineering PDFMaya RajNessuna valutazione finora

- Imantanout LLGDDocumento4 pagineImantanout LLGDNABILNessuna valutazione finora

- Evoked PotentialsDocumento49 pagineEvoked PotentialsparuNessuna valutazione finora

- ISB - PM - Week 4 - Required Assignment 4.2 - TemplateDocumento2 pagineISB - PM - Week 4 - Required Assignment 4.2 - Templatesriram marinNessuna valutazione finora

- 05 Executive SummaryDocumento2 pagine05 Executive SummaryHanumanth T Raj YashuNessuna valutazione finora

- Computers in Human Behavior: Full Length ArticleDocumento9 pagineComputers in Human Behavior: Full Length Articlenabilla rusdiNessuna valutazione finora

- 136 ADMU V Capulong (Roxas)Documento2 pagine136 ADMU V Capulong (Roxas)Trisha Dela RosaNessuna valutazione finora

- Speaking Telephone RoleplaysDocumento2 pagineSpeaking Telephone RoleplaysremimiguelNessuna valutazione finora

- Employee Training and DevelopmentDocumento33 pagineEmployee Training and DevelopmentMoogii50% (2)

- Optimization TheoryDocumento18 pagineOptimization TheoryDivine Ada PicarNessuna valutazione finora

- z2OrgMgmt FinalSummativeTest LearnersDocumento3 paginez2OrgMgmt FinalSummativeTest LearnersJade ivan parrochaNessuna valutazione finora

- Project On SamsungDocumento39 pagineProject On SamsungAbbas0% (1)

- Introduction To Management: Planning & Goal SettingDocumento31 pagineIntroduction To Management: Planning & Goal SettingMaisarah NorzihanNessuna valutazione finora

- Duratone eDocumento1 paginaDuratone eandreinalicNessuna valutazione finora

- Folic AcidDocumento5 pagineFolic Acidjyoti singhNessuna valutazione finora

- Community Mobilizer (Couple)Documento4 pagineCommunity Mobilizer (Couple)Mohammad Asif AbediNessuna valutazione finora

- Interview Tips 1Documento19 pagineInterview Tips 1mdsd57% (7)

- E.R. Hooton, Tom Cooper - Desert Storm - Volume 2 - Operation Desert Storm and The Coalition Liberation of Kuwait 1991 (Middle East@War) (2021, Helion and CompanyDocumento82 pagineE.R. Hooton, Tom Cooper - Desert Storm - Volume 2 - Operation Desert Storm and The Coalition Liberation of Kuwait 1991 (Middle East@War) (2021, Helion and Companydubie dubs100% (5)

- Individual TaxpayersDocumento3 pagineIndividual TaxpayersJoy Orena100% (2)

- Welding of Cast IronDocumento10 pagineWelding of Cast IronKrishnendu RouthNessuna valutazione finora

- Macroeconomics Canadian 8th Edition Sayre Solutions Manual 1Documento9 pagineMacroeconomics Canadian 8th Edition Sayre Solutions Manual 1tyrone100% (52)