Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Quality-Control Analytical Methods - Homogeneity of Dosing Forms PDF

Caricato da

Ma Lourdes PecundoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Quality-Control Analytical Methods - Homogeneity of Dosing Forms PDF

Caricato da

Ma Lourdes PecundoCopyright:

Formati disponibili

Homogeneity of Dosage Forms

.............................................

Abstract Content uniformity is the degree of consistency in

Thomas C. Kupiec, PhD the amount of the drug substance among dosage units.There

Nicole Vu, PhD are two ways to determine content uniformity according to

Analytical Research Laboratories

Oklahoma City, Oklahoma

United States Pharmacopeial Chapter <905>; by means of

Content Uniformity or Weight Variation methods. It is essen-

David Branscum tial that compounding pharmacists know the different methods,

Oklahoma University Health-

Science Center how they work, and when to use each method to determine the

Oklahoma City, Oklahoma content uniformity of their individual dosages.

Have you ever made a batch of 100 tablets or capsules and

thought that every one was identical to the next, or did you think to

yourselfclose enough? There is a way for you to confirm that they

are within the United States Pharmacopeial standards for content

uniformity. You just need to know how and when to test your batch.

First and foremost, verifying the uniformity of your compounded

preparations will help ensure the safety and health of the patient,

which is the overall goal of any preparation you are making. This

is a process that needs to be clearly defined so that time and money

are not wasted as a result of doing quality assurance incorrectly.

Oftentimes, pharmacists will weigh out every type of dosage

form to perform their quality check (i.e., Weight Variation (WV)

method). If this is you, keep reading! This is appropriate in some

situations, but there are many situations where this is not the cor-

rect method to establish uniformity. Simply ensuring that each indi-

vidual dosage unit weighs approximately the same in no way means

that the active pharmaceutical ingredient (API) in each unit is equal,

as the blended powder may not be uniform. There can be variability

in the inactive ingredients versus the active drug in each individual

tablet, but the mean average could still show an acceptable weight.

For example, if you are making batches of 200 tablets or 200 cap-

sules and want to verify the contents of each individual dose but are

not sure where to start, then first you need to determine whether

the Content Uniformity (CU) or WV method can be used. Some

questions you should be asking yourself are: Is the tablet coated

or uncoated? Does the API represent 25 mg or greater and more

than 25% of the total weight? Are the capsules hard or soft? These

types of questions and this article will help outline the proper way

to measure the homogeneity of different compounded dosage forms

using CU and WV methods, and when to apply each test.

Responsibilities of Compounding

Pharmacists

Every pharmacist is responsible for the preparations they

compound, as outlined in the United States Pharmacopoeia (USP)

Chapter <1075> Good Compounding Practices, which discusses the

International Journal of Pharmaceutical Compounding www.ijpc.com

340 Vol. 12 No. 4 | July/August 2008

quality control

IJPC

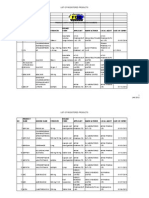

Table 1. Application of Content Uniformity and Weight Variation Tests for

Dosage Forms.1

.......................................................................................................................................................................................................................

Type Subtype Dose and Ratio of Drug

..................................................................................................................................................................

..................................................................................................................................................................

Dosage Form

Substance

25 mg <25 mg

and 25% or <25%

Tablets Uncoated WV CU

Coated Film WV CU

Others CU CU

Capsules Hard WV CU

Soft Suspension, CU CU

emulsion, or

gel

Solutions WV WV

Solids in single-unit containers Single WV WV

component

Multiple Solution WV WV

components freeze-dried in

final container

Others CU CU

Suspension, emulsion, or gel for systemic CU CU

use only, packaged in single-unit containers

WV WV

Solutions for inhalation packaged in glass

or plastic ampuls and intended for use in

nebulizers, and oral solutions packaged in

unit-dose containers and into soft capsules

Inhalations (other than solutions for inhala- CU CU

tion packaged in glass or plastic ampuls and

intended for use in nebulizers) packaged in

premetered dosage units

Transdermal systems CU CU

Suppositories CU CU

Others CU CU

.......................................................................................................................................................................................................................

CU = content uniformity

WV = weight variation

................................................................................................................................................

controls required by compounding pharmacists to ensure identity, ed preparation is usually determined from fewer than the required

strength, quality, and purity. Each step in compounding is critical to number of unit doses that made up the assay sample, and the test

the outcome of the final preparation. Mixing, pH differences, clarity result may not represent the mean potency of a compounded

of components, and capsule weight variation can all contribute to preparation. It is especially critical when the processes involved in

differences in content uniformity.1 compounding have not shown, or the personnel have not demon-

strated, the compounding of a homogeneous preparation. Uni-

formity of a dosage unit is defined by USP Chapter <905> as the

Uniformity of Dosage Units degree of uniformity in the amount of the drug substance among

Conventionally, the mean potency of the API is allowed 10% dosage units.1 The USP has published a set of specific guidelines

deviation from the label claim, and the potency result is derived geared towards the pharmaceutical industry demonstrating two

from testing of a composite mixture of 10 to 20 unit doses. Howev- methodsCU and WVthat can be used to evaluate the unifor-

er, in the compounding environment, the potency for a compound- mity of dosage forms.1

www.IJPC.com International Journal of Pharmaceutical Compounding

Vol. 12 No. 4 | July/August 2008 341

IJPC quality control

FIGURE 1. USP Testing Procedure for dosage unit (lack of homogeneity) and the measurement (analyti-

........................................................................................................................................................................................

cal) error.2 Analytical variation can be minimized during method

Tablets.4 validation to reduce any possible systematic errors. Uniformity is

then determined by calculating the Acceptance Value (AV). The AV

Step 1,

is the limit that the observed mean potency is allowed to deviate

from the label claim. The value of AV is derived from the sum of

two components; (1) the difference between the observed mean and

Test 10 unit doses the reference value, and (2) the width of the tolerance interval.2 So,

accepting or rejecting a batch depends on the width of the tolerance

All 10 unit doses interval and on the shift of the mean from the target value.2 AVs are

> 85% and >115% YES Accept not required for suppositories, transdermal systems, and inhalations

packaged in premetered dosage units.1

RSD > 6%

CU is the test required for the following dosage forms (see

Table 1):1

NO

Transdermal systems (e.g., patches)

Suppositories

1 of 10 unit doses <85% Coated tablets (other than film-coated) containing 25 mg or

or >115% more of a drug of a drug substance that comprises 25% or more

NO Reject (by weight) of one tablet

All 10 unit doses > 75%

Suspension or emulsions or gels in single-unit containers or soft

and >125% capsules that are intended for systemic administration only (not

for those drug products that are intended for topical administra-

tion)

Inhalations (other than solutions for inhalation packaged in glass

or plastic ampules and intended for use in nebulizers) packaged

in premetered dosage units. For inhalers and premetered dosage

Step 2,

YES units labeled for use with a names inhalation device

Solids (including sterile solids) that are packaged in single-unit

containers and contain active or inactive added substances (see

Test additional exceptions for the WV method)

20 unit doses

Use the following general guidelines in evaluating content

uniformity for various dosage forms (see Figure 1):

At most 1 of 30 unit doses NO Reject

<85% or >115% Uncoated, coated, or molded tablets, capsules, oral solutions in

All 30 unit doses >75% unit-dose containers, suspensions or emulsions or gels in single-

and >125%, RSD > 7.8% YES Accept unit containers (that are intended for systemic administration

only), and solids (including sterile solids) in single-unit contain-

........................................................................................................................ ers: If one of the unit doses is not within the required range

RSD = relative standard deviation ( 15% of label claim), then additional dosage units are required

to be tested (20 dosage units).1 Content uniformity is met if all

...................................................................... of the 30 dosage units fall within the 15% range and none are

outside the 25% range.1

Content Uniformity Suppositories: Content uniformity is met if none of the 10 unit

The CU test can be applied in all cases as the gold standard, doses fall outside the 15% range and the relative standard

which uses a specified number of dosages (e.g., 10 unit doses) in an deviation (RSD) is less than or equal to 6%.1 RSD is the sample

assay procedure outlined in each monograph to determine the API standard deviation expressed as a percentage of the mean.1 Also,

content for each unit dose. The CU test is performed in an analyti- uniformity is met if not more than one of the 30 unit doses falls

cal laboratory setting where the contents of each individual dosage outside the 15% range with no individual unit outside the 25%

unit are chemically determined. The method used in content range, and the RSD is not more than 7.8%.1

uniformity testing separates the active from the inactive ingredients Transdermal systems and inhalations packaged in premetered

in each unit dose and evaluates the potency of each active ingredi- dosage units: The additional 20 units must be tested if two units

ent against the reference standard for the respective drugs.1 In the are outside the 15% range or if the RSD is greater than 6%.1

CU method, there are two sources of variation: variability of the For uniformity to be met, not more than 3 dosage units can be

International Journal of Pharmaceutical Compounding www.ijpc.com

342 Vol. 12 No. 4 | July/August 2008

quality control

IJPC

outside the 15% and no dosage unit can be outside the 25% Solids (including sterile solids) that are packaged in single-unit

range, and the RSD cannot exceed 7.8%.1 containers, with or without added substances, whether active

or inactive, that have been prepared from true solutions and

Monograph testing represents the pharmaceutical industry freeze-dried in the final containers and are labeled to indicate

standard and may be very costly to a compounding pharmacy. this method of preparation

Therefore, companies performing the assay may opt to work out an Hard capsules, uncoated tablets, or film-coated tablets, con-

alternative method of quality assurance for evaluating content uni- taining 25 mg or more of a drug substance comprising 25%

formity of compounded preparations. One strategy that a labora- or more, by weight, of the dosage unit or, in the case of hard

tory might employ is that the pharmacist would send in 10 indi- capsules, the capsule contents, except that uniformity of other

vidual unit doses, and the lab would initially use five units to make drug substances present in lesser proportions is demonstrated

a test prep. If the result of the test prep, which represents the batch, by meeting CU requirements.

falls outside the 10% limit for potency, the lab will test additional

five units individually to estimate the AV for content uniformity The following is an example on when to use WV testing:

determination. Laboratories involved in CU testing designed this If you need 25-mg Oxycodone capsules (hard shells), and the total

strategy to make CU testing more available and cost-effective. weight of ingredients is 50 mg, look at table 1 to determine which

The following is an example on when to use CU testing: test is appropriate.

If you need 10-mg Oxycodone capsules (hard shells), and the total 1. You are using capsules (hard shells), so view this row

weight of the ingredients is 20 mg, look at Table 1 to determine 2. Is dose <25 mg? No

which test is appropriate. 3. Is dose <25% of weight of capsule? Determined by 25 mg

divided by total weight of powder in one capsule (50 mg)

1. You are using capsules (hard shells), so view this row. 25 mg/50 mg = 50%. No

2. Is the dose <25 mg? Yes 4. The dose is greater than or equal to 25 mg and greater than

3. Use CU method to determine homogeneity of mixture. 25% of total drug substance; therefore, WV testing is ap-

4. Send 10 unit doses to lab for content uniformity testing. propriate.

5. Use 10 unit doses to determine weight of each individual

Weight Variation capsule and compare AV to USP content uniformity criteria.

WV testing can be done in the pharmacy but should only be

done on the certain unit doses shown in Table 1. There can be

variations from batch to batch due to inadequate mixing or segrega- Conclusion

tion, and even differences in particle size.3 Therefore, it is essential CU and WV methods should be an integral part of compound-

to have a quality-control component to your compounding process. ing to determine the homogeneity of compounded preparations.

In the WV test, 10 dosage units are individually weighed and When applied correctly, content uniformity determination ensures

compared to the percentage of label claim. An AV is calculated as that quality, precision, and safety standards will be met fully. There

in the CU method; except the individual contents are replaced with will always be quality-assurance needs for pharmaceuticals, and

the individual estimated contents based on weight and using assay these guidelines should help in strengthening the future of com-

results of a composite sample derived from 10 unit doses.1 pounding.

WV is the test most often used and misused by pharmacists.

Not that the test is done incorrectly, but it is done on all dosage

units, when it should only be used in certain dosage forms to cor- References

rectly identify the differences in weights of the tablets. When used 1. United States Pharmacopeial Convention, Inc. United States

correctly, this test can be used to determine content uniformity. Pharmacopeia 31National Formulary 26. Rockville, MD: US

Therefore, there are certain conditions and dosage forms in which Pharmacopeial Convention, Inc.; 2007: 101, 363.

quantifying the weight differences can actually determine the per- 2. Banfai B, Ganzler K, Kemny S. Content uniformity and assay

cent differences in the API in the individual dosage units. In some requirements in current regulations. J Chromatogr A 2007;

situations where CU is required, an alternative method is needed 1156(12): 206212.

for ensuring content uniformity, the WV method can be used by 3. Rohrs BR, Amidon GE, Meuri RH et al. Particle size limits to

the pharmacy if the RSD of the concentration per dosage unit (w/w meet USP content uniformity criteria for tablets and capsules.

or w/v) of the drug in the final dosage unit is not more than 2%.1 J Pharm Sci 2006; 95(5): 10491059.

WV methods should be applied to the following dosage forms (see 4. U.S. Food and Drug Administration. Department of Health and

Table 1):1 Human Services. USP Testing Procedure. Slide 13 of 30. [U.S.

Food and Drug Administration Website.] Available at: www.fda.

Solutions for inhalation that are packaged in glass or plastic gov/cder/OPS/scienceboard40902/sld013.htm. Accessed June

ampules and intended for use in nebulizers, and oral solutions 10, 2008.

packaged in unit-dose containers and into soft capsules

......................................................................

Solids (including sterile solids) that are packaged in single-unit Address correspondence to Thomas C. Kupiec, PhD, Analytical

containers and contain no added substances, whether active Research Laboratories, Inc., 840 Research Parkway, Suite 546,

or inactive Oklahoma City, OK 73104. E-mail: tkupiec@arlok.com

www.IJPC.com International Journal of Pharmaceutical Compounding

Vol. 12 No. 4 | July/August 2008 343

Potrebbero piacerti anche

- Quality Control Tests For CapsulesDocumento11 pagineQuality Control Tests For CapsulesM Afan100% (3)

- Calidad de SupositoriosDocumento20 pagineCalidad de SupositoriosFernanda SanchezNessuna valutazione finora

- Bioassay Chapter From BararDocumento13 pagineBioassay Chapter From Bararsameer12584Nessuna valutazione finora

- In Process Quality Control Tests For Pharmaceuticals.Documento17 pagineIn Process Quality Control Tests For Pharmaceuticals.Mankaran Singh100% (13)

- Null 2Documento30 pagineNull 2Sara EltayiebNessuna valutazione finora

- Analytical Method Validation Parameters An Updated Review LAVANYACHOWDARYDocumento8 pagineAnalytical Method Validation Parameters An Updated Review LAVANYACHOWDARYAashish DhawareNessuna valutazione finora

- Pharma Dosage CalculationsDocumento3 paginePharma Dosage CalculationsMaxinne RoseñoNessuna valutazione finora

- Biological Assays: Lecture # 1Documento4 pagineBiological Assays: Lecture # 1Muhammad Abbas Khan JadoonNessuna valutazione finora

- UNIT 05: Reliability: Module OverviewDocumento9 pagineUNIT 05: Reliability: Module OverviewJolly AbellaNessuna valutazione finora

- Dose Equivalents For Antipsychotic DrugsDocumento5 pagineDose Equivalents For Antipsychotic DrugsLorrane NevesNessuna valutazione finora

- Dose Equivalents For Antipsychotic Drugs: The DDD MethodDocumento5 pagineDose Equivalents For Antipsychotic Drugs: The DDD MethodKassandra González BNessuna valutazione finora

- 10282-37930-1-PB ParacetamolDocumento7 pagine10282-37930-1-PB Paracetamolhamam salih badriNessuna valutazione finora

- Invited Review: Sensory Analysis of Dairy Foods: J. Dairy Sci. 90:4925-4937 Doi:10.3168/jds.2007-0332Documento13 pagineInvited Review: Sensory Analysis of Dairy Foods: J. Dairy Sci. 90:4925-4937 Doi:10.3168/jds.2007-0332Beatriz FerreiraNessuna valutazione finora

- Victoria's Heart Rate Design LabDocumento5 pagineVictoria's Heart Rate Design LabVictoria PanNessuna valutazione finora

- Bioavailability and BoequivalenceDocumento47 pagineBioavailability and BoequivalenceSilvyNessuna valutazione finora

- Stage 6 Monograph 25 Feb 2011Documento3 pagineStage 6 Monograph 25 Feb 2011mailtorubal2573Nessuna valutazione finora

- Gordon's Functional Health Patterns Model. The: Assessment Involves Collecting Data That Are UsedDocumento5 pagineGordon's Functional Health Patterns Model. The: Assessment Involves Collecting Data That Are UsedCHINGCHONG SLAYER100% (1)

- Dose Equivalents For Antipsychotic DrugsDocumento5 pagineDose Equivalents For Antipsychotic DrugsrenatoNessuna valutazione finora

- Guidelines On Dissolution Profile Comparison: Udrun ReitagDocumento10 pagineGuidelines On Dissolution Profile Comparison: Udrun ReitagRaju GawadeNessuna valutazione finora

- IVIVC Convolución A. QureshiDocumento10 pagineIVIVC Convolución A. QureshiYonatan Gómez VargasNessuna valutazione finora

- Reliability of Routine Anthropometric Measurements To Estimate Body Composition in Term InfantsDocumento5 pagineReliability of Routine Anthropometric Measurements To Estimate Body Composition in Term InfantsLuana BarrosNessuna valutazione finora

- Dr. Shady Quality Control Pharm D Lecture 1Documento31 pagineDr. Shady Quality Control Pharm D Lecture 1avoice200Nessuna valutazione finora

- 0978-0979 (2091) Weight Variation of Dietary SupplementsDocumento2 pagine0978-0979 (2091) Weight Variation of Dietary Supplementsmelimaulani-1Nessuna valutazione finora

- Assessment of Blend and Content UniformityDocumento14 pagineAssessment of Blend and Content Uniformityshah777100% (1)

- Pharmaceutical Quality ControlDocumento5 paginePharmaceutical Quality ControlAdemola OgundiwinNessuna valutazione finora

- Dose Formulation Analysis NonclinicalDocumento7 pagineDose Formulation Analysis NonclinicaljchapdelainejscNessuna valutazione finora

- Screening and Diagnostic TestsDocumento34 pagineScreening and Diagnostic TestsQuỳnh Anh Phạm HoàngNessuna valutazione finora

- Regulatory Perspectives On Strength-Dependent Dissolution ProfilesDocumento11 pagineRegulatory Perspectives On Strength-Dependent Dissolution ProfilesJminsNessuna valutazione finora

- USP Chapter 1724Documento12 pagineUSP Chapter 1724Daniel Apuan SalviejoNessuna valutazione finora

- In Process Quality Control Pharma PathwayDocumento6 pagineIn Process Quality Control Pharma PathwayDeepakNessuna valutazione finora

- Critical Appraisal of An Article About TherapyDocumento5 pagineCritical Appraisal of An Article About TherapySheila Lyn LacsonNessuna valutazione finora

- In Vivo in Vitro CorrelationDocumento4 pagineIn Vivo in Vitro CorrelationAmira HelayelNessuna valutazione finora

- Calculating and Interpreting Cronbach's Alpha Using Rosenberg Assessment Scale On Paediatrician's Attitude and Perception On Self EsteemDocumento4 pagineCalculating and Interpreting Cronbach's Alpha Using Rosenberg Assessment Scale On Paediatrician's Attitude and Perception On Self EsteemNamrah NaveedNessuna valutazione finora

- FDA's Current Practice and Challenges in The Use of Dissolution Similarity Testing For Demonstration of Bioequivalence - Case StudiesDocumento19 pagineFDA's Current Practice and Challenges in The Use of Dissolution Similarity Testing For Demonstration of Bioequivalence - Case StudiesSrinivas Reddy MaramNessuna valutazione finora

- Biochem LecDocumento2 pagineBiochem LecWinnie Gay UanangNessuna valutazione finora

- Labs and DrugsDocumento10 pagineLabs and DrugsSteven ConejosNessuna valutazione finora

- Formulation of Hypothesis: Nelda Atibagos NacionDocumento7 pagineFormulation of Hypothesis: Nelda Atibagos NacionFerl Diane SiñoNessuna valutazione finora

- Bsn/Nursing Research 2 (NCM 115) : Module # 2Documento5 pagineBsn/Nursing Research 2 (NCM 115) : Module # 2Shane Frances SaborridoNessuna valutazione finora

- Keaslian Penulisan: No Judul Karya Ilmiah & Penulis Variabel Jenis Penelitian HasilDocumento7 pagineKeaslian Penulisan: No Judul Karya Ilmiah & Penulis Variabel Jenis Penelitian HasildonistavoltNessuna valutazione finora

- Jurnal Inovasi Farmasi IndonesiaDocumento7 pagineJurnal Inovasi Farmasi IndonesiaMuhammad Rizki AssaniNessuna valutazione finora

- 1238 2811 1 PBDocumento10 pagine1238 2811 1 PBmarmut imutNessuna valutazione finora

- Health Assessment: Nursing ProcessDocumento7 pagineHealth Assessment: Nursing ProcessAngelrica TumbadoNessuna valutazione finora

- 27 EatingDocumento8 pagine27 EatingpaulaNessuna valutazione finora

- A00-Course Introduction KTDocumento13 pagineA00-Course Introduction KTYussf HassnNessuna valutazione finora

- A Test of The Weight-Based SelDocumento6 pagineA Test of The Weight-Based SelMaria SokoNessuna valutazione finora

- Christina FeistDocumento2 pagineChristina FeistCJ PorrasNessuna valutazione finora

- Biopharmaceutical Classification System: A Strategic Tool For Oral Drug Delivery TechnologyDocumento6 pagineBiopharmaceutical Classification System: A Strategic Tool For Oral Drug Delivery TechnologyAgus PriyonoNessuna valutazione finora

- Biopharmaceutical Classification System: A Strategic Tool For Oral Drug Delivery TechnologyDocumento6 pagineBiopharmaceutical Classification System: A Strategic Tool For Oral Drug Delivery TechnologyHijrawati Ayu WardaniNessuna valutazione finora

- 3-Weight Variation TestDocumento3 pagine3-Weight Variation TestUmair IkhlaqNessuna valutazione finora

- Drug ArithmeticsDocumento7 pagineDrug ArithmeticsKim AmadoNessuna valutazione finora

- Matra KCDocumento8 pagineMatra KCtechnewsfasterNessuna valutazione finora

- College of Nursing and Allied Medical Sciences: WesleyanDocumento4 pagineCollege of Nursing and Allied Medical Sciences: WesleyanPrince Juzzel BanagNessuna valutazione finora

- Hoefelmann Et Al. (2006)Documento6 pagineHoefelmann Et Al. (2006)Sourav ArunNessuna valutazione finora

- PharmaceuticsDocumento12 paginePharmaceuticsKumar GalipellyNessuna valutazione finora

- J Parenter Enteral Nutr - 2021 - Boullata - Parenteral Nutrition Compatibility and Stability A Comprehensive ReviewDocumento27 pagineJ Parenter Enteral Nutr - 2021 - Boullata - Parenteral Nutrition Compatibility and Stability A Comprehensive ReviewSamaria CruzNessuna valutazione finora

- Psyc104 Ni Mars2Documento2 paginePsyc104 Ni Mars2san agustin east agooNessuna valutazione finora

- ACLM-Article-Avoidance of Risky SubstancesDocumento3 pagineACLM-Article-Avoidance of Risky SubstancesMosiah Araújo SilvaNessuna valutazione finora

- Food Research International: Cheryl Chung, Kerstin Olson, Brian Degner, David Julian McclementsDocumento11 pagineFood Research International: Cheryl Chung, Kerstin Olson, Brian Degner, David Julian McclementsDiego AiresNessuna valutazione finora

- Nursing Research Lecture Notes # 5Documento2 pagineNursing Research Lecture Notes # 5Jesamin PacquiaoNessuna valutazione finora

- Flow charts of pharmaceutical quality control tests for different dosage formsDa EverandFlow charts of pharmaceutical quality control tests for different dosage formsNessuna valutazione finora

- Rajini Final Merged ThesisDocumento89 pagineRajini Final Merged ThesispadminiNessuna valutazione finora

- Introduction PharmaceuticsDocumento9 pagineIntroduction PharmaceuticsVIJAY KUMAR TIRUKKACHINessuna valutazione finora

- Las8 DDSDocumento2 pagineLas8 DDSJonille EchevarriaNessuna valutazione finora

- Sue Carson Paracetamol Yoghurt 4Documento24 pagineSue Carson Paracetamol Yoghurt 4dasa_108Nessuna valutazione finora

- 2.0 GPPTEM 2017 Medical Grade PPDocumento40 pagine2.0 GPPTEM 2017 Medical Grade PPngocanh492Nessuna valutazione finora

- Register, 2012Documento233 pagineRegister, 2012Natalia Pika Ambrace0% (1)

- Dosage FormDocumento5 pagineDosage Formqbn9vx7t9jNessuna valutazione finora

- Itm Dosage FormsDocumento15 pagineItm Dosage FormsArun Singh N JNessuna valutazione finora

- Unit 2 Solid and Liquid Dosage Forms: StructureDocumento19 pagineUnit 2 Solid and Liquid Dosage Forms: StructurerajavendranNessuna valutazione finora

- Pharmaceutical Dosage Forms: by S.Bohlooli, PHDDocumento36 paginePharmaceutical Dosage Forms: by S.Bohlooli, PHDvignesh murugesanNessuna valutazione finora

- Stability Considerations For All Dosage Forms of DrugsDocumento3 pagineStability Considerations For All Dosage Forms of DrugsAshraf ShaikhNessuna valutazione finora

- Rb801 Rasashastra and Bhaishajya Kalpana - I 4-0-0-4Documento6 pagineRb801 Rasashastra and Bhaishajya Kalpana - I 4-0-0-4sillypoloNessuna valutazione finora

- Module III For Herbal Extracts Registration in EUDocumento7 pagineModule III For Herbal Extracts Registration in EUAnkush PandeyNessuna valutazione finora

- PEP ExamDocumento18 paginePEP ExamCynthia ObiNessuna valutazione finora

- Formulation, Development and Evaluation of Patient Friendly Dosage Forms of Metformin, Part-II: Oral Soft GelDocumento5 pagineFormulation, Development and Evaluation of Patient Friendly Dosage Forms of Metformin, Part-II: Oral Soft GelkarmumNessuna valutazione finora

- Fasttrack Pharmaceutics Dosage Form and Design PDFDocumento2 pagineFasttrack Pharmaceutics Dosage Form and Design PDFJulianne100% (1)

- Protocol For The Guidance and Recommendation of Document Comp (1) - 1-26Documento26 pagineProtocol For The Guidance and Recommendation of Document Comp (1) - 1-26manoj bhattaraiNessuna valutazione finora

- Guideline On Pharmaceutical Development of Medicines For Paediatric UseDocumento23 pagineGuideline On Pharmaceutical Development of Medicines For Paediatric UseJanssen Cariaga ValdezNessuna valutazione finora

- B.Pharm Semester: IDocumento2 pagineB.Pharm Semester: IkbnarkhedeNessuna valutazione finora

- Controlled Release Technology and Design of Oral Controlled Released Dosage Forms Design and Scale Up of Drag Granulation ProcessDocumento8 pagineControlled Release Technology and Design of Oral Controlled Released Dosage Forms Design and Scale Up of Drag Granulation ProcessYahya IsiedNessuna valutazione finora

- Stage 6 Monograph 25 Feb 2011Documento3 pagineStage 6 Monograph 25 Feb 2011mailtorubal2573Nessuna valutazione finora

- D.Pharma 1st Year New Syllabus 2021 ER20Documento27 pagineD.Pharma 1st Year New Syllabus 2021 ER20AaQib Ali RaZaNessuna valutazione finora

- Dosage FormsDocumento35 pagineDosage FormsHashmaNessuna valutazione finora

- ACIProduct ListDocumento27 pagineACIProduct ListFerdousNessuna valutazione finora

- History of VaccineDocumento17 pagineHistory of VaccineFreekoo NairNessuna valutazione finora

- Usp 1664 Assessment of Drug Product Leachables AssociatedDocumento9 pagineUsp 1664 Assessment of Drug Product Leachables AssociatedChetalee NaikNessuna valutazione finora

- Essential Medicine List (Updated) (Medex - Com.bd)Documento5 pagineEssential Medicine List (Updated) (Medex - Com.bd)Daak ChattalaNessuna valutazione finora

- Ciprofloxacin PDFDocumento20 pagineCiprofloxacin PDFnurvaniNessuna valutazione finora

- Matsui Et Al 2020Documento6 pagineMatsui Et Al 2020Regulatório IndividualNessuna valutazione finora

- Pharmaceutical Dosage FormsDocumento10 paginePharmaceutical Dosage FormsprinceamitNessuna valutazione finora