Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Carboguard 190HB: Selection & Specification Data

Caricato da

Achraf BoudayaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Carboguard 190HB: Selection & Specification Data

Caricato da

Achraf BoudayaCopyright:

Formati disponibili

Carboguard 190HB

Selection & Specification Data Dry Film 4-6 mils (100-150 microns)

Thickness

Generic Type Epoxy-polyamide. Part A and Part B mixed

prior to application.

Solids By Volume

Content CARBOLINE 190 HB 72% 2%

Description CARBOLINE 190 HB can be used over

Carboline inorganic zinc primers.

Particularly recommended as an exterior

Theoretical 25.2 sg. m /I at 25 microns

coating for tank farms and miscellaneous

Coverage 5.04 sq. m/l at 125 microns)

equipment where uniformity of color and

Rate *NOTE: Material losses during mixing and

resistance to salt, alkalies and

application will vary and must be taken into

weathering exposures is required

consideration when estimating job

requirements.

Features CARBOLINE 190 HB has very good

resistance to mild acids and solvents. The

Dry Temp. (non-immersion)

cured film is tough and abrasion resistant.

Resistance Continuous: 200F( 93C)

Non-continuous: 250F(121C)

CHEMICAL RESISTANCE GUIDE :

Exposure Splash and Fumes

Limitations Immersion service, strong acid exposures

Spillage

or areas where chalking is undesirable

Acids Fair Very Good

Chalks upon weathering

Alkalies Excellent Excellent

Solvents Good Very Good

Salt Excellent Excellent Substrates & Surface Preparation

Water Excellent Excellent General Apply over suitably primed metal,

concrete or other surfaces as

FLEXIBILITY: Fair recommended

WEATHERING: Very Good (chalks - result

in fading, most noticeable in dark colors). Steel Apply over clean dry recommended

ABRASION RESISTANCE: Very Good primers.

Concrete

Color Available in a variety of colors. Consult your Apply over clean, dry recommended surfacer

localCarboline representative or Carboline or primer.

Customer Service for availability.

If long term color retention is desired for

esthetic reasons, topcoat with CARBOLINE

134 or other recommended coating.

Application Equipment

CARBOLINE 190 HB Tank Finish, White Listed below are general equipment guidelines for the application of this product. Job

site conditions may require modifications to these guidelines to achieve the desired

0854, is a freely chalking self-cleaning results. General Guidelines:

white product. Consult separate Product

Data Sheet for specific recommendations Spray Remove all oil or grease (rom the surface

Application to be coated with Thinner 2 or Carboline

Primers May be applied directly over inorganic (General) Surface Cleaner 3 (refer to Surface Cleaner

zincs, weathered galvanising, catalyzed 3 Instructions) in accordance with SSPC-

epoxies, phenolics or other coatings as SP 1.

recommended. A mist coat of CARBOLINE

190 HB is recommended when applied over Conventional Use 3/8" minimum I.D. material hose. Hold

inorganic zincs to minimize bubbling. Spray gun approximately 12-14 inches from the

Consult Carboline Technical Service for surface and at a right angle to the surface.

specific recommendations.

Topcoats Normally none. May be topcoated as

recommended to upgrade weathering

resistance, or for higher gloss.

December 2009 replaces December2008

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject to change without prior notice. User must contact Carboline Company to

verify correctness before specifying or ordering. No guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no responsibility for

coverage, performance or injuries resulting from use. Liability, if any, is limited to replacement of products. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE,

EXPRESS OR IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Carboline and Carboguard

are registered trademarks of Carboline Company.

Carboguard 190 HB

Airless Spray Use a 3/8 minimum I.D material hose. Hold preventing the solvent vapor concentration from

gun approximately 18-20 from the surface reaching the lower explosion limit for the solvent

and at a right angle to the surface used. User should test and monitor exposure

levels to insure all personnel are below

guidelines. If not sure or if not able to monitor

Mfr.& gun Pump* levels, use MSHA/NIOSH approved respirator

Binks model 700 B8-36 37: 1

DeVilbiss JGN QFA - 519 Caution This product contains flammable solvents. Keep

510 away from sparks and open flames. All electrical

equipment and installations should be made and

* Teflon packings are recommended and grounded in accordance with the National

are available from pump manufactures. Use Electric Code. In areas where explosion hazards

a 0.017 0.019 tip with 2400 psi exist, workmen should be required to use non-

ferrous tools and wear conductive and non

Brush & Recommended for small areas or touch-up

sparking shoes

Roller only. Avoid rebrushing and rerolling. Use

(General) CARBOLINE Thinner #33 up to 25% by

volume for best results. Two coats may be Application Conditions

required to obtain desired appearance.

Condition Material Surface Ambient Humidiy

Brush Use medium bristle brush or good quality 65-85F 65-85F 60-90F

Normal 65%

short nap roller.. (18-29C) (18-29C) (16-32C)

Roller Recommended for small areas or touch-up Minimum 50F(10C) 50F(10C) 50F (10C) 0%

only. Use good quality short nap roller. 120F

Maximum 90F (32C) 140F(60C) 85%

(49C)

Mixing & Thinning

Mixing & Power mix separately, then combine and Curing Schedule

Ratio mix in the following proportions.

Surface Temp. &

10 ltrs 50% Relative Dry to Recoat Final Cure

set Humidity

CARBOLINE 190 HB Part 5 Ltrs 50F (10C) 3 days 1 week

A 75F (24C) 18 hour 4 days

CARBOLINE 190 HB Part 90F (32C) 10 hours 2 days

5 Ltrs

B

Thinning Thin up to 25% by volume with Packaging, Handling & Storage

CARBOLINE Thinner #15. For hot or windy

Shipping Weight (Approximate)

conditions, use CARBOLINE Thinner #33.

CARBOLINE 190 HB 10 ltrs set ( 15.5 kgs)

NOTE: Use of thinners other than those

Thinner #15 5 ltrs ( 4.4 kgs)

supplied or approved by Carboline may

adversely affect product performance and Thinner #33 5 trs ( 4.5 kgs)

void product warranty, whether express or

implied. Flash Point (Pensky-Martens Closed Cup)

CARBOLINE 190 HB Part A 58F (14C)

Pot Life Eight hours at 75F (24C) and less at CARBOLINE 190 HB Part B 73F (23C)

higher temperatures. Pot life ends when CARBOLINE Thinner # 15 77F (25C)

coating loses body and begins to sag. CARBOLINE Thinner # 33 101F (38C)

Storage Temperature (Store indoors)

& Humidity Temperature: 40-110F (4-43C)

Cleanup & Safety Humidity: 0-100%

Cleanup Use CARBOLINE Thinner # 2

Shelf Life 12 months minimum when stored

Safety Read and follow all caution statements on this at 32C.

product data sheet and on the MSDS for this *Shelf Life: (actual stated shelf life) when kept at recommended

product. Employ normal workmanlike safety storage conditions and in original unopened containers.

precautions. Use adequate ventilation and wear

gloves or use protective cream on face and

hands if hypersensitive. Keep container closed

when not in use.

Ventilation When used in enclosed area, thorough air

circulation must be used during and after

application until the coating is cured. The

ventilation system should be capable of

December 2009 replaces December 2008

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject to change without prior notice. User must contact Carboline Company to

verify correctness before specifying or ordering. No guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no responsibility for

coverage, performance or injuries resulting from use. Liability, if any, is limited to replacement of products. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE,

EXPRESS OR IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Carboline and Carboguard

are registered trademarks of Carboline Company.

Potrebbero piacerti anche

- Series LFII Residential Flush Pendent Sprinklers 4.2 K-FactorDocumento8 pagineSeries LFII Residential Flush Pendent Sprinklers 4.2 K-FactorAchraf BoudayaNessuna valutazione finora

- Series LFII Residential Concealed Pendent Sprinklers, Flat Plate 4.2 K-FactorDocumento4 pagineSeries LFII Residential Concealed Pendent Sprinklers, Flat Plate 4.2 K-FactorAchraf BoudayaNessuna valutazione finora

- Series LFII Residential SprinklersDocumento6 pagineSeries LFII Residential SprinklersAchraf BoudayaNessuna valutazione finora

- Installer Warning!!! Read The Following Cautions Before Handling or Installing Your SprinklersDocumento4 pagineInstaller Warning!!! Read The Following Cautions Before Handling or Installing Your SprinklersAchraf BoudayaNessuna valutazione finora

- Majestic Optima: Technical Data SheetDocumento3 pagineMajestic Optima: Technical Data Sheetaditarian .pNessuna valutazione finora

- Series LFII Residential Horizontal Sidewall Sprinklers 4.2 K-FactorDocumento8 pagineSeries LFII Residential Horizontal Sidewall Sprinklers 4.2 K-FactorAchraf BoudayaNessuna valutazione finora

- Series LFII Residential Pendent Sprinklers 4.9 K-Factor: Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500Documento8 pagineSeries LFII Residential Pendent Sprinklers 4.9 K-Factor: Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500Achraf BoudayaNessuna valutazione finora

- Protect Sprinklers from DamageDocumento4 pagineProtect Sprinklers from DamageAchraf BoudayaNessuna valutazione finora

- Sprinkler Spray PatternsDocumento38 pagineSprinkler Spray PatternsAchraf BoudayaNessuna valutazione finora

- Model G1 & G4 Sprinkler Guards Model G1/S1 & G4/S3 Guards With Shields Series TY-B, TY-FRB, TY-L, and TY-FRL SprinklersDocumento4 pagineModel G1 & G4 Sprinkler Guards Model G1/S1 & G4/S3 Guards With Shields Series TY-B, TY-FRB, TY-L, and TY-FRL SprinklersAchraf BoudayaNessuna valutazione finora

- Recessed Escutcheon Installation GuideDocumento4 pagineRecessed Escutcheon Installation GuideAchraf BoudayaNessuna valutazione finora

- Rociador Ty LDocumento8 pagineRociador Ty LOscar Fernandez SanchezNessuna valutazione finora

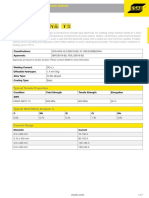

- Esab Pipeweld 6010R: Classifications: ApprovalsDocumento1 paginaEsab Pipeweld 6010R: Classifications: ApprovalsAchraf BoudayaNessuna valutazione finora

- Jotaplast (ID) : Technical Data SheetDocumento3 pagineJotaplast (ID) : Technical Data SheetBilher SihombingNessuna valutazione finora

- Flyer TycoDocumento8 pagineFlyer TycoAchraf BoudayaNessuna valutazione finora

- Energy Absorber Type 32Documento1 paginaEnergy Absorber Type 32Achraf BoudayaNessuna valutazione finora

- Jotashield Flex: Technical Data SheetDocumento3 pagineJotashield Flex: Technical Data SheetAchraf BoudayaNessuna valutazione finora

- Jotashield Extreme: Technical Data SheetDocumento3 pagineJotashield Extreme: Technical Data SheetAchraf BoudayaNessuna valutazione finora

- Weld-On Brackets Type 35Documento1 paginaWeld-On Brackets Type 35Achraf BoudayaNessuna valutazione finora

- Classifications: Approvals:: Typical Tensile PropertiesDocumento1 paginaClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaNessuna valutazione finora

- Classifications: Approvals:: Typical Tensile PropertiesDocumento1 paginaClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaNessuna valutazione finora

- Jotun Essence Easy Clean Matt: Technical Data SheetDocumento3 pagineJotun Essence Easy Clean Matt: Technical Data SheetAchraf BoudayaNessuna valutazione finora

- Classifications: Approvals:: Typical Tensile PropertiesDocumento1 paginaClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaNessuna valutazione finora

- Snubbers Type 30Documento1 paginaSnubbers Type 30Achraf BoudayaNessuna valutazione finora

- Typical Tensile Properties: Classifications: Welding Current: Diffusible Hydrogen: Alloy Type: Coating TypeDocumento1 paginaTypical Tensile Properties: Classifications: Welding Current: Diffusible Hydrogen: Alloy Type: Coating TypeAchraf BoudayaNessuna valutazione finora

- Rigid Struts Type 39Documento1 paginaRigid Struts Type 39Achraf BoudayaNessuna valutazione finora

- Snubbers type 31 absorb heavy loads in nuclear installationsDocumento1 paginaSnubbers type 31 absorb heavy loads in nuclear installationsAchraf BoudayaNessuna valutazione finora

- Telescopic Spring Supports Type 29Documento1 paginaTelescopic Spring Supports Type 29Achraf BoudayaNessuna valutazione finora

- Installation Extensions Type 33Documento1 paginaInstallation Extensions Type 33Achraf BoudayaNessuna valutazione finora

- Sway Braces Type 27Documento1 paginaSway Braces Type 27Achraf BoudayaNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Modeling and Simulating Bodies and GarmentsDocumento203 pagineModeling and Simulating Bodies and GarmentsShoaib AzizNessuna valutazione finora

- Harmonized System CodeDocumento175 pagineHarmonized System CodeHas SaphanaraNessuna valutazione finora

- Management Decision Case: Restoration HardwaDocumento3 pagineManagement Decision Case: Restoration HardwaRishha Devi Ravindran100% (5)

- Podushkin SR14 2016 58 70 PDFDocumento13 paginePodushkin SR14 2016 58 70 PDFellipiNessuna valutazione finora

- SAMSEN Pre Test 051120SpecialEngDocumento14 pagineSAMSEN Pre Test 051120SpecialEngครูปัณณภัสร์ สวัสดิ์ภัสร์Nessuna valutazione finora

- Material Safety Data Sheet: Ink RibbonDocumento5 pagineMaterial Safety Data Sheet: Ink RibbonTomek SpaleniakNessuna valutazione finora

- Inter Organizational Relations in The Business Model of BenettonDocumento19 pagineInter Organizational Relations in The Business Model of BenettonMohit MehtaNessuna valutazione finora

- Examples of Dirty Talk With A High Class Hooker GirlfriendDocumento1 paginaExamples of Dirty Talk With A High Class Hooker GirlfriendNanda Singh100% (1)

- Áo Len Kẻ NgangDocumento5 pagineÁo Len Kẻ Ngangbanhbeo1992002Nessuna valutazione finora

- Helmets NFPA 1971 EV1 User GuideDocumento8 pagineHelmets NFPA 1971 EV1 User GuideForum PompieriiNessuna valutazione finora

- Rainbow Bookmark-Crochet Pattern PDFDocumento4 pagineRainbow Bookmark-Crochet Pattern PDFIrina Carmen BrinzaNessuna valutazione finora

- Shoppers Stop captures Karthik Calling Karthik fashionDocumento2 pagineShoppers Stop captures Karthik Calling Karthik fashionsingsaranNessuna valutazione finora

- Masaba Gupta Interview by FirstpostDocumento5 pagineMasaba Gupta Interview by FirstpostAami KeNessuna valutazione finora

- The 24 Elders of RevelationDocumento10 pagineThe 24 Elders of Revelationkdanielco100% (1)

- Armorsmith: Unique Front-Opening Unique Front-Opening Scalable Plate Carrier (SPC)Documento5 pagineArmorsmith: Unique Front-Opening Unique Front-Opening Scalable Plate Carrier (SPC)L H100% (1)

- Restaurant AuditDocumento4 pagineRestaurant Auditchiahongtan100% (1)

- Churches of RevelationDocumento11 pagineChurches of RevelationmaymorganNessuna valutazione finora

- Class 12 (Vistas) 2016 New EditionDocumento99 pagineClass 12 (Vistas) 2016 New EditionNinderNessuna valutazione finora

- Bo Peep Pure DK Free Digital Pattern Louis and LillyDocumento8 pagineBo Peep Pure DK Free Digital Pattern Louis and LillyChahinez BaNessuna valutazione finora

- Section 4 - Valves Penstocks and ActuatorsDocumento16 pagineSection 4 - Valves Penstocks and Actuatorsgomaa83Nessuna valutazione finora

- CausativesDocumento3 pagineCausativesElysia F.HNessuna valutazione finora

- Clothing Design in Aspect of Ensuring The Physiological and Psychological ComfortDocumento60 pagineClothing Design in Aspect of Ensuring The Physiological and Psychological ComfortMonika BączekNessuna valutazione finora

- Rock Shox Judy Service Guide Rev - A PDFDocumento9 pagineRock Shox Judy Service Guide Rev - A PDFee1993Nessuna valutazione finora

- Critter Corner: What Do You Think This Harp Seal Is Doing?Documento38 pagineCritter Corner: What Do You Think This Harp Seal Is Doing?neluNessuna valutazione finora

- Button Masala Internship - Commgraph PDFDocumento23 pagineButton Masala Internship - Commgraph PDFAbhipsa MallickNessuna valutazione finora

- Sober ScriptDocumento7 pagineSober Scriptapi-568114485Nessuna valutazione finora

- Zinnat 171-23-4956Documento44 pagineZinnat 171-23-4956Md. Zinnat Hossain 171-23-4956Nessuna valutazione finora

- Granada AirsoftDocumento7 pagineGranada AirsoftgoyoNessuna valutazione finora

- Gog2stud 7Documento1 paginaGog2stud 7Mari MNessuna valutazione finora