Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Schedule of Test

Caricato da

Ram NepaliCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Schedule of Test

Caricato da

Ram NepaliCopyright:

Formati disponibili

STANDARD SPECIFICATIONS FOR ROAD AND BRIDGE WORKS

accordance with these Specifications.

Notwithstanding the Engineers approval of a layer, the Contractor shall be responsible

for making good any subsequent damage due to traffic, ingress of water or any other

reason and should any damage occur the layer shall again be subject to proof rolling,

construction control testing and tolerance checks in accordance with these

Specifications.

(2) Other Works and Equipment

Acceptance tests for other works and equipment are detailed in the relevant Sections of

these Specifications.

510 SCHEDULE OF TESTS

(1) Test Schedule

The Contractor shall supply the materials and carry out the works as per specifications

prescribed in the Clauses for the relevant item of work. For ensuring the requisite

quality of construction, the material and works shall be subjected to quality control

tests, as prescribed herein after. The testing frequencies set forth are the desirable and

the Engineer shall have the full authority to carry out additional tests as frequently as

he may deem necessary, to satisfy himself that the materials and works comply with

the appropriate specifications. However, the number of tests recommended in Table

5.2 may be reduced at the discretion of the Engineer if it is felt that consistency in the

quality of materials can still be maintained with reduced number of test.

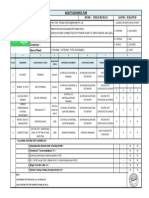

Table 5.2: Control Test and their Minimum Frequency for Road and Bridge

S No PART OR COMPONENT OF Section/ TESTS FREQUENCY

THE WORKS Clause

No.

1 PIPE DRAINS, PIPE CULVERTS 700

AND CONCRETE CHANNELS IDENTIFICATION :

As specified or

Gradation,

required by the

Plasticity Index, CBR In-Situ, Engineer

MATERIALS FOR RE- FILLING 701 Density (95% MDD)

THE TRENCHES

PRODUCTION OF Before starting

2

MATERIALS production

Site Trials: According to

800 the relevant

NATURAL AND CRUSHED Other tests on materials

MATERIALS component of

the works

3 EARTHWORKS

FILL MATERIAL Material Identification, For each new

MDD, OMC, CBR source and in

every 1500 cum

or part of it

900 MC For each new

source and in

every 400 cum or

part of it

One set[ 3 test]

COMPACTION Field Density

per 1000 sqm of

each layer

SECTION 500 QUALITY CONTROL Page 5-11

STANDARD SPECIFICATIONS FOR ROAD AND BRIDGE WORKS

S No PART OR COMPONENT OF Section/ TESTS FREQUENCY

THE WORKS Clause

No.

4 SUBGRADE 1000 Same as mentioned under Same as

UNTREATED SUBGRADES S. No. 3 mentioned under

1003 &

CAPPING LAYERS S. No. 3

MATERIALS 1004

5 MECHANICAL STABILISATION

For each new

IN SITU MATERIAL Material Identification, source and in

MC, MDD, OMC, CBR every 3000 sqm

or part of it

For each new

source and in

STABILISER Grading, ES ( for sand) every 500 cum of

additive material

or part of it

1005

MDD, OMC, CBR For each new

source and in

MIXED MATERIAL

every 400 cum or

part of it

One set of 3 test

per 1000 sqm of

Field Density each layer

COMPACTION

6 LIME STABILISATION

IN SITU MATERIAL Material Identification, For each new

MC, MDD, OMC, CBR source and in

every 400 cum or

part of it

LIME Quality of Lime One test for each

consignment

subject to a

1006

minimum of one

test per five

tones.

MIXED MATERIAL MC One set of two

test per 300 sqm

of each layer

COMPACTION Field Density One set of two

test per 300 sqm

of each layer

7 SUBBASE BASE, HARD 1200

SHOULDER AND GRAVEL

WEARING COURSE

MECHANICALLY STABLE

MATERIAL FOR SUBBASE 1201

MATERIAL Material Identification, For each new

MC, MDD, OMC, CBR source and in

every 400 cum

or part of it

COMPACTION Field Density One set of three

test per 1000 sqm

of each layer

SECTION 500 QUALITY CONTROL Page 5-12

STANDARD SPECIFICATIONS FOR ROAD AND BRIDGE WORKS

S No PART OR COMPONENT OF Section/ TESTS FREQUENCY

THE WORKS Clause

No.

8 GRADED CRUSHED STONE 1202

FOR BASE AND SUBBASE

[WET MIX MACADAM]x

Material Identification, For each new

MC, Gradation Plasticity source and in

index every 200 cum or

part of it

CBR, MDD, OMC, LAA/ For each new

MATERIAL

AIV, Crushing ratio source and in

every 1000 cum

or part of it

COMPACTION Field Density One set of three

test per 1000

sqm of each

layer

9 GRAVEL WEARING COURSE 1205

MATERIAL Material Identification,; For each new

Gradation, Plasticity source and in

index, CBR, LAA/AIV, every 400 cum or

MDD, OMC part of it

COMPACTION Field Density One set of three

test per 1000

sqm of each

layer

10 BITUMINOUS SURFACE AND 1300

BASE COURSE

PRIME COAT - TACK COAT 1302

Quality of Binder as per Certificates from

MATERIAL

IS73( paving bitumen)/ IS suppliers.

217 (Cut back bitumen)/ One set of tests

IS 8887 ( cationic for each 50,000

emulsion) ; penetration, litres of supply or

Absolute and Kinematic part of it.

viscosity, flash point,

ductility, solubility in

Trichloroethylene,

Softening point, Tests on

residue from rolling thin

film oven) Viscosity ratio

at 60C, Ductility:

Binder temperature for At regular close

CONSTRUCTION

Application interval

Rate of spread of binder Three test per day

SECTION 500 QUALITY CONTROL Page 5-13

STANDARD SPECIFICATIONS FOR ROAD AND BRIDGE WORKS

S No PART OR COMPONENT OF Section/ TESTS FREQUENCY

THE WORKS Clause

No.

11 SURFACE DRESSING 1303

MATERIAL Quality of binder: Same as mention

under SNo 10

LAA/AIV, For each new

source and in

every 200 cum or

part of it

Flakiness index, For each new

Elongation index source and in

every 100 cum or

part of it

One test of each

Stripping value, Water source and

absorption of aggregate whenever there is

change in the

quality of

aggregate or

source of

aggregate.

Two test per day/

Grading of aggregate once per 250 cum

CONSTRUCTION Rate of application of Three test per day

chippings/ Binder or 1 test per 5000

sqm

Control temperature of At regular close

binder in boiler, aggregate interval

in the dryer, mix at the

time of laying and rolling

12 PENETRATION MACADAM ( 1304

SEMI GROUT)

MATERIAL Quality of binder: Same as mention

under S.No. 10

LAA/AIV, Gradation For each new

source and in

every 200 cum or

part of it

Flakiness index For each new

source and in

every 100 cum or

part of it.

CONSTRUCTION Rate of application of Three test per day

chippings/ binder or 1 test per 5000

sqm

Binder temperature for At regular close

application interval

SAND SEAL 1305

MATERIAL Quality of binder: Same as mention

under SNo 10

Gradation, Plasticity For each new

13 index source and in

every 200 cum or

part of it

CONSTRUCTION Rate of application of Three test per day

chippings/ binder or 1 test per 5000

SECTION 500 QUALITY CONTROL Page 5-14

STANDARD SPECIFICATIONS FOR ROAD AND BRIDGE WORKS

S No PART OR COMPONENT OF Section/ TESTS FREQUENCY

THE WORKS Clause

No.

Binder temperature for sqm

application At regular close

interval

14 DENSE BITUMINOUS MACADAM 1307/

ASPHALT CONCRETE/ DENSE 1308/

BITUMINOUS MACADAM/

1309

BITUMINOUS CONCRETE

MATERIAL Quality of Binder as per Certificates from

IS73( paving bitumen)/; suppliers.

penetration, Absolute and One set of tests

Kinematic viscosity, flash for each 50,000

point, ductility, solubility

litres of supply or

in Trichloroethylene,

Softening point, Tests on part of it

residue from rolling thin

film oven, Viscosity ratio

at 60C, Ductility

IRC SP 53( modified

bitumen)/IS 15462

(Polymer and Rubber

modified bitumen)/

Penetration, Softening

point, FRAASS breaking

point, Flash point, Elastic

recovery of half thread in

ductilometer, Separation

difference in softening

point, Viscosity at 1500 C,

, Tests on residue from Once per 500

rolling thin film oven) cum and change

Loss in mass, Increase in in source.

softening point, Once test for each

Reduction in penetration,

source and

Elastic recovery of half

change in source.

thread in ductilometer or

Complex modulus

AIV/LAA, Flakiness and

Elongation index,

Soundness test (SSS),

Sand equivalent, Plasticity

Index, Polished stone

value

CONSTRUCTION Mix grading, for individual One set

constituent and mixed consisting of

aggregate from dryer, three for each 400

Stability and void analysis ton of mix subject

of mix including to minimum of

theoretical maximum two test per day

specific gravity of loose per plant

mix, Flow and voids , do

density, Binder content After every 5th

Rate of spread of mix truck load

One test per 700

Density of Compacted sqm area

layer As required

Control temperature of

binder in boiler, aggregate

in the dryer, mix at the

time of laying and rolling

SECTION 500 QUALITY CONTROL Page 5-15

STANDARD SPECIFICATIONS FOR ROAD AND BRIDGE WORKS

S No PART OR COMPONENT OF Section/ TESTS FREQUENCY

THE WORKS Clause

No.

15 OPEN GRADED PREMIX 1310/

SURFACING/ CLOSE GRADED 1311

PREMIX SURFACING

MATERIAL Quality of binder: Same as mention

under SNo 10

LAA/AIV, For each new

source and in

Flakiness index, every 200 cum or

Elongation index part of it

For each new

Stripping value, Water source and in

absorption of aggregate every 100 cum or

part of it

Grading of aggregate One test of each

source and

whenever there is

change in the

quality of

aggregate or

source of

aggregate.

Two test per day/

once per 250 cum

CONSTRUCTION Rate of application of Two test per day

chippings/ Binder per plant or 1 test

per 5000 sqm

Control temperature of At regular close

binder At application interval

16 SAND ASPHALT 1312

MATERIAL Quality of binder: Same as mention

under S.No 10

LAA/AIV, For each new

source and in

every 200 cum or

part of it

Sand equivalent, Plasticity Once test for

Index, stability of mix each source and

change in source

One set

Mix grading, Binder consisting of

content three for each 400

ton of mix subject

to minimum of

two test per day

per plant

17 BITUMINOUS COLD MIX 1313

1314

MATERIAL Quality of emulsion ( Certificates from

binder) An ionic Emulsion suppliers.

as per IS 3117 and One set of tests

Cationic as per ; ( for each 50,000

viscosity at 250C, Bitumen litres of supply or

content, cement mixing, part of it.

sieve test, Miscibility with

water, Tests on residue For each new

etc.) source and in

every 200 cum or

SECTION 500 QUALITY CONTROL Page 5-16

STANDARD SPECIFICATIONS FOR ROAD AND BRIDGE WORKS

S No PART OR COMPONENT OF Section/ TESTS FREQUENCY

THE WORKS Clause

No.

Gradation, Sand part of it

equivalent, water One set

absorption, Soundness test consisting of

( Sodium/ Magnesium three for each 200

Sulphate test) ton

Quality of filer

CONSTRUCTION Rate of spread of One test per 500

Emulsion sqm and not less

than two tests

per day

Regular control

Rate of spread of mixed through checks

material of layer thickness

One set

consisting of

three for each 400

Stability, Flow and voids, ton of mix subject

Binder content to minimum of

two test per day

per plant

One test per 250

sqm of area

Density of compacted mix

layer

18 OTTASEAL 1316

MATERIAL Quality of binder: Same as mention

under SNo 14

Flakiness index One test for each

new source and in

every 250 cum or

part of it

LAA/AIV, , Elongation One set of 3

index/Stripping value specimen for

each new source

and as directed

by the Engineer

One test for 50

Grading cum of aggregate

CONSTRUCTION Temperature of binder At regular close

interval

Rate of Application of Two test per run

Binder

19 CONCRETE 2000

MATERIALS Cements: Acceptance tests Conservative

samples for each

supply and not

less than every

200 t or part of it

Control tests: Chemical Testing in case of

SECTION 500 QUALITY CONTROL Page 5-17

STANDARD SPECIFICATIONS FOR ROAD AND BRIDGE WORKS

S No PART OR COMPONENT OF Section/ TESTS FREQUENCY

THE WORKS Clause

No.

Composition Physical noncompliance of

Properties the mixes or

storage on site for

longer than 1

month

Aggregates: 1 set ( 3 nos ) test

Acceptance tests: for each 10 to 50

CONTROL TESTS: cum and

Grading additional test for

Silt & clay content: each 50 cum of

Organic Impurities concrete t for

Chloride content, sulphate fine aggregate

content, 1 set ( 3 nos ) test

Alkali reactivity, for each 25 to

Water, Admixtures 125 cum and

additional test for

each 125 cum

and 250 t part of

it for coarse

aggregate

As frequently as

Required

Sub-Clause

2004(7) and(8)

CONCRETE Sub-Clause

LAB. TRIALS 2004(3)

SITE TRIALS For 1-5 cum

CONTROL TESTS quantity of work

COMPRESSIVE at one place 1

STRENGTHS set,

For 5.1-15 cum

quantity of work

at one place 2 set

For 15 .1 to 30

cum quantity of

work at one place

3 set

For 30 .1 to 50

cum quantity of

work at one place

4 set

For more than 50

cum quantity of

work at one place

4 set .of sample

plus one

additional for each

50 cum or part

thereof

Early works

every 6 cum or

part of it

SECTION 500 QUALITY CONTROL Page 5-18

STANDARD SPECIFICATIONS FOR ROAD AND BRIDGE WORKS

S No PART OR COMPONENT OF Section/ TESTS FREQUENCY

THE WORKS Clause

No.

REINFORCEMENT

Mechanical properties For 1-25 bundles

0.2 percent proof lot 3 rod (one

stress/ yield stress, from each

Tensile strength/ yield bundle) from

strength ratio, randomly

selected 3

Elongation bundles.

For 26-65

bundles lot 4 rod

( one from each

bundle) from

randomly

selected 4

bundles

For 66-180

bundles lot 5 rod (

one from each

bundle) from

randomly selected

5 bundles

For 181- 300

bundles lot 7 rod

( one from each

bundle) from

randomly

selected 7

bundles

For > 300

bundles lot 10

rod ( one from

each bundle)

from randomly

selected 10

bundles

20 MISCELLANEOUS 2400

STRUCTURES

GABIONS

MATERIALS 2401 Gabion wires : Upto 25 coils two

Tensile Strength, Mass, set of sample

Uniformity and adhesion 26-50 coils three

of Zinc coating set of sample

51-150 coils five

set of sample

151-300 coils

eight set of

sample

SECTION 500 QUALITY CONTROL Page 5-19

STANDARD SPECIFICATIONS FOR ROAD AND BRIDGE WORKS

S No PART OR COMPONENT OF Section/ TESTS FREQUENCY

THE WORKS Clause

No.

>301 coils

thirteen set of

Specific gravity and water sample

absorption of stones At least 3 set of

tests for every

source of material

CRIB WALLS 2402 Gradating of backfill Minimum one

materials test for every 250

cum or part of it

and for each

source of material

SUB-SURFACE DRAINS 2404 Gradation Analysis One set of test for

every 50 cum and

or part of it and

for each change

in source of

material

21 BRICK WORK FOR

STRUCTURES

MATERIALS Quality of Bricks As required

2502 Quality of cement and

sand

MORTAR Control tests Every 10 cum of

2511 Compressive strength of brick work or part

mortar of it.

22 MASONRY FOR STRUCTURES

MATERIALS Quality of cement and

2602

sand

MORTAR Control tests As required

Compressive strength of Every 10 cum of

2610

mortar masonry of part of

it

Note: For works of contract which do not require any qualification and scattered

(located at least 100 m from one location to other similar to road maintenance),

above frequency may reduce up to 50 % at the discretion of the Engineer if it is felt

that consistency in the quality of materials and works can still be maintained with

reduced number of test but not less than as specified in Table 5.3.

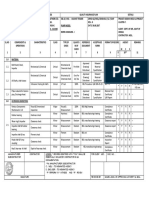

Table 5.3: Control Test and their Minimum Frequency for Small Works /

Maintenance Works of Road and Bridge

S NO PART OR COMPONENT SECTION/ TESTS FREQUENCY

OF THE WORKS CLAUSE NO.

1 EARTHWORKS 900 COMPACTION One set [3 test]

Field Density per 2000 sqm.

of each layer

2 SUBBASE BASE, HARD 1201 COMPACTION One set of three

SHOULDER AND GRAVEL Field Density test per 2000

WEARING COURSE sqm of each

1201

MECHANICALLY STABLE layer

MATERIAL FOR SUBBASE

SECTION 500 QUALITY CONTROL Page 5-20

STANDARD SPECIFICATIONS FOR ROAD AND BRIDGE WORKS

S NO PART OR COMPONENT SECTION/ TESTS FREQUENCY

OF THE WORKS CLAUSE NO.

3 GRADED CRUSHED 1202 COMPACTION One set of three

STONE FOR BASE AND Field Density test per 2000

SUBBASE [WET MIX sqm of each

MACADAM]x layer

COMPACTION One set of three

WATER BOUND Field Density

1203 test per 2000

4 MACADAM FOR BASE

AND Subbase sqm of each

layer

COMPACTION One set of three

GRAVEL WEARING Field Density test per 2000

5 1205

COURSE sqm of each

layer

BITUMINOUS SURFACE 1300

AND BASE COURSE

6

PRIME COAT - TACK COAT 1302

6.1 MATERIAL Quality of Binder Certificates from

as per IS73( paving suppliers.

bitumen)/ IS 217 .

(Cut back

bitumen)/ IS 8887 (

cationic emulsion) ;

penetration,

Absolute and

Kinematic

viscosity, flash

point, ductility,

solubility in

Trichloroethylene,

Softening point,

Tests on residue

from rolling thin

film oven)

Viscosity ratio at

60C, Ductility:

6.2 CONSTRUCTION Binder temperature At regular close

for Application interval

Rate of spread of Three test per

binder day

7 SURFACE DRESSING 1303 Rate of application Three test per

of chippings/ day or 1 test per

CONSTRUCTION Binder 10000 sq. m

At regular close

Control interval

temperature of

binder in boiler,

aggregate in the

dryer, mix at the

time of laying and

rolling

8 PENETRATION MACADAM 1304 Rate of application Three test per

( SEMI GROUT) of chippings/ day or 1 test per

CONSTRUCTION binder 10000 sqm

Binder temperature At regular close

for application interval

9 SAND SEAL 1305 Rate of application Three test per

of chippings/ day or 1 test per

SECTION 500 QUALITY CONTROL Page 5-21

STANDARD SPECIFICATIONS FOR ROAD AND BRIDGE WORKS

S NO PART OR COMPONENT SECTION/ TESTS FREQUENCY

OF THE WORKS CLAUSE NO.

CONSTRUCTION binder 10000 sqm

Binder temperature At regular close

for application interval

10 SLURRY SEAL 1306 Rate of application One per lane per

of slurry mixture km

CONSTRUCTION Quantity of slurry

by weight Daily ( Travel

time of machine)

11 DENSE BITUMINOUS 1307/ 1308/ 1309 Density of One test per

MACADAM ASPHALT Compacted layer 1400 sqm area

CONCRETE/ DENSE Control As required

BITUMINOUS MACADAM/ temperature of

BITUMINOUS CONCRETE

binder in boiler,

CONSTRUCTION aggregate in the

dryer, mix at the

time of laying and

rolling

12 OPEN GRADED PREMIX 1310/ 1311 Rate of application 1 test per 5000

SURFACING/ CLOSE of chippings/ sqm

GRADED PREMIX Binder At regular close

SURFACING Control interval

temperature of

CONSTRUCTION

binder At

application

13 SAND ASPHALT 1312

Density of One test per

CONSTRUCTION Compacted layer 1400 sqm area

Control As required

temperature of

binder in boiler,

aggregate in the

dryer, mix at the

time of laying and

rolling

14 EMULSION AGGREGATE 1313 Quality of emulsion Certificates from

MIX and 1314 ( binder) An ionic suppliers.

COLD ASPHALT Emulsion as per IS

MATERIAL 3117 and Cationic

as per ; ( viscosity

at 250C, Bitumen

content, cement One set

mixing, sieve test, consisting of

Miscibility with three for each

water, Tests on 800 ton of mix

residue etc.)

Stability, Flow and

voids, Binder

content

15 OTTASEAL 1315 Temperature of At regular close

binder interval

CONSTRUCTION One test per run

Rate of Application

of Binder

16 CONCRETE 2000

COMPRESSIVE For 1-15 cum

SECTION 500 QUALITY CONTROL Page 5-22

STANDARD SPECIFICATIONS FOR ROAD AND BRIDGE WORKS

S NO PART OR COMPONENT SECTION/ TESTS FREQUENCY

OF THE WORKS CLAUSE NO.

STRENGTHS quantity of work

at one place 1

set,

For 15 .1 to 30

cum quantity of

work at one

place 2 set

For more than 30

cum quantity of

work at one

place 3 set .of

sample plus one

additional for

each day

concreting.

17 REINFORCEMENT Weight / tensile Certificates from

strength suppliers

18 GABION WIRE 2401 Gabion wires : Upto 50 coils

Mass of Zinc two set of

coating sample

>50 coils four

set of sample

511 QUALITY ASSURANCE PLAN

The Contractor shall submit Quality Assurance Plan (QAP) to the Engineer for his approval.

The Quality Assurance Plan (QAP) shall be based on the detailed Program of the Works,

and process oriented focus on defect prevention, as per Clause 115 of these Specifications.

The Quality Assurance Plan shall include the following:

(1) The Quality Assurance Schedule Comprising of:

(a) The recapitulative test schedule and testing program detailing the list of tests for

compliance, laboratory trials, site trials and trials sections, construction control

tests and their frequencies, tests for acceptance of the completed works with their

dates. As in following tabular form;

S. Description Description Frequency of Total quantity to be tested in Unit Total Test to be Carried Re

N Of Material/ of Test each Mile stone/ year as per Out in each Mile stone / ma

o. activity Laboratory As Per Work Schedule year as per Work rks

Tests Specification Schedule

Milestone I Milestone Milestone I Milestone

/year 1 II /year 2 /year1 II /year 2

(b) Recapitulative list of critical acceptance testing procedures, for equipment or

parts of the works which corresponds to the tasks on the Critical Path according to

the construction Program.

SECTION 500 QUALITY CONTROL Page 5-23

Potrebbero piacerti anche

- Prds & Piping QapDocumento2 paginePrds & Piping QapPavul RajNessuna valutazione finora

- 10.COOPERHEAT HT ProcedureDocumento16 pagine10.COOPERHEAT HT Procedurethanga balanNessuna valutazione finora

- Cable Stayed Bridge (Content)Documento70 pagineCable Stayed Bridge (Content)Ram Nepali100% (3)

- A. Hillerborg-Strip Method Design Handbook-CRC Press (1996)Documento333 pagineA. Hillerborg-Strip Method Design Handbook-CRC Press (1996)Nabigh Ahmad100% (5)

- Paint Thickness Measurement ProcedureDocumento2 paginePaint Thickness Measurement ProcedurenathgsurendraNessuna valutazione finora

- Checklist For Rebar and Concrete WorkDocumento4 pagineChecklist For Rebar and Concrete WorkDwinto RachmadNessuna valutazione finora

- Std. QAP of Expension Joints (March 16)Documento6 pagineStd. QAP of Expension Joints (March 16)ghaghra bridgeNessuna valutazione finora

- 3D Box CulvertDocumento41 pagine3D Box CulvertRam NepaliNessuna valutazione finora

- CGC-ITP-MECH-002-Irrigation SystemDocumento6 pagineCGC-ITP-MECH-002-Irrigation SystemSajad Pk100% (1)

- 2D Portal FrameDocumento16 pagine2D Portal FrameRam NepaliNessuna valutazione finora

- Rate AnalysisDocumento568 pagineRate AnalysisRam Nepali100% (1)

- Rate AnalysisDocumento568 pagineRate AnalysisRam Nepali100% (1)

- Inspection and Test Plan: Cement Stucco (Exterior Plastering)Documento3 pagineInspection and Test Plan: Cement Stucco (Exterior Plastering)Alvene TagocNessuna valutazione finora

- Model Quality Assurance Plan For Pot-Ptfe BearingsDocumento8 pagineModel Quality Assurance Plan For Pot-Ptfe Bearingsghaghra bridgeNessuna valutazione finora

- NORMA API-936 - Testeo A MaterialesDocumento2 pagineNORMA API-936 - Testeo A MaterialesSebastián Álcazar25% (4)

- Overview of Part 2 Failure AnalysisDocumento12 pagineOverview of Part 2 Failure AnalysisAnonymous S9qBDVkyNessuna valutazione finora

- QC - 08 PTCDocumento5 pagineQC - 08 PTCmahendraNessuna valutazione finora

- Acoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsDa EverandAcoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsNessuna valutazione finora

- DOT Pipeline RepairsDocumento18 pagineDOT Pipeline RepairsSeng HeangNessuna valutazione finora

- Bridge Engineering: Maintenance: Bridge Maintenance TechniquesDocumento36 pagineBridge Engineering: Maintenance: Bridge Maintenance TechniquesRam NepaliNessuna valutazione finora

- (Nigel R Hewson) Prestressed Concrete Bridges deDocumento390 pagine(Nigel R Hewson) Prestressed Concrete Bridges deMichael Hii100% (2)

- (SSOP) : Sanitation Standard Operating ProcedureDocumento6 pagine(SSOP) : Sanitation Standard Operating ProcedureAsrel05100% (1)

- Masjid Sahabat - Testing PlanDocumento14 pagineMasjid Sahabat - Testing PlanDinn NsNessuna valutazione finora

- QP 000803 04Documento6 pagineQP 000803 04Ajay RayNessuna valutazione finora

- Insulation QAPDocumento2 pagineInsulation QAPPavul RajNessuna valutazione finora

- 80mm Zigzag MTCDocumento1 pagina80mm Zigzag MTCQAQC ZFNessuna valutazione finora

- 6 SACIC-W-2012 Rev 2Documento5 pagine6 SACIC-W-2012 Rev 2husnain aliNessuna valutazione finora

- Modelquality Assuranceplanforpot 1Documento8 pagineModelquality Assuranceplanforpot 1mouni9301997Nessuna valutazione finora

- Frecuencias de Ensayos en PavimentosDocumento40 pagineFrecuencias de Ensayos en PavimentosMario Esteban Solano RodriguezNessuna valutazione finora

- Inspection and Test Plan: One Sample For Every 100 Cum or Twice WeeklyDocumento3 pagineInspection and Test Plan: One Sample For Every 100 Cum or Twice WeeklyAbhishek ShettyNessuna valutazione finora

- Non-Destructwetestingof Concrete-Methodsoftest: Indian StandardDocumento9 pagineNon-Destructwetestingof Concrete-Methodsoftest: Indian StandardUppala Krishna ChaitanyaNessuna valutazione finora

- Staircases & HandrailsDocumento2 pagineStaircases & HandrailsPavul RajNessuna valutazione finora

- Client:-Project: - Consultant: - Contaractor: - Name of PanelDocumento1 paginaClient:-Project: - Consultant: - Contaractor: - Name of PanelChaturbhai HadiyalNessuna valutazione finora

- Compression Testing Machine Used For Testing of Concrete and Mortar - RequirementsDocumento9 pagineCompression Testing Machine Used For Testing of Concrete and Mortar - RequirementsUppala Krishna ChaitanyaNessuna valutazione finora

- ITP RefractoryDocumento1 paginaITP RefractoryADOFSLNessuna valutazione finora

- Buco Project: Field Installation Tests Visual and Mechanical Inspection Remarks Yes NoDocumento3 pagineBuco Project: Field Installation Tests Visual and Mechanical Inspection Remarks Yes Noதுரைராஜ் இலட்சுமணன்Nessuna valutazione finora

- TATA Painting Specification 43Documento1 paginaTATA Painting Specification 43Suleman KhanNessuna valutazione finora

- NDT-SA-SATORP-UT-60, Rev00, Date 15 Aug-2023Documento20 pagineNDT-SA-SATORP-UT-60, Rev00, Date 15 Aug-2023Md Abu Hanif RajuNessuna valutazione finora

- Quotation For NDT Services (15-Columns, 9 Beams, 10 SoilTests)Documento3 pagineQuotation For NDT Services (15-Columns, 9 Beams, 10 SoilTests)AnchalThapa100% (1)

- SACIC-CV-0005 Rev.04 Packer TestsDocumento2 pagineSACIC-CV-0005 Rev.04 Packer TestsEr Nizamuddin AliNessuna valutazione finora

- Condensate Collection Tank Qap 290722Documento3 pagineCondensate Collection Tank Qap 290722Pavul RajNessuna valutazione finora

- Piping Qap R03 250822Documento2 paginePiping Qap R03 250822Pavul RajNessuna valutazione finora

- PIPING R04 101022 DraftDocumento2 paginePIPING R04 101022 DraftPavul RajNessuna valutazione finora

- Test Requirement & Frequancy of Test For Quality Assurance of Works Based On BOQDocumento5 pagineTest Requirement & Frequancy of Test For Quality Assurance of Works Based On BOQSujan MalbulNessuna valutazione finora

- Metallic Bellow QAPDocumento2 pagineMetallic Bellow QAPPavul RajNessuna valutazione finora

- 2.3 - Mr. Methsara Lokuge - Material Engineer (Matara) PDFDocumento22 pagine2.3 - Mr. Methsara Lokuge - Material Engineer (Matara) PDFmpchanakaNessuna valutazione finora

- Tensile Test UpvcDocumento3 pagineTensile Test UpvcAloka Karunarathne0% (1)

- Er. Jagadiswar M. ShresthaDocumento106 pagineEr. Jagadiswar M. ShresthaAkash KhanalNessuna valutazione finora

- Cofmow ItpDocumento7 pagineCofmow ItpAjay HazarikaNessuna valutazione finora

- Tunnel Work: Material Inspection and Testing Plan (Itp)Documento6 pagineTunnel Work: Material Inspection and Testing Plan (Itp)aksinhadce2Nessuna valutazione finora

- MT Vd-M-U00-Sta-Prc-Byfa003-000-0008Documento8 pagineMT Vd-M-U00-Sta-Prc-Byfa003-000-0008Chandrasekhar mishraNessuna valutazione finora

- Process Piping Guide R2Documento12 pagineProcess Piping Guide R2Edson Araga100% (1)

- QAP Check ListDocumento1 paginaQAP Check Listbed passNessuna valutazione finora

- IPCDocumento8 pagineIPCGerald See TohNessuna valutazione finora

- 2.1.5 Surface Examination, Unclad and Metal-Clad MaterialDocumento1 pagina2.1.5 Surface Examination, Unclad and Metal-Clad MaterialApinan NamkanisornNessuna valutazione finora

- Satr-P-3208 Rev 8 FinalDocumento7 pagineSatr-P-3208 Rev 8 FinalMohamed HaleemNessuna valutazione finora

- Presentation - Irc-15-Dowel Bar PDFDocumento10 paginePresentation - Irc-15-Dowel Bar PDFNandini GurveNessuna valutazione finora

- Euronorm 186-87Documento4 pagineEuronorm 186-87Pedro OliveiraNessuna valutazione finora

- TLJ-QTN-23-230R1 Al Jethoor Engineering Consulting Under Construction Residential Building Concrete InvestigationDocumento3 pagineTLJ-QTN-23-230R1 Al Jethoor Engineering Consulting Under Construction Residential Building Concrete Investigationmohd sumerNessuna valutazione finora

- Seacom Skills University B.Tech Course Laboratory Details (CIVIL Dept.)Documento3 pagineSeacom Skills University B.Tech Course Laboratory Details (CIVIL Dept.)RAVI BARTIANessuna valutazione finora

- Approved ITP 06012023 For WT6Documento1 paginaApproved ITP 06012023 For WT6mohamed irsath100% (1)

- Inspection Testing Plan Guidelines Roadworks 1705928555Documento29 pagineInspection Testing Plan Guidelines Roadworks 1705928555foureight48Nessuna valutazione finora

- Saudi Aramco Test Report: MV Cablebus Continuity and Insulation Resistance Testing SATR-P-3233 3-Jul-18 ElectDocumento6 pagineSaudi Aramco Test Report: MV Cablebus Continuity and Insulation Resistance Testing SATR-P-3233 3-Jul-18 Electkarthi51289Nessuna valutazione finora

- Saudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 31-Mar-19 CPDocumento2 pagineSaudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 31-Mar-19 CPAwais NaeemNessuna valutazione finora

- Dept of WR., Govt. of OdhishaDocumento3 pagineDept of WR., Govt. of OdhishaNaveen NagisettiNessuna valutazione finora

- QAP Final - ASSAMNZRMM11Documento2 pagineQAP Final - ASSAMNZRMM11Jaspreet SinghNessuna valutazione finora

- D6461!99!2007 Standard Specification For Silt Fence MaterialsDocumento3 pagineD6461!99!2007 Standard Specification For Silt Fence Materialsfokat67395Nessuna valutazione finora

- Quality and Inspection Requirements For New and Refurbished Drilling and Well Completion Equipment Once Printed This Specification Becomes An Uncontrolled Copy of The Online VersionDocumento6 pagineQuality and Inspection Requirements For New and Refurbished Drilling and Well Completion Equipment Once Printed This Specification Becomes An Uncontrolled Copy of The Online Versionislam atifNessuna valutazione finora

- Statement of Work PDFDocumento13 pagineStatement of Work PDFElmey Bin JulkeplyNessuna valutazione finora

- Saic A 1011Documento4 pagineSaic A 1011mohammadNessuna valutazione finora

- Polaris Cable QAP As Per IS 694Documento3 paginePolaris Cable QAP As Per IS 694Bhavesh KeraliaNessuna valutazione finora

- जिल्ला दररेट २०७५ ०७६ - final 4Documento149 pagineजिल्ला दररेट २०७५ ०७६ - final 4Kapil MishraNessuna valutazione finora

- Factors Causing The Failure of BridgesDocumento1 paginaFactors Causing The Failure of BridgesRam NepaliNessuna valutazione finora

- Technical Viability of Using Reclaimed Asphalt Pavement in Ahmedabad Brts Corridor For Base CourseDocumento6 pagineTechnical Viability of Using Reclaimed Asphalt Pavement in Ahmedabad Brts Corridor For Base CourseRam NepaliNessuna valutazione finora

- STD Drwing For HighwayDocumento56 pagineSTD Drwing For Highwayvaibhav jain100% (1)

- 30.0m Simply Supported Span, Cast-In-situ, 2-Webbed Prestressed Concrete Slab-DeckDocumento12 pagine30.0m Simply Supported Span, Cast-In-situ, 2-Webbed Prestressed Concrete Slab-DeckRam NepaliNessuna valutazione finora

- ARMP Manual 2017Documento42 pagineARMP Manual 2017Ram NepaliNessuna valutazione finora

- Bridge Hand BookDocumento51 pagineBridge Hand BookPranjal AgrawalNessuna valutazione finora

- Well FoundationDocumento1 paginaWell FoundationRam NepaliNessuna valutazione finora

- 8s L8lehg X) 6f) +8f: X) El D) L G Dfu KMF/FDDocumento3 pagine8s L8lehg X) 6f) +8f: X) El D) L G Dfu KMF/FDRam NepaliNessuna valutazione finora

- Movable BridgesDocumento36 pagineMovable BridgesRam NepaliNessuna valutazione finora

- New Microsoft PowerPoint PresentationDocumento41 pagineNew Microsoft PowerPoint PresentationRam NepaliNessuna valutazione finora

- Tender Notice 06Documento1 paginaTender Notice 06Ram NepaliNessuna valutazione finora

- Abbreviations: IFB . Invitation For BidsDocumento2 pagineAbbreviations: IFB . Invitation For BidsRam NepaliNessuna valutazione finora

- Abbreviations: IFB . Invitation For BidsDocumento2 pagineAbbreviations: IFB . Invitation For BidsRam NepaliNessuna valutazione finora

- New Microsoft PowerPoint PresentationDocumento41 pagineNew Microsoft PowerPoint PresentationRam NepaliNessuna valutazione finora

- Abbreviations: IFB . Invitation For BidsDocumento1 paginaAbbreviations: IFB . Invitation For BidsRam NepaliNessuna valutazione finora

- Irc Gov in SP 013 2004Documento208 pagineIrc Gov in SP 013 2004Ram NepaliNessuna valutazione finora

- Design & Construction of MicropileDocumento49 pagineDesign & Construction of Micropilemaccaferriasia100% (1)

- GEM 25bDocumento29 pagineGEM 25bRam NepaliNessuna valutazione finora

- River Training Works - Case Studies of Ganga Bridge No. 52: Project Report ONDocumento72 pagineRiver Training Works - Case Studies of Ganga Bridge No. 52: Project Report ONRam NepaliNessuna valutazione finora

- 1.basic Design Data: Design Review of BELSOT KHOLA BRIDGE SuperstructureDocumento1 pagina1.basic Design Data: Design Review of BELSOT KHOLA BRIDGE SuperstructureRam NepaliNessuna valutazione finora

- Cambridge IGCSE: CHEMISTRY 0620/51Documento12 pagineCambridge IGCSE: CHEMISTRY 0620/51FFNessuna valutazione finora

- DeflocculationDocumento19 pagineDeflocculationJames LagaloNessuna valutazione finora

- Determining An Optimum Catalyst For Liquid-Phase Dehydration of Methanol ToDocumento7 pagineDetermining An Optimum Catalyst For Liquid-Phase Dehydration of Methanol Toshaka9221Nessuna valutazione finora

- Notes Lecture No 3 Cell Injury and MechanismDocumento5 pagineNotes Lecture No 3 Cell Injury and MechanismDr-Rukhshanda RamzanNessuna valutazione finora

- Polyaluminium Chloride: Product SpecificationsDocumento2 paginePolyaluminium Chloride: Product SpecificationsMonica Choi SeungjunhyungNessuna valutazione finora

- Separating Corn Starch From CornDocumento3 pagineSeparating Corn Starch From CornJagna LannaoNessuna valutazione finora

- Analysis Synthesis and Design of Chemical Processes 3rd Edition Turton Solutions ManualDocumento21 pagineAnalysis Synthesis and Design of Chemical Processes 3rd Edition Turton Solutions ManualdarrenrichncogbpizjkNessuna valutazione finora

- 2D Simulations and Electro-Thermal Analysis of Micro-Heater Using COMSOLDocumento4 pagine2D Simulations and Electro-Thermal Analysis of Micro-Heater Using COMSOLshobiiiscNessuna valutazione finora

- Experiment No.1. (Monograph)Documento3 pagineExperiment No.1. (Monograph)ayeza.sarwar2021Nessuna valutazione finora

- Effect of Temperature On Sliding Wear of AISI 316 L (N) Stainless Steel  " Analysis of Measured Wear and Surface Roughness of Wear TracksDocumento7 pagineEffect of Temperature On Sliding Wear of AISI 316 L (N) Stainless Steel  " Analysis of Measured Wear and Surface Roughness of Wear TracksSamir BoseNessuna valutazione finora

- 1 2Documento65 pagine1 2AQEESHA NUWAIRA BINTI USMAN BN21110154Nessuna valutazione finora

- Offshore Oil & GasDocumento27 pagineOffshore Oil & GasArash HamidiNessuna valutazione finora

- Introduction To Turbulence1Documento28 pagineIntroduction To Turbulence1Mustafa YılmazNessuna valutazione finora

- NIST-JANAF Thermochemical TablesDocumento39 pagineNIST-JANAF Thermochemical TablesVelzaeroNessuna valutazione finora

- EnggDocumento44 pagineEnggAlex NavalNessuna valutazione finora

- Rser D 16 02436R1Documento88 pagineRser D 16 02436R1Jitender KaushalNessuna valutazione finora

- 6th SEM - Sep-22Documento4 pagine6th SEM - Sep-22Jay RanjanNessuna valutazione finora

- USP-NF Atorvastatin CalciumDocumento8 pagineUSP-NF Atorvastatin CalciumPhạm Đức LộcNessuna valutazione finora

- Salama YoussefDocumento1 paginaSalama YoussefYoussef SalamaNessuna valutazione finora

- Digital PH Sensor Orbisint CPS11D: Memosens Glass Electrode For Standard ApplicationsDocumento3 pagineDigital PH Sensor Orbisint CPS11D: Memosens Glass Electrode For Standard ApplicationsAchmad KNessuna valutazione finora

- Thermodynamic Process Tutorial 4 1Documento2 pagineThermodynamic Process Tutorial 4 1Boon Khai ChienNessuna valutazione finora

- Sarmica 2Documento5 pagineSarmica 2Akash RughaniNessuna valutazione finora

- Ecofriendly Finishing of Textile: by Dr. Pintu Pandit Asst. Professor, NIFT PatnaDocumento22 pagineEcofriendly Finishing of Textile: by Dr. Pintu Pandit Asst. Professor, NIFT PatnaARYAN RATHORENessuna valutazione finora

- Toggle Structure and ClassificationDocumento9 pagineToggle Structure and ClassificationRobin TimkangNessuna valutazione finora

- CreepDocumento25 pagineCreepORANG BiasaNessuna valutazione finora

- High Quality Line Fi Lter Elements For All Your Fi Ltration NeedsDocumento2 pagineHigh Quality Line Fi Lter Elements For All Your Fi Ltration NeedsNuc LeusNessuna valutazione finora

- Es Int 9e QQ AspDocumento3 pagineEs Int 9e QQ AspRifaa WidasmaraNessuna valutazione finora