Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SB 366B Carburetor Throttle Body Screw Inspection

Caricato da

Kamal Jit DhimanCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SB 366B Carburetor Throttle Body Screw Inspection

Caricato da

Kamal Jit DhimanCopyright:

Formati disponibili

MANDATORY

652 Oliver Street

Williamsport, PA 17701 U.S.A.

Tel. 570-323-6181

Fax. 570-327-7101

SERVICE BULLETIN

www.lycoming.com

DATE: April 18, 2008 Service Bulletin No. 366B

(Supersedes Service Bulletin No. 366A)

Engineering Aspects are

FAA Approved

SUBJECT: Carburetor Throttle Body Screw Inspection

MODELS AFFECTED: All Lycoming engines equipped with Marvel-Schebler, Facet, Precision, or

Volare updraft carburetor models MA-3A, MA-3PA, MA-3SPA, MA-4SPA,

MA-4-5, MA-4-5AA, and MA-6AA.

TIME OF COMPLIANCE: Within the next 50 hours of engines operation and at each 100 hours of engine

operation thereafter, or anytime fuel stains are evident.

Instances have been reported of leakage through the gasket between the bowl assembly and throttle body

of the carburetor, evidenced by fuel stains in the area of the leak. Leakage of this type may be accompanied

by loose screws that attach the bowl and throttle body.

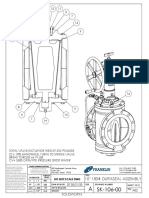

See Figure 1 for illustrative example of the throttle body attaching screws.

INSTRUCTIONS FOR COMPLIANCE:

1. Check the carburetor for evidence of fuel stains on the outside of the bowl along the parting line.

2. Check for movement between the throttle body and bowl.

3. Check each throttle body to bowl attaching screw for looseness by attempting to move the screw

and/or locktab washers with your fingers.

CAUTION

Do not attempt to turn the screw with a screwdriver. Turning the screw with a screwdriver

may compromise the lock washers and increase the likelihood that the screws will become

loose.

4. If there is evidence of fuel stains, movement between the throttle body and bowl, or the throttle body

to bowl attaching screws are loose then remove the carburetor in accordance with the applicable

engine and airframe service manuals. Send the carburetor to a qualified repair station for

troubleshooting and repair. For the most recent listing of qualified repair stations contact Volare

Carburetors at the following:

ISSUED REVISED PAGE NO. REVISION

MO DAY YEAR MO DAY YEAR 1 of 2 B

09 14 73 04 11 08

2008 by Lycoming All Rights Reserved

Volare Carburetors LLC

P.O. Box 44

211 Chase Street

Gibsonville, NC 27249

Phone: (336) 449-5054

5. Reinstall the carburetor in accordance with the applicable engine and airframe service manuals.

6. Inspect the engine installation for damaged or worn motor mounts, and/or evidence of out of balance

conditions. Take appropriate action to correct discrepant conditions found during the inspection.

7. Make an appropriate logbook entry showing compliance with this Service Bulletin.

If after compliance with this Service Bulletin there is continued fuel leakage, or if there are other

conditions not specifically described in this Service Bulletin then contact Lycoming Product Support at 570-

323-6181.

Models MA-3A, MA-3PA, MA-3SPA, and MA-4SPA have four screws. Models MA-4-5,

MA-4-5AA, and MA-6AA have six screws.

Figure 1. Illustrative Example of Throttle Body Attaching Screws

ISSUED REVISED PAGE NO. REVISION

MO DAY YEAR MO DAY YEAR S.B. 366

2 of 2 B

09 14 73 04 11 08

Potrebbero piacerti anche

- 5 ClutchDocumento31 pagine5 ClutchKamal Jit DhimanNessuna valutazione finora

- SB 639 Rocker Arm InspectionDocumento3 pagineSB 639 Rocker Arm InspectionKamal Jit DhimanNessuna valutazione finora

- Cr3213-4-03 Blind Rivet Spec: Additional InformationDocumento2 pagineCr3213-4-03 Blind Rivet Spec: Additional InformationKamal Jit DhimanNessuna valutazione finora

- Service Bulletin1018Documento6 pagineService Bulletin1018Kamal Jit DhimanNessuna valutazione finora

- Alternator Commissioning ManualDocumento67 pagineAlternator Commissioning ManualRakesh KumarNessuna valutazione finora

- Cherry Lock Blind Rivets CA-1005 PDFDocumento38 pagineCherry Lock Blind Rivets CA-1005 PDFKamal Jit DhimanNessuna valutazione finora

- Aircraft Tire ManualDocumento52 pagineAircraft Tire ManualThe United Aviation100% (3)

- GEA 71 Troubleshooting TipsDocumento2 pagineGEA 71 Troubleshooting TipskjdhimanNessuna valutazione finora

- SI 1575 New Conecting Rod BushingDocumento2 pagineSI 1575 New Conecting Rod BushingKamal Jit DhimanNessuna valutazione finora

- SB 639 Rocker Arm InspectionDocumento3 pagineSB 639 Rocker Arm InspectionKamal Jit DhimanNessuna valutazione finora

- SB 369R Engine Inspection After OverspeedDocumento7 pagineSB 369R Engine Inspection After OverspeedKamal Jit DhimanNessuna valutazione finora

- GEA 71 Troubleshooting TipsDocumento2 pagineGEA 71 Troubleshooting TipskjdhimanNessuna valutazione finora

- Tute Sheet 2 - Axial - Shear - Bearing StressDocumento2 pagineTute Sheet 2 - Axial - Shear - Bearing StressKamal Jit DhimanNessuna valutazione finora

- ICAO Safety Management Manual - EUDocumento251 pagineICAO Safety Management Manual - EUA MNessuna valutazione finora

- ICA-172-28-00001 (Fuel Qty Indication)Documento63 pagineICA-172-28-00001 (Fuel Qty Indication)Kamal Jit Dhiman100% (1)

- IntroductionDocumento10 pagineIntroductionKamal Jit DhimanNessuna valutazione finora

- Emergency Airworthiness Directive: FAA Aviation SafetyDocumento3 pagineEmergency Airworthiness Directive: FAA Aviation SafetySushan BajracharyaNessuna valutazione finora

- Thapar Institute of Engineering and Technology Patiala Optimization Methods (UMA-034)Documento2 pagineThapar Institute of Engineering and Technology Patiala Optimization Methods (UMA-034)Kamal Jit DhimanNessuna valutazione finora

- IntroductionDocumento10 pagineIntroductionKamal Jit DhimanNessuna valutazione finora

- Sheet 3 - Strains and Material ConstantsDocumento2 pagineSheet 3 - Strains and Material ConstantsKamal Jit DhimanNessuna valutazione finora

- Tutorial 1 FM PDFDocumento2 pagineTutorial 1 FM PDFKamal Jit DhimanNessuna valutazione finora

- Tute 1-Revision of Normal Streses and Strains PDFDocumento2 pagineTute 1-Revision of Normal Streses and Strains PDFKamal Jit DhimanNessuna valutazione finora

- Tutorial 3 FMDocumento1 paginaTutorial 3 FMKamal Jit DhimanNessuna valutazione finora

- IntroductionDocumento10 pagineIntroductionKamal Jit DhimanNessuna valutazione finora

- Tutorial 2 FMDocumento1 paginaTutorial 2 FMKamal Jit DhimanNessuna valutazione finora

- IntroductionDocumento10 pagineIntroductionKamal Jit DhimanNessuna valutazione finora

- Tutorial 3 FMDocumento1 paginaTutorial 3 FMKamal Jit DhimanNessuna valutazione finora

- SB 518D Oil Cooler Bypass Valve InspectionDocumento2 pagineSB 518D Oil Cooler Bypass Valve InspectionKamal Jit DhimanNessuna valutazione finora

- IntroductionDocumento10 pagineIntroductionKamal Jit DhimanNessuna valutazione finora

- SB 439aDocumento6 pagineSB 439aKamal Jit DhimanNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Series 1204: Orange Research IncDocumento3 pagineSeries 1204: Orange Research IncWilson VelásquezNessuna valutazione finora

- 7 StraighteningDocumento5 pagine7 StraighteningChirag SuleNessuna valutazione finora

- Repair Manual: Repair Level 2 Component ReplacementDocumento52 pagineRepair Manual: Repair Level 2 Component ReplacementMarcelo GomezNessuna valutazione finora

- Jaxworks Small Business Spreadsheet FactoryDocumento66 pagineJaxworks Small Business Spreadsheet Factorypalpat.cmgNessuna valutazione finora

- 8.4 Spherical Roller BearingsDocumento68 pagine8.4 Spherical Roller Bearingsrrobles011Nessuna valutazione finora

- G C4 Geant IngDocumento10 pagineG C4 Geant IngmediaboxkodiNessuna valutazione finora

- Capacities and SpecificationsDocumento14 pagineCapacities and SpecificationsAndrey LuqueNessuna valutazione finora

- Arcoy DovetailerDocumento8 pagineArcoy Dovetailernk186967% (3)

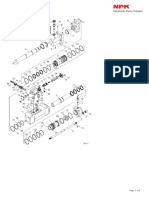

- SK-106-00 10inch 150lbs Reva02 PDFDocumento3 pagineSK-106-00 10inch 150lbs Reva02 PDFBruno GonçalvesNessuna valutazione finora

- Section 6 - Assembly ManualDocumento170 pagineSection 6 - Assembly ManualLuis Torres100% (1)

- Anchor Bolt MSDocumento7 pagineAnchor Bolt MSGaneshNessuna valutazione finora

- Reeeeeeeeeeeeeport 2Documento27 pagineReeeeeeeeeeeeeport 2Mahantesh ValiNessuna valutazione finora

- Manual Copiadoras Ricoh 3352Documento180 pagineManual Copiadoras Ricoh 3352marcos chagoyaNessuna valutazione finora

- GH4 Hammer Assembly Seals KitDocumento6 pagineGH4 Hammer Assembly Seals Kitjose sierraNessuna valutazione finora

- Installation & Operation ManualDocumento12 pagineInstallation & Operation ManualGlendinning Products, LLC.Nessuna valutazione finora

- WV-1 Install InstructionsDocumento11 pagineWV-1 Install InstructionsmkaukolaNessuna valutazione finora

- H300M InstallDocumento16 pagineH300M InstallAleksandarNessuna valutazione finora

- Instrucciones 595-231-E MANUAL-FURLEX-200-TD-300-TD-03-SEPTIEMBRE-2007Documento56 pagineInstrucciones 595-231-E MANUAL-FURLEX-200-TD-300-TD-03-SEPTIEMBRE-2007Acastillaje y JarciasNessuna valutazione finora

- Solenoid directional valvesDocumento4 pagineSolenoid directional valvesJuan Carlos Bermudez CardenasNessuna valutazione finora

- 17.20 Duplex Flexible Coupling S77DXDocumento5 pagine17.20 Duplex Flexible Coupling S77DXguita riefNessuna valutazione finora

- Manual SutorbiltLegendDocumento46 pagineManual SutorbiltLegendsathiyam2kNessuna valutazione finora

- EN Catalogo SchletterDocumento68 pagineEN Catalogo SchletterMarcelo SilvaNessuna valutazione finora

- Continuous Assessment Test I: January 2019 Reg. No.Documento2 pagineContinuous Assessment Test I: January 2019 Reg. No.Venkatram PrabhuNessuna valutazione finora

- Expansion of Osmani International AirportDocumento563 pagineExpansion of Osmani International AirportJayampathi AsangaNessuna valutazione finora

- Catalogue - en - Arcoplus Reversò 6166 626Documento4 pagineCatalogue - en - Arcoplus Reversò 6166 626Niraj BorikarNessuna valutazione finora

- 6b545 User Manual Gas Oven Heinner PDFDocumento50 pagine6b545 User Manual Gas Oven Heinner PDFClaudiu PetracheNessuna valutazione finora

- Civil - Modified Abst Estt..J-Shop 3rd BayDocumento6 pagineCivil - Modified Abst Estt..J-Shop 3rd BaysanjoybapiNessuna valutazione finora

- Toyota Tundra TRD Brake Kit Installation InstructionsDocumento10 pagineToyota Tundra TRD Brake Kit Installation InstructionsJason LancasterNessuna valutazione finora

- P.C. MS14-MS16 (C852) - EngDocumento114 pagineP.C. MS14-MS16 (C852) - EngRicardo Bilbao100% (7)

- K2 Systems - MA - MultiAngle - enDocumento14 pagineK2 Systems - MA - MultiAngle - enjmom18_647241209Nessuna valutazione finora