Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Waste Water

Caricato da

afraz_xecCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Waste Water

Caricato da

afraz_xecCopyright:

Formati disponibili

Engineering and Practical

Design of Membrane

Bioreactors (MBRs) for

Small Flows

PERFORMANCE WASTEWATER SOLUTIONS

Presentation

Flat plate v hollow fiber membranes

Manufacture of flat plate membranes

Design criteria and O&M requirements

Nutrient reduction

Compact membranes

Key design considerations

PERFORMANCE WASTEWATER SOLUTIONS

Technology Selection Issues

Know the Regulations treatment standards & design requirements

Evaluate flows & loads and peaking factors carefully the

size & cost of the plant will directly relate to flows, loads and peaks

Consider an equalization tank to optimize treatment

membrane is a barrier therefore need to design for the peak flow

Evaluate the whole life cost of each viable option

Consider the complexity of O&M and who will manage

Volume of sludge produced

Footprint, Visual impact, Noise & Odor

Phased construction

PERFORMANCE WASTEWATER SOLUTIONS

Membrane Bioreactor

PERFORMANCE WASTEWATER SOLUTIONS

Membranes Compared to traditional

Activated Sludge Processes

PERFORMANCE WASTEWATER SOLUTIONS

MBR Process

High quality effluent

BOD <2 mg/l

SS <1 mg/l

Nitrification to <0.5mg/l ammonia

Total nitrogen removal 10 mg/l

recirculation

Total nitrogen removal to <5 mg/l with

carbon dosed anoxic stages

Micro biological content including

fecal coliform to non-detect levels

PERFORMANCE WASTEWATER SOLUTIONS

Membrane Pore Sizes

Wastewater treatment in the micro & ultra filtration range

Biofilm increases filtration capacity

PERFORMANCE WASTEWATER SOLUTIONS

PLATE DESIGN

Polysulphone or ptfe membrane materials

Plastic plate with spacer fabric

Membrane ultrasonically welded to plate

PERFORMANCE WASTEWATER SOLUTIONS

Membrane Operation

Outside to in flow

Membrane provides absolute barrier

Reduces affect of flow variation

Allows increased MLSS

PERFORMANCE WASTEWATER SOLUTIONS

Cassette

For flows >5,000 gpd

PERFORMANCE WASTEWATER SOLUTIONS

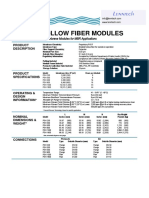

Hollow Fiber Membrane

System

PERFORMANCE WASTEWATER SOLUTIONS

Hollow Fiber Membrane

System

PERFORMANCE WASTEWATER SOLUTIONS

Hollow Fiber Membrane

System

PERFORMANCE WASTEWATER SOLUTIONS

Membrane Selection

Plate or Hollow Fibre?

Plate Hollow Fibre

Footprint Very Good Better

Screening 1/8 inch up to 1/32 inch

O&M Relatively simple Complex

Air requirement High High - Medium

Membrane Infrequent Regular

cleaning 6 to 18 months (backpulse / chemicals daily)

Traditional Small flows High flows

Suitability < 1 million gpd > 100,000 gpd

PERFORMANCE WASTEWATER SOLUTIONS

Air Scour

Cassette design:

Can incorporate or have separate air

distribution system

Provides cross flow to scour membrane

surface & oxygen for biological treatment

PERFORMANCE WASTEWATER SOLUTIONS

Design Criteria

O Design MLSS 12,000 mg/l

O Design sludge age 20 to 30 days

O Typical design flux:

o

15 gpd/ft2 or 25 l/mh @ 10 C

O Relaxation period 5 mins/hr

O Permeate recycle for low flow periods

O Estimated membrane

replacement period 7 10 years

PERFORMANCE WASTEWATER SOLUTIONS

O&M

O Chemical recovery cleaning frequency typically 6 to 18 months

O Sodium hypochlorite + Citric acid in hard water areas (non-

hazardous)

O Chemicals can be disposed through treatment plant

O Foaming can be a problem particularly during commissioning

Clean in place External

PERFORMANCE WASTEWATER SOLUTIONS

MBR Design

Additional aeration

required to meet BOD

loading

PERFORMANCE WASTEWATER SOLUTIONS

Configuration

Operation under a gravity head or permeate pumps

Sludge holding tank required as sludge is withdrawn every 1 to 4

days to maintain the sludge age

Minimum supply includes tanks, blowers, control panel, membrane

cassettes, pipework, valves & level instrumentation

PERFORMANCE WASTEWATER SOLUTIONS

Pre-engineered Package Plants

- can be up to 100,000 as a package plant

- multiple package plants or concrete tanks for applications greater than

100,000 GPD

Capacity Approximate Reactor tank size

Modules

GPD

Height x Width x Length

1 x 25 plate 7,000 12 x 5 x 4

1 x 50 plate 14,000 12 x 9 x 5

2 x 50 plate 28,000 12 x 9 x 106

3 x 50 plate 42,000 12 x 9 x 15

4 x 50 plate 56,000 12 x 9 x 20

5 x 50 plate 70,000 12 x 9 x 25

6 x 50 plate 84,000 12 x 9 x 306

PERFORMANCE WASTEWATER SOLUTIONS

Design Considerations

Inlet / outlet pumping stations

Equalization tank

Inlet screens

Sludge holding tanks

Covers & odor control

Chemical dosing for Phosphorus reduction, Alkalinity

correction, Carbon addition

Call-out alarm or remote monitoring facility

Stand-by generator

Standby equipment philosophy - blowers

Walkways & lifting equipment

Seed sludge to accelerate commissioning

PERFORMANCE WASTEWATER SOLUTIONS

Nutrient Reduction

Nitrogen reduction

Will nitrify due to long sludge age

Temperature low affects biological activity, high requires a

greater oxygen input

Alkalinity required to nitrify (recirculation will recover half

alkalinity lost)

Sufficient carbon & Anoxic tank of sufficient size to reduce DO

to 0.5 mg/l

Phosphorus reduction

Biological or chemical precipitation

Good P reduction

PERFORMANCE WASTEWATER SOLUTIONS

Denitrification by recirculation

Design for TN removal < 10 mg/l

Permeate

MBR

Anoxic

Zone

1/8

Inlet Screens

Mixed Liquor

Recycle

Waste Sludge

Storage

PERFORMANCE WASTEWATER SOLUTIONS

Denitrification by

recirculation

PERFORMANCE WASTEWATER SOLUTIONS

MEMBRANE INSTALLATION

Coill Dubh MBR 335,000 GPD

PERFORMANCE WASTEWATER SOLUTIONS

Compact Membrane

Membrane for flows Integral or separate equalization

from 500 to 5000 gpd tank arrangements

PERFORMANCE WASTEWATER SOLUTIONS

Design Considerations

General Arrangement

Trash tank with effluent filter

Equalization tank

Compatible with standard on-site tanks

Reuse systems will require permeate storage

Membrane cassettes to be light and easy to remove & handle

Design

reduced head of water in standard on-site tanks, requires

permeate pump to maintain flux

anoxic tank required for denitrification

phosphorus can be added via chemical precipitation

PERFORMANCE WASTEWATER SOLUTIONS

Summary

PERFORMANCE WASTEWATER SOLUTIONS

Technology Comparison

Smaller Footprint

Sand filter

Peat Biofilter

Activated

sludge

Fixed film /

moving bed

Membranes

Better Environmental Protection (BOD/SS/N/P)

PERFORMANCE WASTEWATER SOLUTIONS

Membrane - Benefits

High quality effluent

Water reuse

Small footprint

Reduced sludge production

Reduced cost of disinfection

Cost effective for community

size systems particularly where

ammonia or total nitrogen

standards are required range

from $5 to $30 per gpd

Uprating existing systems

PERFORMANCE WASTEWATER SOLUTIONS

Engineering & Practical

Design Considerations

For small flows look for reduced complexity & reduced

operational input

Flat plate generally better than hollow fiber

No back pulsing or chemicals

Gravity design for community systems or permeate pumps for residential

Long periods between chemical cleans

Design

Always consider peak flows

Flux rate compare at the same temperature

Screening requirements

Ultra or micro filtration - pathogen removal

Operation cost - power

Life of membrane material

PERFORMANCE WASTEWATER SOLUTIONS

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Puron Technical Bulletin Modules 300 600 1800 PVDF Rev 11-2 FinalDocumento2 paginePuron Technical Bulletin Modules 300 600 1800 PVDF Rev 11-2 Finalafraz_xecNessuna valutazione finora

- Heat Loss and Gain CalculationDocumento84 pagineHeat Loss and Gain Calculationafraz_xecNessuna valutazione finora

- Water Parameters NeededDocumento1 paginaWater Parameters Neededafraz_xecNessuna valutazione finora

- Cat 6 S-FTP 4 CableDocumento2 pagineCat 6 S-FTP 4 Cableafraz_xecNessuna valutazione finora

- GRP Water Tank SpecsDocumento4 pagineGRP Water Tank Specsafraz_xecNessuna valutazione finora

- Ashghal StandardsDocumento26 pagineAshghal Standardsafraz_xecNessuna valutazione finora

- Hydaranautics MembraneDocumento3 pagineHydaranautics Membraneafraz_xecNessuna valutazione finora

- Koch Puron PSH 300 LDocumento2 pagineKoch Puron PSH 300 Lafraz_xecNessuna valutazione finora

- 16 L200 LHD +GCC-E SpecDocumento2 pagine16 L200 LHD +GCC-E Specafraz_xecNessuna valutazione finora

- Tank Foundation DrawingDocumento1 paginaTank Foundation Drawingafraz_xecNessuna valutazione finora

- Auditing HealthcareDocumento82 pagineAuditing Healthcareafraz_xecNessuna valutazione finora

- All Polypropylene String Wound CartridgesDocumento1 paginaAll Polypropylene String Wound Cartridgesafraz_xecNessuna valutazione finora

- Flexible Conduit SpecsDocumento10 pagineFlexible Conduit Specsafraz_xecNessuna valutazione finora

- Inspection Form For New Construction: Project NameDocumento1 paginaInspection Form For New Construction: Project Nameafraz_xecNessuna valutazione finora

- NLMK in Hot Rolled ProductsDocumento7 pagineNLMK in Hot Rolled Productsafraz_xecNessuna valutazione finora

- Method Statement For The Installation of Water Treatment PlantDocumento12 pagineMethod Statement For The Installation of Water Treatment Plantafraz_xec89% (18)

- Application Form For Miscellaneous Services On Indian PassportsDocumento3 pagineApplication Form For Miscellaneous Services On Indian Passportsafraz_xecNessuna valutazione finora

- Control Cables SpecsDocumento4 pagineControl Cables Specsafraz_xecNessuna valutazione finora

- 18 Process Plant Layout Engineering - Course SyllabusDocumento15 pagine18 Process Plant Layout Engineering - Course Syllabusafraz_xec100% (1)

- PVC Pipe Trench Detail: NotesDocumento1 paginaPVC Pipe Trench Detail: Notesafraz_xecNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- IDP Group - Eia ReportDocumento54 pagineIDP Group - Eia Reportkiller ChanNessuna valutazione finora

- JTC EBS Guidelines (2003)Documento22 pagineJTC EBS Guidelines (2003)rozyNessuna valutazione finora

- 5.0 APP F - Local Authorities Legal RequirementDocumento4 pagine5.0 APP F - Local Authorities Legal RequirementMuhammadHaziqHaiqalNessuna valutazione finora

- Ala'a QaddohaDocumento94 pagineAla'a QaddoharhijazNessuna valutazione finora

- Impo1 1Documento20 pagineImpo1 1mouhcine maouhoubNessuna valutazione finora

- Sodium Dimethyl Dithio Carbamate Toxic For Aquatic LifeDocumento2 pagineSodium Dimethyl Dithio Carbamate Toxic For Aquatic LifeGerry HandoyoNessuna valutazione finora

- Journal of Environmental & Earth Sciences - Vol.5, Iss.1 April 2023Documento125 pagineJournal of Environmental & Earth Sciences - Vol.5, Iss.1 April 2023Bilingual PublishingNessuna valutazione finora

- Presentation of Illegal MiningDocumento11 paginePresentation of Illegal MiningJohn Elton Capili SantosNessuna valutazione finora

- Beneficial Effects of Agnihotra On Environment and AgricultureDocumento10 pagineBeneficial Effects of Agnihotra On Environment and AgriculturePranay AbhangNessuna valutazione finora

- Thesis Title Methodology: "Development of Public Space Along River Narmada-A Case of Hoshangabad City"Documento15 pagineThesis Title Methodology: "Development of Public Space Along River Narmada-A Case of Hoshangabad City"anwarul islamNessuna valutazione finora

- Soil Stabilization of Road by Using Spent WashDocumento7 pagineSoil Stabilization of Road by Using Spent WashInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- SkimmerDocumento20 pagineSkimmerAliZenatiNessuna valutazione finora

- Water Pollution PresentationDocumento59 pagineWater Pollution PresentationKawleen Singh100% (2)

- Ecw311 - Topic 7 Sources For Water SupplyDocumento41 pagineEcw311 - Topic 7 Sources For Water SupplyBernardNessuna valutazione finora

- EE-Conservancy and Water Carriage SystemsDocumento10 pagineEE-Conservancy and Water Carriage SystemsMadhuNessuna valutazione finora

- Oloa 8888 Msds Version 2015Documento7 pagineOloa 8888 Msds Version 2015Nduong NguyenNessuna valutazione finora

- Pola Penambahan Larutan Tawas Untuk Penurunan Kekeruhan Air Sungai MartapuraDocumento6 paginePola Penambahan Larutan Tawas Untuk Penurunan Kekeruhan Air Sungai MartapuraCatria AnugrahNessuna valutazione finora

- Checklist For Control Room Septic Tank & SoakpitDocumento2 pagineChecklist For Control Room Septic Tank & SoakpitRupesh KhandekarNessuna valutazione finora

- Port Alberni Plywood Site Environmental AssessementDocumento39 paginePort Alberni Plywood Site Environmental AssessementKat SlepianNessuna valutazione finora

- Annexure IV (B) EMP-Oriental Structural Engineers Ltd.Documento24 pagineAnnexure IV (B) EMP-Oriental Structural Engineers Ltd.sabul1276Nessuna valutazione finora

- Rainwater Harvesting Final ProjectDocumento35 pagineRainwater Harvesting Final ProjectAditya RautNessuna valutazione finora

- G6 Water and Its Importance WsDocumento3 pagineG6 Water and Its Importance WsKamalNessuna valutazione finora

- Levapor MBBR/IFAS Nitrification Process: An Efficient and Economical Process For Nitrogen RemovalDocumento1 paginaLevapor MBBR/IFAS Nitrification Process: An Efficient and Economical Process For Nitrogen RemovalAmit ChristianNessuna valutazione finora

- Retort Cooling Water IssuesDocumento8 pagineRetort Cooling Water IssuesSatya Pradeep PulakurthiNessuna valutazione finora

- Colstrip 1&2 B Flyash Pond CCR Inflow Design Flood Control System Plan October 2016 BFADocumento513 pagineColstrip 1&2 B Flyash Pond CCR Inflow Design Flood Control System Plan October 2016 BFABrian BrowerNessuna valutazione finora

- Linea 18 PDFDocumento1 paginaLinea 18 PDFSergio LealNessuna valutazione finora

- Appendix 04. Reading ComprehensionDocumento2 pagineAppendix 04. Reading ComprehensionThương ĐơNessuna valutazione finora

- IJRAR23A2716Documento9 pagineIJRAR23A2716Mohit nemadeNessuna valutazione finora

- The Portion of The Plumbing System That Receives Discharges of All Soil and Waste Stacks Within The BuildingDocumento4 pagineThe Portion of The Plumbing System That Receives Discharges of All Soil and Waste Stacks Within The BuildingSharryNessuna valutazione finora

- Water Pollution: Presented By: Esther NG E-Jo Jordan Teah Hong Yek Joan Cheah Ern Lin Teh Wen Paul Teoh Shu WeiDocumento24 pagineWater Pollution: Presented By: Esther NG E-Jo Jordan Teah Hong Yek Joan Cheah Ern Lin Teh Wen Paul Teoh Shu WeiESTHER NG E-JO MoeNessuna valutazione finora