Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Whirlpool Awo-D 411250 PDF

Caricato da

Zoran ProkicTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Whirlpool Awo-D 411250 PDF

Caricato da

Zoran ProkicCopyright:

Formati disponibili

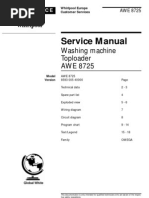

Whirlpool EMEA

SERVICE Customer Services

AWO/D 411250

Service Information

Washing machine Frontloader

AWO/D 411250

8592 327 10100

Last Modification: 09/30/09

Creation Date: 08/14/08

Spare Part List 2

Exploded View 4

Technical Data 6

Wiring Diagram 8

Circuit Diagram 10

Program Chart 12

Testprogram 24

Error Codes 25

Service Bulletin 4812 712 40340 29

Service Bulletin 4812 712 40347 43

Service Bulletin 4812 712 40317 44

Service Bulletin 4812 712 40320 45

Service Bulletin 4812 712 40348 46

Service Bulletin 4812 712 40327 48

Service Bulletin 4812 712 40313 49

Service Bulletin 4812 712 40330 50

Service Bulletin 4812 712 40314 51

Service Bulletin 4812 712 40305 52

This document is only intended for qualified technicans who are aware of the

respective safety regulations.

Subject to modifications

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 2 of 53

Spare Part List

Pos 12NC Description

001 0 4812 440 11579 Cabinet U-SHAPE

003 0 4812 440 11581 Crossbar U-SHAPE

011 0 4812 500 18099 Adjust. foot M8, 112mm

021 0 4812 440 11471 Front 25

024 2 4812 440 11791 Cover rear

024 3 4812 442 18047 Cover plast rear

025 0 4812 440 11582 Support control board U-SHAPE

030 0 4812 440 11654 Table top 42/44 l U-SHAPE UBS possi

040 0 4812 417 18787 Hinge BK

050 0 4812 440 10779 Plinth GW

061 0 4812 466 89033 Counter weight upper, 44 l, EUREKA

061 1 4812 466 89034 Counter weight lower, 44/54 l, EUREKA

061 2 4812 310 39287 Mounting kit weight, EUREKA

081 0 4812 529 18063 Shock absorber U-SHAPE

084 0 4812 466 58023 Silent bloc

086 0 4812 401 18894 Fixation eureka

110 0 4801 111 00265 Handle door

130 0 4812 417 28107 Plate eureka

130 1 4812 417 28108 Plate Doorlock Lower

131 0 4801 111 00266 Lock

131 1 4812 417 28045 Pin Door Lock

131 2 4812 492 58022 Spring Door Lock

135 1 4812 498 18262 Door safety erk

135 2 4812 491 48004 Spring Door Safety

135 3 4812 290 68153 Holder adjust. Door Safety

140 0 4812 450 59812 Door glass DELTA EUREKA

143 0 4812 440 11141 Glassdoor frame

144 0 4812 440 11595 Frame door glas

144 3 4812 502 18669 Screw; 4.0x12

191 0 4812 460 68633 Door bellow eureka 473 50lt

191 1 4812 492 18028 Strap Eureka

191 2 4812 492 98011 Strap

200 0 4801 111 00741 Wash unit EUR-800-1000-44H11

223 0 4812 418 48958 Drum lifter plastic COD/44L/D

271 0 4801 111 01149 Belt 1229/H6 Hutchinson

272 0 4801 111 00742 Pulley EUR/LR

272 3 4812 502 18817 Screw pulley M8x23 Eureka

301 0 4801 111 00884 Control panel

303 0 4812 452 17755 Handle drawer EBL WP25-CPL

331 0 4812 414 58306 Knob timer

331 3 4812 414 58307 Spring Knob timer

332 0 4812 410 29399 Push button 4-opt.

333 0 4812 513 18172 Push button

333 1 4812 410 29401 Push button 2 options

400 0 4801 111 00743 Motor 1BA5736-0WB/EU

400 1 4812 502 18828 Screw Motor, kit

409 0 4812 362 48443 Brush,carbon BSH

421 0 4812 121 18285 Interf.filter

430 0 4812 360 18559 Pump

451 0 4812 259 28919 Heating element 2050W, 230V + NTC

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 3 of 53

Pos 12NC Description

480 0 4812 321 78422 Cable DOM-MOT6-EU

490 0 4819 321 18136 Cable mains 2m SA

491 0 4812 321 28367 Strain relief

491 1 4812 502 38152 Screw 4.8x19

521 0 4801 111 00894 Control unit DOMINO, programmed

521 0 4812 214 70725 Control unit DOMINO,C1W-basic

571 0 4812 271 28558 Valve,magnet

581 0 4812 271 28585 Pressostat 50/25 INVENS.

620 0 4812 239 58046 Module E3/4 Opt.

630 0 4812 280 58048 Door lock

653 0 4812 134 18046 Light guide Prog. Flow

653 1 4812 134 18047 Guide,light Start low

653 2 4812 134 48361 Guide,light 4 opt.

653 3 4812 134 48362 Guide,light options low

691 0 4812 282 19485 Sensor NTC

701 0 4812 530 29329 Hose, inlet; EN 11770 Reflex

702 0 4812 530 29406 Hose valve-dispenser

707 5 4812 310 19102 Nozzle

708 1 4812 530 49392 Bend disp.-tub Eureka

711 0 4812 418 68379 Dispenser 3 ch.

712 0 4812 418 68381 Drawer

713 0 4812 418 68382 Safety device

718 0 4812 526 48226 Siphon

718 1 4812 418 89066 Separator

754 0 4812 530 29495 Drainhose tub-pump Eureka

754 1 4812 530 28832 Lock eco

760 0 4812 480 58385 Filter pump

781 0 4812 530 29496 Hose draining

782 0 4812 530 29497 Hose Pressostat

794 2 4812 401 18549 Clamp hose

900 0 4812 255 18298 Holder outlet hose

900 1 4812 290 88123 Bracket eureka

900 2 4812 401 18501 Clamp hose 19.2 mm

900 3 4812 401 18853 Cable clamp

900 4 4812 401 18414 Clamp hose

900 5 4819 401 18529 Clamp hose

900 8 4812 401 18854 Holder outlet hose

910 0 4812 505 18427 Nut M6 with washer

910 1 4812 502 48344 Screw

911 7 4812 903 08196 Screw M 5X14-Z; M 5X14-Z

930 0 4812 492 38419 Spring suspension-EUREKA

961 0 4812 532 68151 Spacer

965 0 4812 466 68936 Cover

993 0 4819 530 29028 U Curve for outlet hose

993 3 4812 395 58004 Tool

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 4 of 53

Exploded View

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 5 of 53

Exploded View

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 6 of 53

Technical Data

Dimensions + Weight

Product dimensions

Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81.5 - 84 cm

Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59.5 cm

Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57.3 cm

Weight

net . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72 kg

Electrical base data

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230 V 10%

Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 Hz

Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 A

Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ~2.3 kW

Drum data

Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44 l

Wash speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 rpm

Spinning

max. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 800 rpm

Pressostat

Level1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 12/14

Overflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 16

Door lock

Kind of switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Switch with PTC heater of bimetal

Nominal voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230 (90 - 264) V

Locking time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 s

Unlock time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ~85 s

Inlet valve

Nominal voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220 - 240 V / 50 Hz

Rated flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (1.5 - 5 bar) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 l/min

Pressure range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.3 - 10 bar

Nominal resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (20 C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.8 k

Drain pump

Nominal voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220 - 240 V / 50 Hz

Total power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 W

Resistor (coil) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (0.55 - 1 m) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 2 l/min

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 7 of 53

Heating element

Nominal voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230 V + 10 %, -15 %

Total power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2050 W

Resistance (20 C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Leakage current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . < 0.8 mA

NTC sensor

Resistance NTC

0 C 35.9 k

30 C 9.8 k

40 C 6.6 k

50 C 4.6 k

60 C 3.2 k

70 C 2.3 k

95 C 1.1 k

Motor

Resistance contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (20 C)

Stator (full field) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.95

Rotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.85

Tacho generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95.0

Control unit

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DOMINO

Nominal voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230 V / 50 Hz

Output control unit

Motor M7.6 - DSS3.2 > 40 V

Aquastop AQ2.2 - DSS3.2 230 V

In pump step AQ2.1 - DSS3.3 230 V

NTC Not measurable

Pump DP2.1 - DP2.2 230 V

Doorlock DSS3.1 - DSS3.3 230 V

Pressostat E4 - E2 230 V

- empty PR2.1 - E2 230 V

- full PR2.2 - E2 230 V

Valve (Rast 2.5) V2.1 - V2.2 >170 V

Options Not measurable

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 8 of 53

Wiring Diagram

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 9 of 53

Legend

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 10 of 53

Circuit Diagram

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 11 of 53

Legend

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 12 of 53

Program Chart

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 13 of 53

Program Chart

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 14 of 53

Program Chart

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 15 of 53

Program Chart

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 16 of 53

Program Chart

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 17 of 53

Program Chart

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 18 of 53

Program Chart

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 19 of 53

Program Chart

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 20 of 53

Program Chart

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 21 of 53

Program Chart

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 22 of 53

Program Chart

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 23 of 53

Program Chart

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 24 of 53

Testprogram

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 25 of 53

Error Codes

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 26 of 53

Error Codes

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 27 of 53

Error Codes

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 28 of 53

Error Codes

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 29 of 53

Service Bulletin 4812 712 40340

AUTHOR: Ronny Schuricht

Last Update: 05/16/11

VERSION: 2.0

TITLE: machine not spinning

SUBJECT: In order to reduce the risk of foam creation visible for the customer as long lasting cycle and / or not spinning of

the machine new spin profiles are implemented and new service kits are created.

REMEDIAL ACTION

Check motor function

=> If motor is not running at all: check for Motor failure F06

=> If motor is running:

Unbalance:

Unbalance measurement can lead to repeated laundry distribution ramps to come down with measured unbalance. De-

pending on the model it can be a high number of retrials. This is necessary to avoid mechanical damages of the appliance

due to spinning with too high unbalance. If it is not possible to reach an acceptable unbalance level with the distribution

retrials, the appliance will not spin.

Small loads and especially single pieces are more critical than middle and large loads => check with customer for load

conditions instruct customer

In case of selecting Drain & Spin-program, the unbalance measurement is more critical, because information from the

wash cycle is missing. Therefore is a higher probability for retrials in the distribution ramps and eventually for failing spin-

ning at all. Check with customer, if Drain & Spin-cycle was selected or if a complete washing program was selected.

Foam creation:

If during ramp-up for spinning intermediate spins or final spin the pressure switch contact is closed (wash level L1) due

to water ring, foam or partly blocked outlet system (foreign objects, wrong assembly of internal or external hoses, etc.) the

foam routine is started.

If during ramp-up the wash level L1 is detected, the motor stops and the drain pump runs for 30 sec. When reaching level

L0 within 30sec., the ramp-up is repeated. Depending on the model, this can happen up to 3 or up to 5 times.

If foam creation is the cause, then give an advice to the customer to use detergent acc. to the dosing recommendation

given by the detergent supplier. On machines with serial number 341020... or 411020...and lower reprogramme the control

board by ESAM with the latest update.

Frequency variation:

Instable mains frequency can have negative impact on unbalance detection. If the frequency variation is limited to a short

period, it will lead to additional retrials for distribution. In case of permanent frequency variation, it can lead to no spinning

after number of retrials is expired.

If a frequency variation is the cause of the problem, then exchange the control board by the service kits mentioned in

the table below. According to SPC the kits will be available from week 50/2010 onwards.

Each service kit is containing a new basic WAVE control board (CCU) that needs to be programmed by ESAM (with new

SKU), new door lock and wiring between door lock and CCU.

When the appliance is equipped with the new parts it has got the new revision state. That means the 12NC of the machine

has to be changed to the new 12NC code according to the table below by the service technician on each sticker of the

appliance.

One sticker is placed on the inner side of the door and one sticker on the rear panel of the appliance.

Note: A limited number of kits with programmed WAVE boards is shown on the last page.

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 30 of 53

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 31 of 53

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 32 of 53

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 33 of 53

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 34 of 53

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 35 of 53

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 36 of 53

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 37 of 53

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 38 of 53

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 39 of 53

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 40 of 53

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 41 of 53

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 42 of 53

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 43 of 53

Service Bulletin 4812 712 40347

AUTHOR: Ronny Schuricht

Last Update: 11/10/10

VERSION: 1.0

TITLE: drum lifter

SUBJECT: Since week 32/2010 are drum lifter with improved fixation feet as spare parts available. (Since week 31/2010 in

production).

Old and new codes are standardized. If the old code is ordered the new one will be deliverd automatically.

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 44 of 53

Service Bulletin 4812 712 40317

AUTHOR: Ronny Schurricht

Last Update: 07/01/09

VERSION: 1.0

TITLE: Heating Element alternative solution.

SUBJECT: In special conditions it can occur that the heating element after a short period gets broken caused by very hard

water (limestone) or variations in power supply.

REMEDIAL ACTION

If the heating element gets broken under mentioned conditions we recommend using the alternative heating element that is

nickel treated and usable for power supply up to 240V.

According to SPC 600 pieces will be on stock from week 52 onwards.

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 45 of 53

Service Bulletin 4812 712 40320

AUTHOR: Ronny Schuricht

Last Update: 03/31/09

VERSION: 1.0

TITLE: rotary program selector Domino

SUBJECT: In some washing machines with Domino control unit and rotary program selector it was detected, that turning

of program selector is too hard, program selection not possible or program indication is different from selected program.

Related machines are of production week 10 and 11 2009.

REMEDIAL ACTION

If such a failure occurs on machines of mentioned production period, the rotary program selector has got a mechanical

defect. The related control units are supplied by Bitron with production week 09 and 10 2009. They have to be exchanged

according to the spare part list in the related Service Info.

How to identify the related control units:

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 46 of 53

Service Bulletin 4812 712 40348

AUTHOR: Ronny Schuricht

Last Update: 05/16/11

VERSION: 1.0

TITLE: F23 appears, but pressure switch is ok.

SUBJECT: The customer claims the failure indication F23.

REMEDIAL ACTION

Pressure switch Failure

This failure code can be also generated by a defect heater or a defect drain pump or bad harness connections to heater or

drain pump.

To exclude the drain pump and the heater as root cause, please check:

1. Check if the drain pump is running and check for foreign objects in the filter (see F03)

2. Inverse the mains plug polarity (by turning the mains plug or by changing polarity of single connectors of the power cord

on the RFI Filter => ATTENTION: unplug appliance from mains before touching the single connectors!!!)

If with inversed polarity failure code remains F23, continue with checks for Pressure switch. If with inversed polarity failure

code changes to F12, check for Heater failure F12.

Pressure switch failure:

If the CCU can not properly read the OPEN or CLOSED status of the pressure switch contacts or if the CCU detects during

the wash cycle that the pressure switch contact for the wash level L1 (11-14) and the pressure switch contact for level

"empty drum L0"(11-12) are CLOSED or OPEN simultanously for 10 sec., this failure will be displayed.

Potential Causes

Check the wiring connections between the pressure switch and the CCU (2 connectors on pressure switch and 2 connec-

tors on CCU)

Check for proper operation of the pressure switch contacts (without water: 11-14 open, 11-12 closed, with water: 11-14

closed, 11-12 open).

Check the electrical resistance of the pressure switch for open and closed contacts without and with water.

Start the Service program. If the problem persists the Error Code F23 will be displayed.

If no issue found, check other points from hydraulic system like blocked air trap or blocked pressure switch hose (see

failure F01 and F03)

If these actions do not solve the issue and all parts like pressure switch and heating element are working correctly, then

exchange the control board by the new version indicated in the table below.

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 47 of 53

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 48 of 53

Service Bulletin 4812 712 40327

AUTHOR: Ronny Schuricht

Last Update: 01/21/10

VERSION: 1.0

TITLE: "F08"at end of cycle and "clean filter"indication

SUBJECT: A new software for the controlboards mentioned below has been released. The new software includes a modifi-

cation of F08 identification and an improvement of the pump cycle in order to avoid "long drain"and "clean filter"indications,

caused by ecoball sticking.

REMEDIAL ACTION

"F 08": If that failure indication appears at the end of a wash cycle and all parts like heating element and wiring are ok, then

replace the original control board by the new one and program the board by SAM.

"clean filter": If this indication appears, but the pump filter and the drain hoses are empty, not kinked and well mounted

and it is sure, that the indication is related to ecoball sticking in the drain hose (tub-pump) even it is already replaced by

the new version (SB 481271240326), then replace the original control board by the new one and program the board by SAM.

Only the mentioned basic control boards are available with the new software!

Please use the new control boards as spare part only in case of the above described behaviours. For any other rea-

son, please use the control boards according to Service Info.

The control boards will be substituted by the new versions step by step in respect of the production capacity of the supplier.

Its planned to introduce the new control boards in production completely until week39 2009.

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 49 of 53

Service Bulletin 4812 712 40313

AUTHOR: Juergen Reinhardt

Last Update: 11/17/09

VERSION: 1.0

TITLE: F06 randomly displayed in Domino controls

CAUSE

Sensible failure detection in drive system for safety reasons

REMEDIAL ACTION

Please check the following points:

Load:

Was there bulky load in the drum or was the machine overloaded ?

Drive system:

Please check the tacho generator (resistance and cable).

Please guarantee a proper and tight seat of the belt on drive shaft and pulley.

Please check the electrical connections between controls and motor.

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 50 of 53

Service Bulletin 4812 712 40330

AUTHOR: Ronny Schuricht

Last Update: 01/21/10

VERSION: 1.0

TITLE: no water inlet, cable connection to valve broken

SUBJECT: In rare cases the wiring between control board and valve gets broken directly at the connector of the valve.

Reason is a too strong fixation of the water inlet hose, done with a pliers. Result is that the valve gets out of its position and

brakes the cable connection. In addition can be created a short circuit on the control board.

REMEDIAL ACTION

Check the control board for short circuit. If necessary exchange the valve. Fixate the valve in the correct position with a

fixation screw. Exchange the harness between control board and valve. Check and If necessary exchange the inlet hoses

between valve and dispenser.

harness (CCU-valve): 4801 111 00724

fixation screw: 4812 023 08092

hose (valve-disp.): 4812 530 29405

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 51 of 53

Service Bulletin 4812 712 40314

AUTHOR: Ronny Schurricht

Last Update: 07/01/09

VERSION: 2.0

TITLE: Soap dispenser leaking between box and distribution plate.

REMEDIAL ACTION

We have some claims about soap dispenser leaking at the connection between dispenser box and distribution plate. We

recommend exchanging the soap dispenser in the appliance by the new one. The mentioned dispenser has got an improved

distribution plate. Implementation date in production was in week 45 2008. Please keep us informed if you find leakage

issues in machines produced after this week.

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 52 of 53

Service Bulletin 4812 712 40305

AUTHOR: Ronny Schurricht

Last Update: 06/16/08

VERSION: 2.0

TITLE: Over foaming when washing with liquid detergent.

SUBJECT: There are some cases in the field of over foaming and detergent coming out of soap dispenser area during

filling phase. This can occur when there is liquid detergent used.

CAUSE

When the water inlet has got a high pressure and splashes to the liquid detergent in the dispenser box, this creates much

more foam than the inlet system and especially the separator is designed for.

REMEDIAL ACTION

In case of over foaming at the customer:

The correct assembly of inlet hose between detergent box and tub has to be checked.

If its correct, the separator needs to be replaced by a modified one, that has got a wider slot (expanded from I=1mm to I=

2.5mm) in the middle in order to increase the flow rate and avoid over foaming.

New part SC: 4812 418 89066 (same code like old one. Stock has been exchanged).

From week 27/2008 onwards in production the modified separator is included.

REMEDIAL ACTION

If after exchanging the separator still over foaming occurs, its possible to order a flow rate limiter set 4801 310 00098

containing of a flow rate limiter and a sieve.

Whirlpool EMEA www.scc-service.com

8592 327 10100, 09/30/09

Whirlpool EMEA

SERVICE Customer Services

page 53 of 53

According SPC the kit is available from week 14/2009 onwards.

Text

It has to be installed in the inlet valve. The original flow rate limiter (red, 8l/min)) has to be removed. Then the new one

(yellow, 5.5l/min) has to be mounted together with the new sieve. Original sieve could be too long and destroy the limiter

when fixing the inlet hose. The set can only be used if the water inlet pressure is higher than 4 bar, otherwise there is a risk

to create a failure indication of too less water inlet.

Whirlpool EMEA www.scc-service.com

Potrebbero piacerti anche

- Whirlpool Awe 7515-1 SMDocumento43 pagineWhirlpool Awe 7515-1 SMINSTYFLEXNessuna valutazione finora

- Automotive Air Conditioning and Climate Control SystemsDa EverandAutomotive Air Conditioning and Climate Control SystemsValutazione: 4 su 5 stelle4/5 (6)

- Whirlpool Awoe 91400 SMDocumento72 pagineWhirlpool Awoe 91400 SMIoana Ancuța MoiseNessuna valutazione finora

- Marine Electrical Practice: Marine Engineering SeriesDa EverandMarine Electrical Practice: Marine Engineering SeriesValutazione: 4 su 5 stelle4/5 (8)

- Whirlpool Awe50510Documento47 pagineWhirlpool Awe50510European Car Data House Zrt.Nessuna valutazione finora

- Whirlpool Awe 6515 WDocumento41 pagineWhirlpool Awe 6515 WCoryl BlueNessuna valutazione finora

- Whirlpool Awe 2316Documento36 pagineWhirlpool Awe 2316Tamas BaloghNessuna valutazione finora

- The Engineering of Microprocessor Systems: Guidelines on System DevelopmentDa EverandThe Engineering of Microprocessor Systems: Guidelines on System DevelopmentNessuna valutazione finora

- Whirlpool Awo D 5120 EcoDocumento29 pagineWhirlpool Awo D 5120 EcoHoffman RedaotNessuna valutazione finora

- Beginning Digital Electronics through ProjectsDa EverandBeginning Digital Electronics through ProjectsValutazione: 5 su 5 stelle5/5 (1)

- Whirlpool Awo D 53105 Service Manual PDFDocumento29 pagineWhirlpool Awo D 53105 Service Manual PDFbogdan80100% (1)

- Whirlpool Awo D 53105 Service PDFDocumento29 pagineWhirlpool Awo D 53105 Service PDFbogdan80Nessuna valutazione finora

- Awo D 45135 1Documento28 pagineAwo D 45135 1Ioana Ancuța MoiseNessuna valutazione finora

- Whirlpool Aws 63013Documento33 pagineWhirlpool Aws 63013criksuu_795296388Nessuna valutazione finora

- Whirlpool Buttons 22Documento32 pagineWhirlpool Buttons 22Andrei MorariuNessuna valutazione finora

- Whirlpool Awo C 61200 PDFDocumento32 pagineWhirlpool Awo C 61200 PDFCristea GabrielNessuna valutazione finora

- Whirlpool Awo-D7116 SM PDFDocumento32 pagineWhirlpool Awo-D7116 SM PDFDamianNessuna valutazione finora

- Whirlpool Awo C 60100 PDFDocumento32 pagineWhirlpool Awo C 60100 PDFpedav100% (1)

- Whirlpool Awo D 45115Documento23 pagineWhirlpool Awo D 45115Bojan TorbicaNessuna valutazione finora

- Whirlpool Awo D 40100Documento23 pagineWhirlpool Awo D 40100MarkoNessuna valutazione finora

- Whirlpool Awo D 41125 PDFDocumento29 pagineWhirlpool Awo D 41125 PDFsamasca_serbanNessuna valutazione finora

- Whirlpool Awo D 43136 PDFDocumento27 pagineWhirlpool Awo D 43136 PDFМартин АнгеловNessuna valutazione finora

- Whirlpool Awo C 6304 859233710012 En1451842380Documento38 pagineWhirlpool Awo C 6304 859233710012 En1451842380teodoraraicu50% (2)

- Whirlpool Awe 4519 PDocumento32 pagineWhirlpool Awe 4519 PGábor SzőkeNessuna valutazione finora

- Whirlpool Adg 789Documento22 pagineWhirlpool Adg 789Laurentiu GramaNessuna valutazione finora

- Whirlpool Adp 6920 WH 854675101160 En1409162554Documento77 pagineWhirlpool Adp 6920 WH 854675101160 En1409162554Miguel RNessuna valutazione finora

- Whirlpool Aws 63013 859234984014 En1451842448Documento33 pagineWhirlpool Aws 63013 859234984014 En1451842448elsheref 2021Nessuna valutazione finora

- Whirlpool Awe 7519Documento45 pagineWhirlpool Awe 7519István GerencsérNessuna valutazione finora

- Whirlpool Awo D 41105Documento20 pagineWhirlpool Awo D 41105Se RadNessuna valutazione finora

- Whirlpool Awsx 63213Documento33 pagineWhirlpool Awsx 63213Iulian LupseNessuna valutazione finora

- Whirlpool w77Documento56 pagineWhirlpool w77Walter RizzatoNessuna valutazione finora

- Whirlpool Awe 60410Documento34 pagineWhirlpool Awe 60410Buitinės Technikos RemontasNessuna valutazione finora

- Whirlpool CDLR 60250 BLDocumento33 pagineWhirlpool CDLR 60250 BLPE TruNessuna valutazione finora

- Bauknecht TK Care 17bDocumento19 pagineBauknecht TK Care 17bcrisbo88Nessuna valutazione finora

- Bauknecht TK Care 6b DiDocumento20 pagineBauknecht TK Care 6b DiSledge Hammer100% (1)

- Whirlpool Adp 4108 1 WHDocumento80 pagineWhirlpool Adp 4108 1 WHStanislav TodorovNessuna valutazione finora

- Whirlpool TDLR 65231Documento41 pagineWhirlpool TDLR 65231Constantin UdreaNessuna valutazione finora

- Whirlpool Adg 8798 SMDocumento24 pagineWhirlpool Adg 8798 SMgnujsamatNessuna valutazione finora

- Whirlpool FSCR 90430 859209010010 En1451844160Documento31 pagineWhirlpool FSCR 90430 859209010010 En1451844160Danny DanNessuna valutazione finora

- Whirlpool Awe 2516Documento26 pagineWhirlpool Awe 2516Adrienn Zs.Nessuna valutazione finora

- Whirlpool Adg 175Documento16 pagineWhirlpool Adg 175Gabriel TanaseNessuna valutazione finora

- Service InformationDocumento32 pagineService Informationesharp016257Nessuna valutazione finora

- Service Manual: Built-In Oven Akp 242 IxDocumento5 pagineService Manual: Built-In Oven Akp 242 IxNeoNessuna valutazione finora

- Service InformationDocumento9 pagineService InformationNelu BarbuNessuna valutazione finora

- Service Manual Whirlpool WWDE 8612Documento15 pagineService Manual Whirlpool WWDE 8612JulienNessuna valutazione finora

- Service: Spare Part ListDocumento12 pagineService: Spare Part ListLlewellyn OliverNessuna valutazione finora

- Schema Masina Spalat Whirlpool FL 243Documento11 pagineSchema Masina Spalat Whirlpool FL 243Micu Adrian DanutNessuna valutazione finora

- Service Manual Awz - 241Documento14 pagineService Manual Awz - 241Marcelino Lage LaredoNessuna valutazione finora

- Whirlpool Awe8727Documento20 pagineWhirlpool Awe8727vicearellanoNessuna valutazione finora

- Adp 6837 PCDocumento21 pagineAdp 6837 PColivierh65Nessuna valutazione finora

- Service Manual: Built-In Oven Akp 120 IxDocumento6 pagineService Manual: Built-In Oven Akp 120 IxMário CoutoNessuna valutazione finora

- Whirlpool At328aluDocumento6 pagineWhirlpool At328aluGustavo ValdezNessuna valutazione finora

- Whirlpool Awe 8725Documento18 pagineWhirlpool Awe 8725Genoveva CostNessuna valutazione finora

- Whirlpool Awod 41135Documento20 pagineWhirlpool Awod 41135smara_1009Nessuna valutazione finora

- Whirlpool Awg 1212 ProDocumento16 pagineWhirlpool Awg 1212 Protomislav javisNessuna valutazione finora

- AVM510Documento12 pagineAVM510PablosoNessuna valutazione finora

- Service Manual: Tumble Dryer Air Vent AWG 263Documento6 pagineService Manual: Tumble Dryer Air Vent AWG 263Oscar CamposNessuna valutazione finora

- Goldair GCF 501r Manual PDFDocumento2 pagineGoldair GCF 501r Manual PDFZoran Prokic33% (3)

- LG gr-349 389 SQF PDFDocumento41 pagineLG gr-349 389 SQF PDFionagyb100% (1)

- CvoroviDocumento82 pagineCvoroviAna Lekan100% (2)

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Refrigerator: Service ManualDocumento54 pagineRefrigerator: Service ManualZoran ProkicNessuna valutazione finora

- Manual BlueSolar PWM Light 12 24V Charge Controller EN A4Documento1 paginaManual BlueSolar PWM Light 12 24V Charge Controller EN A4Zoran ProkicNessuna valutazione finora

- Installation and User's Manual - Atlas - Cayman 88 - Tigres - Falkon PDFDocumento55 pagineInstallation and User's Manual - Atlas - Cayman 88 - Tigres - Falkon PDFZoran ProkicNessuna valutazione finora

- CvoroviDocumento82 pagineCvoroviAna Lekan100% (2)

- MXT 3 XDocumento61 pagineMXT 3 XZoran ProkicNessuna valutazione finora

- GX2200 Om Usa Em044n170 PDFDocumento152 pagineGX2200 Om Usa Em044n170 PDFZoran ProkicNessuna valutazione finora

- Silent7300H ManualeServizio IngDocumento16 pagineSilent7300H ManualeServizio IngZoran ProkicNessuna valutazione finora

- Acti 9 A9MEM3200Documento2 pagineActi 9 A9MEM3200Zoran ProkicNessuna valutazione finora

- Silent7300H ManualeServizio IngDocumento16 pagineSilent7300H ManualeServizio IngZoran ProkicNessuna valutazione finora

- TLP250 Datasheet en 20190617Documento7 pagineTLP250 Datasheet en 20190617Zoran ProkicNessuna valutazione finora

- Norcold 6162Documento41 pagineNorcold 6162w4445555100% (1)

- 74584TL en User Manual 190903Documento68 pagine74584TL en User Manual 190903c_rosales_morenoNessuna valutazione finora

- Gorenje w6443sDocumento42 pagineGorenje w6443sZoran Prokic100% (3)

- Matrix T3x-03 AC Treadmill Service Manual PDFDocumento73 pagineMatrix T3x-03 AC Treadmill Service Manual PDFZoran ProkicNessuna valutazione finora

- Service Manual: Norcold, Inc. P.O. Box 4248 Sidney, OH 45365-4248Documento31 pagineService Manual: Norcold, Inc. P.O. Box 4248 Sidney, OH 45365-4248Zoran ProkicNessuna valutazione finora

- Gorenje w6443sDocumento42 pagineGorenje w6443sZoran Prokic100% (3)

- Hyundai Inverter Drive N50 ManualDocumento76 pagineHyundai Inverter Drive N50 ManualPREVISTONessuna valutazione finora

- Service Manual: Norcold, Inc. P.O. Box 4248 Sidney, OH 45365-4248Documento31 pagineService Manual: Norcold, Inc. P.O. Box 4248 Sidney, OH 45365-4248Zoran ProkicNessuna valutazione finora

- Truma Spare PartsDocumento56 pagineTruma Spare PartsZoran Prokic100% (1)

- RMDT8505Documento56 pagineRMDT8505Zoran ProkicNessuna valutazione finora

- The Physics of WavesDocumento465 pagineThe Physics of WavesIván RoaNessuna valutazione finora

- 09 2008 EXACT PLUS Bedienungsanleitung Englisch Ab EPN0408022Documento33 pagine09 2008 EXACT PLUS Bedienungsanleitung Englisch Ab EPN0408022Zoran ProkicNessuna valutazione finora

- En Foliant 520hpsDocumento2 pagineEn Foliant 520hpsZoran ProkicNessuna valutazione finora

- RML9335 Install InstructionsDocumento40 pagineRML9335 Install InstructionsZoran ProkicNessuna valutazione finora

- The Physics of WavesDocumento465 pagineThe Physics of WavesIván RoaNessuna valutazione finora

- Ideal TriumphDocumento52 pagineIdeal TriumphZoran ProkicNessuna valutazione finora

- Summary of The Anxious Generation by Jonathan Haidt: How the Great Rewiring of Childhood Is Causing an Epidemic of Mental IllnessDa EverandSummary of The Anxious Generation by Jonathan Haidt: How the Great Rewiring of Childhood Is Causing an Epidemic of Mental IllnessNessuna valutazione finora

- The Compound Effect by Darren Hardy - Book Summary: Jumpstart Your Income, Your Life, Your SuccessDa EverandThe Compound Effect by Darren Hardy - Book Summary: Jumpstart Your Income, Your Life, Your SuccessValutazione: 5 su 5 stelle5/5 (456)

- The One Thing: The Surprisingly Simple Truth Behind Extraordinary ResultsDa EverandThe One Thing: The Surprisingly Simple Truth Behind Extraordinary ResultsValutazione: 4.5 su 5 stelle4.5/5 (709)

- Can't Hurt Me by David Goggins - Book Summary: Master Your Mind and Defy the OddsDa EverandCan't Hurt Me by David Goggins - Book Summary: Master Your Mind and Defy the OddsValutazione: 4.5 su 5 stelle4.5/5 (383)

- The Body Keeps the Score by Bessel Van der Kolk, M.D. - Book Summary: Brain, Mind, and Body in the Healing of TraumaDa EverandThe Body Keeps the Score by Bessel Van der Kolk, M.D. - Book Summary: Brain, Mind, and Body in the Healing of TraumaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Summary: Atomic Habits by James Clear: An Easy & Proven Way to Build Good Habits & Break Bad OnesDa EverandSummary: Atomic Habits by James Clear: An Easy & Proven Way to Build Good Habits & Break Bad OnesValutazione: 5 su 5 stelle5/5 (1635)

- How To Win Friends and Influence People by Dale Carnegie - Book SummaryDa EverandHow To Win Friends and Influence People by Dale Carnegie - Book SummaryValutazione: 5 su 5 stelle5/5 (556)

- The Whole-Brain Child by Daniel J. Siegel, M.D., and Tina Payne Bryson, PhD. - Book Summary: 12 Revolutionary Strategies to Nurture Your Child’s Developing MindDa EverandThe Whole-Brain Child by Daniel J. Siegel, M.D., and Tina Payne Bryson, PhD. - Book Summary: 12 Revolutionary Strategies to Nurture Your Child’s Developing MindValutazione: 4.5 su 5 stelle4.5/5 (57)

- Summary of 12 Rules for Life: An Antidote to ChaosDa EverandSummary of 12 Rules for Life: An Antidote to ChaosValutazione: 4.5 su 5 stelle4.5/5 (294)

- The War of Art by Steven Pressfield - Book Summary: Break Through The Blocks And Win Your Inner Creative BattlesDa EverandThe War of Art by Steven Pressfield - Book Summary: Break Through The Blocks And Win Your Inner Creative BattlesValutazione: 4.5 su 5 stelle4.5/5 (273)

- Summary of The Algebra of Wealth by Scott Galloway: A Simple Formula for Financial SecurityDa EverandSummary of The Algebra of Wealth by Scott Galloway: A Simple Formula for Financial SecurityNessuna valutazione finora

- Summary of Atomic Habits by James ClearDa EverandSummary of Atomic Habits by James ClearValutazione: 5 su 5 stelle5/5 (169)

- Book Summary of Ego Is The Enemy by Ryan HolidayDa EverandBook Summary of Ego Is The Enemy by Ryan HolidayValutazione: 4.5 su 5 stelle4.5/5 (387)

- Mindset by Carol S. Dweck - Book Summary: The New Psychology of SuccessDa EverandMindset by Carol S. Dweck - Book Summary: The New Psychology of SuccessValutazione: 4.5 su 5 stelle4.5/5 (328)

- Summary of The Galveston Diet by Mary Claire Haver MD: The Doctor-Developed, Patient-Proven Plan to Burn Fat and Tame Your Hormonal SymptomsDa EverandSummary of The Galveston Diet by Mary Claire Haver MD: The Doctor-Developed, Patient-Proven Plan to Burn Fat and Tame Your Hormonal SymptomsNessuna valutazione finora

- Steal Like an Artist by Austin Kleon - Book Summary: 10 Things Nobody Told You About Being CreativeDa EverandSteal Like an Artist by Austin Kleon - Book Summary: 10 Things Nobody Told You About Being CreativeValutazione: 4.5 su 5 stelle4.5/5 (128)

- Essentialism by Greg McKeown - Book Summary: The Disciplined Pursuit of LessDa EverandEssentialism by Greg McKeown - Book Summary: The Disciplined Pursuit of LessValutazione: 4.5 su 5 stelle4.5/5 (187)

- Make It Stick by Peter C. Brown, Henry L. Roediger III, Mark A. McDaniel - Book Summary: The Science of Successful LearningDa EverandMake It Stick by Peter C. Brown, Henry L. Roediger III, Mark A. McDaniel - Book Summary: The Science of Successful LearningValutazione: 4.5 su 5 stelle4.5/5 (55)

- Designing Your Life by Bill Burnett, Dave Evans - Book Summary: How to Build a Well-Lived, Joyful LifeDa EverandDesigning Your Life by Bill Burnett, Dave Evans - Book Summary: How to Build a Well-Lived, Joyful LifeValutazione: 4.5 su 5 stelle4.5/5 (62)

- We Were the Lucky Ones: by Georgia Hunter | Conversation StartersDa EverandWe Were the Lucky Ones: by Georgia Hunter | Conversation StartersNessuna valutazione finora

- Sell or Be Sold by Grant Cardone - Book Summary: How to Get Your Way in Business and in LifeDa EverandSell or Be Sold by Grant Cardone - Book Summary: How to Get Your Way in Business and in LifeValutazione: 4.5 su 5 stelle4.5/5 (86)

- How Not to Die by Michael Greger MD, Gene Stone - Book Summary: Discover the Foods Scientifically Proven to Prevent and Reverse DiseaseDa EverandHow Not to Die by Michael Greger MD, Gene Stone - Book Summary: Discover the Foods Scientifically Proven to Prevent and Reverse DiseaseValutazione: 4.5 su 5 stelle4.5/5 (84)

- Summary of When Things Fall Apart: Heart Advice for Difficult Times by Pema ChödrönDa EverandSummary of When Things Fall Apart: Heart Advice for Difficult Times by Pema ChödrönValutazione: 4.5 su 5 stelle4.5/5 (22)

- Summary of Million Dollar Weekend by Noah Kagan and Tahl Raz: The Surprisingly Simple Way to Launch a 7-Figure Business in 48 HoursDa EverandSummary of Million Dollar Weekend by Noah Kagan and Tahl Raz: The Surprisingly Simple Way to Launch a 7-Figure Business in 48 HoursNessuna valutazione finora

- The 5 Second Rule by Mel Robbins - Book Summary: Transform Your Life, Work, and Confidence with Everyday CourageDa EverandThe 5 Second Rule by Mel Robbins - Book Summary: Transform Your Life, Work, and Confidence with Everyday CourageValutazione: 4.5 su 5 stelle4.5/5 (329)

- Summary, Analysis, and Review of Daniel Kahneman's Thinking, Fast and SlowDa EverandSummary, Analysis, and Review of Daniel Kahneman's Thinking, Fast and SlowValutazione: 3.5 su 5 stelle3.5/5 (2)

- Blink by Malcolm Gladwell - Book Summary: The Power of Thinking Without ThinkingDa EverandBlink by Malcolm Gladwell - Book Summary: The Power of Thinking Without ThinkingValutazione: 4.5 su 5 stelle4.5/5 (114)

- Tiny Habits by BJ Fogg - Book Summary: The Small Changes That Change EverythingDa EverandTiny Habits by BJ Fogg - Book Summary: The Small Changes That Change EverythingValutazione: 4.5 su 5 stelle4.5/5 (111)