Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Table 8 - Test Sequences and Requirements For Unscreened Separable Connectors (Excluding Shrouded Terminations)

Caricato da

junigr0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

22 visualizzazioni1 paginaTest sekvenca

Titolo originale

Test Sekvenca GI

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoTest sekvenca

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

22 visualizzazioni1 paginaTable 8 - Test Sequences and Requirements For Unscreened Separable Connectors (Excluding Shrouded Terminations)

Caricato da

junigrTest sekvenca

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

60502-4 IEC:2005 37

Table 8 Test sequences and requirements for unscreened separable connectors

(excluding shrouded terminations)

Tests 1) Requirements Test methods Test sequences

of IEC 61442 (see Figure 5)

5.1 5.2 5.3 5.4

1 AC or d.c. voltage AC for 5 min at 4,5 U 0 or d.c. for Clause 4 or 5 x x x

15 min at 4 U 0

2 Partial discharge 2) 10 pC max. at 1,73 U 0 Clause 7 x

3 Impulse at t 3) 10 impulses of each polarity Clause 6 x

4 Thermal short-circuit Two short-circuits at I sc of Clause 10 x x 7)

(screen) 6) the cable screen.

No visible deterioration

5 Thermal short-circuit Two short-circuits to raise Clause 11 x x 7)

(conductor) conductor to sc of the cable.

No visible deterioration

6 Dynamic One short-circuit at I d Clause 12 x

short-circuit 8) No visible deterioration

7 Heating cycles in air 30 cycles 4) at t 3) and 2,5 U 0 Clause 9 x

8 Heating cycles under 30 cycles 4) at t 3) and 2,5 U 0 Clause 9 x

water

9 Disconnect/connect 9) Five complete operations. x x x

No visible damage to contact

10 Partial discharge 2) at 10 pC max. at 1,73 U 0 Clause 7 x

t 3),

5) and ambient

temperature

11 Impulse 10 impulses of each polarity Clause 6 x x x

12 AC voltage 15 min at 2,5 U 0 Clause 4 x x x

13 Humidity 10) 300 h at 1,25 U 0 , see Table 13 Clause 13 x

14 Examination For information only 11) x x x x

1) Unless otherwise specified, tests shall be carried out at ambient temperature.

2) Not required for accessories installed on 3,6/6 (7,2) kV cables having unscreened insulation.

3) t is the maximum cable conductor temperature in normal operation +5 K to 10 K.

4) 8 h total with 2 h steady and 3 h cooling.

5) Measurement is made at the end of the heating period.

6) This test applies only to separable connectors that are equipped with a connection to, or adaptor for, the

metallic screen of the cable.

7) Thermal short-circuit may be combined with the dynamic short-circuit.

8) Only required for single-core cable accessories designed for initial peak currents i p > 80 kA and three-core

accessories designed for i p > 63 kA. Value of I d shall be declared by the manufacturer.

9) The test shall be carried out only when the cable is de-energized.

10) Test to be carried out with three samples in a test terminal box.

11) It is advised that the accessory is examined for signs of any of the following:

(i) cracking in the filling media and/or tape or tube components

and/or (ii) a moisture path across a primary seal

and/or (iii) corrosion and/or tracking and/or erosion which would, in time, lead to failure of the accessory

and/or (iv) leakage of any insulating material.

Potrebbero piacerti anche

- GTP 6.6KV - UE - 11 KV - E - IS13573 P2Documento1 paginaGTP 6.6KV - UE - 11 KV - E - IS13573 P2kinidudissaNessuna valutazione finora

- Potential Induced Degradation of Photovoltaic Modules: Influence of Temperature and Surface ConductivityDocumento49 paginePotential Induced Degradation of Photovoltaic Modules: Influence of Temperature and Surface ConductivitymkcforuNessuna valutazione finora

- International Standard (CEI IEC 60055-1Documento13 pagineInternational Standard (CEI IEC 60055-1abboali99240% (1)

- 66 KV Cable and AccessoriesDocumento4 pagine66 KV Cable and AccessoriesSandip AhireNessuna valutazione finora

- Edr 5124Documento11 pagineEdr 5124adanNessuna valutazione finora

- HVT 250 Edr5219 PDFDocumento8 pagineHVT 250 Edr5219 PDFMax FerreNessuna valutazione finora

- Transformers SpecificationDocumento9 pagineTransformers SpecificationduleepabowatteNessuna valutazione finora

- 2022 Summer Question Paper (Msbte Study Resources)Documento4 pagine2022 Summer Question Paper (Msbte Study Resources)Shubham BhatjireNessuna valutazione finora

- Anleitung Iec 60945 Tests PDFDocumento3 pagineAnleitung Iec 60945 Tests PDFap1948Nessuna valutazione finora

- Electrical Machine 3Documento4 pagineElectrical Machine 3AbhishekNessuna valutazione finora

- 132KV Sub StationDocumento11 pagine132KV Sub StationMurali MohanNessuna valutazione finora

- GTP of 400kv CVT Rev 01 - D 98Documento3 pagineGTP of 400kv CVT Rev 01 - D 98annuvyasNessuna valutazione finora

- Norm e CoLDocumento2 pagineNorm e CoLSTEFANALINLUCIANNessuna valutazione finora

- 3UA Thermally Delayed Overload Relays Class 10: Technical Data According To IEC 947-4Documento4 pagine3UA Thermally Delayed Overload Relays Class 10: Technical Data According To IEC 947-4NEOGQHNessuna valutazione finora

- Polypropylene Ppa 684d47baceDocumento6 paginePolypropylene Ppa 684d47baceRafael PaivaNessuna valutazione finora

- Cabling ESD StudyDocumento7 pagineCabling ESD StudydarinhomeNessuna valutazione finora

- Unit Auxiliary Transformer DatasheetDocumento6 pagineUnit Auxiliary Transformer DatasheetYulianti Rahmi PurnamawatiNessuna valutazione finora

- Wima FKP 2-9257 2Documento10 pagineWima FKP 2-9257 2aoctaNessuna valutazione finora

- Data SheetDocumento3 pagineData SheetDavid Salgado SalgadoNessuna valutazione finora

- Pre-Commissioning Tests For Power Cable R3Documento18 paginePre-Commissioning Tests For Power Cable R3Fahimuddin QureshiNessuna valutazione finora

- Overcurrent and Earthfault Relay Type CDG. Millenium VersionDocumento8 pagineOvercurrent and Earthfault Relay Type CDG. Millenium VersionAONLANessuna valutazione finora

- Technical Specifications For 33 KV Xlpe Insulated Underground Cables 1. ScopeDocumento22 pagineTechnical Specifications For 33 KV Xlpe Insulated Underground Cables 1. Scopethumula.rameshNessuna valutazione finora

- IET Lecture LV Wiring Design September 14Documento36 pagineIET Lecture LV Wiring Design September 14HP LooiNessuna valutazione finora

- JET Sample Paper ElectricalDocumento4 pagineJET Sample Paper ElectricalDhasu Mna NeyazNessuna valutazione finora

- 220 KV Cable Inspection ReportDocumento4 pagine220 KV Cable Inspection Report9782279059Nessuna valutazione finora

- ACJ1112Documento6 pagineACJ1112Holly SmithNessuna valutazione finora

- Cable Rating Verification For North Arm BridgeDocumento7 pagineCable Rating Verification For North Arm Bridgebcdavid100% (1)

- 4e4a 7671 4E4A TABLEDocumento1 pagina4e4a 7671 4E4A TABLEiqkhanukNessuna valutazione finora

- Mech 6561 Assignment 2Documento2 pagineMech 6561 Assignment 2Ashish SharmaNessuna valutazione finora

- JQ Relays: High Electrical & Mechanical Noise Immunity RelayDocumento6 pagineJQ Relays: High Electrical & Mechanical Noise Immunity RelayEdwin Andrés Villar RojasNessuna valutazione finora

- TS VCB (Id&od), CRPDocumento86 pagineTS VCB (Id&od), CRPraj_stuff006Nessuna valutazione finora

- Questions From Relay and Protection SchemeDocumento2 pagineQuestions From Relay and Protection SchemeChandan ChetriNessuna valutazione finora

- UL Test Comparison Saft Input On DO Revised IEC 62660rDocumento13 pagineUL Test Comparison Saft Input On DO Revised IEC 62660rPulkit100% (1)

- Earthing Calculation - DC SideDocumento2 pagineEarthing Calculation - DC SideANAND100% (1)

- Operate Only When Utility Supply Is Not AvailableDocumento5 pagineOperate Only When Utility Supply Is Not AvailableAli HassanNessuna valutazione finora

- 2353 - Specification - 33kV CT and PTDocumento18 pagine2353 - Specification - 33kV CT and PTARYA JENANessuna valutazione finora

- Page 1 of 2Documento2 paginePage 1 of 2AnirudhBandiNessuna valutazione finora

- Safety IEC 61730 - 2004 - 2007Documento6 pagineSafety IEC 61730 - 2004 - 2007FAE_CazadorNessuna valutazione finora

- JET-2022 Electrical Sample Paper: - DomainDocumento4 pagineJET-2022 Electrical Sample Paper: - DomainVIKASH KUMAR SINGHNessuna valutazione finora

- VCB SpecificationDocumento19 pagineVCB SpecificationprashantNessuna valutazione finora

- Ieee 80 Grounding Design SystemDocumento103 pagineIeee 80 Grounding Design SystemReynante100% (1)

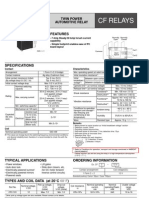

- CF Relays Eng 0Documento3 pagineCF Relays Eng 0mkafetzisNessuna valutazione finora

- Mech - Eng - TX ReleyDocumento6 pagineMech - Eng - TX ReleyAndreyATCNessuna valutazione finora

- Terminations and Joints For XLPE-Insulated Medium Voltage Cables PDFDocumento12 pagineTerminations and Joints For XLPE-Insulated Medium Voltage Cables PDFmagdy5220% (1)

- T Proc Notices Notices 040 K Notice Doc 39826 154073019 PDFDocumento281 pagineT Proc Notices Notices 040 K Notice Doc 39826 154073019 PDFabbastceNessuna valutazione finora

- D 01aDocumento40 pagineD 01aذوالفقار حبيبNessuna valutazione finora

- Ultra-Miniature, Highly SensitiveDocumento4 pagineUltra-Miniature, Highly SensitivemariotexmNessuna valutazione finora

- Is 1554 2 1988Documento21 pagineIs 1554 2 1988Sunil Devdutt ThakoreNessuna valutazione finora

- Earthing Calculation - RafelDocumento2 pagineEarthing Calculation - RafelANANDNessuna valutazione finora

- Technical Specifications For 11 KV Xlpe Insulated Underground Cables 1.0 ScopeDocumento22 pagineTechnical Specifications For 11 KV Xlpe Insulated Underground Cables 1.0 Scopethomas chinNessuna valutazione finora

- A ADocumento24 pagineA AOsvaldo Chimbas100% (1)

- SOP - Megger Testing (20220224)Documento7 pagineSOP - Megger Testing (20220224)Alexander TanNessuna valutazione finora

- 18th BS7671 Practice Paper 3Documento6 pagine18th BS7671 Practice Paper 3dvt2365100% (1)

- Data SheetDocumento6 pagineData SheetcornolioNessuna valutazione finora

- MF72 1 10RMDocumento7 pagineMF72 1 10RMRafonixscribdNessuna valutazione finora

- Is13779 PDFDocumento49 pagineIs13779 PDFKingkulkNessuna valutazione finora

- 11 KV VCBDocumento3 pagine11 KV VCBajaymannNessuna valutazione finora

- Voltage Surges Caused by Contactor CoilsDocumento6 pagineVoltage Surges Caused by Contactor CoilsRajuNessuna valutazione finora

- Memristor Modeling in MATLAB®&SimulinkDocumento6 pagineMemristor Modeling in MATLAB®&Simulinkjoseamh69062247Nessuna valutazione finora

- SMA LACB Flyer Update BID21 ENDocumento4 pagineSMA LACB Flyer Update BID21 ENadilsonrodriguesNessuna valutazione finora

- Biogas Technology: Construction, Utilization and Operation ManualDocumento52 pagineBiogas Technology: Construction, Utilization and Operation ManualDwi Cahyo NugrohoNessuna valutazione finora

- Guide To The Systems Engineering Body of Knowledge (Sebok), Version 1.1Documento51 pagineGuide To The Systems Engineering Body of Knowledge (Sebok), Version 1.1António FerreiraNessuna valutazione finora

- 240-109607332 Eskom Plant Labelling Abbreviation StandardDocumento638 pagine240-109607332 Eskom Plant Labelling Abbreviation StandardiabhuaNessuna valutazione finora

- 8×8 LED Matrix MAX7219 With Scrolling Text & Android Control Via BluetoothDocumento15 pagine8×8 LED Matrix MAX7219 With Scrolling Text & Android Control Via BluetoothakashlogicNessuna valutazione finora

- Metrolla Steels Industrial Visit ReportDocumento39 pagineMetrolla Steels Industrial Visit ReportSanjay R Nair100% (1)

- Kioti Daedong NX4520, NX5020, NX5520, NX6020 Tractors Service Manual 10-2019Documento19 pagineKioti Daedong NX4520, NX5020, NX5520, NX6020 Tractors Service Manual 10-2019LisakolyNessuna valutazione finora

- 350W AmplifierDocumento5 pagine350W AmplifiermoisesNessuna valutazione finora

- Blog #2Documento2 pagineBlog #2Anonymous uxozDvwYNessuna valutazione finora

- SEMIKRON Product Catalogue 2014 2015Documento167 pagineSEMIKRON Product Catalogue 2014 2015cesar oliveira0% (1)

- Instruction Manual: Oil-Lubricated Rotary Vane Vacuum Pumps RA 0750 ADocumento32 pagineInstruction Manual: Oil-Lubricated Rotary Vane Vacuum Pumps RA 0750 AYunisNessuna valutazione finora

- Wrights Offshore Hydrate Remediation Skid ArticleDocumento4 pagineWrights Offshore Hydrate Remediation Skid ArticleAnonymous ItzBhUGoiNessuna valutazione finora

- 130195mitsubishi ManualDocumento16 pagine130195mitsubishi ManualAbdul Noor KhanNessuna valutazione finora

- Liebherr Enquiry Data Sheet Hydraulic Cylinders EsDocumento2 pagineLiebherr Enquiry Data Sheet Hydraulic Cylinders EsDaniel Castillo PeñaNessuna valutazione finora

- SWOT Analysis of Viyellatex Spinning LimitedDocumento81 pagineSWOT Analysis of Viyellatex Spinning LimitedHossain RanaNessuna valutazione finora

- Work at Height Questions For Height PassDocumento3 pagineWork at Height Questions For Height PassPravash Mohanty100% (1)

- Insurer Offer Letter DV 2Documento5 pagineInsurer Offer Letter DV 2Lycan de LunaNessuna valutazione finora

- Olefins-All Product CatalogDocumento28 pagineOlefins-All Product Catalogayon_hossen242Nessuna valutazione finora

- ANNEX 9 - FacilitationDocumento62 pagineANNEX 9 - FacilitationSyahid Macheda100% (1)

- Potable Water Tank Calculation PDFDocumento37 paginePotable Water Tank Calculation PDFboysitumeangNessuna valutazione finora

- Codex 2017 enDocumento713 pagineCodex 2017 enJIgnacio123Nessuna valutazione finora

- Cloud Paas and Iaas Playbook 2993836Documento35 pagineCloud Paas and Iaas Playbook 2993836Blizard80Nessuna valutazione finora

- Exercise 4.7: CH 4 SupplementalDocumento12 pagineExercise 4.7: CH 4 SupplementalAngelica Diolata100% (1)

- 3 Types of Lasers and ApplicationsDocumento2 pagine3 Types of Lasers and ApplicationsHemlata AgarwalNessuna valutazione finora

- 14HDocumento2 pagine14HWiliam Vega Farias100% (2)

- Excel To C I For Positive in PutDocumento23 pagineExcel To C I For Positive in PuthimanshuNessuna valutazione finora

- Module 1: Introduction To Operating System: Need For An OSDocumento18 pagineModule 1: Introduction To Operating System: Need For An OSshikha2012Nessuna valutazione finora

- Service Manual: Model Code - Kib19Bp3-CmgDocumento11 pagineService Manual: Model Code - Kib19Bp3-Cmgpravin jadavNessuna valutazione finora

- Comb - Chemkin - Format PDFDocumento5 pagineComb - Chemkin - Format PDFMUHAMMAD FAREEZ IZWAN BIN ABDUL JALILNessuna valutazione finora