Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

API 610 Data Sheet 1 PDF

Caricato da

Suresh Kumar MittapalliTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

API 610 Data Sheet 1 PDF

Caricato da

Suresh Kumar MittapalliCopyright:

Formati disponibili

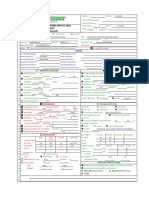

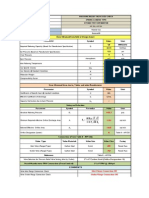

JOB NO. ITEM NO.

PURCHASE ORDER NO.

SPECIFICATION NO.

CENTRIFUGAL PUMP (API 610-8TH) REVISION NO. DATE

DATA SHEET PAGE 1 OF 5 BY

U.S. CUSTOMARY UNITS

1 APPLICABLE TO: PROPOSALS PURCHASE AS BUILT

2 FOR UNIT

3 SITE SERVICE

4 NO. REQ PUMP SIZE TYPE NO. STAGES

5 MANUFACTURER MODEL SERIAL NO.

6 NOTES: INFORMATION BELOW TO BE COMPLETED: BY PURCHASER BY MANUFACTURER BY MANUFACTURER OR PURCHASER

7 GENERAL (3.1.1)

8 PUMPS TO OPERATE IN (PARALLEL) NO. MOTOR DRIVEN NO. TURBINE DRIVEN

9 (SERIES) WITH PUMP ITEM NO. PUMP ITEM NO.

10 GEAR ITEM NO. MOTOR ITEM NO. TURBINE ITEM NO.

11 GEAR PROVIDED BY MOTOR PROVIDED BY TURBINE PROVIDED BY

12 GEAR MOUNTED BY MOTOR MOUNTED BY TURBINE MOUNTED BY

13 GEAR DATA SHT. NO. MOTOR DATA SHT. NO. TURBINE DATA SHT. NO.

14 OPERATING CONDITIONS SITE AND UTILITY DATA (CONT'D)

15 CAPACITY, NORMAL (GPM) RATED (GPM) WATER SOURCE

16 OTHER CHLORIDE CONCENTRATION (PPM) (3.5.2.6)

17 SUCTION PRESSURE MAX./RATED / (PSIG) INSTRUMENT AIR: MAX/MIN PRESS / (PSIG)

18 DISCHARGE PRESSURE (PSIG) LIQUID

19 DIFFERENTIAL PRESSURE (PSI) TYPE OR NAME OF LIQUID

20 DIFF. HEAD (FT) NPSHA (FT) PUMPING TEMPERATURE

21 PROCESS VARIATIONS (3.1.2) NORMAL (F) MAX. (F) MIN. (F)

22 STARTING CONDITIONS (3.1.3) VAPOR PRESSURE (PSIA) @ (F)

23 SERVICE: CONT. INTERMITTENT (STARTS/DAY) RELATIVE DENSITY (SPECIFIC GRAVITY):

24 PARALLEL OPERATION REQ'D (2.1.11) NORMAL MAX MIN

25 SITE AND UTILITY DATA SPECIFIC HEAT, Cp (BTU/LB F)

26 LOCATION: (2.1.29) VISCOSITY (cP) @ (F)

27 INDOOR HEATED UNDER ROOF MAX. VISCOSITY (cP)

28 OUTDOOR UNHEATED PARTIAL SIDES CORROSIVE/EROSIVE AGENT (2.11.1.8)

29 GRADE MEZZANINE CHLORIDE CONCENTRATION (PPM) (3.5.2.6)

30 ELECTRIC AREA CLASSIFICATION (2.1.22 / 3.1.5) H2S CONCENTRATION (PPM) (2.11.1.11)

31 CL GR DIV LIQUID (2.1.3) HAZARDOUS FLAMMABLE

32 WINTERIZATION REQ'D TROPICALIZATION REQ'D. OTHER

33 SITE DATA (2.1.29) PERFORMANCE

34 ALTITUDE (FT) BAROMETER (PSIA) PROPOASAL CURVE NO. RPM

35 RANGE OF AMBIENT TEMPS: MIN/MAX. / (F) IMPELLER DIA. RATED MAX. MIN. (IN.)

36 RELATIVE HUMIDITY: MIN / MAX / (%) RATED POWER (BHP) EFFICIENCY (%)

37 UNUSUAL CONDITIONS: (2.1.23) DUST FUMES MINIMUM CONTINUOUS FLOW:

38 OTHER THERMAL (GPM) STABLE (GPM)

39 UTILITY CONDITIONS: PREFERRED OPERATING REGION TO (GPM)

40 STEAM: DRIVERS HEATING ALLOWABLE OPERATING REGION TO (GPM)

41 MIN (PSIG) (F) (PSIG) (F) MAX HEAD @ RATED IMPELLER (FT)

42 MAX (PSIG) (F) (PSIG) (F) MAX POWER @ RATED IMPELLER (BHP)

43 ELECTRICITY DRIVERS HEATING CONTROL SHUTDOWN NPSHR AT RATED CAPACITY (FT) (2.1.8)

44 VOLTAGE SUCTION SPECIFIC SPEED (2.1.9)

45 HERTZ MAX. SOUND PRESS. LEVEL REQ'D (dBA) (2.1.14)

46 PHASE EST MAX SOUND PRESS. LEVEL (dBA) (2.1.14)

47 COOLING WATER: (2.1.17) REMARKS:

48 TEMP. INLET (F) MAX. RETURN (F)

49 PRESS. NORM (PSIG) DESIGN (PSIG)

50 MIN RETURN (PSIG) MAX ALLOW DP (PSI)

06/95 SHT 1 OF 5 API610.XLS REV 0

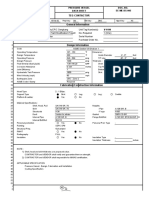

JOB NO. ITEM NO.

CENTRIFUGAL PUMP (API 610-8TH) REVISION NO. DATE

DATA SHEET PAGE 2 OF 5 BY

U.S. CUSTOMARY UNITS

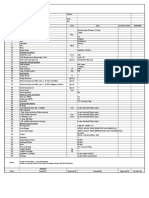

1 CONSTRUCTION CONSTRUCTION (CONT)

2 APPLICABLE STANDARD: SHAFT DIAMETER BETWEEN BEARINGS (IN)

3 API 610 8TH EDITION SPAN BETWEEN BEARING CENTERS (IN)

4 OTHER (SEE REMARKS) SPAN BETWEEN BEARING & IMPELLER (IN)

5 PUMP TYPE: (1.1.2) REMARKS

6 OH2 BB1 VS1 VS6

7 OH3 BB2 VS2 VS7

8 OH6 BB3 VS3 OTHER COUPLINGS: (3.2.2) DRIVER - PUMP

9 BB4 VS4 MAKE

10 BB5 VS5 MODEL

11 NOZZLE CONDITIONS: (2.3.2) RATING (HP/100 RPM)

12 SIZE (IN) FLANGE FAC'G POSITION LUBRICATION

13 RATING (LBS) LIMITED END FLOAT REQUIRED

14 SUCTION SPACER LENGTH (IN)

15 DISCHARGE SERVICE FACTOR

16 BALANCE DRUM DRIVER HALF COUPLING MOUNTED BY: (3.2.11)

17 PRESSURE CASING CONNECTIONS: (2.3.3) PUMP MFR. DRIVER MFR. PURCHASER

18 NO. SIZE (NPS) TYPE COUPLING PER API 671 (5.2.7)

19 DRAIN BASEPLATES:

20 VENT API BASEPLATE NUMBER (APPENDIX M)

21 PRESSURE GAUGE NON-GROUT CONSTRUCTION: (3.3.13/5.3.7.3.5)

22 TEMP GAUGE REMARKS:

23 WARM-UP

24 BALANCE / LEAK-OFF

25 CYLINDRICAL THREADS REQUIRED (2.3.3) MATERIAL

26 CASING MOUNTING: ( SEE SEPARATE SHEET FOR VERTICLES) APPENDIX H CLASS (2.11.1.1)

27 CENTERLINE NEAR CENTERLINE MIN DESIGN METAL TEMP (2.11.4.5) (F)

28 FOOT SEPARATE MOUNTING PLATE BARREL/CASE IMPELLER

29 IN-LINE CASE/IMPELLER WEAR RINGS

30 CASING SPLIT: SHAFT

31 AXIAL RADIAL DIFFUSERS

32 CASING TYPE: COUPLING SPACER/HUBS

33 SINGLE VOLUTE MULTIPLE VOLUTE DIFFUSER COUPLING DIAPHAGMS (DISKS)

34 OVERHUNG BETWEEN BEARINGS BARREL REMARKS:

35 CASE PRESSURE RATING:

36 MAX ALLOWABLE WORKING PRESSURE (PSIG)

37 @ (F) BEARINGS AND LUBRICATION

38 HYDROTEST PRESSURE (PSIG) BEARING (TYPE/NUMBER):

39 SUCT'N PRESS. REGIONS MUST BE DESIGNED FOR MAWP (2.2.4) RADIAL /

40 ROTATION: (VIEWED FROM COUPLING END) THRUST /

41 CW CCW REVIEW AND APPROVE THRUST BEARING SIZE (5.2.5.2.4)

42 IMPELLERS INDIVIDUALLY SECURED (5.2.2.2) LUBRICATION: (2.10)

43 REMARKS: GREASE FLOOD RING OIL

44 FLINGER PURGE OIL MIST PURE OIL MIST

45 BOLT OH3 PUMP TO PAD/FOUNDATION (5.1.2.4) CONSTANT LEVEL OILER PREFERENCE (SEE REMARKS) (2.9.2.2)

46 SHAFT: PRESSURE LUBE SYS (5.2.6) API-610 API-614

47 SHAFT DIAMETER AT COUPLING (IN) OIL VISC. ISO GRADE (5.2.6.5)

48 REMARKS:

49

50

51

06/95 SHT 2 OF 5 API610.XLS REV 0

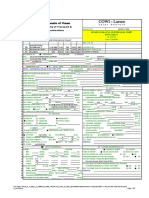

JOB NO. ITEM NO.

CENTRIFUGAL PUMP (API 610-8TH) REVISION NO. DATE

DATA SHEET PAGE 3 OF 5 BY

U.S. CUSTOMARY UNITS

1 BEARINGS AND LUBRICATION (CONT) MECHANICAL SEAL OR PACKING (CONT)

2 OIL HEATER REQ'D ELECTRIC STEAM (2.9.2.9/5.2.6.3) VAPOR PRESSURE (PSIA) @ (F)

3 OIL PRESS TO BE GREATER THAN COOLANT PRESS (5.2.6.2.b) HAZARDOUS FLAMMABLE OTHER

4 REMARKS FLOW RATE MAX/MIN / (GPM)

5 PRESSURE REQUIRED MAX/MIN / (PSIG)

6 TEMPERATURE REQUIRED MAX/MIN / (F)

7 MECHANICAL SEAL OR PACKING QUENCH FLUID:

8 SEAL DATA: (2.7.2) NAME OF FLUID

9 SEE ATTACHED API-682 DATA SHEET (2.7.2) FLOW RATE (GPM)

10 NON-API 682 SEAL (2.7.2) SEAL FLUSH PIPING: (2.7.3.19 AND APPENDIX D)

11 APPENDIX H SEAL CODE (2.11.1.1) SEAL FLUSH PIPING PLAN

12 SEAL MANUFACTURER TUBING CARBON STEEL

13 SIZE AND TYPE / PIPE STAINLESS STEEL

14 MANUFACTURER CODE AUXILIARY FLUSH PLAN

15 SEAL CHAMBER DATA: (2.1.6/2.1.7) TUBING CARBON STEEL

16 TEMPERATURE (F) PIPE STAINLESS STEEL

17 PRESSURE (PSIG) PIPING ASSEMBLY: (3.5.2.10.1)

18 FLOW (GPM) THREADED UNIONS SOCKET WELDED

19 SEAL CHAMBER SIZE (TABLE 2.3) FLANGED TUBE TYPE FITTINGS

20 TOTAL LENGTH (IN) CLEAR LENGTH (IN) PRESSURE SWITCH (PLAN 52/53) TYPE

21 SEAL CONSTRUCTION: PRESSURE GUAGE (PLAN 52/53)

22 SLEEVE MATERIAL LEVEL SWITCH (PLAN 52/53) TYPE

23 GLAND MATERIAL LEVEL GUAGE (PLAN 52/53)

24 AUX SEAL DEVICE (2.7.3.20) TEMP INDICATOR (PLANS 21, 22, 23, 32, 41)

25 JACKET REQUIRED (2.7.3.17) HEAT EXCHANGER (PLAN 52/53)

26 GLAND TAPS: (2.7.3.14) REMARKS

27 FLUSH (F) DRAIN (D) BARRIER/BUFF. (B)

28 QUENCH (Q) COOLING (C) LUBRICATION (G)

29 HEATING (H) LEAKAGE PUMPED FLUID (P) PACKING DATA: (APPENDIX C)

30 BAL'NCE FLUID (E) EXTERNAL FLUID INJECTION (X) MANUFACTURER

31 SEAL FLUIDS REQUIREM'T AND AVAILABLE FLUSH LIQUID: TYPE

32 NOTE: IF FLUSH LIQUID IS PUMPAGE LIQUID (AS IN FLUSH PIPING SIZE NO. OF RINGS

33 PLANS 11 TO 41), FOLLWING FLUSH LIQUID DATA IS NOT REQ'D. PACKING INJECTION REQUIRED

34 SUPPLY TEMPERATURE MAX/MIN / (F) FLOW (GPM) @ (F)

35 RELATIVE DENSITY (SPECIFIC GRAVITY) @ (F) LANTERN RING

36 NAME OF FLUID STEAM AND COOLING WATER PIPING

37 SPECIFIC HEAT, Cp (BTU/LB F) COOLING WATER PIPING PLAN (3.5.4.1)

38 VAPOR PRESSURE (PSIA) @ (F) COOLING WATER REQUIREMENTS

39 HAZARDOUS FLAMMABLE OTHER SEAL JACKET/BRG HSG (GPM) @ (PSIG)

40 FLOW RATE MAX/MIN / (GPM) SEAL HEAT EXCHANGER (GPM) @ (PSIG)

41 PRESSURE REQUIRED MAX/MIN / (PSIG) QUENCH (GPM) @ (PSIG)

42 TEMPERATURE REQUIRED MAX/MIN / (F) TOTAL COOLING WATER (GPM)

43 BARRIER/BUFFER FLUID (2.7.3.21): STEAM PIPING: TUBING PIPE

44 SUPPLY TEMPERATURE MAX/MIN / (F) REMARKS

45 RELATIVE DENSITY (SPECIFIC GRAVITY) @ (F)

46 NAME OF FLUID

47 ADDITIONAL REMARKS:

48

49

50

51

06/95 SHT 3 OF 5 API610.XLS REV 0

JOB NO. ITEM NO.

CENTRIFUGAL PUMP (API 610-8TH) REVISION NO. DATE

DATA SHEET PAGE 4 OF 5 BY

U.S. CUSTOMARY UNITS

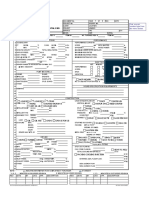

1 INSTRUMENTATION MOTOR DRIVE (CONT) (3.1.5)

2 VIBRATION: REMARKS

3 NONCONTACTING (API 670) TRANSDUCER

4 PROVISION FOR MOUNTING ONLY (2.9.2.11)

5 FLAT SURFACE REQ'D (2.9.2.12) SURFACE PREPARATION AND PAINT

6 SEE ATTACHED API 670 DATA SHEET MANUFACTURER'S STANDARD

7 MONITORS AND CABLES (3.4.3.3) OTHER (SEE BELOW)

8 REMARKS PUMP:

9 PUMP SURFACE PREPARATION

10 PRIMER

11 TEMPERATURE AND PRESSURE: FINISH COAT

12 RADIAL BRG METAL TEMP THRUST BRG METAL TEMP BASEPLATE: (3.3.18)

13 PROVISION FOR INSTRUMENTS ONLY BASEPLATE SURFACE PREPARATION

14 SEE ATTACHED API-670 DATA SHEET PRIMER

15 TEMP GAUGES (WITH THERMOWELLS) (3.4.1.3) FINISH COAT

16 OTHER SHIPMENT: (4.4.1)

17 PRESSURE GAUGE TYPE (3.4.2.2) DOMESTIC EXPORT EXPORT BOXING REQUIRED

18 LOCATION OUTDOOR STORAGE MORE THAN 6 MONTHS

19 REMARKS SPARE ROTOR ASSEMBLY PACKAGED FOR:

20 HORIZONTAL STORAGE VERTICAL STORAGE

21 TYPE OF SHIPPING PREPARATION

22 SPARE PARTS (TABLE 6.1) REMARKS

23 START-UP NORMAL MAINTENANCE

24 SPECIFY

25 WEIGHTS

26 MOTOR DRIVEN:

27 MOTOR DRIVE (3.1.5) WEIGHT OF PUMP (LBS)

28 MANUFACTURER WEIGHT OF BASEPLATE (LBS)

29 (HP) (RPM) WEIGHT OF MOTOR (LBS)

30 HORIZONTAL VERTICAL WEIGHT OF GEAR (LBS)

31 FRAME TOTAL WEIGHT (LBS)

32 SERVICE FACTOR TURBINE DRIVEN:

33 VOLTS/PHASE/HERTZ / / WEIGHT OF BASEPLATE (LBS)

34 TYPE WEIGHT OF TURBINE (LBS)

35 ENCLOSURE WEIGHT OF GEAR (LBS)

36 MINIMUM STARTING VOLTAGE (3.1.6) TOTAL WEIGHT (LBS)

37 TEMPERATURE RISE REMARKS

38 FULL LOAD AMPS

39 LOCKED ROTOR AMPS

40 INSULATION OTHER PURCHASE REQUIREMENTS

41 STARTING METHOD COORDINATION MEETING REQUIRED (6.1.3)

42 LUBE REVIEW FOUNDATION DRAWINGS (2.1.27)

43 VERTICAL THRUST CAPACITY REVIEW PIPING DRAWINGS

44 UP (LBS) DOWN (LBS) OBSERVE PIPING CHECKS

45 BEARINGS (TYPE / NUMBER): OBSERVE INITIAL ALIGNMENT CHECK

46 RADIAL / CHECK ALIGNMENT AT OPERATING TEMPERATURE

47 THRUST / CONNECTION DESIGN APPROVAL (2.11.3.5.4)

48 REMARKS:

49

50

06/95 SHT 4 OF 5 API610.XLS REV 0

JOB NO. ITEM NO.

CENTRIFUGAL PUMP (API 610-8TH) REVISION NO. DATE

DATA SHEET PAGE 5 OF 5 BY

U.S. CUSTOMARY UNITS

1 OTHER PURCHASER REQUIREMENTS (CONT) QA INSPECTION AND TEST (CONT'D)

2 RIGGING DEVICE REQ'D FOR TYPE OH3 PUMP (5.1.2.7) ADDITIONAL INSPECTION REQUIRED FOR:

3 HYDRODYNAMIC THRUST BRG SIZE REVIEW REQ'D (5.2.5.2.4) (4.2.1.3)

4 LATERAL ANALYSIS REQUIRED (5.1.3.3/5.2.4.1) MAG PARTICLE LIQUID PENETRANT

5 ROTOR DYNAMIC BALANCE (5.2.4.2) RADIOGRAPHIC ULTRASONIC

6 MOUNT SEAL RESERVOIR OFF BASEPLATE (3.5.1.4) ALTERNATE ACCEPTANCE CRITERIA (SEE REMARKS) (4.2.2.1)

7 INSTALLATION LIST IN PROPOSAL (6.2.3L) HARDNESS TEST REQUIRED FOR:

8 SPARE ROTOR VERTICAL STORAGE (5.2.9.2) (4.2.3.2)

9 TORSIONAL ANALYSIS/REPORT (2.8.2.6) WETTING AGENT HYDROTEST (4.3.2.5)

10 PROGRESS REPORTS REQUIRED (6.3.4) VENDOR SUBMIT TEST PROCEDURES (4.3.1.2/6.2.5)

11 REMARKS: RECORD FINAL ASSEMBLY RUNNING CLEARANCES

12 INSPECTION CHECK-LIST (APPENDIX N) (4.1.6)

13 REMARKS

14 QA INSPECTION AND TEST

15 REVIEW VENDORS QA PROGRAM (4.1.7)

16 PERFORMANCE CURVE APPROVAL GENERAL REMARKS

17 SHOP INSPECTION (4.1.4) REMARK 1:

18 TEST WITH SUBSTITUTE SEAL (4.3.3.1.2)

19 TEST NON-WIT WIT OBSERVE

20 HYDROSTATIC (4.3.2)

21 PERFORMANCE (4.3.3)

22 NPSH (4.3.4.1) REMARK 2:

23 COMPLETE UNIT TEST (4.3.4.2)

24 SOUND LEVEL TEST (4.3.4.3)

25 CLEANLINESS PRIOR TO

26 FINAL ASSEMBLY (4.2.3.1)

27 NOZZLE LOAD TEST (3.3.6) REMARK 3:

28 BRG HSG RESONANCE

29 TEST (4.3.4.5)

30 REMOVE/INSPECT

31 HYDRODYNAMIC BEARINGS

32 AFTER TEST (5.2.8.5) REMARK 4:

33 AUXILIARY EQUIPMENT

34 TEST (4.3.4.4)

35

36

37 MATERIAL CERTIFICATION REQUIRED (2.11.1.7) REMARK 5:

38 CASING IMPELLER SHAFT

39 OTHER

40 CASTING REPAIR PROCEDURE APPROVAL REQ'D (2.11.2.5)

41 INSPECTION REQUIRED FOR CONNECTION WELDS (2.11.3.5.6)

42 MAG PARTICLE LIQUID PENETRANT REMARK 6:

43 RADIOGRAPHIC ULTRASONIC

44 INSPECTION REQUIRED FOR CASTINGS (4.2.1.3)

45 MAG PARTICLE LIQUID PENETRANT

46 RADIOGRAPHIC ULTRASONIC

47 ADDITIONAL REMARKS:

48

49

50

51

06/95 SHT 5 OF 5 API610.XLS REV 0

JOB NO. ITEM NO.

VERTICAL PUMP (API 610-8TH) REVISION NO. DATE

SUPPLEMENTAL DATA SHEET PAGE 1 OF 1 BY

U.S. CUSTOMARY UNITS

1 VERTICAL TYPE (FIG 1.1) VS1 VS2 VS3 VS4 VS5 VS6 VS7 OTHER

2 REMARKS

3

4

5

6 VERTICAL PUMPS VERTICAL PUMPS (CONT'D)

7 PUMP THRUST: (+) UP (-) DOWN LINE SHAFT: OPEN ENCLOSED

8 AT MIN FLOW (LBS) (LBS) LINE SHAFT DIAMETER (IN) TUBE DIAMETER (IN)

9 AT RATED FLOW (LBS) (LBS) LINE SHAFT COUPLING:

10 AT MAX FLOW (LBS) (LBS) SLEEVE & KEY THREADED

11 MAX THRUST (LBS) (LBS) SUCTION CAN THICKNESS (IN)

12 SOLEPLATE (IN) X (IN) LENGTH (FT)

13 SOLEPLATE THICKNESS (IN) DIAMETER (FT)

14 COLUMN PIPE: FLANGED THREADED SUCTION STRAINER TYPE

15 DIAMETER (IN) LENGTH (FT) FLOAT & ROD FLOAT SWITCH

16 GUIDE BUSHINGS: IMPELLER COLLETS ACCEPTABLE (2.5.2)

17 NUMBER HARDENED SLEEVES UNDER BEARINGS (5.3.9.7)

18 LINE SHAFT BEARING SPACING (IN) RESONANCE TEST (5.3.8.2)

19 GUIDE BUSHING LUBE: STRUCTURAL ANALYSIS (5.3.4.1)

20 WATER OIL DRAIN PIPED TO SURFACE (5.3.12.6)

21 GREASE PUMPAGE

22

23

24

25 CENTERLINE OF DISCHARGE

26 SUMP ARRANGEMENT

27

28 GRADE GRADE

29 DATA

30 LOW PUMP ELEVATION LOW

31 SUMP PUMP LIQUID LENGTH (1ST STG IMPELLER) LIQUID

32 DEPTH LENGTH

33 SUBMERGENCE REQ'D

34

35

36

37

38

39

40 SUMP DIMENSION

41

42

43

44 SUMP DEPTH (FT) PUMP LENGTH (FT)

45

46 SUMP DIMENSION (FT) SUBMERGENCE REQ'D (FT)

47

48 LOW LIQUID (FT) CENTERLINE DISCHARGE HEIGHT (FT)

49

50 DATUM ELEVATION (FT)

51

06/95 SHT 1 OF 1 API610.XLS REV 0

Potrebbero piacerti anche

- vs1 DatasheetDocumento22 paginevs1 DatasheetMojtabaNessuna valutazione finora

- Data Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)Documento3 pagineData Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)André HeunisNessuna valutazione finora

- Specification Datasheet For Instrument Air Compressor PackageDocumento5 pagineSpecification Datasheet For Instrument Air Compressor PackageBarata RendengNessuna valutazione finora

- 22-DS-R-001 Rev 1 API 617 GTCPsDocumento25 pagine22-DS-R-001 Rev 1 API 617 GTCPsChike Nwachukwu100% (1)

- Mechanical Data Sheet Backwash Pump: Pt. Yusonda Mahayasa NusantaraDocumento5 pagineMechanical Data Sheet Backwash Pump: Pt. Yusonda Mahayasa NusantaraAhmad RifaiNessuna valutazione finora

- Centrifugal Pump Data SheetDocumento20 pagineCentrifugal Pump Data SheetMojtabaNessuna valutazione finora

- Data Sheet Multiphase Pump BornermanDocumento5 pagineData Sheet Multiphase Pump BornermanUmar Ijaz KhanNessuna valutazione finora

- API 675 Pump DatasheetDocumento2 pagineAPI 675 Pump DatasheetArun CPNessuna valutazione finora

- Mechanical Data Sheet For Fuel Gas FiltersDocumento4 pagineMechanical Data Sheet For Fuel Gas FilterssudjonoNessuna valutazione finora

- Datasheet Rev 1Documento7 pagineDatasheet Rev 1Tauasi TauasisNessuna valutazione finora

- Air Blowe DatasheetDocumento1 paginaAir Blowe DatasheetMoein PNessuna valutazione finora

- Intro To TBE For PumpDocumento2 pagineIntro To TBE For PumpMuhammad RidhwanNessuna valutazione finora

- Centrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)Documento9 pagineCentrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)tutuionutNessuna valutazione finora

- STD PIP VECQ1001 2009 Vessel Shop Qualification ProcedureDocumento27 pagineSTD PIP VECQ1001 2009 Vessel Shop Qualification ProcedureNikunj KNessuna valutazione finora

- Strainer DatasheetDocumento1 paginaStrainer DatasheetdgmprabhakarNessuna valutazione finora

- SA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02Documento5 pagineSA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02altipatlarNessuna valutazione finora

- Technical Bid Evaluation (Attachment9) - 1178067845726Documento16 pagineTechnical Bid Evaluation (Attachment9) - 1178067845726vikas100% (1)

- TGT M WPP DS 0012 - C - Datasheet For Caisson Sump PumpDocumento7 pagineTGT M WPP DS 0012 - C - Datasheet For Caisson Sump Pumpvovancuong8Nessuna valutazione finora

- IPB-OCS-KEA-MEC-DAT-0024 Rev0 Mechanical Data Sheet For Fire Water PumpDocumento4 pagineIPB-OCS-KEA-MEC-DAT-0024 Rev0 Mechanical Data Sheet For Fire Water PumpsudjonoNessuna valutazione finora

- Safety Relief Valve Specification SheetDocumento5 pagineSafety Relief Valve Specification Sheetdgmprabhakar0% (1)

- Erbil Refinery Diesel Filling Pump Data SheetDocumento5 pagineErbil Refinery Diesel Filling Pump Data SheetSardar PerdawoodNessuna valutazione finora

- SA-980-P-11448 - API 685 Tank Transfer Pump PZ - Vert02Documento5 pagineSA-980-P-11448 - API 685 Tank Transfer Pump PZ - Vert02altipatlarNessuna valutazione finora

- Polyacrylamide Plant: Mechanical Datasheet For Steam TrapsDocumento2 paginePolyacrylamide Plant: Mechanical Datasheet For Steam Trapsbecpavan100% (1)

- Peco Filter CaseDocumento11 paginePeco Filter CaseLuis MaureraNessuna valutazione finora

- Air Eliminator Datasheet PDFDocumento2 pagineAir Eliminator Datasheet PDFbecpavanNessuna valutazione finora

- 610 10th Ed Datasheets (SI)Documento11 pagine610 10th Ed Datasheets (SI)sjois_hsNessuna valutazione finora

- Datasheet of Deluge ValveDocumento2 pagineDatasheet of Deluge ValveAlvin SmithNessuna valutazione finora

- Customer Name Date Bid Due Date: Sweco Fab Inc. Customer RFQ FormDocumento2 pagineCustomer Name Date Bid Due Date: Sweco Fab Inc. Customer RFQ FormGustavo GarciaNessuna valutazione finora

- TDS For Y-StrainerDocumento2 pagineTDS For Y-StrainerRAGHVENDRA PRATAP SINGHNessuna valutazione finora

- SEO-OPTIMIZED TITLEDocumento3 pagineSEO-OPTIMIZED TITLEwado11Nessuna valutazione finora

- Separator Design GuideDocumento37 pagineSeparator Design GuideSanjay ParmarNessuna valutazione finora

- Centrifugal Pump Data Sheet InsightsDocumento1 paginaCentrifugal Pump Data Sheet Insightspkitchen25Nessuna valutazione finora

- API 676 Datasheet PDFDocumento6 pagineAPI 676 Datasheet PDFPierre Norris0% (1)

- API 650 Datasheet 1Documento16 pagineAPI 650 Datasheet 1alwacsNessuna valutazione finora

- Coriolis Mass Flow MeterDocumento2 pagineCoriolis Mass Flow MeterSreejesh SundaresanNessuna valutazione finora

- Pig Launcher & ReceiverDocumento4 paginePig Launcher & ReceiverMEHDI100% (1)

- Globe Valve1 DatasheetDocumento1 paginaGlobe Valve1 DatasheetobumuyaemesiNessuna valutazione finora

- ATTACHMENT 1-TECHNICAL BID EVALUATION FOR VALVES ATTACHEMENT AG 1 Rev 1Documento4 pagineATTACHMENT 1-TECHNICAL BID EVALUATION FOR VALVES ATTACHEMENT AG 1 Rev 1eko123Nessuna valutazione finora

- Pressure Relief Valve Sizing and Selection CheckDocumento2 paginePressure Relief Valve Sizing and Selection CheckGiftObionochieNessuna valutazione finora

- 1308-306-MEC-DTS-001 - Rev.1 - Cryogenic Flexible HoseDocumento3 pagine1308-306-MEC-DTS-001 - Rev.1 - Cryogenic Flexible HoseKira RaNessuna valutazione finora

- HSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterDocumento2 pagineHSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterThanh Phuc NguyenNessuna valutazione finora

- API 650 Tank Nozzle Loads - Can Not Use WRC For Tank Nozzle CheckDocumento3 pagineAPI 650 Tank Nozzle Loads - Can Not Use WRC For Tank Nozzle CheckDam Vo100% (1)

- 01 T121-HA-02005 Specification For Metering Skid PDFDocumento13 pagine01 T121-HA-02005 Specification For Metering Skid PDFMayur Patel100% (2)

- (0152) 4664-MSP-001 - API610 Centrifugal PumpsDocumento6 pagine(0152) 4664-MSP-001 - API610 Centrifugal PumpsSixto Gerardo Oña AnaguanoNessuna valutazione finora

- Data Sheet Ball ValveDocumento1 paginaData Sheet Ball ValveIkhsan Hj SiratNessuna valutazione finora

- Loading Arm Design DatasheetDocumento3 pagineLoading Arm Design Datasheetsenkuttuvan0% (1)

- TQ - Air Fin Cooler (CS) - ModificationDocumento6 pagineTQ - Air Fin Cooler (CS) - ModificationAvinash ShuklaNessuna valutazione finora

- (6648-0200-5-PS-DS-0026) 200-C-51 - Rev.FDocumento15 pagine(6648-0200-5-PS-DS-0026) 200-C-51 - Rev.FMohamed OuichaouiNessuna valutazione finora

- 100-T-1100 Methanol Tank SampleDocumento3 pagine100-T-1100 Methanol Tank SampleSachinl PatelNessuna valutazione finora

- Flame ArresterDocumento16 pagineFlame Arresteriran1362Nessuna valutazione finora

- Pressure Vessel Data Sheet for TEG ContactorDocumento2 paginePressure Vessel Data Sheet for TEG ContactorElias EliasNessuna valutazione finora

- ITP For Reciprocating PumpDocumento2 pagineITP For Reciprocating PumpShahShNessuna valutazione finora

- Attachment-6 TBE ANSI Pump BCUDocumento31 pagineAttachment-6 TBE ANSI Pump BCURanu Januar100% (1)

- Brown & Root, Inc.: Centrifugal Pump (Api 610-8Th) Data Sheet Si UnitsDocumento15 pagineBrown & Root, Inc.: Centrifugal Pump (Api 610-8Th) Data Sheet Si UnitsLipika GayenNessuna valutazione finora

- Hoja de Datos de BombaDocumento5 pagineHoja de Datos de Bombaluis zambranoNessuna valutazione finora

- Página: 1 De: 5Documento6 paginePágina: 1 De: 5Rathawit SingpanjanateeNessuna valutazione finora

- Reciprocating Pump (Api 674-2Nd) Data Sheet Si Units: GeneralDocumento10 pagineReciprocating Pump (Api 674-2Nd) Data Sheet Si Units: GeneraltxagusNessuna valutazione finora

- Brown & Root, Inc.: Rotary Pump (Api 676-2Nd) Data Sheet U.S. Customary UnitsDocumento4 pagineBrown & Root, Inc.: Rotary Pump (Api 676-2Nd) Data Sheet U.S. Customary UnitsLipika GayenNessuna valutazione finora

- Data Sheet No. Ds-P-5983 Rev. 1: Centrifugal Pump Data Sheet U.S. Customary UnitsDocumento10 pagineData Sheet No. Ds-P-5983 Rev. 1: Centrifugal Pump Data Sheet U.S. Customary Unitsrajindo1Nessuna valutazione finora

- Modern Power Station Practice: Mechanical Boilers, Fuel-, and Ash-Handling PlantDa EverandModern Power Station Practice: Mechanical Boilers, Fuel-, and Ash-Handling PlantA. SherryValutazione: 4 su 5 stelle4/5 (5)

- Resources Bearing Split Isolators For Split Pillow BlocksDocumento2 pagineResources Bearing Split Isolators For Split Pillow BlocksSuresh Kumar MittapalliNessuna valutazione finora

- Resources Bearing Split Isolators For Split Pillow BlocksDocumento2 pagineResources Bearing Split Isolators For Split Pillow BlocksSuresh Kumar MittapalliNessuna valutazione finora

- Annaya House Plan-ModelDocumento1 paginaAnnaya House Plan-ModelSuresh Kumar MittapalliNessuna valutazione finora

- Resources Bearing Bearing Isolator Interchange2005Documento2 pagineResources Bearing Bearing Isolator Interchange2005Suresh Kumar MittapalliNessuna valutazione finora

- Resources Bearing Guardian KlozureDocumento2 pagineResources Bearing Guardian KlozureSuresh Kumar MittapalliNessuna valutazione finora

- Resources Bearing Klozure Split GuardianDocumento2 pagineResources Bearing Klozure Split GuardianSuresh Kumar MittapalliNessuna valutazione finora

- KLZ 2-56 - TechMan - RevF - 080310 - Compressed PDFDocumento64 pagineKLZ 2-56 - TechMan - RevF - 080310 - Compressed PDFteguh_setiono0% (1)

- Resources Bearing Guardian Wall Chart PDFDocumento1 paginaResources Bearing Guardian Wall Chart PDFSuresh Kumar MittapalliNessuna valutazione finora

- Automatic Cars Comparison PDFDocumento2 pagineAutomatic Cars Comparison PDFSuresh Kumar MittapalliNessuna valutazione finora

- AR Thompson Bearing IsolatorsDocumento2 pagineAR Thompson Bearing IsolatorsSuresh Kumar MittapalliNessuna valutazione finora

- Bearing Isolator: Pump, Electric Motor and Split Pillow Block Interchange ManualDocumento60 pagineBearing Isolator: Pump, Electric Motor and Split Pillow Block Interchange ManualSuresh Kumar MittapalliNessuna valutazione finora

- Hai! Apa Kabar?: Hi! How Are You?Documento6 pagineHai! Apa Kabar?: Hi! How Are You?Suresh Kumar MittapalliNessuna valutazione finora

- Resources Bearing Bearing Isolator FamilyDocumento4 pagineResources Bearing Bearing Isolator FamilySuresh Kumar MittapalliNessuna valutazione finora

- Resources Bearing Guardian IsolatorDocumento2 pagineResources Bearing Guardian IsolatorSuresh Kumar MittapalliNessuna valutazione finora

- Compare Hyundai Elite I20 (2017-2018) Vs Honda WR-V Vs Maruti Suzuki Vitara Brezza Vs Maruti Suzuki BalenoDocumento2 pagineCompare Hyundai Elite I20 (2017-2018) Vs Honda WR-V Vs Maruti Suzuki Vitara Brezza Vs Maruti Suzuki BalenoSuresh Kumar MittapalliNessuna valutazione finora

- Dimensioni - Dimensions V 100-2L G Y - 2013 Rev.01Documento1 paginaDimensioni - Dimensions V 100-2L G Y - 2013 Rev.01Suresh Kumar MittapalliNessuna valutazione finora

- 17-7 PH Data SheetDocumento2 pagine17-7 PH Data SheetsksiddiqueNessuna valutazione finora

- P4 11 Esd142 GB PDFDocumento1 paginaP4 11 Esd142 GB PDFSuresh Kumar MittapalliNessuna valutazione finora

- 3 o Ring Guide Issue 7 PDFDocumento32 pagine3 o Ring Guide Issue 7 PDFthailanNessuna valutazione finora

- 316 316L Data SheetDocumento2 pagine316 316L Data SheetHanna ChanNessuna valutazione finora

- Dry - Gas - Seal - Blowdown PDFDocumento5 pagineDry - Gas - Seal - Blowdown PDFchemsac2Nessuna valutazione finora

- Characteristic Data Standard MaterialsDocumento6 pagineCharacteristic Data Standard MaterialsSuresh Kumar MittapalliNessuna valutazione finora

- Size A B C D E F G H J K: EAL PecificationsDocumento1 paginaSize A B C D E F G H J K: EAL PecificationsSuresh Kumar MittapalliNessuna valutazione finora

- Fluoro Slicone Data SheetDocumento2 pagineFluoro Slicone Data SheetSuresh Kumar MittapalliNessuna valutazione finora

- Ammonia and Urea ProductionDocumento10 pagineAmmonia and Urea Productionwaheed_bhattiNessuna valutazione finora

- API682Documento16 pagineAPI682peach5Nessuna valutazione finora

- Caustic Soda Production Processes in IndiaDocumento5 pagineCaustic Soda Production Processes in IndiaSuresh Kumar MittapalliNessuna valutazione finora

- Counter Sunk Head Dimensions PDFDocumento6 pagineCounter Sunk Head Dimensions PDFSuresh Kumar MittapalliNessuna valutazione finora

- ALS DynamicO RIngsGlandsDocumento1 paginaALS DynamicO RIngsGlandsSuresh Kumar MittapalliNessuna valutazione finora

- ReliableSeals CE May2016Documento10 pagineReliableSeals CE May2016Suresh Kumar MittapalliNessuna valutazione finora

- Regular chimney inspections extend plant operationsDocumento6 pagineRegular chimney inspections extend plant operationstecvidyaNessuna valutazione finora

- Laboratory Manual Machine Shop 1 PDFDocumento59 pagineLaboratory Manual Machine Shop 1 PDFVinz Bryan AlmacenNessuna valutazione finora

- 0s SangDocumento77 pagine0s SangBijin PulikkottilNessuna valutazione finora

- NORD-Painting CodeDocumento3 pagineNORD-Painting CodeubabNessuna valutazione finora

- Hemoglobin Oxidation-Reduction BiochemistryDocumento5 pagineHemoglobin Oxidation-Reduction BiochemistryYasmine AzzackiyahNessuna valutazione finora

- Combustion Properties GuideDocumento41 pagineCombustion Properties GuideHarshini BaskaranNessuna valutazione finora

- Santoprene™ 101-64: Thermoplastic VulcanizateDocumento4 pagineSantoprene™ 101-64: Thermoplastic VulcanizateMohitNessuna valutazione finora

- Indowud Brochure Revised PDFDocumento10 pagineIndowud Brochure Revised PDFsurabhi narangNessuna valutazione finora

- ReviewerDocumento14 pagineReviewerLigaya FlamehazeNessuna valutazione finora

- Rate CardDocumento6 pagineRate CardRavi SrivastavaNessuna valutazione finora

- Antioxidant activity of phenolic pigments from cocoa hullsDocumento6 pagineAntioxidant activity of phenolic pigments from cocoa hullsdjguevara1Nessuna valutazione finora

- Himalaya Health CareDocumento38 pagineHimalaya Health Careactive1cafeNessuna valutazione finora

- Pipe and Fitting ChartDocumento12 paginePipe and Fitting Chartyulianus_sr100% (2)

- ASTM D 5861-Ensayo de Adhesión FRP A Sustrato MetálicoDocumento2 pagineASTM D 5861-Ensayo de Adhesión FRP A Sustrato MetálicoFernando Alfredo Sepúlveda JiménezNessuna valutazione finora

- JEE Main 2014 - Test 4 (Paper I) Code ADocumento16 pagineJEE Main 2014 - Test 4 (Paper I) Code AMrigankJainNessuna valutazione finora

- Microwave, IR, NMR spectroscopy techniquesDocumento1 paginaMicrowave, IR, NMR spectroscopy techniquesSaikiranNessuna valutazione finora

- BlowersDocumento65 pagineBlowersmartin.rubenNessuna valutazione finora

- Msds Aminosol CSP 115Documento6 pagineMsds Aminosol CSP 115NARAYAN DESAINessuna valutazione finora

- Carbon Black ProcessDocumento4 pagineCarbon Black ProcessAnonymous azD9vQD100% (1)

- Cyanide-Free Gold Ore Dressing Agent PDFDocumento13 pagineCyanide-Free Gold Ore Dressing Agent PDFAldemar Arciniegas100% (1)

- Catalog Copeland KCLDocumento40 pagineCatalog Copeland KCLIsidro MendozaNessuna valutazione finora

- Unit 7 - Week 4: Assignment 4Documento3 pagineUnit 7 - Week 4: Assignment 4Ananda VijayasarathyNessuna valutazione finora

- 2010 Proportional CatalogDocumento16 pagine2010 Proportional CatalogjondesousaNessuna valutazione finora

- Rubber Property-Abrasion Resistance (Rotary Drum Abrader) : Standard Test Method ForDocumento9 pagineRubber Property-Abrasion Resistance (Rotary Drum Abrader) : Standard Test Method Formohammed karasnehNessuna valutazione finora

- Boiler ConstructionDocumento56 pagineBoiler ConstructionRanvir RajNessuna valutazione finora

- Refining and Petrochemicals CourseworkDocumento9 pagineRefining and Petrochemicals CourseworkMichael GregoryNessuna valutazione finora

- Wear Plate SpecsDocumento4 pagineWear Plate SpecsJuan Carlos EspinozaNessuna valutazione finora

- PHMSA Form 10 Standard Breakout Tank Insp 2008Documento21 paginePHMSA Form 10 Standard Breakout Tank Insp 2008Irvansyah RazadinNessuna valutazione finora

- Acid BassDocumento41 pagineAcid BassRobert Edwards100% (1)

- RocksDocumento5 pagineRocksangelic dailyNessuna valutazione finora