Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Data Sheet HV-HR It

Caricato da

Kemo TufoDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Data Sheet HV-HR It

Caricato da

Kemo TufoCopyright:

Formati disponibili

Technical Data Sheet

Societ Bulloneria Europea S.p.A.

High-strength structural bolting for preloading Doc. N.: 090710

System HR and HV Hexagon bolt, nut and Rev. n.: 01 Data: 12/02/2015

washers assemblies Pagina 1 di 3

1. Applicable standard

EN 14399-1 High strength structural bolting for preloading General Requirements

EN 14399-2 High strength structural bolting for preloading Suitability test for

preloading

EN 14399-3 High strength structural bolting for preloading System HR Hexagon

bolt and nut assemblies

EN 14399-4 High strength structural bolting for preloading System HV Hexagon

bolt and nut assemblies

EN 14399-5 High strength structural bolting for preloading Plain washers

EN 14399-6 High strength structural bolting for preloading Plain chamfered

washers

DIN 18800-7 Steel Structures Execution and constructors qualification

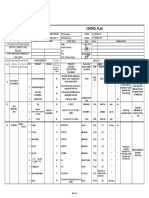

2. Systems of bolt/nut/washer assemblies

System HR Sistem HV

Bolt/nut assembly EN 14399-3 EN 14399-4

Marking HR HV

Property classes 8.8 / 8 10.9 / 10 10.9 / 10

Washers EN 14399-5 or EN 14399-6

Marking HR HV

Suitability test for

EN 14399-2

preloading

RIPRODUZIONE VIETATA SBE/010/QUA REV01

Technical Data Sheet

Societ Bulloneria Europea S.p.A.

High-strength structural bolting for preloading Doc. N.: 090710

System HR and HV Hexagon bolt, nut and Rev. n.: 00 Data: 10/07/2009

washers assemblies Pagina 2 di 3

3. Specifications and reference standards

Bolt Nut Washer

EN 14399-5 or

Dimensions and tolerances EN 14399-3 or EN 14399-4

EN 14399-6

Material Steel

Tolerance ISO 6g (a) ISO 6H or 6AZ

Thread n.a.

Standard ISO 261, ISO 965-2, ISO 965-5

8.8 or 10.9 (HR) 8 or 10 (HR)

Mechanical Property class Hardness

10.9 (HV) 10 (HV)

properties 300-370 HV

Standard ISO 898-1 ISO 898-2

Impact Value KV min = 27J at 20C

n.a.

strength Standard ISO 148 ISO 10045-1

Normal As processed (b)

Surface finish Hot dip galvanized ISO 10684

Others To be agreed

(c)

Surface discontinuities ISO 6157-1 ISO 6157-2

Acceptability ISO 3269

(a) The tolerance class specified applies before hot-dip galvanizing. Hot-dip galvanized bolts are intended

for assembly with oversize tapped nuts;

(b) As processed means the normal finishing resulting from manufacture with a light coating of oil;

(c) Parts shall be uniform and free from irregularities or detrimental defects. No protruding burrs shall

appear on the washer.

4. Functional characteristics of the assembly (ref. EN 14399-2)

k-class Information Requested values

K0 NPD No Performance Determined No requirements

K1 Range of individual test value ki 0,10 ki 0,16

Mean test value km 0,10 km 0,23

K2

Coefficient of variation of k-factor Vk Vk 0,10

RIPRODUZIONE VIETATA SBE/010/QUA REV01

Technical Data Sheet

Societ Bulloneria Europea S.p.A.

High-strength structural bolting for preloading Doc. N.: 090710

System HR and HV Hexagon bolt, nut and Rev. n.: 00 Data: 10/07/2009

washers assemblies Pagina 3 di 3

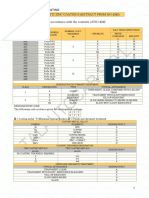

5. Tightening

5.1 Torque method

The bolts shall be tightened using a torque wrench offering a suitable operating range. Hand or power

operated wrenches may be used. Impact wrenches may be used for the first step of tightening for each

bolt.

a) a first tightening step: the wrench shall be set to a torque value of about 0,75 Mr,i with Mr,i =

Mr,2 or Mr,test.This first step shall be completed for all bolts in one connection prior to

commencement of the second step;

b) a second tightening step: the wrench shall be set to a torque value of 1,10 Mr,i with Mr,i = Mr,2

or Mr,test.

Diameter Preload [kN] Torque 1,1 Mr,i (Nm) Km

M12 59 100 0,129

M14 81 160 0,129

M16 110 250 0,129

M18 134 340 0,128

M20 172 450 0,119

M22 212 650 0,127

M24 247 800 0,123

M27 321 1250 0,131

M30 393 1650 0,127

M33 486 2200 0,125

M36 572 2800 0,124

Tightening torque Mr (=1,10 Mr,i) showed on nuts packaging has to be applied using calibrated torque

wrenches with accuracy of 4% according to EN ISO 6789 by rotation of the nut; different tightening

procedures have to be approved by experimental tightening tests under site conditions as specified in annex H

of European Standard EN 1090-2: 2008+A1:2011.

5.1 Combined method

Tightening by the combined method comprises two steps:

a) a first tightening step, using a torque wrench offering a suitable operating range. The wrench shall be

set to a torque value of about 0,75 Mr,i with Mr,i = Mr,2 or Mr,1 or Mr,test. This first step shall be

completed for all bolts in one connection prior to commencement of the second step;

b) a second tightening step in which a specified part turn is applied to the turned part of the assembly.

The position of the nut relative to the bolt threads shall be marked after the first step, using a marking

crayon or marking paint, so that the final rotation of the nut relative to the thread in this second step can

be easily determined.

Total nominal thickness "t" of parts to be Further rotation to be applied, during the

connected (including all packs and washers) second step of tightening

d = bolt diameter Degrees Part turn

t<2d 60 1/6

2d_t<6d 90 1/4

6 d _ t _ 10 d 120 1/3

NOTE Where the surface under the bolt head or nut (allowing for taper washers, if used) is not

perpendicular to the bolt axis, the required angle of rotation should be determined by testing

RIPRODUZIONE VIETATA SBE/010/QUA REV01

Potrebbero piacerti anche

- WASI NORM Tech - Handbuch-EDocumento32 pagineWASI NORM Tech - Handbuch-EKemo TufoNessuna valutazione finora

- 18263446-Jaguar XJR 1997-2003 Workshop Service Repair Manual PDFDocumento2.490 pagine18263446-Jaguar XJR 1997-2003 Workshop Service Repair Manual PDFAdan Flores CorreaNessuna valutazione finora

- PDFDocumento264 paginePDFLeobardo Genaro Roque NájeraNessuna valutazione finora

- Imds Recommendation 001 Annex IDocumento33 pagineImds Recommendation 001 Annex IAnjali DeshpandeNessuna valutazione finora

- Geomet 321Documento2 pagineGeomet 321Satnam Rachna FastenersNessuna valutazione finora

- The Company'S Factory Production Control System (FPC) FPC 0: BackgroundDocumento7 pagineThe Company'S Factory Production Control System (FPC) FPC 0: BackgroundSandy D. RockNessuna valutazione finora

- QF PQD Full 03.07.2021Documento357 pagineQF PQD Full 03.07.2021Sangram PatilNessuna valutazione finora

- Plating Control Plan-31 MARCH 09Documento10 paginePlating Control Plan-31 MARCH 09Rohtash fastner100% (1)

- BS Iv Himalayan Parts Catalogue PDFDocumento87 pagineBS Iv Himalayan Parts Catalogue PDFAnonymous O9TX7Yl74% (19)

- Jed-257 008 en LDocumento4 pagineJed-257 008 en LcroplaninecNessuna valutazione finora

- WV - TL245Documento9 pagineWV - TL245Juan José Viñas MéndezNessuna valutazione finora

- BMW GS 90010-1 2020-01 EN (Metallic Coatings and Inorganic Coating Systems)Documento12 pagineBMW GS 90010-1 2020-01 EN (Metallic Coatings and Inorganic Coating Systems)Adrian Graciano100% (2)

- 024 - Mechanical Properties of Fasteners Made of Carbon Steel and Alloy Steel PDFDocumento1 pagina024 - Mechanical Properties of Fasteners Made of Carbon Steel and Alloy Steel PDFRonak RanaNessuna valutazione finora

- JIS B0419-1991 (Dung Sai Kich Thuoc)Documento1 paginaJIS B0419-1991 (Dung Sai Kich Thuoc)Giang Nguyễn BáNessuna valutazione finora

- Motor Jac Weichai ViejoDocumento41 pagineMotor Jac Weichai Viejosamuel ortega100% (3)

- Fabory Fasteners Mechanical SpecDocumento10 pagineFabory Fasteners Mechanical SpecGilang Bhisma100% (1)

- GEOMETDocumento4 pagineGEOMETtoyota952Nessuna valutazione finora

- Hexalubulour BoltDocumento20 pagineHexalubulour BoltMitesh MakvanaNessuna valutazione finora

- Wire RoadDocumento16 pagineWire Road02081987Nessuna valutazione finora

- CS-11000Documento17 pagineCS-11000Engenharia APedro100% (1)

- Finish Method P90 1. Scope: Finishing Methods 7.0 FM100 7/9/2019Documento5 pagineFinish Method P90 1. Scope: Finishing Methods 7.0 FM100 7/9/2019JoshNessuna valutazione finora

- Material Specification: Specification: Revision Date: Revision LevelDocumento2 pagineMaterial Specification: Specification: Revision Date: Revision LevelReginaldo Santos100% (1)

- Geomet 500 PDFDocumento2 pagineGeomet 500 PDFKaran Chadha100% (1)

- Rig Up Equipment-Rigging SheaveDocumento20 pagineRig Up Equipment-Rigging SheaveANDREYNessuna valutazione finora

- Data & Specifications: 3299N030 4-Stroke EnginesDocumento9 pagineData & Specifications: 3299N030 4-Stroke EnginesShadi MuhammedNessuna valutazione finora

- Om XR12-25 PDFDocumento214 pagineOm XR12-25 PDFВладимир ТимофеевNessuna valutazione finora

- EN14399-HS Bolted Assemblies For PreloadingDocumento8 pagineEN14399-HS Bolted Assemblies For Preloadinggabimaier31Nessuna valutazione finora

- Fastener PDFDocumento12 pagineFastener PDFdiegomilitojNessuna valutazione finora

- Corrosion Testing and MeasurementsDocumento9 pagineCorrosion Testing and MeasurementsVaish NaviNessuna valutazione finora

- Heat Treatment - Self Assessment - CQ 9Documento12 pagineHeat Treatment - Self Assessment - CQ 9sunil mathewNessuna valutazione finora

- Effect of Boron PDFDocumento8 pagineEffect of Boron PDFKishan krNessuna valutazione finora

- Comparison of Anti-Loosening Characteristics of Various M14 Threaded FastenersDocumento8 pagineComparison of Anti-Loosening Characteristics of Various M14 Threaded Fastenerssoumyajit dasNessuna valutazione finora

- Industrial Fasteners, Nuts & BoltsDocumento79 pagineIndustrial Fasteners, Nuts & BoltsMudduKrishna shettyNessuna valutazione finora

- Ti SPC Ohe Fasteners 0120 PDFDocumento31 pagineTi SPC Ohe Fasteners 0120 PDFCounter RoverNessuna valutazione finora

- National Machinery - Cold Forming Glossary of TermsDocumento17 pagineNational Machinery - Cold Forming Glossary of Termssergio_daqNessuna valutazione finora

- TL245 English 2004Documento8 pagineTL245 English 2004Elliott RussellNessuna valutazione finora

- Carbon Steel Billets, Blooms, Slabs and Bars For Forgings - Specification (Fifth Revision)Documento12 pagineCarbon Steel Billets, Blooms, Slabs and Bars For Forgings - Specification (Fifth Revision)SreenathaNessuna valutazione finora

- Ralin Group Brochure 2013Documento3 pagineRalin Group Brochure 2013n1ghtfallNessuna valutazione finora

- M6x1.0x23 Long HHS Control PlanDocumento2 pagineM6x1.0x23 Long HHS Control PlanDhanluxmi AutomaticsNessuna valutazione finora

- Austempered Ductile Iron Castings: Standard Specification ForDocumento9 pagineAustempered Ductile Iron Castings: Standard Specification ForRaja Hone0% (1)

- Fasteners Part-3 Is.1369.1.1993Documento9 pagineFasteners Part-3 Is.1369.1.1993Manish ThakurNessuna valutazione finora

- 3 ThreeBond 1227 ENGLISH-convertido (1Documento8 pagine3 ThreeBond 1227 ENGLISH-convertido (1Alfonso De La RosaNessuna valutazione finora

- Engineering Standards: Material Specification Metals GM6435MDocumento6 pagineEngineering Standards: Material Specification Metals GM6435MAkmal NizametdinovNessuna valutazione finora

- ASTM A563 - Portland BoltDocumento5 pagineASTM A563 - Portland BoltamrNessuna valutazione finora

- AQL 2.5 (Normal)Documento3 pagineAQL 2.5 (Normal)Jahidul IslamNessuna valutazione finora

- Zinc Plating: Randhir Kumar Singh Asst Professor OpjitDocumento16 pagineZinc Plating: Randhir Kumar Singh Asst Professor OpjitRahul PandeyNessuna valutazione finora

- Mechanical Properties - Bolt, Nut, FastenersDocumento4 pagineMechanical Properties - Bolt, Nut, FastenersmegatornadoNessuna valutazione finora

- ISO 4020 ExtractDocumento2 pagineISO 4020 ExtractBartek HajaNessuna valutazione finora

- Complete Immersion Phosphating LineDocumento8 pagineComplete Immersion Phosphating LineStay AwayNessuna valutazione finora

- Blackodizing CPDocumento1 paginaBlackodizing CPx yNessuna valutazione finora

- Astm b117 Testing v1Documento3 pagineAstm b117 Testing v1maddumaNessuna valutazione finora

- Trivalent Chromates FAQDocumento3 pagineTrivalent Chromates FAQfastenersworldNessuna valutazione finora

- Steel Bolts and Nuts and Similar Norm 2377: ObjectiveDocumento9 pagineSteel Bolts and Nuts and Similar Norm 2377: ObjectiveanhthoNessuna valutazione finora

- Metric Screw Dimensions ISO Fasteners PDFDocumento2 pagineMetric Screw Dimensions ISO Fasteners PDFHarshal JadhavNessuna valutazione finora

- Ford 970Documento4 pagineFord 970amanNessuna valutazione finora

- Material Specification Sheet: 1.7102 DIN EN 10089 SAE: 9254 Jis: Sup 12 Material Group: Chemical CompositionDocumento1 paginaMaterial Specification Sheet: 1.7102 DIN EN 10089 SAE: 9254 Jis: Sup 12 Material Group: Chemical CompositionRajaSekarsajjaNessuna valutazione finora

- Tycoons - Specs of Carbon Steel Wire - 10B21, 10B38, 1010, 4140Documento1 paginaTycoons - Specs of Carbon Steel Wire - 10B21, 10B38, 1010, 4140Alexis BarolinNessuna valutazione finora

- Metal Forming Process and DefectsDocumento7 pagineMetal Forming Process and DefectsPradeep Kumar BowmarajuNessuna valutazione finora

- Silicon Nitride Bearing Balls: Standard Specification ForDocumento8 pagineSilicon Nitride Bearing Balls: Standard Specification ForkrutikNessuna valutazione finora

- Din 2393-2Documento0 pagineDin 2393-2Yalavarthi ChandrasekharNessuna valutazione finora

- Hammer Drive ScrewDocumento1 paginaHammer Drive ScrewNisa BN QANessuna valutazione finora

- FastenerDocumento46 pagineFastenerTechproNessuna valutazione finora

- Controlling Heat Treatment Distortion in Gear Rings - MachineMfgDocumento37 pagineControlling Heat Treatment Distortion in Gear Rings - MachineMfgxiao mingNessuna valutazione finora

- High Strength Structural Bolting Assemblies For Preloading, According To EN 14399. Technical Information For UseDocumento8 pagineHigh Strength Structural Bolting Assemblies For Preloading, According To EN 14399. Technical Information For UseAlexander MarinovNessuna valutazione finora

- Ferrometal Steel Construction FastenersDocumento48 pagineFerrometal Steel Construction FastenersMilos VukobratNessuna valutazione finora

- S12 LVBushingCantilever Presentation PDFDocumento14 pagineS12 LVBushingCantilever Presentation PDFManikandan P Engineering EEENessuna valutazione finora

- Specification For HV Transformer (Hyundai Heavy Industries CO., LTD.)Documento32 pagineSpecification For HV Transformer (Hyundai Heavy Industries CO., LTD.)Oleksandr RakshaNessuna valutazione finora

- I Nternati NAL Standard: Mechanical Properties of Faster ErsDocumento12 pagineI Nternati NAL Standard: Mechanical Properties of Faster ErsAhmed Hamed ElezabyNessuna valutazione finora

- Improved Virtual Machine Load Balance UsDocumento12 pagineImproved Virtual Machine Load Balance UsKemo TufoNessuna valutazione finora

- Corrosion Protection of Hot Dip Galvaniz PDFDocumento11 pagineCorrosion Protection of Hot Dip Galvaniz PDFKemo TufoNessuna valutazione finora

- Chambersburg Engineering Company, Chambersburg, PaDocumento2 pagineChambersburg Engineering Company, Chambersburg, PaKemo TufoNessuna valutazione finora

- EC Firmware Update SOP For Windows enDocumento6 pagineEC Firmware Update SOP For Windows enStereo PodNessuna valutazione finora

- Methods of Regeneration of Spent Picklin PDFDocumento4 pagineMethods of Regeneration of Spent Picklin PDFKemo TufoNessuna valutazione finora

- SAMPAG ANCHOR CHANELS CatalogueNo.8 PDFDocumento40 pagineSAMPAG ANCHOR CHANELS CatalogueNo.8 PDFKemo TufoNessuna valutazione finora

- Prediction of Damage in Cold Bulk Forming ProcessesDocumento4 paginePrediction of Damage in Cold Bulk Forming ProcessesKemo TufoNessuna valutazione finora

- ISO-GUM and Supplements Are Utilized For QA of BCA Data: Yasuo IwakiDocumento31 pagineISO-GUM and Supplements Are Utilized For QA of BCA Data: Yasuo IwakiKemo TufoNessuna valutazione finora

- Numerical and Physical Modelling of ColdDocumento19 pagineNumerical and Physical Modelling of ColdKemo TufoNessuna valutazione finora

- ASF Katalog 2018 - GBDocumento108 pagineASF Katalog 2018 - GBKemo TufoNessuna valutazione finora

- Alt Codes Reference Sheet: Hold Down The "Alt" Key Then Enter The Code On The Numeric Keypad With Num Lock OnDocumento1 paginaAlt Codes Reference Sheet: Hold Down The "Alt" Key Then Enter The Code On The Numeric Keypad With Num Lock OnKemo TufoNessuna valutazione finora

- Tpi 205 de en PDFDocumento162 pagineTpi 205 de en PDFKemo TufoNessuna valutazione finora

- Kayış Kasnak Hesabı PDFDocumento2 pagineKayış Kasnak Hesabı PDFKemo TufoNessuna valutazione finora

- Gingerbread House and Man - Full DescriptionDocumento2 pagineGingerbread House and Man - Full DescriptionKemo TufoNessuna valutazione finora

- CAI-ELP-01 - ELink Plug Customer Assembly Instructions-R0Documento17 pagineCAI-ELP-01 - ELink Plug Customer Assembly Instructions-R0albeertoNessuna valutazione finora

- Riser Diagram: Produced by An Autodesk Student VersionDocumento1 paginaRiser Diagram: Produced by An Autodesk Student VersionMark Kenneth BaldoqueNessuna valutazione finora

- Pro-Shift STD Ps150-16 Transmission Parts Catalog: Bulletin No T210-PS0-16 Revised June 1999Documento39 paginePro-Shift STD Ps150-16 Transmission Parts Catalog: Bulletin No T210-PS0-16 Revised June 1999jacintoNessuna valutazione finora

- Hollow-Ceiling Anchor FHY 07122016 070337Documento5 pagineHollow-Ceiling Anchor FHY 07122016 070337lbhnsw5930Nessuna valutazione finora

- Customer TCM-4028-001 TCU-2800 Universal Harness With OptionDocumento2 pagineCustomer TCM-4028-001 TCU-2800 Universal Harness With OptionDavid FuentesNessuna valutazione finora

- Electrical Schematic 1650L Crawler: V M P TDocumento1 paginaElectrical Schematic 1650L Crawler: V M P TCarlos PinedaNessuna valutazione finora

- Manual SO2164430-i1Documento80 pagineManual SO2164430-i1Savinda JanszNessuna valutazione finora

- Illustrated Part Breakdown: MODEL: T30-P Engine Air StarterDocumento4 pagineIllustrated Part Breakdown: MODEL: T30-P Engine Air StarterTAYFUNNessuna valutazione finora

- Hydraulic Pump P37XDocumento6 pagineHydraulic Pump P37XdianNessuna valutazione finora

- SE Bikes - 2014 Tripel - Bike ArchivesDocumento2 pagineSE Bikes - 2014 Tripel - Bike ArchivesMark ArchambeaultNessuna valutazione finora

- Manual Pipe and Bolt Threading Machine: Warning!Documento71 pagineManual Pipe and Bolt Threading Machine: Warning!AlejandroNessuna valutazione finora

- Mec Ba Threads Bs 93Documento5 pagineMec Ba Threads Bs 93enricoNessuna valutazione finora

- CK30 WM 03 ClutchDocumento16 pagineCK30 WM 03 ClutchvixentdNessuna valutazione finora

- 902900-616 DespieceDocumento331 pagine902900-616 DespieceLIBERTADNessuna valutazione finora

- Sistema Hidráulico BynDocumento2 pagineSistema Hidráulico BynRoyer MamaniNessuna valutazione finora

- Range Rover Classic Parts Section & Design Modification HistoryDocumento38 pagineRange Rover Classic Parts Section & Design Modification Historygabe arsNessuna valutazione finora

- Fill Rite KitsDocumento127 pagineFill Rite Kitsroberto carlos ortizNessuna valutazione finora

- Hexagon Head Bolts/Screws: Metric Series-DimensionsDocumento7 pagineHexagon Head Bolts/Screws: Metric Series-DimensionsVishal MistryNessuna valutazione finora

- A New 3 Cylinder 1.2l Advanced Downsizing TechnologyDocumento14 pagineA New 3 Cylinder 1.2l Advanced Downsizing TechnologybiopoweredNessuna valutazione finora

- Maq de Sorvete c716 Taylor Manual TécnicoDocumento26 pagineMaq de Sorvete c716 Taylor Manual TécnicoGuilherme AugustoNessuna valutazione finora

- HTTPSWWW - Lutz-Hydraulik - bizimagesKatalogeKP KM 20 30 PDFDocumento112 pagineHTTPSWWW - Lutz-Hydraulik - bizimagesKatalogeKP KM 20 30 PDFimv9797Nessuna valutazione finora

- Sem 680DDocumento2 pagineSem 680DVinoth KumarNessuna valutazione finora

- 303 I6 EnginesDocumento69 pagine303 I6 EngineslukeNessuna valutazione finora