Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Annex 14 - Piping Spec

Caricato da

bisworupmTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Annex 14 - Piping Spec

Caricato da

bisworupmCopyright:

Formati disponibili

POWER SYSTEMS

MODIFICATIONS TABLE

REV PREPARED CHECKED APPROVED DATE MODIFICATIONS STAT.

A AM MP/AK KS 17/05/12 FIRST ISSUE GFR

REVISED AS PER CLIENT COMMENTS

B K. SUTHAR R. MURUGAN D. SHAH 31/12/13

H-6746000CA00001EC PIPES & PIPE FITTINGS-TECHNICAL SPECIFICATION 2/B

POWER SYSTEMS

Table of Content

1. PURPOSE .................................................................................................................................................................... 4

2. REFERENCE DOCUMENT .............................................................................................................................................. 4

3. GENERAL .................................................................................................................................................................... 5

3.1 ENVIRONMENTAL CONDITIONS ............................................................................................................................... 5

3.2 WATER ANALYSIS .................................................................................................................................................... 5

4. PAINTING & PRESERVATION ........................................................................................................................................ 6

4.1 PAINTING PROCEDURE FOR CARBON STEEL PIPES & FITTINGS ................................................................................. 6

4.2 GALVANIZING.......................................................................................................................................................... 6

5. DESIGN PRESSURE & MATERIAL SELECTION ................................................................................................................. 7

6. INSULATION FOR PIPING ............................................................................................................................................. 7

7. TECHNICAL PARTICULARS ............................................................................................................................................ 9

8. BRANCH TABLE ......................................................................................................................................................... 16

H-6746000CA00001EC PIPES & PIPE FITTINGS-TECHNICAL SPECIFICATION 3/B

POWER SYSTEMS

1. PURPOSE

The purpose of this specification is to define the technical requirements for design, fabrication, and factory

inspections for Pipes & Pipe Fittings of the following systems of TASHIDING Hydro Electric Project:

Cooling Water System

Drainage & Dewatering System

Compressed Air System

Fire Protection System

Oil Handling System

Turbine related pipes

Generator related pipes

2. REFERENCE DOCUMENT

Particular Technical Specification Volume 3A

General Technical Specification Volume 3B

Following codes, regulations and standards:

Codes Description

IS 3589 : 2001 Steel Pipes for Water and Sewage (168.3 to 2540 mm Outside

Diameter)

IS 1239 : 2004 Steel Tubes, Tubulars and Other Wrought Steel Fittings - Specification

ASTM A 53 : 2002 Standard Specification for Pipe, Steel, Black and Hot Dipped, Zinc

Coated, Welded & Seamless

ASTM A 105 : 2003 Specification for carbon steel forgings for piping application.

ASTM A 106 : 2004 Standard Specification for Seamless Carbon Steel Pipe for High

Temperature Service

ASTM A 182 : 2004 Standard Specification for Forged or Rolled Alloy and Stainless Steel

Pipe Flanges, Forged Fittings, and Valves and Parts for High-

Temperature Service

ASTM A 213 : 1999 Standard Specification for seamless Ferritic & Austenitic Alloy-steel

Boiler, Superheater, & Heat-Exchanger Tubes.

ASTM A 234 : 2001 Specification for Piping Fittings of Wrought Carbon Steel and Alloy

Steel for Moderate and High Temperature Service

ASTM A 312 : 2004 Standard Specification for Seamless, Welded, and Heavily Cold

Worked Austenitic Stainless Steel Pipes

ASTM A 403 : 2007 Standard specification for Wrought Austenitic Stainless Steel Piping

Fittings

ISO 898 Part-1 : 2009 Mechanical properties of fasteners made of carbon steel and alloy

steel -- Part 1: Bolts, screws and studs

ISO 898 Part-2 : 1992 Mechanical Properties of Fasteners - Part 2: Nuts with Specified Proof

Load Values - Coarse Thread

ISO 3506 Part-1 : Mechanical properties of corrosion-resistant stainless steel fasteners -

2010 - Part 1: Bolts, screws and studs

H-6746000CA00001EC PIPES & PIPE FITTINGS-TECHNICAL SPECIFICATION 4/B

POWER SYSTEMS

Codes Description

ISO 3506 Part-2 : Mechanical properties of corrosion-resistant stainless steel fasteners -

1998 - Part 2: Nuts

ISO 4014 : 2011 Dimensional standard for Hexagonal head bolts, Product Grade A & B

ISO 4032 : 1999 Dimensional standard for Hexagonal nuts, Product Grade A & B

ISO : 7089 : 2000 Plain Washer Normal Series Product Grade A

ISO 1461 : 2009 Hot dip galvanized coating on fabricated iron and steel articles -

specifications and test methods

ISO 8501 : 1994 Preparation of steel substrates before application of paints and related

products

ASME B 16.5 : 1996 Steel Pipe Flanges and Flanged Fittings.

ASME B 16.9 : 2003 Factory-made wrought Butt-Welding Fittings

ASME B 16.11 : 2001 Forged Steel Fittings, Socket Welding and Threaded.

ASME B 16.20 : 2000 Metallic Gaskets for pipe flanges : Ring Joint, Spiral-Wound and

Jacketed

ASME B 16.21 : 2005 Non-metallic Flat Gaskets for Pipe Flanges

ASME B 31.1 : 2001 Power Piping (Code for pressure piping)

ASME B 36.10 : 2004 Dimensional standard for welded & seamless wrought steel pipe

ASME B 36.19 : 2004 Dimensional Standard for Stainless steel Pipe

MSS-SP-83 : 2001 Class 3000# steel pipe unions socket welding and threaded

DIN 975 :2003 Threaded rod / stud bolts

3. GENERAL

3.1 ENVIRONMENTAL CONDITIONS

1. Maximum ambient temperature 40 C

2. Minimum ambient temperature 2 C

3. Maximum Relative Humidity 98%

4. Minimum Relative Humidity 40%

5. Maximum raw water temperature 25 C

6. Minimum raw water temperature 2 C

3.2 WATER ANALYSIS

Parameter Value

PH 7.2

Alkalinity as CaCO3 (mg/l) 50

Total Hardness CaCO3 (mg/l) 120

Calcium as Ca (mg/l) 42

Chloride as Cl (mg/l) 22

Sodium as Na (mg/l) 3

H-6746000CA00001EC PIPES & PIPE FITTINGS-TECHNICAL SPECIFICATION 5/B

POWER SYSTEMS

4. PAINTING & PRESERVATION

4.1 PAINTING PROCEDURE FOR CARBON STEEL PIPES & FITTINGS

DFT Min.

Procedure Product description Shade

(m)

Surface

Preparation Sa 2 to Sa 3 as per ISO 8501

(Blasting)

Primer coat 2 component Epoxy based Red

(Done at Manuf. Oxide primer with anticorrosive 50 m Red / Grey

End) Zinc Phosphate pigment

2 component Epoxy based paint

Intermediate coat Grey /

with Micaceous Iron Oxide 120 m

(Done at Site) Brown

pigment.

Final coat 2 component Epoxy based finish As per

60 m

(Done at Site) paint with high gloss Clause no. 5

TOTAL 230 m

Note:

All Pipes & Fittings (Embedded or Overground) - Surface preparation & Primer coat shall be done.

Painting is not required on Galvanized and Stainless Steel pipes.

Same procedure is applicable for pipe spools.

4.2 GALVANIZING

Hot dip galvanizing shall be carried out as per ISO 1461.

H-6746000CA00001EC PIPES & PIPE FITTINGS-TECHNICAL SPECIFICATION 6/B

POWER SYSTEMS

5. DESIGN PRESSURE & MATERIAL SELECTION

Design

System Pressure Material Colour Code

KG/CM2

Cooling water system 10 Carbon Steel RAL 6029 (Mint Green)

Drainage & Dewatering System 10 Carbon Steel RAL 6029 (Mint Green)

Fire Fighting System 16 Carbon steel RAL 3000 (Flame Red)

LP Compressed Air System 10.5 Carbon steel RAL 5012 (Light Blue)

Oil Handling System 10 Carbon steel RAL 2000 (Yellow Orange)

TURBINE PIPES

Penstock drain pipe 42 Carbon steel RAL 6029 (Mint Green)

Spiral case drain pipe 42 Carbon steel RAL 6029 (Mint Green)

Pit drain pipe 10 Carbon steel RAL 6029 (Mint Green)

Shaft seal leakage pipe 10 Carbon steel RAL 6029 (Mint Green)

Head cover pump drain pipe 10 Carbon steel RAL 6029 (Mint Green)

Balancing pipe 42 Carbon steel RAL 6029 (Mint Green)

Pressure Taps 42 Stainless steel -

Bottom ring drain pipe 10 Carbon steel RAL 6029 (Mint Green)

Shaft seal circuit after fine filters 10 Stainless steel -

GENERATOR PIPES

Oil mist system 10 Carbon steel RAL 2000 (Yellow Orange)

Lower bearing cooler oil piping 10 Carbon steel RAL 2000 (Yellow Orange)

Upper bearing cooler oil piping 10 Carbon steel RAL 2000 (Yellow Orange)

Braking system 40 Stainless steel -

Jacking system 220 Stainless steel -

HP Oil Injection 150 Stainless steel -

6. INSULATION FOR PIPING

Suitable insulation with vapour proof cover (if required) to prevent condensation shall be provided as per below

guidelines:

Cooling Water System: Piping inside generator barrel and pipes running above electrical installation such

as panels.

Drainage & Dewatering System and Fire Fighting System: Pipes running above electrical installation such

as panels.

H-6746000CA00001EC PIPES & PIPE FITTINGS-TECHNICAL SPECIFICATION 7/B

POWER SYSTEMS

7. THICKNESS CALCULATION B

The overall formula used by ASME B31.1 for pressure Solution has been used:

tm= PDo / 2(SE + Py) + A

Where,

tm= Minimum required wall thickness of pipe, mm

P = Design pressure, Kg/cm2

Do = Outside diameter of the pipe, mm

S = Allowable stress, Kg/cm2

E = Weld joint efficiency or quality factor (1.0 for seamless and 0.85 for ERW pipes)

y = Dimensionless constant which varies with temperature, in this case it is 0.4

A= Corrosion Allowance, 1.5mm

A mill tolerance of 12.5% has been considered during thickness calculation.

The details of thickness selection have been elaborated in the respective Tables.

H-6746000CA00001EC PIPES & PIPE FITTINGS-TECHNICAL SPECIFICATION 8/B

POWER SYSTEMS

TECHNICAL PARTICULARS FOR CS PIPES, PIPE FITTINGS & HARDWARES

2

For Fire Fighting System - Design pressure - 16 kg/cm B

For LP Compressed Air System - Design pressure 10.5 kg/cm2

DIMENSIONAL

SIZE (NB) RATING / THK (mm) JOINT DESCRIPTION TYPE MATERIAL

STANDARD

From To PIPES

15 40 Sch. 40 SW Seamless pipes, Plain End - ASTM A 106 GR B ASME B 36.10M

50 80 Sch. 40 BW Seamless pipes, Bevelled End - ASTM A 106 GR B ASME B 36.10M

100 150 HEAVY BW ERW pipes, Bevelled End - IS 1239 (Part I) IS 1239 (Part I)

200 250 6.3 mm thk BW ERW pipes, Bevelled End - IS 3589 (Fe 330) IS 3589

FITTINGS

Elbows, half & full coupling, ASME B 16.11/

15 40 2000 #/3000 # SW Forged ASTM A 105

Tees, Reducers, Caps, Unions MSS-SP-83

Sch. 40/

Elbows, Branching, Tees,

50 150 As per Thk of BW Formed ASTM A234 WPB ASME B 16.9

Reducers, Caps

connecting pipe

As per Thk of Elbows, Branching, Tees,

200 250 BW Formed ASTM A234 WPB ASME B 16.9

connecting pipe Reducers, Caps

SLIP ON FLANGES/BLIND FLANGES

50 250 Class 150 # - Raised face Forged ASTM A 105 ASME B 16.5

BOLTS / STUDS

Hexagonal Head Bolts / ISO-4014 CL8.8 A2C

M10 M36 - - - ISO-898 Part-I

Stud Bolts /DIN 975 CL. 8.8 A2C

NUTS

M10 M36 - - Nuts - ISO-898 Part-2 ISO 4032 CL-8 A2C

WASHERS

M10 M36 - - Plain Washer - Mild Steel ISO 7089-200 HV A2C

GASKETS

Non asbestos

compressed gasket

ALL SIZES 1 mm to 3 mm - Gasket - (UNIKLINGER Cl- ASME B 16.21

18 / CHAMPION

AF120)

Note: Downstream piping of deluge valve system (For Fire Fighting System) shall be Galvanized Carbon Steel.

H-6746000CA00001EC PIPES & PIPE FITTINGS-TECHNICAL SPECIFICATION 11/B

POWER SYSTEMS

Note:

End connection of all pipes & pipe fittings for instruments shall be of screwed/threaded (BSPP).

All pipe fittings shall be of seamless type.

The selected pipe thickness and schedule is the minimum required size, if the selected size & thickness is not

available, next higher size will be used.

Other pipes/ fittings, which are not specified in the specification, will be decided as per supplier

proposal/standard practices.

ABBREVIATIONS:

BW : Butt Weld

SW : Socket Weld

ERW : Electric Resistance Welded

PE : Plain End

SCH : Schedule

BSPP : British Standard Parallel Pipe threads

NBR : Nitrile Butadiene Rubber

H-6746000CA00001EC PIPES & PIPE FITTINGS-TECHNICAL SPECIFICATION 15/B

POWER SYSTEMS

B

9. BRANCH TABLE

CARBON STEEL MATERIAL

8 1/4'' T

15 1/2'' RT T

20 3/4'' RT RT T

25 1'' RT RT RT T

32 1.1/4'' RT RT RT RT T

40 1.1/2'' RT RT RT RT RT T

Z E

50 2'' RT T

65 2.1/2''

I

80 3''

S

100 4''

125 5''

R U N

150 6'' T

200 8'' HC RT T

250 10'' RT T

300 12'' D RT T

350 14'' RT T

400 16'' RT T

450 18'' RT T

500 20'' RT T

550 22'' RT T

600 24'' RT T

1/4'' 1/2'' 3/4'' 1'' 1.1/4'' 1.1/2'' 2'' 2.1/2'' 3'' 4'' 5'' 6'' 8'' 10'' 12'' 14'' 16'' 18'' 20'' 22'' 24''

8 15 20 25 32 40 50 65 80 100 125 150 200 250 300 350 400 450 500 550 600

B R A N C H S I Z E

H-6746000CA00001EC PIPES & PIPE FITTINGS-TECHNICAL SPECIFICATION 16/B

POWER SYSTEMS

STAINLESS STEEL MATERIAL B

8 1/4'' T

15 1/2'' RT T

20 3/4'' RT RT T

25 1'' RT RT RT T

32 1.1/4'' RT RT RT RT T

40 1.1/2'' RT RT RT RT RT T

E

50 2'' RT T

Z

I

80 3'' D T

S

100 4'' HC D RT T

R U N

150 6'' D D D T

200 8'' D D D RT T

1/4'' 1/2'' 3/4'' 1'' 1.1/4'' 1.1/2'' 2'' 3'' 4'' 6'' 8''

8 15 20 25 32 40 50 80 100 150 200

B R A N C H S I Z E

LEGEND:

T - Equal Tee,

RT - Reducing Tee,

HC - Half Coupling,

D - Direct Connection.

H-6746000CA00001EC PIPES & PIPE FITTINGS-TECHNICAL SPECIFICATION 17/B

Table of Content

1. PURPOSE .......................................................................................................................................................................................... 3

2. PAINTING PROCEDURE FOR CARBON STEEL PIPES, PIPE SUPPORTS, CLAMPS AND FITTINGS ..................................................... 3

3. PAINTING PROCEDURE ON WELDING AREA AFTER ERECTION AT SITE FOR PIPE, CLAMP AND FITTINGS..................................... 4

4. PAINT MANUFACTURER BRAND NAME & DESIGNATION ................................................................................................................ 5

5. PAINTING PROCEDURE ON WELDING AREA OF HOT DIP GALVANIZED PIPES & FITTINGS AT SITE ............................................... 5

HSJCPA01-000 000 000 EC Page 2

1. PURPOSE

The purpose of Painting specification is to define painting procedure for carbon steel pipe , pipe

fittings, pipe supports & clamps, which are to be used for Alstom hydro project at site as well as work

D shop.

This specification is not applicable for pipes, fittings used for bracing and temporary support.

2. PAINTING PROCEDURE FOR CARBON STEEL PIPES, PIPE SUPPORTS, CLAMPS AND FITTINGS

Procedure Product description DFT Shade Volume INSPECTION

Min. solid REQUIREMENTS

(m) (Min.)

Surface

Sa 2 to Sa 3 as per Visual / Roughness

Preparation

ISO 8501 measurement

(Blasting)

2 component Epoxy

Primer coat based Red Oxide

(Done at primer with 50 m Red / Grey 45% Thickness & Adhesion

Manuf. End) anticorrosive Zinc

Phosphate pigment

Intermediate 2 component Epoxy

coat based paint with

120 m Grey / Brown 75% Thickness & Adhesion

(Done at Micaceous Iron

Site) Oxide pigment.

Final coat * 2 component Epoxy As per

(Done at based finish paint 60 m contract / 50% Thickness & Adhesion

Site) with high glossy specification

TOTAL 230 m

* Final coat for Pipes and pipe fittings exposed to sunlight shall be applied with 2 components

acrylic based polyurethane topcoat cured with aliphatic Isocyanate

Notes :

1. All Pipes & Fittings (Embedded or Overground) - Surface preparation & Primer coat shall be

done from supplier/ manufacturer's end before dispatch to site.

2. Painting is not required on Galvanized pipes.

3. Paint approved brands : Akzo Nobel, Jotun paints, Berger, Hempel paint, Asian paint and

Sigma paint. Do not mix two brands in single system.

D 4. Rust prevention treatment on inside surface of process pipes and pipe fittings is not

required. Site shall take care for removal of the same during erection/commissioning.

5. All process pipes/pipe spool used in the product / system shall be closed tightly from the ends

with Plastic/PVC labirinth type end caps by supplier before dispatch. The condition of cap

shall be check by site every quarterly and if required same shall be replaced

HSJCPA01-000 000 000 EC Page 3

6. Pipe fittings shall be supplied without end caps.

7. Fittings Includes: Elbows, Bends, Tee, Reducer, Flanges, Couplings, unions, etc.

8. In case of pipe spools supplied from manufacturer, same procedure is applicable.

3. PAINTING PROCEDURE ON WELDING AREA AFTER ERECTION AT SITE FOR PIPE, CLAMP AND

FITTINGS

DFT Volume

INSPECTION

Procedure Product description Min. Shade solid

REQUIREMENTS

(m) (Min.)

Surface

Manual Cleaning - Visual

Preparation

Rough grinding & ( For surface

(Done at

solvent cleaning. roughness)

site)

2 component

Primer coat modified epoxy high

(Done at solid mastic / 80 m Red / Grey 75% Thickness & Adhesion

site) surface tolerant

paint/ self-priming.

Intermediate 2 component Epoxy

coat based paint with

120 m Grey 75% Thickness & Adhesion

(Done at Micaceous Iron

Site) Oxide pigment.

Final coat 2 component Epoxy As per

(Done at based finish paint 60 m contract / 50% Thickness & Adhesion

Site) with high glossy specification

TOTAL 260 m

Notes :

1. Paint approved brands : Akzo Nobel, Jotun paints, Hempel paint, Berger paint, Asian paint

and Sigma paint. Do not mix two brands in single system.

2. Solvent cleaning means all types of organic solvent like Kerosene, Xylene and all paints

thinner.

3. For any damage in the primer coat during transportation, the above painting procedure shall

be followed.

HSJCPA01-000 000 000 EC Page 4

4. PAINT MANUFACTURER BRAND NAME & DESIGNATION

Sr. No. MFG. Name Primer coat Intermediate coat Final coat

1 Akzo Nobel Interguard 269 red Interguard 475 HS MIO Interthane 990

2 Jotun paints Penguard primer red Penguard Express MIO Hardtop XP PU

Berger thane finish -

Product code 682

3 Berger paints Epilux 610 primer Epilux 155 HB MIO

(Mixing ration 4 : 1 -

Base : Hardener)

Notes : For final colour shade (i.e RAL No.), please refer respective project piping specification.

5. PAINTING PROCEDURE ON WELDING AREA OF HOT DIP GALVANIZED PIPES & FITTINGS AT SITE

DFT Volume

INSPECTION

Procedure Product description Min. Shade solid

REQUIREMENTS

(m) (Min.)

Clean by manually

Surface

with wire brush /

Preparation

solvent cleaning/ Visual

(Done at

degreasing/ sand

site)

paper.

Primer coat Cold Galvanizing

(Done at spray as per ASTM 30 m Silver Grey Thickness

site) A-780

Final coat Cold Galvanizing

(Done at spray as per ASTM 30 m Silver Grey Thickness

Site) A-780

TOTAL 60 m

Notes :

1. Approved material - Any brand Cold galvanizing material complying to ASTM A-780.

2. Incase of pipe spools supplied from manufacturer, same procedure is applicable.

The above mentioned painting procedures/ thickness of paint/ colour shade is the minimum

requirement. However for any project specific requirement, respective piping specification shall be

referred.

HSJCPA01-000 000 000 EC Page 5

Caution:

1. Before applying Intermediate coat on pipe & pipe fittings at site oil stains if any shall be

removed with solvent cleaning/ emery paper.

2. For flanges, the machined surface where the gasket will be fixed (Raised face incase of SORF

flange & flat face incase of SOFF flange) shall be prevented from rust by applying tectyl 506.

D Except machined surface all other surface (including bolt holes) shall be applied with primary

coat at supplier end.

3. Grease shall be applied on threads of pipe & pipe fittings & no tectyl should be applied on

threads of pipe & pipe fittings.

HSJCPA01-000 000 000 EC Page 6

Potrebbero piacerti anche

- Material Requisition For Bolt and Nuts-Rev0Documento5 pagineMaterial Requisition For Bolt and Nuts-Rev0altipatlarNessuna valutazione finora

- 03c EIL MR 3002 dd1059Documento146 pagine03c EIL MR 3002 dd1059Kalai Selvan100% (1)

- EIL - Formats - PMI PDFDocumento53 pagineEIL - Formats - PMI PDFABHISHEK SINGHNessuna valutazione finora

- Foam Monitor - F - 091318Documento16 pagineFoam Monitor - F - 091318rusli bahtiarNessuna valutazione finora

- Piping Spec: CS150 TFS 1021: Engineering StandardDocumento4 paginePiping Spec: CS150 TFS 1021: Engineering Standardbmanojkumar16Nessuna valutazione finora

- ANSI-B16.47 Ser B Blind and Welding Neck FlangesDocumento7 pagineANSI-B16.47 Ser B Blind and Welding Neck FlangesRicelles Silveira MartinsNessuna valutazione finora

- Gis 42-102Documento38 pagineGis 42-102Felix JaimesNessuna valutazione finora

- Day 6 Welding Process, Electrode - FCAW, GTAW & SAWDocumento65 pagineDay 6 Welding Process, Electrode - FCAW, GTAW & SAWRohit Kamble100% (1)

- ES 49BranchConnections PDFDocumento7 pagineES 49BranchConnections PDFprabuharan89Nessuna valutazione finora

- Project:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportDocumento4 pagineProject:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportEngr Saeed AnwarNessuna valutazione finora

- 4-Procedure Pipe To SoilDocumento7 pagine4-Procedure Pipe To SoilKhanh DTNessuna valutazione finora

- Buried Pipes and Fittings Painting SpecDocumento5 pagineBuried Pipes and Fittings Painting SpecRohan Sharma50% (2)

- Reliance Industries Limited Line History Sheet For CS Piping Without PWHTDocumento1 paginaReliance Industries Limited Line History Sheet For CS Piping Without PWHTRavi ShankarNessuna valutazione finora

- Astm C795Documento4 pagineAstm C795Nacer KisyNessuna valutazione finora

- Short List of Applied Piping Standard PDFDocumento3 pagineShort List of Applied Piping Standard PDFmohamad3010Nessuna valutazione finora

- Tender Document - GAIL - MIJ PDFDocumento17 pagineTender Document - GAIL - MIJ PDFVeer GangjiNessuna valutazione finora

- Es 01 PDFDocumento10 pagineEs 01 PDFharryNessuna valutazione finora

- Polyurethane Lining and Coating Specification Penstock Welded Joints 20120327Documento12 paginePolyurethane Lining and Coating Specification Penstock Welded Joints 20120327anbilselvamNessuna valutazione finora

- Types of Flanges-Definition of FlangesDocumento4 pagineTypes of Flanges-Definition of FlangesindikumaNessuna valutazione finora

- Brittle Fracture of Carbon Steel Piping During Hydrostatic TestingDocumento4 pagineBrittle Fracture of Carbon Steel Piping During Hydrostatic TestingSH1961Nessuna valutazione finora

- 9.Mb21 5f Externally Finned TubesDocumento4 pagine9.Mb21 5f Externally Finned Tubesyulianus_srNessuna valutazione finora

- Strainer DescriptionDocumento321 pagineStrainer DescriptionChirag ShahNessuna valutazione finora

- Pipe Spacing From Perisher Handbook PG 194Documento8 paginePipe Spacing From Perisher Handbook PG 194Asif Haq100% (1)

- ACME Chemicals: High Pressure Steam (HS) PipingDocumento40 pagineACME Chemicals: High Pressure Steam (HS) PipingRamu NallathambiNessuna valutazione finora

- Saudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Documento1 paginaSaudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Mohammed Hamed BaganNessuna valutazione finora

- Reliance Industries Limited Line History Sheet For Low Alloy Steel PipingDocumento2 pagineReliance Industries Limited Line History Sheet For Low Alloy Steel PipingRavi ShankarNessuna valutazione finora

- E25NAFLON Expansion BellowsDocumento22 pagineE25NAFLON Expansion BellowsRezza Octova GochirNessuna valutazione finora

- Technical Data NRL 02301Documento8 pagineTechnical Data NRL 02301Attiq Ahmad ChoudhryNessuna valutazione finora

- PFI ES-1-1992 Internal Machining and Solid Machined Backing Rings For Circumferential Butt Welds PDFDocumento8 paginePFI ES-1-1992 Internal Machining and Solid Machined Backing Rings For Circumferential Butt Welds PDFfatapia74Nessuna valutazione finora

- Specification For Fire Water HydrantDocumento5 pagineSpecification For Fire Water HydrantThiru AnanthNessuna valutazione finora

- Material Requisition For Expansion Joint - Rev1Documento4 pagineMaterial Requisition For Expansion Joint - Rev1altipatlarNessuna valutazione finora

- Interseal 670HDocumento2 pagineInterseal 670Hmadmax_mfpNessuna valutazione finora

- 2 Specification For GRP PipingDocumento4 pagine2 Specification For GRP Pipinggc_panchaNessuna valutazione finora

- HDPE Butt Fusion Weld Inspection and Imaging PDFDocumento19 pagineHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdNessuna valutazione finora

- Sa 961 PDFDocumento10 pagineSa 961 PDFaruntpeNessuna valutazione finora

- T&A Flange Insulation Kits PDFDocumento4 pagineT&A Flange Insulation Kits PDFJuan CarlosNessuna valutazione finora

- Brosur Globond Alumunium Composite PanelDocumento8 pagineBrosur Globond Alumunium Composite PanelDede SubhanNessuna valutazione finora

- Process Industry Practices Fabrication/Installation Details Vessel Toleran (Elevation)Documento1 paginaProcess Industry Practices Fabrication/Installation Details Vessel Toleran (Elevation)Federico GonzálezNessuna valutazione finora

- Anchor Bolt and Setting TemplateDocumento5 pagineAnchor Bolt and Setting Templatemadhu_bgrNessuna valutazione finora

- LT26G PDFDocumento4 pagineLT26G PDFraul gonzalezNessuna valutazione finora

- FOR Construction: Specifications For Identification of Piping MaterialDocumento12 pagineFOR Construction: Specifications For Identification of Piping MaterialajmainNessuna valutazione finora

- Vefv1100m 5Documento1 paginaVefv1100m 5Tariq HussainNessuna valutazione finora

- Storage Tank API 650Documento20 pagineStorage Tank API 650jalison07xNessuna valutazione finora

- ITPDocumento1 paginaITPVenkatesh PethurajNessuna valutazione finora

- Asme Code For Ultrasonic Testing The Knowledge Sinequation: Ashok J. TrivediDocumento7 pagineAsme Code For Ultrasonic Testing The Knowledge Sinequation: Ashok J. TrivediMax Celis CNessuna valutazione finora

- W P Ss 004Documento12 pagineW P Ss 004BETLAHORENessuna valutazione finora

- Astm A 335Documento8 pagineAstm A 335Ruben Dario Espinoza Vasquez100% (1)

- GTL WPSDocumento6 pagineGTL WPSYoucef ChorfaNessuna valutazione finora

- Material Requisition For Expansion Joint - Rev7Documento5 pagineMaterial Requisition For Expansion Joint - Rev7altipatlarNessuna valutazione finora

- Pressure VesselsDocumento14 paginePressure VesselsChevronelleNessuna valutazione finora

- Induced Vibration HXDocumento7 pagineInduced Vibration HXPatricia.PNessuna valutazione finora

- Eadips Manual Engl PDFDocumento390 pagineEadips Manual Engl PDFbkarabasevicNessuna valutazione finora

- Din 2526Documento1 paginaDin 2526MartinsaikiNessuna valutazione finora

- Smith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureDocumento8 pagineSmith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureWong Chung MengNessuna valutazione finora

- TighteningofStructuralBolts 31-35Documento5 pagineTighteningofStructuralBolts 31-35masaud akhtarNessuna valutazione finora

- KochDocumento181 pagineKochRichard FelipNessuna valutazione finora

- Project HSE Requirements ManualDocumento14 pagineProject HSE Requirements ManualHamid MansouriNessuna valutazione finora

- BPDocumento36 pagineBPThiruvenkatasamy Elangovan100% (2)

- 903-10004-SPC-M-001 Piping Material SpecificationDocumento15 pagine903-10004-SPC-M-001 Piping Material SpecificationChitradeep FalguniyaNessuna valutazione finora

- Letter of Introduction To Colliers (KDPL Mall Project) - 118 Dt. 08.06.22Documento3 pagineLetter of Introduction To Colliers (KDPL Mall Project) - 118 Dt. 08.06.22bisworupmNessuna valutazione finora

- Letter of Introduction To GAR Corporation - 107 - Dt. 10.5.22Documento3 pagineLetter of Introduction To GAR Corporation - 107 - Dt. 10.5.22bisworupmNessuna valutazione finora

- Letter of Introduction To Colliers (KDPL Mall Project) - 119 Dt. 09.06.22Documento3 pagineLetter of Introduction To Colliers (KDPL Mall Project) - 119 Dt. 09.06.22bisworupmNessuna valutazione finora

- Letter of Introduction To Ark Group - 134 Dt. 30.06.22Documento3 pagineLetter of Introduction To Ark Group - 134 Dt. 30.06.22bisworupmNessuna valutazione finora

- Letter of Introduction To Ashoka Builders Private Limited - 108 - Dt. 21.5.22Documento3 pagineLetter of Introduction To Ashoka Builders Private Limited - 108 - Dt. 21.5.22bisworupmNessuna valutazione finora

- Letter of Introduction To Bhavya Constructions PVT Ltd. - 122 Dt. 22.06.22Documento3 pagineLetter of Introduction To Bhavya Constructions PVT Ltd. - 122 Dt. 22.06.22bisworupmNessuna valutazione finora

- 003 Elect - Electrical Earthing System Installation PDFDocumento110 pagine003 Elect - Electrical Earthing System Installation PDFbisworupmNessuna valutazione finora

- Attachment 5 - Valve Design Table PDFDocumento8 pagineAttachment 5 - Valve Design Table PDFbisworupmNessuna valutazione finora

- Shamsur Rahman Kobita Samagra PDFDocumento716 pagineShamsur Rahman Kobita Samagra PDFbisworupm100% (1)

- Disclosure To Promote The Right To InformationDocumento33 pagineDisclosure To Promote The Right To InformationbisworupmNessuna valutazione finora

- Civil Spec - NTPC, RamagundamDocumento41 pagineCivil Spec - NTPC, Ramagundambisworupm100% (1)

- Troilokyanath Mukhopadhyay RachanasangrahaDocumento882 pagineTroilokyanath Mukhopadhyay RachanasangrahabisworupmNessuna valutazione finora

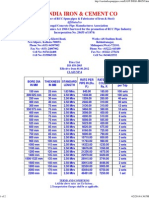

- East India Iron & Cement Co: Affiliated ToDocumento2 pagineEast India Iron & Cement Co: Affiliated TobisworupmNessuna valutazione finora

- East India Iron & Cement Co: .Vat at 4% All Applicableon Ex-Factory RateDocumento1 paginaEast India Iron & Cement Co: .Vat at 4% All Applicableon Ex-Factory RatebisworupmNessuna valutazione finora

- Dual Plate Check Valve WeightDocumento1 paginaDual Plate Check Valve WeightbisworupmNessuna valutazione finora

- East India Iron & Cement Co: .Vat at 4% All Applicableon Ex-Factory RateDocumento1 paginaEast India Iron & Cement Co: .Vat at 4% All Applicableon Ex-Factory RatebisworupmNessuna valutazione finora

- Advances in Diverse Industrial Applications of Nano CompositesDocumento588 pagineAdvances in Diverse Industrial Applications of Nano CompositesJosé RamírezNessuna valutazione finora

- Kramers 1946Documento20 pagineKramers 1946fabio1199Nessuna valutazione finora

- Centrifugal Chiller Fundamentals Guide PDFDocumento33 pagineCentrifugal Chiller Fundamentals Guide PDFKhizerNessuna valutazione finora

- Stress AnalysisDocumento60 pagineStress AnalysisTejas DesaiNessuna valutazione finora

- Blue Casa - Cleo CountyDocumento8 pagineBlue Casa - Cleo CountyAbhinav KishoreNessuna valutazione finora

- A Study On Estimation and Costing of A Seven Storied Residential Building in Dhaka CityDocumento9 pagineA Study On Estimation and Costing of A Seven Storied Residential Building in Dhaka CityPallavi PatilNessuna valutazione finora

- Steam BlowingDocumento21 pagineSteam BlowingAbhishek JainNessuna valutazione finora

- Slab Bridge DesignDocumento73 pagineSlab Bridge DesignAmy MengistuNessuna valutazione finora

- Natural Bend Radius Cal Rev. C PDFDocumento3 pagineNatural Bend Radius Cal Rev. C PDFhamid sobirin100% (2)

- 100AFEDocumento191 pagine100AFEchris pNessuna valutazione finora

- Mahendra Engineering College) : Internal Assessment - II, OCTOBER-2020Documento3 pagineMahendra Engineering College) : Internal Assessment - II, OCTOBER-2020ajithNessuna valutazione finora

- 8 Reinforced Concrete Structure - Park Paulay PDFDocumento388 pagine8 Reinforced Concrete Structure - Park Paulay PDFPercy Abel Mamani LipaNessuna valutazione finora

- Wall Treatments: Arshpreet Kaur Matharoo L-2015-HSC-10-BIDDocumento38 pagineWall Treatments: Arshpreet Kaur Matharoo L-2015-HSC-10-BIDAISXOXONessuna valutazione finora

- 64721B510BF11337E10000000AD5062ADocumento1 pagina64721B510BF11337E10000000AD5062AKailas NimbalkarNessuna valutazione finora

- Steel Slag in ConcreteDocumento4 pagineSteel Slag in ConcreteGreissy Margory Reynaga CalderonNessuna valutazione finora

- Properties of SteamDocumento8 pagineProperties of Steamadithi udupaNessuna valutazione finora

- Finite Element (FE) Shear Modeling of Woven Fabric Textile CompositeDocumento7 pagineFinite Element (FE) Shear Modeling of Woven Fabric Textile Compositeranim najibNessuna valutazione finora

- RebarsDocumento5 pagineRebarsJohny Lou LuzaNessuna valutazione finora

- Casting Defects & CausesDocumento15 pagineCasting Defects & CausesAbhinav Pratap MauryaNessuna valutazione finora

- Analysis of Cracked and Uncracked SectionsDocumento9 pagineAnalysis of Cracked and Uncracked SectionsDC TVNessuna valutazione finora

- AASHTO-2009 Highway Signs 159 PDFDocumento1 paginaAASHTO-2009 Highway Signs 159 PDFer_rahmansNessuna valutazione finora

- M2 NDT Liquid Penetrant TestingDocumento41 pagineM2 NDT Liquid Penetrant TestingAravind SANessuna valutazione finora

- Wrapping Coating Application SequenceDocumento2 pagineWrapping Coating Application SequencesenthilkumarNessuna valutazione finora

- Short AnswerDocumento10 pagineShort AnswerNarendra Singh Shekhawat100% (1)

- Safety Inspection ChecklistDocumento3 pagineSafety Inspection ChecklistBobby IM Sibarani100% (4)

- Argon Purging Systems (APS), Applicable To Purging Induction Melting Furnaces and Induction PowerDocumento12 pagineArgon Purging Systems (APS), Applicable To Purging Induction Melting Furnaces and Induction Powernirav patelNessuna valutazione finora

- Glo Sikacontrol Aer 200 PDocumento4 pagineGlo Sikacontrol Aer 200 PKing MKNessuna valutazione finora

- Data Sheet: Amadeus ProjectDocumento7 pagineData Sheet: Amadeus ProjectErikikoNessuna valutazione finora

- Alucobest Aluminum Composite Panel For Architectural & BuildingDocumento12 pagineAlucobest Aluminum Composite Panel For Architectural & BuildingAli ZhangNessuna valutazione finora

- Geothermal Heat PumpDocumento17 pagineGeothermal Heat PumpMudassir Hussain83% (6)