Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Aircraft Pneumatic Systems Overview

Caricato da

Damon LeongDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Aircraft Pneumatic Systems Overview

Caricato da

Damon LeongCopyright:

Formati disponibili

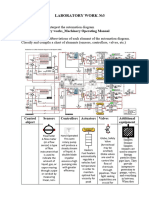

HIGH PRESSURE MEDIUM PRESSURE LOW PRESSURE

Stored in metal bottles 100psi 150psi As primary gyro instrument/ backup

1000psi 3000psi Not include in air bottle instrument

Pressure bottle with 2 Gain bleed air from turbine engine Used together with an engine driven vacuum

valves: compressor section pump to :

1. Charging valve Engine bleed air routed to 1. Evacuate instrument case

2. -Control valve 2. Filtered air pulled into instrument to

pressure controlling unit then to

Cannot recharge in flight spin gyro

desired operating unit 2 vane type pumps used to provide instrument

airflow :

INTRODUCTION STANDARD

Advantage: DISADVANTAGE:

PRECAUTIONS:

Fluid power

Air is Small leakage is

system use Air compressor

universabally hard to detect

compressible air lubrication oil

available in In high pressure

PNEUMATIC

Used to powered should be checked

inexhaustible system, system

aircraft daily I.A.W

supply cannot be

instrument & manufacturer

Units are recharge in flight

back up system instruction

simple/lightweig Do not allow

Principle same as After oil is added,

ht continuous

hydraulic except filler plug should be

No return operation

pressure in torque & safety

system required Large volume to

system can wire is properly

No fire hazard/ move large

reduce gradually installed

Component must explosion components

from maximum to

zero pressure. be checked for

danger are Not suitable for

minimised

Air in this system highest standard of heavy/large

cleanliness Contamination working function

must be kept

Leak testing must minimised by

clean & free from

be performed I.A.W proper filter

RELIEF VALVE CHECK VALVE VARIABLE RESTRICTOR DESSICANT/MOISTURE SEPERATOR

Used to prevent damage Used both in hydraulic & Consist of an adjustable needle Collect water in air on a baffle & holds it until

components pneumatic valve system shut down

Act as pressure limiting Only allow one direction of Depend on direction turned, An electrical heater in base prevents water

units/prevent excessive airflow needle valve moves sharp point from freezing

pressure from bursting If air enter in reverse either into/out of small opening Any moisture not removed by separator will be

direction, air pressure close To decrease/increase size of absorbed by dehydrating agent

CONTROL VALVE RESTRICTOR FILTER SHUTTER VALVE

Control amount of air pressure Classified as control valve in Protect system against Allow pneumatic sources to operate from ground

in operating subsystem pneumatic system dirt/contaminants source

Consist 3 port housing: Consists of an orifice with A micronic filter consist a Provide an emergency pneumatic backup for

1. 2 poppet valves large inlets port & a small housing with 2 ports: hydraulic operated landing gear/brake system in

2. A control lever with 2 outlet port 1. A replacable filter

case of failure

cartridge

lobes Small outlet port reduce

airflow and actuating unit

2. relief valve

Potrebbero piacerti anche

- Instrument Technology: Telemetering and Automatic ControlDa EverandInstrument Technology: Telemetering and Automatic ControlNessuna valutazione finora

- Low Pressure System: PneumaticDocumento1 paginaLow Pressure System: PneumaticDamon LeongNessuna valutazione finora

- BOOTSDocumento9 pagineBOOTSDamon LeongNessuna valutazione finora

- AE221 Lec05 Activity2 GROUP8 5Documento4 pagineAE221 Lec05 Activity2 GROUP8 5Robert YerroNessuna valutazione finora

- 4VacuumPumps Gauges10-11Documento2 pagine4VacuumPumps Gauges10-11ISKT-IsıtmaSogutmaKlimaTesisatNessuna valutazione finora

- Series (25A-) VP#44 (R) - X555 (-##), VP#44-X597: Instruction ManualDocumento6 pagineSeries (25A-) VP#44 (R) - X555 (-##), VP#44-X597: Instruction ManualMae BecherNessuna valutazione finora

- LH150S10 D2.9L4 Skid-3Documento2 pagineLH150S10 D2.9L4 Skid-3Jack SetengahNessuna valutazione finora

- Enerpac PA Series CatalogDocumento3 pagineEnerpac PA Series CatalogTitanplyNessuna valutazione finora

- 321 - Дудник ЛР№3Documento8 pagine321 - Дудник ЛР№3Роман ДудникNessuna valutazione finora

- Chapter 11 - Valves and Actuators With The NAMUR-InterfaceDocumento13 pagineChapter 11 - Valves and Actuators With The NAMUR-InterfaceJoseph MagonduNessuna valutazione finora

- Mantenimiento Compresor ScrollDocumento8 pagineMantenimiento Compresor ScrollHugovillarruelNessuna valutazione finora

- 01 - Pressure Reducing ValveDocumento132 pagine01 - Pressure Reducing ValveHydro NguyenNessuna valutazione finora

- Bomba de Vacion ME 8SI 696190 - GBDocumento28 pagineBomba de Vacion ME 8SI 696190 - GBalexjcc10Nessuna valutazione finora

- Volvo Wheel Loader: Standard Equipment Hydraulic System Steering SystemDocumento6 pagineVolvo Wheel Loader: Standard Equipment Hydraulic System Steering SystemFernando RíosNessuna valutazione finora

- Air-Main Charging Systems: DHS 4.0 Series Compact Assistants That Make A Big DifferenceDocumento12 pagineAir-Main Charging Systems: DHS 4.0 Series Compact Assistants That Make A Big DifferenceandreaNessuna valutazione finora

- Single Aisle Technical Training Manual T1 (IAE V2500) (LVL 2&3) PneumaticDocumento50 pagineSingle Aisle Technical Training Manual T1 (IAE V2500) (LVL 2&3) PneumaticAnh NguyenXuanNessuna valutazione finora

- Pneumatic Controls and Designs: Wendell Z. BuenaobraDocumento11 paginePneumatic Controls and Designs: Wendell Z. BuenaobraJohn Paul DaliopacNessuna valutazione finora

- Pneumatics CTUDocumento54 paginePneumatics CTUCryl Jake SubingSubingNessuna valutazione finora

- Topic 4 (Aircond)Documento38 pagineTopic 4 (Aircond)muhammadarifh7Nessuna valutazione finora

- Industrial Pneumatics Basics - by CEREBRO SWITCH-desbloqueadoDocumento80 pagineIndustrial Pneumatics Basics - by CEREBRO SWITCH-desbloqueadoFernando MatiasNessuna valutazione finora

- Denso CRD Injectors: Toyota 1KD-FTV: 2005 - 2018 Hiace 2005 - 2015 Hilux 2006 - 2015 Prado Injector OperationDocumento6 pagineDenso CRD Injectors: Toyota 1KD-FTV: 2005 - 2018 Hiace 2005 - 2015 Hilux 2006 - 2015 Prado Injector OperationZahid Hussain100% (5)

- Lube Pump Operator ManualDocumento8 pagineLube Pump Operator ManualSergeyNessuna valutazione finora

- Bombas Hidraulicas Toque DET-and-DAT-SeriesDocumento2 pagineBombas Hidraulicas Toque DET-and-DAT-SeriesTecnico HYTORCNessuna valutazione finora

- Power Unit PDFDocumento17 paginePower Unit PDFgawaNessuna valutazione finora

- 03 Introduction To Hydraulic and PneumaticDocumento4 pagine03 Introduction To Hydraulic and Pneumaticapi-3731420100% (1)

- WWTP Aeration Upgrades O and M Manual Vol 10 ComplDocumento50 pagineWWTP Aeration Upgrades O and M Manual Vol 10 ComplCrisnuel RamirezNessuna valutazione finora

- 1268Documento20 pagine1268ChiragNessuna valutazione finora

- PRV Valve PDFDocumento20 paginePRV Valve PDFhindro kusumantoNessuna valutazione finora

- Turbair Blower (Type RT)Documento2 pagineTurbair Blower (Type RT)Amir AbbaszadehNessuna valutazione finora

- Penberthy EductorDocumento16 paginePenberthy EductorVikk SuriyaNessuna valutazione finora

- Pneumatic System: Introduction: AdvantagesDocumento3 paginePneumatic System: Introduction: AdvantagesDamon LeongNessuna valutazione finora

- Fan Tech HMI Series Technical Manual Rev A: CautionDocumento15 pagineFan Tech HMI Series Technical Manual Rev A: CautionJamin SmtpngNessuna valutazione finora

- Robotics and Automation - Unit-2 (Part 1)Documento19 pagineRobotics and Automation - Unit-2 (Part 1)jaiganeshNessuna valutazione finora

- Chapter 12 - Aircraft De-Icing SystemDocumento42 pagineChapter 12 - Aircraft De-Icing SystemDamon LeongNessuna valutazione finora

- What Is Compressor ?Documento12 pagineWhat Is Compressor ?RAJEEV RANJAN KUMARNessuna valutazione finora

- Single Aisle Pneumatic System Training ManualDocumento60 pagineSingle Aisle Pneumatic System Training ManualangeNessuna valutazione finora

- 737 300/400/500 Boeing: ATA 36 PneumaticDocumento51 pagine737 300/400/500 Boeing: ATA 36 PneumaticmaryNessuna valutazione finora

- Operating and Maintenance Instructions: Keystone Figure 79 Pneumatic ActuatorDocumento13 pagineOperating and Maintenance Instructions: Keystone Figure 79 Pneumatic ActuatorjorgeNessuna valutazione finora

- H YDRAULICS1Documento1 paginaH YDRAULICS1Damon LeongNessuna valutazione finora

- Flowmaster Rotary Driven Electric Pump, 120/230 Vac Models: 85598 (400#) and 85599 (120#) Series "A"Documento25 pagineFlowmaster Rotary Driven Electric Pump, 120/230 Vac Models: 85598 (400#) and 85599 (120#) Series "A"Rhyan FFNessuna valutazione finora

- EN Brochure OPTIMA Compact DN50-DN300Documento6 pagineEN Brochure OPTIMA Compact DN50-DN300Onkar DograNessuna valutazione finora

- Auto Series Hydraulic Presses SheetDocumento2 pagineAuto Series Hydraulic Presses SheetgpradiptaNessuna valutazione finora

- Zutp E413e GBDocumento2 pagineZutp E413e GBjason.agatsiotisNessuna valutazione finora

- Regulators 299HDocumento20 pagineRegulators 299HAlberto CastellanosNessuna valutazione finora

- Chemetron FM-200 Gamma Specs PDFDocumento6 pagineChemetron FM-200 Gamma Specs PDFAhmed Hassan0% (1)

- Fm200 Data SheetDocumento10 pagineFm200 Data SheetMahmoud EldusokyNessuna valutazione finora

- FMEA AnalysisDocumento30 pagineFMEA AnalysisThivanka Nirushan Withanage100% (1)

- ABB Instrumentation: Pipeline Booster Station Control SystemsDocumento6 pagineABB Instrumentation: Pipeline Booster Station Control SystemsPatricio AcuñaNessuna valutazione finora

- Air Starter Unit A300: A300 Camel SpecificationDocumento1 paginaAir Starter Unit A300: A300 Camel SpecificationAhmad Yani S NoorNessuna valutazione finora

- Janus MV FM200 BrochureDocumento22 pagineJanus MV FM200 BrochurenoisNessuna valutazione finora

- HPR 02 LindeDocumento1 paginaHPR 02 LindeEduardo NeryNessuna valutazione finora

- Pressurization Unit (B10 PDFDocumento2 paginePressurization Unit (B10 PDFAlkaf QuraishiNessuna valutazione finora

- Groz Rac DD 2-11-24!1!2 HP Direct Drive Air CompressorDocumento6 pagineGroz Rac DD 2-11-24!1!2 HP Direct Drive Air CompressorMaroof AliNessuna valutazione finora

- Complete PVDF Jp180Documento2 pagineComplete PVDF Jp180bivomixNessuna valutazione finora

- A SeriesDocumento10 pagineA SeriesagorbatenkoNessuna valutazione finora

- DS1351 LV Series Marine FM-200Documento20 pagineDS1351 LV Series Marine FM-200kidmuNessuna valutazione finora

- Brosur IBBSDocumento8 pagineBrosur IBBSzenoniusz768Nessuna valutazione finora

- SpDesGuide5 02 IXDocumento84 pagineSpDesGuide5 02 IXjesus_manrique2753Nessuna valutazione finora

- HP Boiler Control ValvesDocumento32 pagineHP Boiler Control ValveshalloihrNessuna valutazione finora

- 8496grease PumpDocumento8 pagine8496grease Pumpilyaswinduaji014Nessuna valutazione finora

- BAE Systems Jetstream 31 G-CCPW 10-12Documento16 pagineBAE Systems Jetstream 31 G-CCPW 10-12Damon LeongNessuna valutazione finora

- Meeting of MinutesDocumento4 pagineMeeting of MinutesDamon LeongNessuna valutazione finora

- Chapter 1 - Number and ArithmeticsDocumento22 pagineChapter 1 - Number and ArithmeticsDamon LeongNessuna valutazione finora

- Chapter 12 - Aircraft De-Icing SystemDocumento42 pagineChapter 12 - Aircraft De-Icing SystemDamon LeongNessuna valutazione finora

- Mpu 31231Documento13 pagineMpu 31231JoycewongNessuna valutazione finora

- Chapter 7 - Emergency Furnishing Fire ExtinguishersDocumento20 pagineChapter 7 - Emergency Furnishing Fire ExtinguishersDamon LeongNessuna valutazione finora

- Chapter 4 - TrigonometryDocumento18 pagineChapter 4 - TrigonometryDamon LeongNessuna valutazione finora

- Eddy Current Braking SystemDocumento5 pagineEddy Current Braking SystemDamon LeongNessuna valutazione finora

- John Strickland Aviation ExpertDocumento2 pagineJohn Strickland Aviation ExpertDamon LeongNessuna valutazione finora

- Chapter 2 - AlgebraDocumento28 pagineChapter 2 - AlgebraDamon LeongNessuna valutazione finora

- Air Compressor OSDocumento2 pagineAir Compressor OSDamon LeongNessuna valutazione finora

- Sample Policy StatementDocumento1 paginaSample Policy StatementDamon LeongNessuna valutazione finora

- Chapter 3 - Passenger Compartment EquipmentDocumento87 pagineChapter 3 - Passenger Compartment EquipmentDamon Leong100% (1)

- Chapter 13 - Rain Protection Control SystemDocumento14 pagineChapter 13 - Rain Protection Control SystemDamon Leong100% (1)

- Aircraft Cabin Interior System - AssignmentDocumento2 pagineAircraft Cabin Interior System - AssignmentDamon Leong0% (1)

- Cabin AssignmentDocumento33 pagineCabin AssignmentDamon Leong100% (1)

- 2 - Flight Compartment EquipmentsDocumento46 pagine2 - Flight Compartment EquipmentsDamon LeongNessuna valutazione finora

- Chapter 4 - Aircraft GalleyDocumento40 pagineChapter 4 - Aircraft GalleyDamon Leong60% (5)

- 1 - Cabin Interior System - IntroductionDocumento25 pagine1 - Cabin Interior System - IntroductionDamon LeongNessuna valutazione finora

- RR VIPER 522 MAINTENANCE MANUAL REVISIONDocumento209 pagineRR VIPER 522 MAINTENANCE MANUAL REVISIONTarmizy MZaki100% (2)

- HS-125 R6Documento184 pagineHS-125 R6Damon Leong100% (1)

- Assignment 4Documento2 pagineAssignment 4Damon LeongNessuna valutazione finora

- Consumable Equipment List PDFDocumento2 pagineConsumable Equipment List PDFDamon LeongNessuna valutazione finora

- Hs 125 Part 2Documento289 pagineHs 125 Part 2Damon Leong100% (1)

- Oxygen Tank Removal Practical 1Documento2 pagineOxygen Tank Removal Practical 1Damon LeongNessuna valutazione finora

- Mohamad Jamalulail Bin Hamzah: 12, JALAN USJ 6/6B, 47610 SUBANG JAYA, Selangor Darul EhsanDocumento2 pagineMohamad Jamalulail Bin Hamzah: 12, JALAN USJ 6/6B, 47610 SUBANG JAYA, Selangor Darul EhsanDamon LeongNessuna valutazione finora

- HS-125 R6Documento184 pagineHS-125 R6Damon Leong100% (1)

- Turbinefuel Metering SystemDocumento21 pagineTurbinefuel Metering SystemDamon LeongNessuna valutazione finora

- TranslationDocumento13 pagineTranslationDamon LeongNessuna valutazione finora

- Turbine Fuel SystemDocumento66 pagineTurbine Fuel SystemDamon Leong100% (1)

- Behaviour of Real FluidsDocumento27 pagineBehaviour of Real FluidschileNessuna valutazione finora

- Duct Size S. No. Width Height Length Pari. Area Qty. AHU 01 Final AreaDocumento15 pagineDuct Size S. No. Width Height Length Pari. Area Qty. AHU 01 Final Areanim_gourav1997Nessuna valutazione finora

- Sample Pipe IsometricsDocumento2 pagineSample Pipe Isometricslinkinpark11129116Nessuna valutazione finora

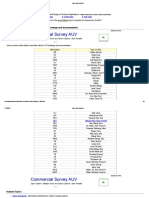

- Commercial Survey AUV: Valve AbbreviationsDocumento8 pagineCommercial Survey AUV: Valve AbbreviationsMario StrašniNessuna valutazione finora

- 3.10.E.pv25G Pneumatic Control Valves DN15-100-EnDocumento6 pagine3.10.E.pv25G Pneumatic Control Valves DN15-100-EnSon Trinh PhuongNessuna valutazione finora

- Establishing Proper Pressure Drop For Feedwater Flow Control ValvesDocumento5 pagineEstablishing Proper Pressure Drop For Feedwater Flow Control ValvesAkshay SetlurNessuna valutazione finora

- Procedure PipeDocumento4 pagineProcedure PipejoeknotNessuna valutazione finora

- 10.6 Safety Valves Operating DiagramDocumento1 pagina10.6 Safety Valves Operating DiagramDangolNessuna valutazione finora

- Gas Compression: A Primer on Rotary CompressorsDocumento5 pagineGas Compression: A Primer on Rotary CompressorsLe Anh DangNessuna valutazione finora

- Zero Governor DesignDocumento6 pagineZero Governor DesignM.H.Nessuna valutazione finora

- Solenoid Valves for High Pressure Applications 1/4”-2Documento1 paginaSolenoid Valves for High Pressure Applications 1/4”-2Nguyễn KhoaNessuna valutazione finora

- Basic Operation and Function of Control ValvesDocumento65 pagineBasic Operation and Function of Control ValvesEdgar Huanca0% (1)

- Plate Heat Exchanger Design in ExcelDocumento6 paginePlate Heat Exchanger Design in Excelamitkray67% (12)

- Vacuum Breaker ValvesDocumento5 pagineVacuum Breaker ValvesSCR_010101Nessuna valutazione finora

- 5456 de Filter PressDocumento6 pagine5456 de Filter PressmbhadelNessuna valutazione finora

- Asme Ansi A 13.1Documento4 pagineAsme Ansi A 13.1Deniss GálvezNessuna valutazione finora

- Intercooler, Aftercooler and Antisurge Control: 1. One CasingDocumento3 pagineIntercooler, Aftercooler and Antisurge Control: 1. One CasingzsmithNessuna valutazione finora

- Fluid Mechanics: 200 MM 0.0225 500 M 0.2 M /s 9.81 M/sDocumento57 pagineFluid Mechanics: 200 MM 0.0225 500 M 0.2 M /s 9.81 M/sRamesh MundaNessuna valutazione finora

- Lab Report 4Documento7 pagineLab Report 4api-300265822100% (1)

- MOD11Documento11 pagineMOD11BhaskerNegiNessuna valutazione finora

- Check Valve Failure - Closed: HariniDocumento5 pagineCheck Valve Failure - Closed: Harinimarco8garciaNessuna valutazione finora

- Meson Gate Valve 620767Documento1 paginaMeson Gate Valve 620767syed aliNessuna valutazione finora

- R Randen Engg - Bhushan - Valves Enq - 18Documento3 pagineR Randen Engg - Bhushan - Valves Enq - 18Vinayak PujariNessuna valutazione finora

- Theoretical Approaches Regarding The VENTURI EffectDocumento4 pagineTheoretical Approaches Regarding The VENTURI EffectJose A AbrahamNessuna valutazione finora

- Vortex SheddingDocumento3 pagineVortex SheddingMaheshNessuna valutazione finora

- 7-Directional Control ValvesDocumento45 pagine7-Directional Control ValvesMahmmod Al-QawasmehNessuna valutazione finora

- AS4041 PRESSURE PIPING - REQUIRED PRESSURE DESIGN WALL THICKNESSDocumento33 pagineAS4041 PRESSURE PIPING - REQUIRED PRESSURE DESIGN WALL THICKNESSaike_5Nessuna valutazione finora

- HP Bypass Valves Type ARS: ApplicationDocumento2 pagineHP Bypass Valves Type ARS: Applicationbb84sharmaNessuna valutazione finora

- Natural Gas Transmission Flow Equation and FactorsDocumento43 pagineNatural Gas Transmission Flow Equation and Factorsangel3reyesNessuna valutazione finora

- Valve Leakage Rates Test STDDocumento5 pagineValve Leakage Rates Test STD윤병택Nessuna valutazione finora