Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Mech-V-Design of Machine Elements I (10me52) - Assignment

Caricato da

ArunTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Mech-V-Design of Machine Elements I (10me52) - Assignment

Caricato da

ArunCopyright:

Formati disponibili

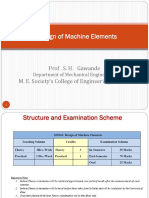

Design of Machine Elements I

ASSIGNMENT QUESTIONS

10ME52

UNIT 1

INTRODUCTION

1. What are the factors to be considered for selection of material for a machine component?

2. What are the basic requirements of machine elements? Explain briefly.

3. Draw stress - strain diagram for mild steel subjected to tension. Explain the significance of

salient points.

4. Identify the following engineering materials giving specifications:

i) FG350.

ii) FeE300.

iii) C35Mn75.

iv) X20Cr18Ni2.

5. An unknown weight falls through 10 mm on a collar rigidly attached to the lower end of a

vertical bar 3000 mm long and 600 mm2 in section. If the maximum instantaneous extension of

bar is 2mm, what is the corresponding stress and the value of unknown weight?

Take E = 200 kN/mm2.

6. A point in a structural member subjected to plane stress is shown in Fig.Q.l(b). Determine the

following:

i) Normal and tangential stress intensities on plane MN inclined at 45.

ii) Principal stresses and their direction

iii) Maximum shear stress and the direction of the planes on which it occurs.

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 1

Design of Machine Elements I

7. Define Machine Design? Explain the importance of material selection in design?

10ME52

8. What are the advantages of malleable cast iron over white or grey castiron?

9. A standard alloy steel used for making engineering components is 20Cr18 Ni2. State the

composition of the steel.

10. List at least five important non-metals commonly used in machine design.

11. State at least 5 important mechanical properties of materials to be considered in machine

design.

12. Define resilience and discuss its implication in the choice of materials in machine design.

13. Discuss factor of safety in view of the reliability in machine design.

14. Suggest briefly the steps to be followed by a designer.

15. Define standards and codes.

16. Briefly explain the important mechanical properties of metals.

17. Draw stress-strain diagram for a ductile material and a brittle material and show the salient

points on them.

18. What is an adaptive design?

19. How are plain carbon steel designated?

20. Sketch and explain biaxial, triaxial and principal stresses.

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 2

Design of Machine Elements I

UNIT 2

DESIGN FOR STATIC AND IMPACT STRENGTH

10ME52

1. Explain the following theories of failure:

a. Maximum normal stress theory.

b. Maximum distortion energy theory.

2. A round stepped shaft is made of brittle material cast iron FG 260 and subjected to a

bending moment of 15 N-m as shown in Fig.Q2 (b). The stress concentration factor at the

fillet is 1.5. Determine the, following:

i. Step diameter.

ii. Magnitude of stress at fillet.

iii. Factor of safety.

b.

3. Derive an expression for impact stress in a bar of cross section' A' and length 'L' due to

the impact of a load 'W' falling from a height 'h' on the bar, as shown in Fig. Q2 (c).

a.

4. What is stress concentration? Explain the methods to reduce the stress concentration.

5. A steel rod of 40mm diameter and 200mm long, supported at one end is subjected to an

axial tensile load of 10kN at the free end. Determine the tensile stress in the rod.

6. A shaft is loaded by a torque of 5 KN-m. The material has a yield point of 350 MPa. Find

the required diameter using

(a) Maximum shear stress theory

(b) Maximum distortion energy theory. Take a factor of safety of 2.5.

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 3

Design of Machine Elements I

10ME52

7. The flat bar shown in figure is 10 mm thick and is pulled by a force P producing a total

change in length of 0.2 mm. Determine the maximum stress developed in the bar. Take

E= 200 GPa.

8. Find the maximum stress developed in a stepped shaft subjected to a twisting moment of

100 Nm as shown in figure. What would be the maximum stress developed if a bending

moment of 150 Nm is applied.

9. Derive an expression for stress induced in a rod due to the axial impact of a weight W

dropped from a height h on to a collar attached at the free end of the rod. What is the

stress due to suddenly applied load?

10. A steel rod 1.5m long resists an impact load of 2kN dropped through a distance of 50mm

along its axis. Limiting tha maximum stress in the rod to 150MPa, determine i) The

diameter of the rod required ii) Impact factor. Take E=200GPa.

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 4

Design of Machine Elements I

UNIT 3

10ME52

DESIGN FOR FATIGUE STRENGTH

1. Explain cumulative fatigue damage.

2. Derive Goodman's equation.

3. A circular bar of 500 mm length is supported freely at its two ends. It is acted upon by a

central concentrated cyclic load having a minimum value of 20kN and a maximum value

of 50kN. Determine the diameter of bar by taking a factor of safety of 2, size effect of

0.85, surface finish factor of 0.9. The material properties of bars are given by: ultimate

strength of 650 MPa, yield strength of 500 MPa and endurance strength of 350 MPa.

4. A 60 mm diameter cold drawn steel bar is subjected to a completely reversed torque of

100 Nm and an applied bending moment that varies between 400 Nm and -200 Nm. The

shaft has a machined finish and has a 6 mm diameter hole drilled transversely through it.

If the ultimate tensile stress u and yield stress y of the material are 600 MPa and 420

MPa respectively, find the factor of safety.

5. Derive Soderberg's equation.

6. A portion of a connecting link made of steel is shown in figure The tensile axial force F

fluctuates between 15 KN to 60 KN. Find the factor of safety if the ultimate tensile

strength and yield strength for the material are 440 MPa and 370 MPa respectively and

the component has a machine finish.

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 5

Design of Machine Elements I

UNIT 4

THREADED FASTENERS

10ME52

1. 12 M20 x 2.5C bolts are used to hold the cylinder head of a reciprocating air compressor in

position. The air pressure is 7 MPa and the cylinder bore diameter is 100 mm. A soft copper

gasket with long bolts is used for sealing. If the tensile yield stress of the bolt material is 500

MPa find the suitability of the bolt for the purpose. Check if the joint is leak proof and also if

any joint separation may occur.

2. In a steam engine the steam pressure is 2 MPa and the cylinder diameter is 250 mm. The

contact surfaces of the head and cylinder are ground and no packing is required. Choose a

suitable bolt so that the joint is leak proof. Assume number of bolts to be used is 12.

3. Write a note on bolt of uniform strength

4. A Flange bearing as shown in Figure is fastened to a frame by means of 4 bolts, spaced

equally on a 500mm bolt circle. The dia of the bearing flange in 650mm and a load of 400

kN acts at a distance of 250mm from the frame. Determine the size of bolt, taking allowable

tensile stress in the bolt material as 60N/m2. Two dowel pins are provided to take up the

shear load.

5. A bolt is subjected to initial loading of 5 kN and final tensile load of 9 kN. Determine the

size of the bolt, if the allowable stress is 80 MPa and K = 0.05.

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 6

Design of Machine Elements I

UNIT 5

DESIGN OF SHAFTS

10ME52

1. What do you understand by shaft, axle and spindle?

2. What are the common ferrous materials for a shaft?

3. How do the strength of a steel material for shafting is estimated in ASME design code

for shaft?

4. What is an equivalent stress?

5. What are the limiting values of the angle of twist of a shaft?

6. What are the assumptions made to derive the equation for critical frequency? Why

critical frequency is important in shaft design?

7. Broadly, what are the types of bearings?

8. Highlight friction characteristics of bearings.

9. Prove that a hollow shaft is stronger and stiffer than a solid shaft of same length, weight

and material.

10. If a shaft and key are made of same material, determine the length of the key required in

terms of shaft diameter, taking key width and key thickness. Assume keyway factor as

0.75.

11. The standard cross- section of a flat key, which is fitted on a 50 mm diameter shaft is

16 x 10 mm. The key is transmitting 475 N-m torque from the shaft to the hub. The key

is made of commercial steel for which yield strength in both tension and compression

may be taken as 230 N/mm2. Determine the minimum length of key required if the factor

of safety is 3.

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 7

Design of Machine Elements I

UNIT 6

COTTER AND KNUCKLE JOINTS, KEYS AND COUPLINGS

10ME52

1. Design a typical cotter joint to transmit a load of 50 kN in tension or compression. Consider

that the rod, socket and cotter are all made of a material with the following allowable

stresses:

Allowable tensile stress y = 150 MPa

Allowable crushing stress c = 110 MPa

Allowable shear stress y = 110 MPa.

2. Two mild steel rods are connected by a knuckle joint to transmit an axial force of 100 kN.

Design the joint completely assuming the working stresses for both the pin and rod materials

to be 100 MPa in tension, 65MPa in shear and 150 MPa in crushing.

3. Two 30 mm diameter shafts are connected by pins in an arrangement shown in figure. Find

the pin diameter if the allowable shear stress of the pins is 100 MPa and the shaft transmits

5kW at 150 rpm.

4. A heat treated steel shaft of tensile yield strength of 350 MPa has a diameter of 50 mm. The

shaft rotates at 1000 rpm and transmits 100 kW through a gear. Select an appropriate key for

the gear.

5. Design a typical rigid flange coupling for connecting a motor and a centrifugal pump shafts.

The coupling needs to transmit 15 KW at 1000 rpm. The allowable shear stresses of the shaft,

key and bolt materials are 60 MPa,50 MPa and 25 MPa respectively. The shear modulus of

the shaft material may be taken as 84GPa. The angle of twist of the shaft should be limited to

1 degree in 20 times the shaft diameter.

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 8

Design of Machine Elements I

UNIT 7

RIVETED AND WELDED JOINTS

10ME52

1. What should be essential qualities of a rivet and its material?

2. What are the uses of snap headed, counter shank headed, conical headed and pan headed

rivets?

3. Two plates of 7 mm thickness are connected by a double riveted lap joint of zigzag pattern.

Calculate rivet diameter, rivet pitch and distance between rows of rivets for the joint. Assume

St = 90MPa, Ss = 60MPa, Sc = 120MPa.

4. How is a rivet joint of uniform strength designed?

5. Two mild steel tie rods having width 200 mm and thickness 12.5 mm are to be connected by

means of a butt joint with double cover plates. Find the number of rivets needed if the

permissible stresses are 80 MPa in tension, 65 MPa in shear and 160 MPa in crushing.

6. A plate 50 mm wide and 12.5 mm thick is to be welded to another plate by means of parallel

fillet welds. The plates are subjected to a load of 50 kN. Find the length of the weld. Assume

allowable shear strength to be 56 MPa.

7. Two plates 200 mm wide and 10 mm thick are to be welded by means of transverse welds at

the ends. If the plates are subjected to a load of 70 kN, find the size of the weld assuming the

allowable tensile stress 70 MPa.

8. A 50 mm diameter solid shaft is to be welded to a flat plate and is required to carry a torque

of 1500 Nm. If fillet joint is used foe welding what will be the minimum size of the weld

when working shear stress is 56 MPa.

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 9

Design of Machine Elements I

UNIT 8

POWER SCREWS

10ME52

1. Derive the equation for maximum efficiency of square threaded screw.

2. The C-clamp shown in figure uses a 10 mm screw with a pitch of 2 mm. The frictional

coefficient is 0.15 for both the threads and the collar. The collar has a frictional diameter of

16 mm. The handle is made of steel with allowable bending stress of 165 MPa. The capacity

of the clamp is 700 N.

(a) Find the torque required to tighten the clamp to full capacity.

(b) Specify the length and diameter of the handle such that it will not bend unless the rated

capacity of the clamp is exceeded. Use 15 N as the handle force.

3. A single square thread power screw is to raise a load of 50 KN. A screw thread of major

diameter of 34 mm and a pitch of 6 mm is used. The coefficient of friction at the thread and

collar are 0.15 and 0.1 respectively. If the collar frictional diameter is 100 mm and the screw

-1

turns at a speed of 1 rev s find (a) the power input to the screw. (b) the combined efficiency

of the screw and collar.

4. A weight of 500 kN is raised at a speed of 6 m/min by a two screw rods with square threads

of 50 x 8 cut on them. The screw rods are driven through level gear drives by a motor.

Determine (i) The torque required to raise the load (ii) The speed of rotation of the screw rod

assuming the threads are double start (iii) The maximum stresses induced in screw rod.

(iv) The efficiency of screw drive. (v) The length of nuts for the purpose of supporting the

load.

*************

Department of Mechanical Engineering, SJBIT, Bengaluru.

Page 10

Potrebbero piacerti anche

- Investigating Population Growth SimulationDocumento11 pagineInvestigating Population Growth Simulationapi-3823725640% (3)

- Operations ManagementDocumento290 pagineOperations Managementrockon60594% (104)

- Nursing Care PlansDocumento10 pagineNursing Care PlansGracie S. Vergara100% (1)

- Decision Modeling Applications and Spreadsheet SolutionsDocumento25 pagineDecision Modeling Applications and Spreadsheet SolutionsaniketkaushikNessuna valutazione finora

- Design of Machine Elements Volume 1Documento11 pagineDesign of Machine Elements Volume 1marvin0% (1)

- 3-Assignment 1 - Fatigue Failure PDFDocumento1 pagina3-Assignment 1 - Fatigue Failure PDFAsyraf YazidNessuna valutazione finora

- Chapter14 Solutions 11eDocumento43 pagineChapter14 Solutions 11e종운Nessuna valutazione finora

- Mechanical Vibrations: Vibration Isolation DesignDocumento11 pagineMechanical Vibrations: Vibration Isolation DesignNABIL HUSSAINNessuna valutazione finora

- UMR Introduction 2023Documento110 pagineUMR Introduction 2023tu reves mon filsNessuna valutazione finora

- Design of Machine Element ProblemsDocumento2 pagineDesign of Machine Element Problemsmaxpayne5550% (1)

- Assignment 02 - Machine DesignDocumento2 pagineAssignment 02 - Machine DesignRatan Sadanandan O MNessuna valutazione finora

- Design of Machine Elements II: Curved BeamsDocumento255 pagineDesign of Machine Elements II: Curved BeamsAjayNessuna valutazione finora

- Machine Design Assignment-1Documento2 pagineMachine Design Assignment-1RAJAT RAJNessuna valutazione finora

- ME8492 Important Questions and AnswersDocumento123 pagineME8492 Important Questions and Answersyuvaraj gopalNessuna valutazione finora

- 4363 111 Machine Design IDocumento6 pagine4363 111 Machine Design Iyogesh_b_k100% (2)

- 5.2 Flanged Bolt CouplingDocumento11 pagine5.2 Flanged Bolt CouplingShayneBumatay0% (1)

- Machine Design IIDocumento23 pagineMachine Design IIBinar Arum OktaviaNessuna valutazione finora

- Limit and Fit Data BooDocumento18 pagineLimit and Fit Data Booविशाल पुडासैनीNessuna valutazione finora

- Mech-V-Design of Machine Elements I (10me52) - SolutionDocumento63 pagineMech-V-Design of Machine Elements I (10me52) - SolutionTolbert D'SouzaNessuna valutazione finora

- Design of Transmission Systems Question BankDocumento10 pagineDesign of Transmission Systems Question BankDesejo SozinandoNessuna valutazione finora

- Multi-plate clutch problems for power transmission calculationsDocumento6 pagineMulti-plate clutch problems for power transmission calculationsShweta BramhaneNessuna valutazione finora

- DOME-2 Notes QPapers PDFDocumento305 pagineDOME-2 Notes QPapers PDFSumit KumarNessuna valutazione finora

- Unit I DME I 13 09 2021Documento68 pagineUnit I DME I 13 09 2021Vaibhav JainNessuna valutazione finora

- Design of ShaftsDocumento2 pagineDesign of ShaftsÖzgür AtaseverNessuna valutazione finora

- COTTER & KNUCKLE JOINT DESIGNDocumento30 pagineCOTTER & KNUCKLE JOINT DESIGNSumitKumar0% (1)

- DMM1 Important QuestionsDocumento2 pagineDMM1 Important QuestionsChand Basha Shaik100% (1)

- Tutorial Sheet No 1 On Spur GearDocumento3 pagineTutorial Sheet No 1 On Spur GearChirayuNessuna valutazione finora

- Capacity and Demand in Units Period Regular Time Overtime Subcontract DemandDocumento3 pagineCapacity and Demand in Units Period Regular Time Overtime Subcontract DemandVinay Kumar0% (1)

- VEC MT1 Question Bank Manufacturing ProcessesDocumento10 pagineVEC MT1 Question Bank Manufacturing ProcessesElumalai Pc100% (1)

- Chapter 3 brakes analysisDocumento37 pagineChapter 3 brakes analysiskibromgidey12Nessuna valutazione finora

- MosDocumento42 pagineMosSajjan Kumar100% (2)

- A1. Examples: Belt Drives Examples and WorksheetDocumento3 pagineA1. Examples: Belt Drives Examples and WorksheetAb_AlizadehNessuna valutazione finora

- Machine Design Lab ManualDocumento28 pagineMachine Design Lab ManualEr Raghvendra Singh100% (1)

- Design of Machine ElementsDocumento12 pagineDesign of Machine ElementsSai ThotaNessuna valutazione finora

- Machine Design NotesDocumento349 pagineMachine Design NotesAkshay More100% (1)

- VMKV Engineering College Question Bank on Machine Design ElementsDocumento14 pagineVMKV Engineering College Question Bank on Machine Design ElementsSatwik PriyadarshiNessuna valutazione finora

- Mechanical Engineering Test Assignment: Solution Numerical 1Documento9 pagineMechanical Engineering Test Assignment: Solution Numerical 1Raj PatelNessuna valutazione finora

- PDF Friction - Chapter 3Documento17 paginePDF Friction - Chapter 3Loranie SulukangNessuna valutazione finora

- Mee3001 Design-Of-Machine-Elements TH 1.3 47 Mee3001 17 PDFDocumento2 pagineMee3001 Design-Of-Machine-Elements TH 1.3 47 Mee3001 17 PDFAK PRODUCTIONSNessuna valutazione finora

- Design of Machine ElementsDocumento92 pagineDesign of Machine ElementsDida Khaling100% (2)

- DME Lesson Plan As Per NBADocumento3 pagineDME Lesson Plan As Per NBASabareesan Subramanian0% (1)

- Additive Manufacturing A Framework For ImplementationDocumento8 pagineAdditive Manufacturing A Framework For Implementationnicero555Nessuna valutazione finora

- Kinematics of Machinery NotesDocumento65 pagineKinematics of Machinery NotesVenkatesh Rajamani100% (1)

- Course Code Course Title: ME212 Machine Drawing 1 6 5Documento4 pagineCourse Code Course Title: ME212 Machine Drawing 1 6 5Kantha RaoNessuna valutazione finora

- Machine design philosophy and procedure considerationsDocumento20 pagineMachine design philosophy and procedure considerationsS VNessuna valutazione finora

- PPT3 - Mechanical Behavior, Testing and Manufacturing Properties of Materials Rev (New)Documento30 paginePPT3 - Mechanical Behavior, Testing and Manufacturing Properties of Materials Rev (New)aekimNessuna valutazione finora

- Design and Analysis of PROTECTED FLANGE COUPLING Solidworks 2016 and ANSYS WorkbenchDocumento27 pagineDesign and Analysis of PROTECTED FLANGE COUPLING Solidworks 2016 and ANSYS Workbenchamu100% (1)

- TRANSMISSION DESIGNDocumento18 pagineTRANSMISSION DESIGNMURALI KRISHNAN RNessuna valutazione finora

- Refrigeration and Air Conditioning Course OverviewDocumento9 pagineRefrigeration and Air Conditioning Course OverviewAsif jabarNessuna valutazione finora

- Shaft Design Bearing SelectionDocumento2 pagineShaft Design Bearing Selectionfma381bNessuna valutazione finora

- 1 DesignDocumento54 pagine1 DesignDr. Aung Ko LattNessuna valutazione finora

- Machine Design Tutorial Sheet QuestionsDocumento3 pagineMachine Design Tutorial Sheet Questionsabhishek chaurasiyaNessuna valutazione finora

- Project Title ListDocumento12 pagineProject Title ListShrishant PatilNessuna valutazione finora

- An Introduction To Plant LayoutDocumento34 pagineAn Introduction To Plant LayoutMadhu Shankar UndurtyNessuna valutazione finora

- Introduction To GDDocumento8 pagineIntroduction To GDCatalin FinkelsteinNessuna valutazione finora

- Problems CH-11 Strain Energy (Blank)Documento28 pagineProblems CH-11 Strain Energy (Blank)محمد خريبطNessuna valutazione finora

- Advantages - Disadvantages.research InstrumentsDocumento1 paginaAdvantages - Disadvantages.research InstrumentsStephen Rosales100% (1)

- DAutonomous Toggle Scissor JackDocumento19 pagineDAutonomous Toggle Scissor JackAsad Ali100% (1)

- DMM - I Question Bank For StudentsDocumento11 pagineDMM - I Question Bank For StudentsDushyanthkumar DasariNessuna valutazione finora

- DMM - I Question Bank For StudentsDocumento11 pagineDMM - I Question Bank For StudentsDushyanthkumar DasariNessuna valutazione finora

- Kings: Department of Mechanical EngineeringDocumento14 pagineKings: Department of Mechanical EngineeringAdam AhmadNessuna valutazione finora

- UNIT-1: Department of Mechanical EngineeringDocumento14 pagineUNIT-1: Department of Mechanical EngineeringManivannan JeevaNessuna valutazione finora

- QB Unit-1,2Documento5 pagineQB Unit-1,2Agranshu BhardwajNessuna valutazione finora

- Dme Lab Sheets Ii Iii IvDocumento4 pagineDme Lab Sheets Ii Iii IvA58Vikas UbovejaNessuna valutazione finora

- R K Mohanty: Faculty Member, Sir SPBT College, Central Bank of India, MumbaiDocumento39 pagineR K Mohanty: Faculty Member, Sir SPBT College, Central Bank of India, Mumbaiyashovardhan3singhNessuna valutazione finora

- Industrial Relation of LawDocumento3 pagineIndustrial Relation of LawArunNessuna valutazione finora

- Tradind DerivativesDocumento2 pagineTradind DerivativesArunNessuna valutazione finora

- JeeDocumento1 paginaJeeArunNessuna valutazione finora

- Objectives:: MBA Final Year Project Case Study Report On Security Analysis and Portfolio ManagementDocumento1 paginaObjectives:: MBA Final Year Project Case Study Report On Security Analysis and Portfolio ManagementArunNessuna valutazione finora

- IitDocumento1 paginaIitArunNessuna valutazione finora

- MBA HR ProjectDocumento3 pagineMBA HR ProjectArunNessuna valutazione finora

- Mech-I-Basic Electronics Engg AssignmentDocumento6 pagineMech-I-Basic Electronics Engg AssignmentArunNessuna valutazione finora

- NSC MbaDocumento2 pagineNSC MbaArunNessuna valutazione finora

- IitDocumento1 paginaIitArunNessuna valutazione finora

- Operations management topics for projectsDocumento1 paginaOperations management topics for projectsArunNessuna valutazione finora

- MBA All TopicsDocumento2 pagineMBA All TopicsArunNessuna valutazione finora

- 200 Questions and Answers On Practical Civil Engineering Works 2008Documento84 pagine200 Questions and Answers On Practical Civil Engineering Works 2008ramdj100% (4)

- Intercultural Assessment of SustainabilityDocumento92 pagineIntercultural Assessment of SustainabilityVisvanath GunashekarNessuna valutazione finora

- Intercultural Assessment of SustainabilityDocumento92 pagineIntercultural Assessment of SustainabilityVisvanath GunashekarNessuna valutazione finora

- 1 Financial Performance of A Co Operative Bank PDFDocumento2 pagine1 Financial Performance of A Co Operative Bank PDFArunNessuna valutazione finora

- MSC Mba ProjectsDocumento2 pagineMSC Mba ProjectsmhmhabeebNessuna valutazione finora

- Financial Analysis of Commercial BankDocumento86 pagineFinancial Analysis of Commercial BankArunNessuna valutazione finora

- Icici Bank Comparison With Other BanksDocumento13 pagineIcici Bank Comparison With Other BanksMukul BabbarNessuna valutazione finora

- Circulatory System Packet BDocumento5 pagineCirculatory System Packet BLouise SalvadorNessuna valutazione finora

- Esaote MyLabX7Documento12 pagineEsaote MyLabX7Neo BiosNessuna valutazione finora

- Indonesia Organic Farming 2011 - IndonesiaDOCDocumento18 pagineIndonesia Organic Farming 2011 - IndonesiaDOCJamal BakarNessuna valutazione finora

- UNICESS KR Consmetics Maeteria Nunssupjara 01apr23Documento44 pagineUNICESS KR Consmetics Maeteria Nunssupjara 01apr23ZB ChuaNessuna valutazione finora

- Bio-Tank Guidelines for Indian RailwayDocumento51 pagineBio-Tank Guidelines for Indian Railwayravi100% (2)

- 3-Step Mindset Reset: Overcome Self-Doubt with Mel Robbins' TrainingDocumento11 pagine3-Step Mindset Reset: Overcome Self-Doubt with Mel Robbins' TrainingBožana RadošNessuna valutazione finora

- Nutrition During PregnancyDocumento8 pagineNutrition During PregnancyHalliahNessuna valutazione finora

- Right To HealthDocumento9 pagineRight To HealthPriya SharmaNessuna valutazione finora

- wch13 01 Rms 20230817Documento24 paginewch13 01 Rms 20230817halcieeschNessuna valutazione finora

- Consumer Behaviour: Group ProjectDocumento5 pagineConsumer Behaviour: Group ProjectAanchal MahajanNessuna valutazione finora

- Board Review Endocrinology A. ApiradeeDocumento47 pagineBoard Review Endocrinology A. ApiradeePiyasak NaumnaNessuna valutazione finora

- Full SyllabusDocumento409 pagineFull SyllabusSanthana BharathiNessuna valutazione finora

- PERSONS Finals Reviewer Chi 0809Documento153 paginePERSONS Finals Reviewer Chi 0809Erika Angela GalceranNessuna valutazione finora

- C. Drug Action 1Documento28 pagineC. Drug Action 1Jay Eamon Reyes MendrosNessuna valutazione finora

- Valvula de Leve MasterDocumento20 pagineValvula de Leve Masterguillermo trejosNessuna valutazione finora

- A. Kumar Aswamy Job Offer LetterDocumento1 paginaA. Kumar Aswamy Job Offer LetterHimanshu PatelNessuna valutazione finora

- Hinduism Today April May June 2015Documento43 pagineHinduism Today April May June 2015jpmahadevNessuna valutazione finora

- Soal UTS Bahasa Inggris SMP Semester Genap Tahun Ajaran 2020Documento5 pagineSoal UTS Bahasa Inggris SMP Semester Genap Tahun Ajaran 2020awan MustofaNessuna valutazione finora

- ERS M22 PC4 FerryDocumento2 pagineERS M22 PC4 FerryouakgoodNessuna valutazione finora

- Apc 8x Install Config Guide - rn0 - LT - enDocumento162 pagineApc 8x Install Config Guide - rn0 - LT - enOney Enrique Mendez MercadoNessuna valutazione finora

- Sub Erna RekhaDocumento2 pagineSub Erna Rekhasurabhi mandalNessuna valutazione finora

- Biology (Paper I)Documento6 pagineBiology (Paper I)AH 78Nessuna valutazione finora

- Genetically Engineered MicroorganismsDocumento6 pagineGenetically Engineered Microorganismsaishwarya joshiNessuna valutazione finora

- SM RSJ 420 800Documento77 pagineSM RSJ 420 800elshan_asgarovNessuna valutazione finora

- Hydrogeological Characterization of Karst Areas in NW VietnamDocumento152 pagineHydrogeological Characterization of Karst Areas in NW VietnamCae Martins100% (1)

- FB77 Fish HatcheriesDocumento6 pagineFB77 Fish HatcheriesFlorida Fish and Wildlife Conservation CommissionNessuna valutazione finora

- Lesson Plan 7 Tabata TrainingDocumento4 pagineLesson Plan 7 Tabata Trainingapi-392909015100% (1)