Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CBR Test Results for River Sand Used in Embankment Construction

Caricato da

SA023Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CBR Test Results for River Sand Used in Embankment Construction

Caricato da

SA023Copyright:

Formati disponibili

The Construction of Kanchpur, Meghna, Gumti 2nd Bridges

and Rehabilitation of Existing Bridges (Package No. PW-01)

OSJI Joint Venture

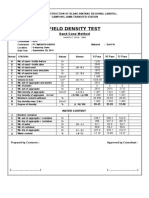

WORK SHEET FOR CALIFORNIA BEARING RATIO (CBR) FOR EMBANKMENT MATERIALS

(AASHTO - T - 193)

Purpose of Use

Embankment

RFI No

Type of Material

River Sand

Lab Ref. No:

MDD:

OMC= 10.6 %

Date of Test

1.696 g/cm3

OSJI-RFI-O- 0669

12.01.17

DENSITY (BEFORE SOAKING)

Mould No.

Mould no - 04

Mould no - 02

Mould no- 03

No. of Layers

No. of Blows per Layer

10

30

65

Wt. of Wet Soil+Mould+Base Plate W 1

9440

9656.5

9691

Wt. of Mould+Base Plate

5849.4

5682.2

5544.4

3590.6

3974.3

4146.6

cm3

2141.21

2115

2108

g/cm3

1.677

1.879

1.967

g/cm3

1.522

1.715

1.824

#DIV/0!

#DIV/0!

#DIV/0!

Mould no - 04

Mould no - 02

Mould no- 03

10

30

65

Wt. of Soil in Mould

W2

W 3 = (W 1-W 2)

Volume of Mould

V1

Wet Density

Dry Density

Ywet=(W 3/V1)

Ydry=Ywet/(100+m/100)

MOISTURE CONTENT (BEFORE SOAKING)

Mould No.

No. of Blows per Layer

Container No.

#33

#34

#31

#32

#15

Wt. of Container + Wet Soil

(W 1)

185.5

178.8

171.5

159.0

119.6

Wt. of Container + Dry Soil

(W 2)

173.6

167.1

160.8

150.1

113.9

(W 3 = W 1-W 2)

11.9

11.7

10.7

8.9

5.7

(W 4)

55.40

53.60

52.60

53.20

42.40

Wt. of Dry Soil

(W 5 = W 2-W 4)

118.2

113.5

108.2

96.9

71.5

Moisture Content

m= (W 3/W 5)x100

10.1

10.3

9.9

9.2

8.0

Wt. of Moisture

Wt. of Container

Average Moisture Content

10.2

9.5

7.9

Remarks:..

Contractor : OSJI Joint Venture

Tested by

Name:

Signature:

Date:

M.E.

Material Manager

The Engineer: OC-JBSI-KEI-NE-SMEC JV in associa

with BCL-DevCON-ACE

Inspector/M. & P.E.

S.M. & P.E./RE

truction of Kanchpur, Meghna, Gumti 2nd Bridges

bilitation of Existing Bridges (Package No. PW-01)

OSJI Joint Venture

RING RATIO (CBR) FOR EMBANKMENT MATERIALS

AASHTO - T - 193)

OSJI-RFI-O- 0669

12.01.17

Y (BEFORE SOAKING)

Mould no- 03

5

65

9691

5544.4

4146.6

2108

1.967

1.824

#DIV/0!

ONTENT (BEFORE SOAKING)

Mould no- 03

65

#30

125.6

119.6

6.0

42.00

77.6

7.7

7.9

The Engineer: OC-JBSI-KEI-NE-SMEC JV in association

with BCL-DevCON-ACE

S.M. & P.E./RE

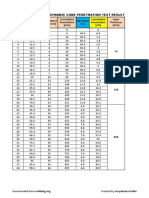

The Construction of Kanchpur, Meghna, Gumti 2nd Bridges

and Rehabilitation of Existing Bridges (Package No. PW-01)

OSJI Joint Venture

WORK SHEET FOR CALIFORNIA BEARING RATIO (CBR) FOR BASE COURSE MATERIALS

Purpose Of Use: Embankment

RFI No

OSJI-RFI-K-

Type of Material: River Sand

Document No

Date:

15.01.17

Conversion Factor: y = 0.0041 X + 0.0403 (From Calibrat

SWELLING DATA

Mould Number

Mould no - 04

Mould no - 02

10

30

No. of Blows per Layer

Immersion Height of Specimen

Time

Gauge

Swell

(Day)

Reading

(mm)

117

mm

Mould no- 03

65

Height of Specimen

117

mm

Height of Specimen

Date

Time

04.01.2017

11:30AM

05.01.2017

11:30AM

0.0

0.0

0.5

0.01

06.01.2017

11:30AM

10

0.0

0.0

1.5

0.02

07.01.2017

11:30AM

12

0.1

0.1

0.03

08.01.2017

11:30AM

15

11

0.11

0.09

0.06

Gauge

Reading

Swell

(mm)

Gauge

Reading

0.09

Swell

(mm)

0.08

SOAKING DATA

Mould Number

Mould no - 04

Mould no - 02

10

30

65

No. of Blows per Layer

Mould no- 03

Wt. of Soil + Mould + Base Plate (Before Soaking)

9782

9963

9893

Wt. of Soil + Mould + Base Plate (After Soaking)

9868

10019

9926

Water Absorbed

86.0

56.0

33.0

Wt. of Soil in Mould

3590.6

3974.3

4146.6

% Water Absorbed

2.4

1.4

0.8

MOISTURE CONTENT (AFTER SOAKING)

Mould No.

No. of Blows per Layer

Portion of the mould

Can No.

Wt. of Wet. Soil + Can

Wt. of Dry Soil + Can

Wt. of Water

Wt. of Can

Wt. of Dry Soil

Moisture Content %

Mould no - 04

10

Top

17

219.2

200.7

18.5

42.4

158.3

11.7

Mould no - 02

30

Top

13

211.0

194.6

16.4

42.9

151.7

10.8

Bottom

16

212.7

197.2

15.5

55.3

141.9

10.9

11.30

Ave. Moisture Content %

Mould no- 03

Bottom

9

198

183

15.0

43.04

140.0

10.7

65

Top

2

165.0

154.0

11.0

42.7

111.3

9.9

10.76

9.81

Mould no - 02

30

Reading

Load (kN)

40

0.2043

85

0.3888

110

0.4913

245

1.0448

300

1.2703

530

2.2133

650

2.7053

950

3.9353

1435

5.9238

Mould no- 03

65

CBR DATA

Mould No.

No. of Blows per Layer

Penetration

0.025 in.(0.64 mm)

0.050 in.(1.27 mm)

0.075 in.(1.91 mm)

0.100 in.(2.54 mm)

0.125 in.(3.18 mm)

0.150 in.(3.81 mm)

0.175 in.(4.45 mm)

0.200 in.(5.08 mm)

0.300 in.(7.62 mm)

Mould no - 04

10

Reading

Load (kN)

22

0.1305

48

0.2371

90

0.4093

130

0.5733

200

0.8603

245

1.0448

300

1.2703

438

1.8361

992

4.1075

The Engineer: OC-JBSI-KEI-NE-SMEC JV in associa

BCL-DevCON-ACE

Contractor : OSJI Joint Venture

Tested by

Name:

Signature:

Date:

M.E.

Reading

13

125

300

530

750

980

1210

1500

1960

Material Manager

Inspector/M. & P.E.

S.M. & P.E./R

nstruction of Kanchpur, Meghna, Gumti 2nd Bridges

habilitation of Existing Bridges (Package No. PW-01)

OSJI Joint Venture

EARING RATIO (CBR) FOR BASE COURSE MATERIALS

OSJI-RFI-K-

15.01.17

Conversion Factor: y = 0.0041 X + 0.0403 (From Calibration Chart)

SWELLING DATA

Mould no- 03

65

117

mm

%

0.05

SOAKING DATA

Mould no- 03

65

9893

9926

33.0

4146.6

0.8

E CONTENT (AFTER SOAKING)

Mould no- 03

Bottom

5

161.5

150.9

10.6

42.04

108.9

9.7

9.81

CBR DATA

Mould no- 03

65

Load (kN)

0.0936

0.5528

1.2703

2.2133

3.1153

4.0583

5.0013

6.1903

8.0763

The Engineer: OC-JBSI-KEI-NE-SMEC JV in association with

BCL-DevCON-ACE

S.M. & P.E./RE

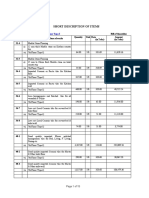

The Construction of Kanchpur, Meghna, Gumti 2 nd Bridges

and Rehabilitation of Existing Bridges (Package No. PW-01)

OSJI Joint Venture

WORK SHEET FOR CALIFORNIA BEARING RATIO (CBR) FOR BASE COURSE MATERIALS

Mix Proportions :25 mm -8%,20mm-35%,12.5mm-15%,S.Sand-32%,F.sand-10%

RFI No

Purpose Of Use: Base Course

Document No

Date:

Plunger Dia-50mm

Corre ction of Load Pe ne tration Curve

10 Blow s/Laye r

CBR at 2.54 m m = 4.34 %

CBR at 5.08 m m = 9.29 %

6

5

3.94

4

3

1.84

Corre ction of Load Pe ne tration Curve

30 Blow s /Laye r

CBR at 2.54 m m = 7.9 %

CBR at 5.08 m m = 19.89 %

Load in kN

5

Load in k N

Standard Load for Penetration: For 2.54 mm = 13.54 Kn and 5.08mm = 20.31 Kn

2

1

5.08

2.54

2.54

Corre ction of Load Pene tration Curve

65 Blow s / Laye r

CBR at 2.54 m m = 16.82 %

CBR at 5.08 m m = 32.25 %

10

Penetration on mm

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5

Dry Density versus CBR

Corre cte d CBR (%)

Load in k N

Pe netration

on m

0 0.5 1 1.5

2 2.5 3 3.5

4 m4.5 5 5.5 6 6.5 7 7.5 8

9

8

7

1.04

0.57

6.19

30 blows per layer

CBR-14 %

5

4

10 blows per layer

2.21

2

1.611

1

0

0

2.54

Pe ne tration on m m

3

4

5.08

5

1.500

6

% Compacton

Dry Density, g/cm3

CBR %

100%

1.696

95%

1.611

14.2

1.550

1.600

1.650

Dry De ns

ity as 1.700

Molde d 1.750

(g/cm 3)1.800

Remarks:

The Engineer: OC-JBSI-KEI-NE-SMEC JV in asso

BCL-DevCON-ACE

Contractor : OSJI Joint Venture

Tested by

Signature:

Name

Date:

M.E.

Material Manager

Inspector/M. & P.E.

he Construction of Kanchpur, Meghna, Gumti 2nd Bridges

nd Rehabilitation of Existing Bridges (Package No. PW-01)

OSJI Joint Venture

NIA BEARING RATIO (CBR) FOR BASE COURSE MATERIALS

OSJI-RFI-O- 051

OSJI-QC-RPT-O-SB-28

26.11.2016

Corre ction of Load Pe ne tration Curve

30 Blow s /Laye r

CBR at 2.54 m m = 7.9 %

CBR at 5.08 m m = 19.89 %

Load in kN

6

5

4

3

2

1

5.08

Penetration on mm

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8

Dry Density versus CBR

Corre cte d CBR (%)

65 blows per layer

30 blows per layer

1.500

1.550

1.600

1.650

Dry De ns

ity as 1.700

Molde d 1.750

(g/cm 3)1.800

1.850

1.900

The Engineer: OC-JBSI-KEI-NE-SMEC JV in association with

BCL-DevCON-ACE

S.M. & P.E./RE

Potrebbero piacerti anche

- The California Bearing Ratio (CBR) (1/1) : (3) - Penetration (1) - DensityDocumento8 pagineThe California Bearing Ratio (CBR) (1/1) : (3) - Penetration (1) - Densityabdallah abdurhman aliNessuna valutazione finora

- CBR TestDocumento7 pagineCBR Testjaffna100% (1)

- FDTDocumento12 pagineFDTMansoor AliNessuna valutazione finora

- Slump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45Documento37 pagineSlump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45ChManikumarNessuna valutazione finora

- CBR Test Data SheetDocumento6 pagineCBR Test Data SheetgimanuNessuna valutazione finora

- Field Density Test: Sand Cone MethodDocumento1 paginaField Density Test: Sand Cone MethodRyuki WilliamNessuna valutazione finora

- CompactionDocumento100 pagineCompactionVaibhav PatilNessuna valutazione finora

- Concrete CalculationDocumento10 pagineConcrete CalculationkwameNessuna valutazione finora

- CBR Chart AnalysisDocumento29 pagineCBR Chart AnalysisIsran TomiaNessuna valutazione finora

- Job:-Wight Nile Sugar Company: Borehole & T.P No:-Sample Type: - Depth MDocumento16 pagineJob:-Wight Nile Sugar Company: Borehole & T.P No:-Sample Type: - Depth Mabdallah abdurhman aliNessuna valutazione finora

- Sand Replacement TestDocumento8 pagineSand Replacement Testkrishna buildconNessuna valutazione finora

- Furniture Storage Yard Technical SanctionDocumento14 pagineFurniture Storage Yard Technical SanctionSoigne ConsultantsNessuna valutazione finora

- Concrete Pavement Design Details and Construction Practices Companion WorkbookDocumento13 pagineConcrete Pavement Design Details and Construction Practices Companion Workbookrobert_salas_14Nessuna valutazione finora

- Mix Design PosterDocumento1 paginaMix Design PosterAbhilash KumarNessuna valutazione finora

- Consolidated Drained Direct Shear Test: (IS: 2720 (Part 13) - 1986)Documento1 paginaConsolidated Drained Direct Shear Test: (IS: 2720 (Part 13) - 1986)Biplab dattaNessuna valutazione finora

- Design and properties of high strength self compacting concreteDocumento2 pagineDesign and properties of high strength self compacting concretePrachi TaoriNessuna valutazione finora

- CBR Test ResultsDocumento167 pagineCBR Test ResultsDotan NutodNessuna valutazione finora

- Astm D422 Sieve Analysis: Client: ProjectDocumento1 paginaAstm D422 Sieve Analysis: Client: ProjectHassan RazaNessuna valutazione finora

- Shree Balaji Test House Pvt. Ltd. Geotechnical ReportDocumento64 pagineShree Balaji Test House Pvt. Ltd. Geotechnical ReportPhani Krishna BadipatiNessuna valutazione finora

- Bill of Quantities for Bituminous Road Work at Suzlon GeneratorsDocumento8 pagineBill of Quantities for Bituminous Road Work at Suzlon GeneratorsEr. Naseem SayyedNessuna valutazione finora

- P01 Soil Inv ReportDocumento20 pagineP01 Soil Inv ReportDileep K NambiarNessuna valutazione finora

- Direct Shear Test On Salt Range SampleDocumento10 pagineDirect Shear Test On Salt Range Samplemuhammad irfanNessuna valutazione finora

- Client Caterpillar Signs PMC Compaction Test by Sand ReplacementDocumento1 paginaClient Caterpillar Signs PMC Compaction Test by Sand ReplacementBrahammanand BairwaNessuna valutazione finora

- Results of Compressive Strength of Concrete / Grout CubesDocumento1 paginaResults of Compressive Strength of Concrete / Grout CubesSABEASNNessuna valutazione finora

- M30 Concrete Mix DesignDocumento4 pagineM30 Concrete Mix DesignrajupetalokeshNessuna valutazione finora

- Field Permeability Test-3Documento1 paginaField Permeability Test-3P Allen Samuel IgnatiusNessuna valutazione finora

- Ground Improvement Technioques For High WaysDocumento31 pagineGround Improvement Technioques For High WaysDevendra Sharma100% (1)

- 06 - Allowable Wastages PDFDocumento1 pagina06 - Allowable Wastages PDFsunil singhNessuna valutazione finora

- Gradation Sand Jan 2018Documento54 pagineGradation Sand Jan 2018viswanath kasiNessuna valutazione finora

- Calculation: Formula For Moisture Content W (Weight of Water/ Weight of Soil) X 100Documento8 pagineCalculation: Formula For Moisture Content W (Weight of Water/ Weight of Soil) X 100SilverfangNessuna valutazione finora

- Determination of Field Density of Soil by Core Cutter MethodDocumento3 pagineDetermination of Field Density of Soil by Core Cutter MethodsiddiqueakbarNessuna valutazione finora

- Field Permeability Test-2Documento1 paginaField Permeability Test-2P Allen Samuel IgnatiusNessuna valutazione finora

- Geotechnical Laboratory Measurements For Engineers: Unconsolidated Undrained Triaxial Compression TestDocumento5 pagineGeotechnical Laboratory Measurements For Engineers: Unconsolidated Undrained Triaxial Compression TestYusi SulastriNessuna valutazione finora

- Axial Capacity of Pile FoundationDocumento32 pagineAxial Capacity of Pile FoundationChowdhury Priodeep100% (1)

- Analysis of DCPT ResultDocumento4 pagineAnalysis of DCPT ResultAvinash LalNessuna valutazione finora

- Mat Boundary Spring Generator With KX Ky KZ KMX KMy KMZDocumento3 pagineMat Boundary Spring Generator With KX Ky KZ KMX KMy KMZcesar rodriguezNessuna valutazione finora

- Excel Workbook No. 06 Relative CompactionDocumento6 pagineExcel Workbook No. 06 Relative CompactionBig Boss100% (1)

- Dynamic Cone Penetration Test AnalysisDocumento4 pagineDynamic Cone Penetration Test AnalysisBai Alleha MusaNessuna valutazione finora

- Calculations For Safe Bearing CapacityDocumento3 pagineCalculations For Safe Bearing Capacityimran khanNessuna valutazione finora

- Grafik DCPDocumento10 pagineGrafik DCPYoviDwiyanaNessuna valutazione finora

- SOIL HYDROMETER TESTDocumento48 pagineSOIL HYDROMETER TESTAnonymous 0JPCPZHNNessuna valutazione finora

- Punjab Water Supply & Sewerage Division Brick Test ReportsDocumento34 paginePunjab Water Supply & Sewerage Division Brick Test ReportsAnbuNessuna valutazione finora

- Test Results of TMT Steel Bar: Forwarded ToDocumento5 pagineTest Results of TMT Steel Bar: Forwarded ToRakesh7770Nessuna valutazione finora

- Lateral Analysis Vertical Analysis: Pvsytandmmax LvsqdwandqupDocumento30 pagineLateral Analysis Vertical Analysis: Pvsytandmmax LvsqdwandqupNadeem HassoonNessuna valutazione finora

- Particle size analysis methods and calculationsDocumento4 pagineParticle size analysis methods and calculationssilkymilkyNessuna valutazione finora

- Final Report 00 - 1187-Rev00Documento31 pagineFinal Report 00 - 1187-Rev00wafikmh4Nessuna valutazione finora

- Maximum Dry Density (Proctor)Documento3 pagineMaximum Dry Density (Proctor)ratoooooja24Nessuna valutazione finora

- Date: 19.02.2020 CC Kerb Stone (Core) Test Report The Executive Engineer, Project Central 10, BBMP BangaloreDocumento2 pagineDate: 19.02.2020 CC Kerb Stone (Core) Test Report The Executive Engineer, Project Central 10, BBMP BangaloreVithun PoojaryNessuna valutazione finora

- Cube Strength & Cylinder StrengthDocumento5 pagineCube Strength & Cylinder StrengthRAJKUMAR CHATTERJEE. (RAJA.)Nessuna valutazione finora

- K-Value Test - AfDocumento33 pagineK-Value Test - AfDivanshu SeerviNessuna valutazione finora

- Ultrasonic Pulse VelocityDocumento3 pagineUltrasonic Pulse VelocityanpyaaNessuna valutazione finora

- Summary of Balance Quantity R17 27-10-18Documento75 pagineSummary of Balance Quantity R17 27-10-18Priyank DUbeyNessuna valutazione finora

- Paper For Bearing Capacity PDFDocumento4 paginePaper For Bearing Capacity PDFernestnsabimana74Nessuna valutazione finora

- Concrete CubesDocumento7 pagineConcrete CubesMohammed AbbasNessuna valutazione finora

- Proyek Lokasi Material: Dynamic Cone Penetrometer Test (DCPT)Documento4 pagineProyek Lokasi Material: Dynamic Cone Penetrometer Test (DCPT)Ikhromul Khoirul AqshomNessuna valutazione finora

- CBR Test ManualDocumento6 pagineCBR Test ManualmmNessuna valutazione finora

- 1.CORRELATION OF SOIL TEST (Gram Per Cubic CM)Documento6 pagine1.CORRELATION OF SOIL TEST (Gram Per Cubic CM)Moe Oo HtunNessuna valutazione finora

- C.B.R CombinedDocumento9 pagineC.B.R Combinedusman ali usman aliNessuna valutazione finora

- Alnile Street CBRDocumento27 pagineAlnile Street CBRabdallah abdurhman aliNessuna valutazione finora

- CBR Test Results for Southern Bypass Phase II MultanDocumento22 pagineCBR Test Results for Southern Bypass Phase II MultanISHTIAQ NOORNessuna valutazione finora

- Evolution of Six SigmaDocumento3 pagineEvolution of Six SigmaBeshoy GergesNessuna valutazione finora

- 8396 SignedDocumento115 pagine8396 SignedSA023Nessuna valutazione finora

- Combined Gradation For BinderDocumento3 pagineCombined Gradation For BinderSA023Nessuna valutazione finora

- Role and Responsibility of Master Black BeltsDocumento2 pagineRole and Responsibility of Master Black Beltsyash sharmaNessuna valutazione finora

- Eccentric FootingsDocumento34 pagineEccentric FootingsMelaku Seyoum0% (1)

- Abstractfor 7th Floor - MonabiDocumento15 pagineAbstractfor 7th Floor - MonabiSA023Nessuna valutazione finora

- Purpose of Six Sigma SlidesDocumento4 paginePurpose of Six Sigma SlidesNabeel RamzanNessuna valutazione finora

- 2 - Six Sigma Foundations and PrinciplesDocumento7 pagine2 - Six Sigma Foundations and PrinciplesBeshoy GergesNessuna valutazione finora

- Evolution of Six SigmaDocumento3 pagineEvolution of Six SigmaBeshoy GergesNessuna valutazione finora

- Water Supply Vertical Line: Project:MonabiDocumento4 pagineWater Supply Vertical Line: Project:MonabiSA023Nessuna valutazione finora

- Defference Betwn Flat Slab & Beam-SlabDocumento1 paginaDefference Betwn Flat Slab & Beam-SlabSA023Nessuna valutazione finora

- Eccentric FootingsDocumento34 pagineEccentric FootingsMelaku Seyoum0% (1)

- 05 C1M1V4b - Six Six Sigma MethodologyDocumento3 pagine05 C1M1V4b - Six Six Sigma Methodologyyash sharmaNessuna valutazione finora

- Abstractfor 7th Floor - MonabiDocumento15 pagineAbstractfor 7th Floor - MonabiSA023Nessuna valutazione finora

- Terimakasih Project Bill of QuantitiesDocumento13 pagineTerimakasih Project Bill of QuantitiesSA023Nessuna valutazione finora

- Rebar Measurement Sheet for Monabi ProjectDocumento234 pagineRebar Measurement Sheet for Monabi ProjectSA023Nessuna valutazione finora

- Prota StrucutreDocumento61 pagineProta StrucutreAnonymous QHfIVes9r100% (1)

- Qa QC Engineer Interview Questions and Answers Guide.: Global GuidelineDocumento13 pagineQa QC Engineer Interview Questions and Answers Guide.: Global GuidelineSA023Nessuna valutazione finora

- The Use of Polymer Solutions For Deep Excavations Lessons From Far Eastern Experience PDFDocumento11 pagineThe Use of Polymer Solutions For Deep Excavations Lessons From Far Eastern Experience PDFSA023Nessuna valutazione finora

- BUET Test Report 500W October 2014Documento2 pagineBUET Test Report 500W October 2014SA023Nessuna valutazione finora

- Oracle Primavera Hot Keys Shortcut by A.ElhendawiDocumento1 paginaOracle Primavera Hot Keys Shortcut by A.ElhendawiSA023Nessuna valutazione finora

- Financials-Bank Asia 2017Documento134 pagineFinancials-Bank Asia 2017SA023Nessuna valutazione finora

- BUET Test Report 500W October 2014Documento2 pagineBUET Test Report 500W October 2014SA023Nessuna valutazione finora

- Control ChartDocumento6 pagineControl ChartMade ArianiNessuna valutazione finora

- Straight To The Point Emil Vohlert PDFDocumento34 pagineStraight To The Point Emil Vohlert PDFSA023Nessuna valutazione finora

- 9907X0069 - 1 Operating InstructionsDocumento14 pagine9907X0069 - 1 Operating InstructionsSA023Nessuna valutazione finora

- Primavera (Exercise 6) .Pdf0Documento7 paginePrimavera (Exercise 6) .Pdf0RAKESH RANJANNessuna valutazione finora

- BNBC 2015 Earthquake LoadingDocumento2 pagineBNBC 2015 Earthquake LoadingSA023100% (1)

- OSJI Plan Cover TemplateDocumento1 paginaOSJI Plan Cover TemplateSA023Nessuna valutazione finora

- Filling Sand, Sylhet Sand, 4.75mm Stone, Geotextile SamplingDocumento3 pagineFilling Sand, Sylhet Sand, 4.75mm Stone, Geotextile SamplingSA023Nessuna valutazione finora

- Burnco Gravel Pit in Parkland CountyDocumento26 pagineBurnco Gravel Pit in Parkland CountyElise StolteNessuna valutazione finora

- Terrarium ConstructionDocumento3 pagineTerrarium Constructionacc123440% (1)

- On Killing A TreeDocumento12 pagineOn Killing A TreearavNessuna valutazione finora

- Lehmann 2009 Terra Preta, in Encyclopedia of Soil ScienceDocumento5 pagineLehmann 2009 Terra Preta, in Encyclopedia of Soil ScienceFernanda CastroNessuna valutazione finora

- Rom Scavenger HuntDocumento4 pagineRom Scavenger Huntapi-460279201Nessuna valutazione finora

- Turkish Forest Laws and Their Effect On Private Ownership of LandDocumento16 pagineTurkish Forest Laws and Their Effect On Private Ownership of LandelplastiNessuna valutazione finora

- Ilocos Norte Quickstat January 2015Documento5 pagineIlocos Norte Quickstat January 2015redNessuna valutazione finora

- Marketing Practices of Falcata Growers in Tagbina, Surigao Del Sur, PhilippinesDocumento8 pagineMarketing Practices of Falcata Growers in Tagbina, Surigao Del Sur, PhilippinesWyzty DelleNessuna valutazione finora

- Weathering and Erosion Web-QuestDocumento3 pagineWeathering and Erosion Web-Questapi-268569185Nessuna valutazione finora

- Diva 06Documento114 pagineDiva 06ecubaorozcoNessuna valutazione finora

- Seed Germination Lab: Effects of Temperature and WaterDocumento3 pagineSeed Germination Lab: Effects of Temperature and Waterashwathimahendran100% (1)

- MINISTRY OF FOREST AND ENVIRONMENT ROLEDocumento3 pagineMINISTRY OF FOREST AND ENVIRONMENT ROLEReubenPhilipNessuna valutazione finora

- Mountain Pygmy-Possum Burramys Action StatementDocumento5 pagineMountain Pygmy-Possum Burramys Action Statementapi-328095923Nessuna valutazione finora

- Assessment I (Soal Dan Jawab)Documento6 pagineAssessment I (Soal Dan Jawab)AlyNessuna valutazione finora

- What Is So Interesting About The Place?Documento4 pagineWhat Is So Interesting About The Place?KhinantiSukmaArpinaNessuna valutazione finora

- The Amazon Rainforest Internet Assignment: - SurinameDocumento4 pagineThe Amazon Rainforest Internet Assignment: - Surinameapi-278203839Nessuna valutazione finora

- Cases From Paras Book Property Part 3Documento133 pagineCases From Paras Book Property Part 3Cecil Bernabe100% (1)

- Fybcom Evs MarDocumento284 pagineFybcom Evs MarAdline SerraoNessuna valutazione finora

- Northampton Zoning For URBDocumento6 pagineNorthampton Zoning For URBAdam Rabb CohenNessuna valutazione finora

- Agri Module 3 LC BasedDocumento18 pagineAgri Module 3 LC BasedJean Caloy Falucho100% (1)

- Importance of Urban PlanningDocumento1 paginaImportance of Urban PlanningNoor MohdNessuna valutazione finora

- Climate Adaptations in Tropical RainforestsDocumento9 pagineClimate Adaptations in Tropical Rainforestshweta173Nessuna valutazione finora

- DENR Guidebook For CRMPDocumento180 pagineDENR Guidebook For CRMPRichard BalaisNessuna valutazione finora

- TPM ChecklistDocumento14 pagineTPM Checklistmuneerpp100% (2)

- Tube Well and Designs Assigmnt and Presentation (Group1)Documento39 pagineTube Well and Designs Assigmnt and Presentation (Group1)Abdullah100% (1)

- Viewpoint Calculating Depletion Units of Production Method Oil Gas June 2016Documento7 pagineViewpoint Calculating Depletion Units of Production Method Oil Gas June 2016KCNessuna valutazione finora

- The Rivers: The 2010 Umpqua Edition Features Stories About The North, South and Main UmpquaDocumento24 pagineThe Rivers: The 2010 Umpqua Edition Features Stories About The North, South and Main UmpquaNews-Review of Roseburg OregonNessuna valutazione finora

- IELTS Listening Test0012Documento8 pagineIELTS Listening Test0012catalin_albu_4Nessuna valutazione finora

- A Critical Review of The Economy of The Chalcolithic People of InamgaonDocumento27 pagineA Critical Review of The Economy of The Chalcolithic People of InamgaonKrisha DesaiNessuna valutazione finora

- Morrelganj Upazila Census ResultsDocumento12 pagineMorrelganj Upazila Census ResultsShafiqul Islam TutulNessuna valutazione finora