Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CFD Analysis of A 210 MW Tangential Fired Boiler

Caricato da

Innovative Research PublicationsTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CFD Analysis of A 210 MW Tangential Fired Boiler

Caricato da

Innovative Research PublicationsCopyright:

Formati disponibili

International Journal of Scientific Engineering and Technology

Volume No.6 Issue No.1, pp: 39-44

ISSN:2277-1581

01 Jan. 2017

CFD Analysis of a 210 MW Tangential Fired Boiler

Jaladi Himachandra , L.S.V Prasad

Heat transfer in Energy Systems, Department of Mechanical Engineering,College of Engineering (A),

Andhra University, Visakhapatnam, Andhra Pradesh, India

Corresponding Email: himachandra.jaladi@gmail.com

Abstract: Power generation is very important for development

of Human race. Losses and efficiency takes a major role in

effective utilization of energy. CFD analysis is done on the 210

MW tangentially fired pulverized tower type boiler.

Temperature and velocities at different positions are obtained.

Oxygen and Carbon dioxide mass fractions are estimated.

Combustion behavior and coal particle trajectories are

estimated. This analysis is utilized to examine the water wall

and inside water flow behavior.

Keywords: Tangential fired boiler, Water wall, Temperature

distribution, Velocity distribution, Heat transfer coefficient,

water vapour volume fraction.

I. INTRODUCTION

The performance optimization of boiler is very important to get

higher efficiencies. Optimisation should be done to increase the

efficiency and life time of the boiler. The effective use of coal is

crucial to conserve the fast depleting resources. It is very

difficult to construct the real time boiler to test the conditions.

So, it is wise and truly economical to use a computational tool

(CFD) to test the boiler under different conditions [1-5]. Over

the past three decades CFD has been offering promising results

in the combustion modeling and boiler analysis.

To achieve higher combustion efficiency, the major influencing

factors such as the particle size distribution, gas and particle

temperatures, local heat release, local oxygen concentration,

kinetic parameters for coal de-volatilization and char oxidation,

char properties should be understood thoroughly [6-7]. The heat

transfer characteristics and void fraction are very important to

maintain the boiler feed water system and circulation ratio. The

water volume fraction and velocities should be closely observed

in order to achieve maximum heat transfer and better circulation.

Only few studies have addressed the effect of operating

conditions (such as burner load, excess air etc.) in the India. In

the present study, an attempt is done to estimate the

temperatures, velocities and path of particles. The boiler

geometry and operating conditions along with the mathematical

model used are discussed in the subsequent sections. Results

simulated are based on real time data.

II. Furnace geometry and operating conditions

The three-dimensional geometry was created using Catia. An

isotropic view of the geometry and grid system is shown in Fig.

1. The mesh contained 172,640 nodes with 169,867 hexagonal

cells. In order to make accurate quantitative predictions about

combustion behavior, it is important that an appropriate

geometry is created with suitable meshing techniques.

Primary, secondary and end air nozzle inlet details are taken

according to the actual burner dimensions. The swirl angle is not

IJSET@2017

considered for the present study. The furnace geometry of the

simulated boiler can be seen in Fig. 1.

The tangential wall fired coal furnace is 61125 mm high,

12395.2 mm wide and 11557 mm deep and with an installed

capacity of 210 MW. The specifications of the furnace geometry

and original drawing are given in Table 1. The coal analysis is

shown in Table 2.

The water walls are designed using Ansys. An istropic view of

the geometry and grid system is shown in Fig 2. The mesh

contains 41283 nodes with 40342 tetrahedral cells. The water

wall height is of 50 m, diameter of 127 * 12.5 mm- 80 no.s and

the material is SA160 Gr.C.

Table 1 specifications of furnace geometry

Parameter (m)

Value(mm)

Height

61125

Horizontal

12395.2

Vertical

11557

Fig 1 Furnace geometry and meshing

Fig 2 water wall geometry and meshing

Page 39

International Journal of Scientific Engineering and Technology

Volume No.6 Issue No.1, pp: 39-44

Table 2 Proximity and ultimate analysis

Proximity analysis

CONSTITUENTS

MASS FACTION PERCENTAGE

Moisture

4.10

Volatile matter

28.94

Ash

39.48

Fixed carbon

27.48

Ultimate analysis

Moisture

4.10

Mineral matter

43.44

Carbon

41.86

Hydrogen

3.09

Nitrogen

1.52

Sulfur

0.34

Oxygen

5.66

Coal Particle Size = 70 m (200 mesh)

Calorific value of the coal sample is 3480 kCal/K

THE BOUNDARY CONDITIONS

The boundary conditions considered for the present analysis are

as follows:

Inlet conditions:

Mass flow rate:

Primary air flow: 230 T/hr

Secondary air flow: 440 T/hr

Fuel: 130 T/hr

Temperature:

Primary air flow: 90oC

Secondary air flow: 300 oC

Fuel: 90oC

Pressure:

Primary air flow: 260 mm WC

Secondary air flow: 100 mm WC

Fuel: 260 mm WC

Furnace pressure: - 15 mm WC

Out let pressure of boiler: - 40 mm WC

Walls: Adiabatic or constant wall temperature

Flow: No-slip condition at the walls; u = 0, v = 0, w = 0.

Temperature: Walls at the surfaces inside the combustion

chamber are covered by the saturating steam tubes at constant

temperature at T = 621.32 K

The boundary conditions considered for the water walls are as

follows:

Water wall boundary conditions

Inlet: Pressure: 16.18 MPa

Temperature: 348.4oC

Outlet: Pressure: 16.17 MPa

Temperature: 348.4oC

Adiabatic flame temperature inside the furnace is assumed to be

1400 K which is estimated from CFD analysis and real time data.

ASSUMPTIONS

IJSET@2017

ISSN:2277-1581

01 Jan. 2017

The problem is modeled with the following general assumptions:

1. The flow is steady and incompressible.

2. Variable fluid properties.

3. Turbulent Flow

4. Instantaneous combustion with the chemical reaction

much faster than the turbulence time scale.

5. The steam temperature is assumed as the tube wall

temperature.

The full three-dimensional Navier-Stokes equations are

employed with five species transport equations.

III. Mathematical model:

The mathematical model is used here based on the commercial

CFD code, FLUENT [15], where the gas flow is described by the

time averaged equations of global mass momentum, enthalpy

and species mass fraction. The particle phase equations

formulated in Lagrangian form and the coupling between phases

is introduced through particle sources of Eularian gas-phase

equations. The standard k- turbulence model, single mixture

fraction probability density function (PDF) and the P1 radiation

models are used in the present simulations.

For the bulk of engineering combustion systems the mixing

process proceeds much more slowly than the chemistry and as a

result the mixing rate almost always determines the rate of

combustion [11]. Therefore, for the predominant industry case of

diffusion or non-premixed combustion it normally suffices to

solve a conservation equation for a mixing variable called the

mixture fraction in order to determine the temperature and

concentrations of major species. In this study, a simplified coal

combustion furnace is modeled using the non-premixed

combustion model for the reaction chemistry. The following

steps describe the method followed, after creating the required

geometry.

1) A PDF table for a pulverized coal fuel using the pre-PDF

preprocessor was prepared for medium volatile coal.

2) FLUENT inputs for non-premixed combustion chemistry

modeling were estimated.

3) A discrete second phase of coal particles was defined.

4) Simulations were carried out first without involving reactions

and discrete phase coal particles and then once the convergence

is achieved, simulations were continued involving reacting

discrete phase coal particles.

The composition in terms of atom fraction of H, C, N, O, along

with the lower heating value and heat capacity of the fuel are

defined using the data obtained from power plant. The fuel

composition inputs were determined using proximate and

ultimate analysis data provided. Table 2 summarizes the

proximate and ultimate analysis data (db: drybasis; daf: dry-ashfree basis), which was used to derive the elemental composition

of the volatile stream. The volatile release model is based on a

single kinetic rate model [15,16] This model states that the rate

of production of volatile gases is given by a first order reaction

and the rate constant is expressed in an Arrhenius form, which

correlates rates of weight loss with temperature.

As in most practical fossil-fuel combustion simulations, the

incompressible form of the equations of motion using a finite

volume form of the discretization equations are solved with

SIMPLE-based approaches. It is also assumed that the flow field

Page 40

International Journal of Scientific Engineering and Technology

Volume No.6 Issue No.1, pp: 39-44

ISSN:2277-1581

01 Jan. 2017

is at a steady-state and the solution procedure is simplified by

solving a steady-state form of equation of motion. For many

combustion processes, radiation is not only the dominant energy

transport mechanism but also one of the most complex problems.

The accuracy of the radiation calculation depends on a

combination of the accuracy of calculation method and the

accuracy to which the properties of the radiating media and

surrounding walls are known [17]. The P1 radiation model is

used to account for the exchange of radiation between gas and

particulates, with cell based WSGGM model (weighted-sum-of

gray-gases model), which specifies a composition dependent

absorption coefficient. All thermodynamic data including

density, specific heat, and formation of enthalpies are extracted

from the pre-PDF chemical database.

IV. VALIDATION OF CFD ANALYSIS IN FURNACE

ZONE

The predicted temperatures at the furnace exit as estimated using

CFD is found to be 1385K, while the live data as recorded for

the same conditions was reported as 1430K. The predicted molar

fraction of oxygen (%) and carbon dioxide (%) at the furnace

exit are 0.9% and 14% respectively from CFD analysis. The

measured molar fractions of oxygen (%) and carbon dioxide (%)

at the furnace exit were found to be 7% and 13% respectively.

The error in estimation of temperature is 3.3% while the

deviations for the oxygen and carbon dioxide mass fractions are

14% and 7.14% respectively. Since the estimated values using

CFD is in close agreement with the recorded live data in the

boiler, CFD analysis holds good and was further used in the

subsequent analysis.

Table 3 validation for the CFD

Temperature (K)

Oxygen

( % molar fraction)

Carbon dioxide

( % molar fraction)

Plant measurement

CFD

1430

1382

13

14

V RESULTS AND DISCUSSION

The pulverized coal supported with combustion air and flue gas

velocity distribution across the cross sections along the furnace

height is shown in Fig 3.The coal particulates with combustion

air enters the combustion zone with an average velocity of 45

m/s and the flue gas is found to flow with an average velocity of

26 m/s at the exit of the combustion zone.

Fig 3 Velocity magnitude

IJSET@2017

Fig 4 Contours of static Temperature

The presence of tangential fired system generates a swirling fire

ball at the center of the combustion zone which is shown in Fig

4. The swirling flow is stronger at the lower level approximately

13 m from ground level as compared at 30m from the ground

level. The maximum temperature of 1850 K is found to exist at

the central part of the furnace. In the upper region

(approximately around 25m to 30m), the swirling flow is

remarkably reduced as seen in Fig 5.

The path lines as observed in Fig 5 indicates the particulates

dispersing upwards leading to reduced swirling movement by

virtue of slightly negative draft maintained above the combustion

zone. The streamlines and trajectories show very complicated

three-dimensional flow characteristics which promote the mixing

of the air and coal particles and thereby enhancing heat transfer

via bulk motion. The flows located near the burners show more

activity than in other locations.

The flue gas and coal particles from the higher burners pass

around the surface of the fire-ball region. As a result, the

residence times of the flue gas, and coal particles injected from

the higher burners are shorter as compared to the flue gas and

coal particles injected from the lower burners. The average

residence time of the flue gas within the boiler is 2.7 seconds.

Coal de volatilization and char combustion take place while the

coal particles are traveling around the furnace.

Fig 5 Path lines of the Flue gas

Page 41

International Journal of Scientific Engineering and Technology

Volume No.6 Issue No.1, pp: 39-44

ISSN:2277-1581

01 Jan. 2017

Residence time and turbulence are always considered together:

The more the turbulence inside furnace, the longer the residence

time for the coal particles. It is obvious that the residence time

depends on the location of the burner. The residence time

decreases with increasing elevation of the burner.

Fig 8 Oxygen distribution in tangential fired boiler

Fig 6 Temperature fields in a coal fired furnace

The temperature distribution across the furnace cross section is

shown in Fig 6. The temperature of the pre-heated air entering

the tangential burners is found to be at 343 K. The temperature

of the flue gas is found to exist at a temperature of 1630 K at the

center of the furnace except at few locations probably due to

reverse flow of flame which acts as a source of ignition to the

incoming fresh coal. As the flue gas moves upward, the

temperature of the flue gas decreases due to the heat transfer to

the surrounding water walls. The flue gas leaves the boiler

furnace with an average temperature of 1,383 K. The high

temperature zones are closely related to NO x formation which is

dependent on local temperature.

Fig 9 Mass weighted average of oxygen mass fraction along

the furnace elevation

The mass fraction of oxygen presence inside the furnace is

depicted in Fig.8. The oxygen concentration in the furnace is

relatively higher near the burners. The available oxygen is found

to be quickly consumed during the combustion processes. Due to

this, the oxygen mass fraction rapidly decreases across the

combustion chamber. Further the oxygen content is found to be

maximum near the hopper, there is a proportionate drop in

oxygen content near the burner.

Fig 9 shows the oxygen mass fraction variation along the

elevation of the combustion zone. With increase in elevation, the

mass weighted average of oxygen increases up to 25 meters; this

is due to utilization of available secondary air at higher

elevations. Further with increase in the elevation, the mass

weighted average of oxygen remains constant because of the

complete combustion of the coal.

Fig 7 Area weighted average temp along the elevation of

combustion zone

Fig 7 shows the temperature variation along the elevation inside

the combustion zone. The gas temperature is found to increase

steadily with elevation and a peak temperature is noticed at

approximately 25m. The burners inside the furnace are restricted

up to 25m and the temperature is found to drop marginally

thereafter. A strong swirling motion with induced turbulence is

observed up to 25m. The peak temperature of 1236 0 C is

observed near the burners.

IJSET@2017

Fig 10 Carbon dioxide distribution in tangential fired boiler

Page 42

International Journal of Scientific Engineering and Technology

Volume No.6 Issue No.1, pp: 39-44

ISSN:2277-1581

01 Jan. 2017

increasing flue gas temperature. The profile observed indicates a

definite phase transformation occurring inside the tube with

increase in flue gas temperature inside the furnace.

Fig 11 Mass weighted avg. of carbon dioxide mass fraction

along the furnace elevation

The carbon dioxide distribution across the cross sections is

shown in Fig 10. As carbon dioxide being a byproduct of

combustion, the content of carbon dioxide is found to be

maximum near the burner and a systematic pattern is observed

across the combustion chamber with marginal drop with

elevation. Carbon dioxide content is observed to be minimum

near the hopper zone

Fig 11 shows cross sectional mass weighted average of carbon

dioxide variation along the elevation in the combustion zone. As

the elevation increases, the mass weighted average of carbon

dioxide increases, this is due to rapid utilization of secondary air.

Beyond 20m of elevation the mass weighted average of carbon

dioxide is found to increase marginally due to complete

combustion.

Fig 13 Water vapor volume fraction (mixture) at 900 oC,

10000 C and 11000 C

Table 4 Heat transfer coefficients comparison

Heat

transfer

coefficient

Method

(W/m2K)

Kandiker

9460

Shah

9157

CFD

9477

The CFD simulation results are compared with correlations

obtained using Shah and Kandiker for validating the simulation

results as shown in Table 4. A close agreement with an error of

less than 4% is observed between the CFD analysis estimated

heat transfer coefficients. While Shah correlation showed 3.3 %

deviation and Kandiker correlation showed much lower

deviation of 0.179%.

CFD simulation for the different wall temperatures has been

carried out. The values for particular case is tabulated in Table

5.It can be observed that the heat transfer coefficient decreases

with increase in temperature of the furnace wall.

Table 5 Heat transfer coefficients for different wall

temperatures

htp (W/m2K)

Method

Fig 12 Contour of velocity (mixture) at 900 oC, 10000 C and

11000 C

The variation of velocity of two phase mixture at 900oC, 1000oC

and 1100oC are shown in Fig 12. The velocity of the mixture is

found to increase with increasing flue gas temperature. The

possible reason for local acceleration could be due to enhanced

two phase formation across the tube leading to increased

buoyancy effect observed along the tube.

The variation of vapor volume fraction at 900oC, 1000oC and

1100oC are shown in Fig 13 respectively. The vapor volume

fraction of the mixture is found to increase significantly with

IJSET@2017

CFD(wall at 9000 C)

0

9477

CFD (wall at 1000 C)

9728

CFD (wall at 11000 C)

10345

VI. CONCLUSION

The critical parameters inside the furnace were evaluated using

CFD and compared with the recorded live data in a 210 MW

tangential fired coal boiler. The conclusions drawn from the

present analysis are summarized below.

Page 43

International Journal of Scientific Engineering and Technology

Volume No.6 Issue No.1, pp: 39-44

1. The CFD simulations of tower type boiler using fluent are

found to be in close agreement with correlations published in

literature. The predicted molar fractions of oxygen and

carbon di oxide at the furnace exit are 6% and 14%

respectively. The measured molar fractions of oxygen and

carbon di oxide at the furnace exit are 7% and 13%. The error

obtained for temperature is 3.3% while the deviations for the

oxygen and carbon di oxide mass fractions are 14% and

7.14% respectively.

2. The area mass weighted temperature steadily increases up to

25 meters and estimated to be 1357oC.

3. As the elevation increases, the mass weighted average of

oxygen mass fraction increases up to 25 meters, further

increase in elevation leads to constant oxygen mass fraction.

4. Kandiker and Shah correlations were used in the evaluation

of heat transfer coefficients and found to be 9460 W/m 2K and

9157 W/m2K respectively. While the CFD analysis yielded a

value of 9477 W/m2K. Since the estimated and CFD values

fall in the range more than 3000 W/m 2K, this certainly

indicates a phase transformation phenomenon. As the

working fluid flows along the water wall. Shah correlation

conceded a 3.3% deviation and Kandiker correlation had a

deviation of 0.179%.

5. Heat transfer coefficients for different wall temperatures are

evaluated using CFD. At 900 0C, 10000C and 11000C the heat

transfer coefficients obtained are 9477 W/m2K, 9728 W/m2K,

10345 W/m2K respectively.

6. The residence time of particles as observed from particle

trajectories indicates that at lower elevations, the residence

time is more as compared to fuel particles from higher

elevations.

REFERENCES

i. Scott C. Hill, L. Douglas Smoot, A Comprehensive threedimensional model for simulation of combustion systems: PCGE-3,

Energy Fuels 7(1993) 874883.

ii. V.I. Kouprianov, Modelling of thermal characteristics for a

furnace of a500 MW boiler fired with high-ash coal, Energy 26 (2001)

839853.

iii. M.P. Mathur, D. Gera, M. Freeman, Computational Fluid

Dynamics Modelling Analysis of Combustors, Fluent, Inc., Collins

Ferry Road, Morgantown, West Virginia, 2002.

IJSET@2017

ISSN:2277-1581

01 Jan. 2017

iv. P.L. Stephenson, Mathematical modelling of semi-anthracite

combustion in a single burner furnace, Fuel 82 (2003) 20692073.

v. T. Sabel, B. Risio, S. Unterberger, U. Schnell, K.R.G. Hein,

M. Kab,U. Priesmeier, H.U. Thierbach, Full scale measurements and

mathematical modelling studies for the investigation of the combustion

behaviour of a modern bituminous coal-fired boiler, IFRF Combust. J.

(2001) 120 (Article number 200102).

vi. Minghou Xu, J.L.T. Azevedo, M.G. Carvalho, Modeling of a

front wall fired utility boiler for different operating conditions, Comput.

Methods Appl. Mech. Eng. 190 (2001) 35813590.

vii. S. Chapman, T.G. Cowling, The Mathematical Theory of

Non-Uniform Gases, Cambridge University Press, Cambridge, UK,

1990.

viii. S. Niksa, Coal Combustion Modelling, IEAPER/31, IEA Coal

Research,London, 1996.

ix. Eddy H. Chui, M.J. Douglas, Y. Tan, Modelling of oxy-fuel

combustion for a western Canadian sub-bituminous coal, Fuel 82

(2003) 12011210..

x. T. Abbas, P.G. Costen, F.C. Lockwood, 26th Symposium

(International) on Combustion, The Combustion Institute, 1996, p.

3041.

xi. P.G. Costen, D. Dajnak, M. Messina, F.C. Lockwood, T.

Abbas, C.

xii. Bertrand, N.H. Kandamby, V. Sakthitharan, I. Siera, S. Yousif,

On the prediction and control of industrial combustors by mathematical

xiii. modelling, Paper presented at 2002 Australian Symposium on

Combustion and The Seventh Australian Flame Days, Adelaide,

February 2002.

xiv. J. Truelove, D. Helcombe, 23rd Symposium (International)

on Combustion, The Combustion Institute, 1990, p. 963.

xv. B.S. Brewster, L.D. Smoot, S.H. Barthelson, D.E. Thornock,

Energy Fuels 9 (1995) 870.

xvi. J.M. Jones, P.M. Patterson, M. Pourkashanian, A. Williams,

A. Arenillas, F. Rubiera, Fuel 78 (1999) 1171.

xvii. FLUENT, FLUENT Users Guide, , 2015 Lebanon, USA.

xviii.

Williams, R. Backreedy, R. Habib, J.M. Jones, M.

Pourkashanian, Modelling coal combustion: the current position, Fuel

81 (2002) 605618.

xix. M. Eaton, L.D. Smoot, S.C. Hill, C.N. Eatough, Components,

formulations, solutions, evaluation, and application of comprehensive

combustion models, Prog. Energy. Combust. Sci. 25 (1999) 387436

xx. V.T. Sathyanathan, K.P. Mohammad, Prediction of unburnt

carbon in tangentially fired boiler using Indian coals, Fuel 83 (16)

(November 2004) 22172227.

Page 44

Potrebbero piacerti anche

- Mechanics and Free Fall - FIDPDocumento4 pagineMechanics and Free Fall - FIDPAustin Capal Dela Cruz100% (1)

- MSC - Adams TutorialDocumento17 pagineMSC - Adams Tutorialjuandpg0% (1)

- SchmertmannDocumento13 pagineSchmertmannkabasy20150% (1)

- Vesic 1975 Bearing Capacity of Shallow FoundationsDocumento27 pagineVesic 1975 Bearing Capacity of Shallow Foundationst.w.c.100% (2)

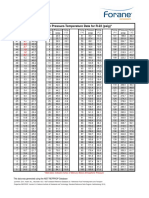

- Forane 22 Saturation Pressure Temperature DataDocumento1 paginaForane 22 Saturation Pressure Temperature Datavineeth100% (1)

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasDa EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNessuna valutazione finora

- Boiler Tube CoatingsDocumento61 pagineBoiler Tube CoatingsRahul DeshmukhNessuna valutazione finora

- Performance Evaluation and Off Design Analysis of The HP and LP Feed Water Heaters On A 3 135 MW Coal Fired Power Plant 2168 9873 1000308Documento14 paginePerformance Evaluation and Off Design Analysis of The HP and LP Feed Water Heaters On A 3 135 MW Coal Fired Power Plant 2168 9873 1000308hari reddyNessuna valutazione finora

- Chapter 7 Pulverisers PlantDocumento11 pagineChapter 7 Pulverisers PlantBineet Kumar VarmaNessuna valutazione finora

- Clean Air Flow TestDocumento27 pagineClean Air Flow TestDebabrata TantubaiNessuna valutazione finora

- Study of Circulating Coal Fluidized BoilersDocumento5 pagineStudy of Circulating Coal Fluidized BoilersSwaraj BiswasNessuna valutazione finora

- WholeDocumento236 pagineWholechala100% (1)

- Technical Specification For Fly Ash Handling System, R0Documento7 pagineTechnical Specification For Fly Ash Handling System, R0SumitskbNessuna valutazione finora

- Principles of Fluidized Bed BoilersDocumento27 paginePrinciples of Fluidized Bed BoilersssNessuna valutazione finora

- Blueprint Your Pulverizer for Improved Performance and CapacityDocumento4 pagineBlueprint Your Pulverizer for Improved Performance and CapacityvnchromeNessuna valutazione finora

- Properties of Coals To Self HeatDocumento47 pagineProperties of Coals To Self HeatDiego Martínez FernándezNessuna valutazione finora

- Root Cause Identification and Elimination of Problems in Soot Blowers of Chemical Recovery BoilersDocumento7 pagineRoot Cause Identification and Elimination of Problems in Soot Blowers of Chemical Recovery BoilersDodi SuhendraNessuna valutazione finora

- Improving Air Preheater PerformanceDocumento11 pagineImproving Air Preheater PerformancejaveddvcNessuna valutazione finora

- Coal MillDocumento6 pagineCoal MillAnonymous NxpnI6jCNessuna valutazione finora

- Hydraulic Pressure DropDocumento40 pagineHydraulic Pressure DropErdincNessuna valutazione finora

- Boiler fouling and slagging prevention with intelligent sootblowingDocumento8 pagineBoiler fouling and slagging prevention with intelligent sootblowingSuganya LokeshNessuna valutazione finora

- 1A2. Circulating Fluidized Bed Combustion Technology (CFBC)Documento1 pagina1A2. Circulating Fluidized Bed Combustion Technology (CFBC)kumarmm1234Nessuna valutazione finora

- Air Preheater Technical PaperDocumento21 pagineAir Preheater Technical Paperchekoti koushikNessuna valutazione finora

- APCW TadipatriDocumento25 pagineAPCW TadipatriChanna BasavaNessuna valutazione finora

- Foundrybench D19 Good Practice GuideDocumento196 pagineFoundrybench D19 Good Practice GuideGangadharKasinathSastryNessuna valutazione finora

- Diagnosing Pulverizer Performance: Storm Technologies, Inc. October 2015Documento6 pagineDiagnosing Pulverizer Performance: Storm Technologies, Inc. October 2015Firlan MaulanaNessuna valutazione finora

- Role of Structure in Strategy FinalDocumento36 pagineRole of Structure in Strategy FinalNithin VrNessuna valutazione finora

- A Solution For Preventing Fouling in CFBC Boiler by K.K.parthibanDocumento30 pagineA Solution For Preventing Fouling in CFBC Boiler by K.K.parthibanparthi20065768100% (2)

- KIET Group of Institutions, GhaziabadDocumento12 pagineKIET Group of Institutions, GhaziabadSandeep ChhabraNessuna valutazione finora

- Accidents in Power PlantsDocumento6 pagineAccidents in Power PlantsHitesh Navlani100% (1)

- Mill ProjectDocumento5 pagineMill ProjectChaitanya Dev SadaphalNessuna valutazione finora

- Industrial Training Project Report (SECURED) PDFDocumento192 pagineIndustrial Training Project Report (SECURED) PDFAshish UppuNessuna valutazione finora

- Numerical Investigation of Combustion Optimization in A Tangential Firing Boiler Considering Steam Tube OverheatingDocumento15 pagineNumerical Investigation of Combustion Optimization in A Tangential Firing Boiler Considering Steam Tube OverheatingYogesh DewangNessuna valutazione finora

- Operation Manual: HRM1700M Vertical Roller Coal MillDocumento30 pagineOperation Manual: HRM1700M Vertical Roller Coal MillAhmed ElhusseinyNessuna valutazione finora

- Fluidized Bed CombustionDocumento32 pagineFluidized Bed CombustionAbdul AhadNessuna valutazione finora

- Steam Turbine Theory ExplainedDocumento17 pagineSteam Turbine Theory ExplainedbhaskarNessuna valutazione finora

- Mechanical Ash Handling SystemDocumento19 pagineMechanical Ash Handling Systemasdffdsa550Nessuna valutazione finora

- Air Monitoring Combustion Air Power BoilersDocumento189 pagineAir Monitoring Combustion Air Power BoilersAnonymous zdCUbW8HfNessuna valutazione finora

- Failure Investigation of Super Heater Tubes of CoaDocumento24 pagineFailure Investigation of Super Heater Tubes of CoaMahsaNessuna valutazione finora

- Air Pre-Heater: Rajneesh VachaspatiDocumento68 pagineAir Pre-Heater: Rajneesh VachaspatiRajneesh VachaspatiNessuna valutazione finora

- Emissions Control Thermal Power PDFDocumento20 pagineEmissions Control Thermal Power PDFTanzir MusaNessuna valutazione finora

- Compendium Delhi PDFDocumento223 pagineCompendium Delhi PDFsrinivasgillalaNessuna valutazione finora

- 7.summary of Boiler PerfDocumento46 pagine7.summary of Boiler PerfRAJESH KUMARNessuna valutazione finora

- Beater Wheel MillsDocumento11 pagineBeater Wheel MillsParmasamy SubramaniNessuna valutazione finora

- Module 8 - Energy Performance Assessment of BoilersDocumento24 pagineModule 8 - Energy Performance Assessment of BoilersAnonymous a19X9GHZNessuna valutazione finora

- B&W FBC Boiler Opeating Experience With U BeamsDocumento9 pagineB&W FBC Boiler Opeating Experience With U BeamsNath BoyapatiNessuna valutazione finora

- Technologies for Reducing Particulate Emissions from Thermal Power PlantsDocumento35 pagineTechnologies for Reducing Particulate Emissions from Thermal Power PlantsNaveen ReddyNessuna valutazione finora

- CoalDocumento89 pagineCoalRizki AmeliaNessuna valutazione finora

- CFBC BoilersDocumento11 pagineCFBC BoilersManoj DesaiNessuna valutazione finora

- Condensate Extraction Pump: GeneralDocumento5 pagineCondensate Extraction Pump: GeneralAnonymous DKv8vpNessuna valutazione finora

- A. Indira National Power Training InstituteDocumento80 pagineA. Indira National Power Training InstituteAyan MajiNessuna valutazione finora

- Thermal Power Plants and Future Scope Batch 2Documento194 pagineThermal Power Plants and Future Scope Batch 2Govinda Kabra100% (1)

- Coal Beneficiation TechnologyDocumento5 pagineCoal Beneficiation TechnologyChandan Das100% (1)

- ASME Coal Fineness Sampling ProcedureDocumento4 pagineASME Coal Fineness Sampling ProcedureRoby SzNessuna valutazione finora

- Optimize Raymond Bowl Mill PerformanceDocumento10 pagineOptimize Raymond Bowl Mill Performancednageshm4n244Nessuna valutazione finora

- Eng Day Enamel For Air PreheaterDocumento15 pagineEng Day Enamel For Air PreheaterBangun WijayantoNessuna valutazione finora

- Guy - Time and Spectrum Analysis Paper - Part IDocumento25 pagineGuy - Time and Spectrum Analysis Paper - Part Ikeepmoshing100% (1)

- Ash (Wet & Dry) Handling SystemDocumento4 pagineAsh (Wet & Dry) Handling SystemআসিফহাসানখানNessuna valutazione finora

- Fluid Coupling in Belt Conveyor DrivesDocumento12 pagineFluid Coupling in Belt Conveyor Drivesnoelaroboi100% (2)

- Suspension (PC) Combustion: Chungen YinDocumento47 pagineSuspension (PC) Combustion: Chungen YinAakash RanjanNessuna valutazione finora

- Coal Management SystemDocumento12 pagineCoal Management SystemBiswajit DuttaNessuna valutazione finora

- Coal Properties and Effect On Combustion PDFDocumento25 pagineCoal Properties and Effect On Combustion PDFMuhammad ArshadNessuna valutazione finora

- Municipal Solid Waste to Energy Conversion Processes: Economic, Technical, and Renewable ComparisonsDa EverandMunicipal Solid Waste to Energy Conversion Processes: Economic, Technical, and Renewable ComparisonsNessuna valutazione finora

- Mohammad Zadeh 2002Documento9 pagineMohammad Zadeh 2002Reza RhiNessuna valutazione finora

- Simulation of Non-Premixed Natural Gas FlameDocumento4 pagineSimulation of Non-Premixed Natural Gas FlameArul RizkiNessuna valutazione finora

- Case Study: Implementation of 5S Methodology in JCB Assembly Business Unit Material StorageDocumento6 pagineCase Study: Implementation of 5S Methodology in JCB Assembly Business Unit Material StorageInnovative Research PublicationsNessuna valutazione finora

- Named Data NetworkingDocumento2 pagineNamed Data NetworkingInnovative Research PublicationsNessuna valutazione finora

- Analysis On Quenching Cracks of Engine CrankshaftDocumento4 pagineAnalysis On Quenching Cracks of Engine CrankshaftInnovative Research PublicationsNessuna valutazione finora

- Analysis On The Generation and Control of Strip Defects On The Surface of Color Coated PlatesDocumento3 pagineAnalysis On The Generation and Control of Strip Defects On The Surface of Color Coated PlatesInnovative Research PublicationsNessuna valutazione finora

- Social Network Analysis For Web-Based CommunityDocumento4 pagineSocial Network Analysis For Web-Based CommunityInnovative Research PublicationsNessuna valutazione finora

- Fluoride Removal Efficiency of Commercially Available Reverse Osmosis Water Purifying Systems in Removing Fluoride Ions From Drinking Water in IndiaDocumento4 pagineFluoride Removal Efficiency of Commercially Available Reverse Osmosis Water Purifying Systems in Removing Fluoride Ions From Drinking Water in IndiaInnovative Research PublicationsNessuna valutazione finora

- Rainfall-Runoff Modeling Using Artificial Neural Networks and HEC - HMS (Case Study: Catchment of Gharasoo)Documento4 pagineRainfall-Runoff Modeling Using Artificial Neural Networks and HEC - HMS (Case Study: Catchment of Gharasoo)Innovative Research PublicationsNessuna valutazione finora

- Power Transformer Protection Using Fuzzy Logic Based ControllerDocumento5 paginePower Transformer Protection Using Fuzzy Logic Based ControllerInnovative Research PublicationsNessuna valutazione finora

- The Experimental Study of Eccentric Loadingfor Piled Raft Foundations Settling On Slope CrestDocumento5 pagineThe Experimental Study of Eccentric Loadingfor Piled Raft Foundations Settling On Slope CrestInnovative Research PublicationsNessuna valutazione finora

- Structural Analysis of A Charcoal Sieving Machine Under Dynamic LoadDocumento3 pagineStructural Analysis of A Charcoal Sieving Machine Under Dynamic LoadInnovative Research PublicationsNessuna valutazione finora

- Design of Quick-Sensing Device For Temperature Difference Generation Environment Based On Single Chip MicrocomputerDocumento3 pagineDesign of Quick-Sensing Device For Temperature Difference Generation Environment Based On Single Chip MicrocomputerInnovative Research PublicationsNessuna valutazione finora

- 3D Modeling of Complex Structure Based On AutoCAD VBADocumento3 pagine3D Modeling of Complex Structure Based On AutoCAD VBAInnovative Research PublicationsNessuna valutazione finora

- Review of The Development of Several True 3D Display TechnologyDocumento5 pagineReview of The Development of Several True 3D Display TechnologyInnovative Research PublicationsNessuna valutazione finora

- Computational EconomicsDocumento2 pagineComputational EconomicsInnovative Research PublicationsNessuna valutazione finora

- Information EngineeringDocumento2 pagineInformation EngineeringInnovative Research PublicationsNessuna valutazione finora

- Information EngineeringDocumento2 pagineInformation EngineeringInnovative Research PublicationsNessuna valutazione finora

- Wearable ComputingDocumento3 pagineWearable ComputingInnovative Research PublicationsNessuna valutazione finora

- Surveillance NetworksDocumento2 pagineSurveillance NetworksInnovative Research PublicationsNessuna valutazione finora

- Estimating Sea Level Change at The Egyptian Coasts Using Different Data SourcesDocumento9 pagineEstimating Sea Level Change at The Egyptian Coasts Using Different Data SourcesInnovative Research PublicationsNessuna valutazione finora

- Preliminary Study On Dimocarpus Longan Peel As Inhibitors For The Pitting Corrosion of 5052-O and 6061-O Aluminium Alloys in Artificial Brine SolutionDocumento4 paginePreliminary Study On Dimocarpus Longan Peel As Inhibitors For The Pitting Corrosion of 5052-O and 6061-O Aluminium Alloys in Artificial Brine SolutionInnovative Research PublicationsNessuna valutazione finora

- Online Laboratory: Roy G. Perry College of Engineering Prairie View A&M University Prairie View, TX 77446Documento2 pagineOnline Laboratory: Roy G. Perry College of Engineering Prairie View A&M University Prairie View, TX 77446Innovative Research PublicationsNessuna valutazione finora

- Internet AddictionDocumento2 pagineInternet AddictionInnovative Research PublicationsNessuna valutazione finora

- Computational ElectromagneticsDocumento3 pagineComputational ElectromagneticsInnovative Research PublicationsNessuna valutazione finora

- Mobile InternetDocumento2 pagineMobile InternetInnovative Research PublicationsNessuna valutazione finora

- Identity TheftDocumento3 pagineIdentity TheftInnovative Research PublicationsNessuna valutazione finora

- Comparative Print Quality Analysis of Screen Printing and Liquid Ink Based Digital Printing MachinesDocumento3 pagineComparative Print Quality Analysis of Screen Printing and Liquid Ink Based Digital Printing MachinesInnovative Research PublicationsNessuna valutazione finora

- Computational Physics: An IntroductionDocumento2 pagineComputational Physics: An IntroductionInnovative Research PublicationsNessuna valutazione finora

- Role of Coaching Institutes in IndiaDocumento5 pagineRole of Coaching Institutes in IndiaInnovative Research PublicationsNessuna valutazione finora

- Effect of Alccofine and Foundry Slag On Compressive Strength of High Strength ConcreteDocumento4 pagineEffect of Alccofine and Foundry Slag On Compressive Strength of High Strength ConcreteInnovative Research PublicationsNessuna valutazione finora

- Valence MOTheoryDocumento50 pagineValence MOTheoryRodolfo Angulo OlaisNessuna valutazione finora

- Assignment 1 (ELE8306 - 21)Documento5 pagineAssignment 1 (ELE8306 - 21)umarsaboNessuna valutazione finora

- Chapter 9 VibrationDocumento83 pagineChapter 9 Vibration胡宇晟Nessuna valutazione finora

- Design and Fabrication of Plastic Bottle and Can Crusher For Recycling PurposeDocumento3 pagineDesign and Fabrication of Plastic Bottle and Can Crusher For Recycling PurposeInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Curtain Wall Calculation PDFDocumento134 pagineCurtain Wall Calculation PDFAlaaBadwy100% (1)

- ch13 DynamicsDocumento64 paginech13 DynamicsIfea WongNessuna valutazione finora

- Atomic Structure Basic ConceptsDocumento39 pagineAtomic Structure Basic ConceptsTithiparna SenguptaNessuna valutazione finora

- Unit7 Day9 CheckforunderstandingDocumento21 pagineUnit7 Day9 Checkforunderstandingapi-261280967Nessuna valutazione finora

- Modern Materials' Atomic StructureDocumento47 pagineModern Materials' Atomic StructureAngelica MartinezNessuna valutazione finora

- Mechanisms Design L 2-1 IntroductionStructural Analysis of MechanismsDocumento24 pagineMechanisms Design L 2-1 IntroductionStructural Analysis of MechanismsaliNessuna valutazione finora

- D Shirmohammadi - A Compensation-Based Power Flo Method - IEEE TPS - 1998 - ConsultDocumento10 pagineD Shirmohammadi - A Compensation-Based Power Flo Method - IEEE TPS - 1998 - ConsultJorge Luis Vega HerreraNessuna valutazione finora

- Quantum Physics Practice QuestionsDocumento2 pagineQuantum Physics Practice QuestionsKrizzi Dizon GarciaNessuna valutazione finora

- Science Lesson Plan: Rubrics On Assessing The Performance of Group ActivityDocumento1 paginaScience Lesson Plan: Rubrics On Assessing The Performance of Group ActivityRowena Sta MariaNessuna valutazione finora

- Column Design Prokon.Documento16 pagineColumn Design Prokon.akankwasaNessuna valutazione finora

- The Relevance of YS/UTS RatioDocumento21 pagineThe Relevance of YS/UTS RatiocarrespmNessuna valutazione finora

- Physics Investigatory ProjectDocumento18 paginePhysics Investigatory ProjectRΛJIBUL ISLΛMNessuna valutazione finora

- Physics Form 4. Chapter 2. 2.5 ForceDocumento49 paginePhysics Form 4. Chapter 2. 2.5 ForceNuridahBintiZaimi100% (1)

- Bending Deflection - Macaulay Step Functions: AE1108-II: Aerospace Mechanics of MaterialsDocumento9 pagineBending Deflection - Macaulay Step Functions: AE1108-II: Aerospace Mechanics of MaterialsAyanwale-cole pelumi AkeemNessuna valutazione finora

- Line-Scanning Laser Scattering System For Fast Defect Inspection of A Large Aperture SurfaceDocumento10 pagineLine-Scanning Laser Scattering System For Fast Defect Inspection of A Large Aperture SurfaceAyman IsmailNessuna valutazione finora

- Rate of Reaction FactorsDocumento3 pagineRate of Reaction FactorsFungai mhlangaNessuna valutazione finora

- Quantum Field Theory Notes by JaffeDocumento17 pagineQuantum Field Theory Notes by JaffedbranetensionNessuna valutazione finora

- Negative Sequence Protection For Ac MotorsDocumento4 pagineNegative Sequence Protection For Ac MotorsAbhishek KukrejaNessuna valutazione finora

- Transformers:: " Transformers Are The Heart of The Alternating Current System." - William Stanley Jr.Documento13 pagineTransformers:: " Transformers Are The Heart of The Alternating Current System." - William Stanley Jr.SRIRAM SATHISHNessuna valutazione finora

- Quantum Mechanics EssentialsDocumento56 pagineQuantum Mechanics EssentialsMuhammad ZeeshanNessuna valutazione finora